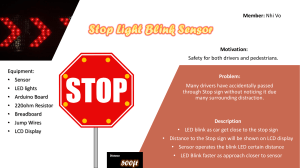

UNIVERSITY OF ENGINEERING & MANAGEMENT, KOLKATA University Area, Plot No. III – B/5, New Town, Action Area – III, Kolkata – 700160. A PROJECT REPORT ON Accident Prevention Protocol (PHASE 2) Submitted in partial fulfilment of the requirements for the award of the degree of Bachelor of Technology in ELECTRONICS & COMMUNICATION ENGINEERING Submitted By SOUMYADEEP GHOSAL University Roll No. 12019009002145 DEEPRO BARDHAN University Roll No. 12019009002096 TAPABROTA GHOSH University Roll No. 12019009002063 JOYDIP RAJ University Roll No. 12019009002147 ANUBHAV BHADRA University Roll No. 12019009002086 Under the guidance of PROF. ARPITA DAS ACKNOWLEDGEMENT We would like to take this opportunity to thank and acknowledge with due courtesy everyone whose cooperation and encouragement throughout the ongoing course of this project remains invaluable to us. We are sincerely grateful to our guide Prof. Arpita Das of the Department of Electronics & Communication Engineering, UEM, Kolkata, for her wisdom, guidance and inspiration that helped us to go through with this project and take it to where it stands now. We would also like to express our sincere gratitude to Prof. Soumen Banerjee, HOD, Electronics & Communication Engineering, UEM, Kolkata and all other departmental faculties for their ever-present assistant and encouragement. Last but not the least, we would like to extend our warm regards to our families and peers who have kept supporting us and always had faith in our work. SOUMYADEEP GHOSAL <<Student Name_1>> TAPABROTO GHOSH <<Student Name_3>> ANUBHAV BHADRA <<Student Name_5>> DEEPRO BARDHAN <<Student Name_2>> JOYDIP RAJ <<Student Name_4>> TABLE OF CONTENTS 1. ABSTRACT. ....................................................................................... 4 2. INTRODUCTION ............................................................................ 5 3. MATERILS ........................................................................................ 6 a. b. c. d. e. f. g. h. POWER SUPPLY .........................................................................6 AUDRINO UNO ATMEGA 328 .................................................. 6 RELAY MODULE ........................................................................ 7 MQ-3 ALCOHOL SENSOR ......................................................... 8 LCD DISPLAY .............................................................................8 DC MOTOR .................................................................................. 9 BUZZER ....................................................................................... 9 ULTRASONIC SENSOR ............................................................ 9 4. METHODS .......................................................................................10 a. b. c. d. e. BLOCK DIAGRAM ..................................................................... 10 FLOW CHART ..............................................................................10 SYSTEM OPERATIONS .............................................................. 11 SOFTWARE IMPLEMENTATION ............................................. 12 SYSTEM DESIGN ......................................................................... 12 5. RESULT ........................................................................................... 15 6. DISCUSSION ................................................................................... 16 7. CONCLUSION ................................................................................. 18 ABSTRACT This study proposed an efficient technique for eradicating the upsurge in the number of cases of roads accidents caused by excessive intake of alcohol by drivers on the Nigerian roads. This study developed a prototype that has alcohol detection and engine locking system, distance denser by using an Arduino Uno microcontroller interfaced with an alcohol sensor along with an LCD screen and a DC motor and Ultrasonic senser to demonstrate the concept. The system uses MQ-3 alcohol sensor to continuously monitor the blood alcohol content (BAC) to detect the existence of liquor in the exhalation of a driver. By placing the sensor on the steering wheel, our system has the capacity to continuously check alcohol level from the driver’s breath. The ignition will fail to start if the sensors detects content of alcohol in the driver’s breath. In case the driver got drunk while driving, the sensor will still detect alcohol in his breath and stop the engine so that the car would not accelerate any further and the driver can park by the roadside. And the Ultrasonic sensor will detect the distance between the vehicles to determine the safe distance. Results from testing the proposed system adequately matched the requirements for starting a car’s engine once the level of alcohol detected in the breath of the driver is higher than the prescribed level permissible by law. And if alcohol is not detected then Ultrasonic sensors will activate and determine the safe distance. If the distance is less then the system will alert the driver by a beeping sound and displaying that distance in the LCD screen. Conclusion: Experimental results show that the alcohol sensor was able to respond quickly when alcohol is detected and also have the ability to operate the Ultrasonic sensor if alcohol is not detected for safe distance measurement for the system. Introduction These days, majority of road accidents are caused by drink-driving. Drunken drivers are in an unstable condition and so, rash decisions are made on the highway which endangers the lives of road users, the driver inclusive. The enormity of this menace transcends race or boundary. In India, the problem is being tackled by issuing laws prohibiting the act of drivers getting drunk before or while driving as well as delegating law enforcements agents to arrest and persecute culprits. However, effective monitoring of drunken drivers is a challenge to the policemen and road safety officers. The reason for this stems from the natural inability of human beings to be omnipresent as well as omniscience within the same space and time. This limited ability of law enforcement agents undermines every manual effort aimed at curbing drinkdriving. There is therefore the need for an automatic alcohol detection system that can function without the restriction of space and time. The Indian Bureau of Statistics reported 11, 363 road accidents in 2016. Although the report stated speed violation as the foremost cause of these accidents, it can safely be inferred that most of the cases would have been due to driver’s unstable condition caused by drivers getting drunk before they drive. The investigation done by the World Health Organization in 2008 shows that about 50%-60% of traffic accidents are related to drink-driving.More so, WHO data on road traffic deaths revealed 1.25 million traffic deaths were recorded globally in 2013 with the low- and middle-income countries having higher fatality rates per 100 000 population (24.1 and 18.4 respectively). Data collected showed that 67.2% of commercial vehicles drivers in Nigeria admitted to drinking alcohol during working days. This shows that most drivers, especially commercial and heavy duty trucks drivers engage in drink-driving, which can lead to accident. Law sets a legal limit of 0.5 g/100mL blood alcohol concentration (BAC), any level above that is said to be illegal. In this paper, the illegal limit is taken as 0.4. The BAC depicts the quantity of alcohol in a certain volume of blood. It is measured as either grams of ethanol per deciliter of blood (g/fdl, commonly used in the United States), or milliliters of blood, (mg/ml, used in much of Europe). For BAC level from 0.4 to 0.6, drivers feel dazed/confused or otherwise disoriented, and it is generally not safe for a driver to drive a vehicle under such condition. Also, BAC level for 0.7 to 0.8 makes a driver’s mental, physical and sensory functions to be severely impaired. At this stage, a driver is inactive and incapable of driving. BAC level of 0.2 to 0.3 is still not safe but the driver still has a little degree of self-control. Distance measurement has important applications in automotive and industrial applications. The distance In this project we have implemented such a measurement system which uses a ultrasonic sensor, arduino and server motor Ultrasonic sensors are versatile for the distance measurement and it is quite fast for the common application. The transmitted waves are reflected back from the object and received by the sensor again. From there we can get the distance further by calculations we can detect the distance between the vehicles. This shows us the way that we can drive safely in highways when we can observe the distance between multiple vehicles form our system for a safe purpose. Materials Our proposed work consists of various units that make up the system: the power supply unit, the alcohol detection unit, the engine locking unit, ignition system unit, display unit, alarm unit and indicating unit. An LCD display will be fitted inside the car to act as an indicator to the motorist together with everyone in the vehicle. A DC motor is used as the car engine to demonstrate the concept of engine locking. Ultrasonic sensors are connected to the ATmega328 microcontroller for sensing the distance and send it to the controller so that it can calculate the distance from the data provided from the sensor. ATmega328 microcontroller under the brand name of Arduino Uno will be used to keep looking for the output from the alcohol sensor and from Ultrasonic sensor. The Arduino Uno sketch which is the environment for programming is used to write the code, compile, generate hex file and load it to the microcontroller. POWER SUPPLY: Our system is powered with a 9V battery. A 5V DC supply as required by the microcontroller, sensor and display unit. While other components like DC motor require 1.5V and the Relay need 5V. The Arduino Uno board has already been designed to operate without the use of transformer, the system can be powered via the USB connection from computer or with an external power supply of 7 to 12V. The External (non-USB) power can come either from an AC-to-DC adapter (wall-wart) or battery. Any voltage that is above 12V will make the control device to burn thereby destroying the board. It is advisable to use voltage between 7 - 12V. ATMEGA328 MICROCONTROLLER UNIT The proposed system is built around ATmega328 Arduino Uno microcontroller board. The unit consists of 14 pins which allows inflow and outflow of feeding (it is possible to use 6 of those pins as Pulse Width Modulation signal outputs), 6 continuous signal with time changing quantity, 16 megahertz electronic oscillator, a Universal Serial Bus port, a power connector, an on-board voltage regulator, ICSP header, and a reset button. The Atmega328 has 32 KB flash memory, 2 KB SRAM and 1 KB EEPROM. RELAY MODULE A power relay module is an electrical switch that is operated by an electromagnet. When electrical current is passed through a coil, it generates a magnetic field that in turn activates the armature. This movement of the movable contacts makes or breaks a connection with the fixed contact. They are designed to be controlled with low voltages like 3.3V like the ESP32, ESP8266, etc, or 5V like your Arduino. MQ-3 ALCOHOL GAS SENSOR The sensor is made of Tin Dioxide (SnO2) sensitive layer. The sensor is configured with a high sensitivity to alcohol and small sensitivity to Benzene. It has a simple drive circuit with fast response, stability, and long life. It has an analog interface type. On the sensor, port pins 1, 2 and 3 represents the output, GND and VCC respectively LCD DISPLAY UNIT LCD display is used for displaying the message sent from the remote location. The LCD module displays alphanumeric, kana (Japanese characters) and symbols. It consists of 16 pins (8 data lines, 3 control lines, 2 power lines, 1 contrast line and 2 pins for back light LED connection). Data line and control line are connected to the microcontroller. The LCD display power rating is as stated below: Current (𝐼𝐷𝐷) (𝑉𝐷𝐷 = 5.0𝑣) … … … … .1.0𝑚𝐴 − 3.0𝑚𝐴 𝑚𝑎𝑥 Range of 𝑉𝐷𝐷 − 𝑉0 … … … … … … .1.5~5.25𝑉 𝑜𝑟 5.0 ± 0.25 DC MOTOR The DC motor is an electric DC motor used to demonstrate the concept of engine locking. Here in this work, the DC motor will be connected to pin 9 on the microcontroller, when alcohol is detected the DC motor stops in other to indicate that alcohol is detected and continue running when there is no alcohol detected. Buzzer The alarm unit used is a buzzer which indicates when alcohol is detected. The buzzer used belongs to the PS series. The PS series are highperformance buzzers that employ Uni-morph piezoelectric elements and are designed for easy incorporation into various circuits. They have very low power consumption in comparison to electromagnetic units. It has a voltage requirement of 2V and is connected to pin 10 of the microcontroller. Ultrasonic Sensor (HC-SRO4): Ultrasonic sensors emit short, high-frequency sound pulses at regular intervals. These propagate in the air at the velocity of sound. If they strike an object, then they are reflected back as echo signals to the sensor , which itself computes the distance to the target based on the time-span between emitting the signal and receiving the echo. As the distance to an object is determined by measuring the time of flight and not by the intensity of the sound, ultrasonic sensors are excellent at suppressing background interference. Methods BLOCK DIAGRAM Block diagram of the proposed system is shown below. It consists of power supply section, MQ-3 alcohol sensor, DC motor, LCD, microcontroller, alarm. The various units were designed and tested separately. FLOW CHART The flow chart of the system is shown below. The system algorithm comprises of three main steps. First is to boot up the system, next is the measuring state, this stage measure the amount of alcohol level from the drivers. A prescribed set limit will be given as input to the microcontroller, once the alcohol level exceeds the limit the car will not start. STEP 1: Power on the system STEP 2: checks for alcohol concentration STEP 3: if alcohol is detected STEP 3.1: turn off car engine STEP 4: Else STEP 4.1: Ultrasonic sensor Activates STEP 4.2: IF distance less than 3ft STEP 4.3: Display Distance and ALERT system activates STEP 4.4: ELSE STEP 4.5: Go to STEP 4 STEP 5: Car engine running STEP 6: Go to step 1 SYSTEM OPERATIONS The detected analog voltage values are read by the microcontroller; the Arduino Uno board contains 8 channels, 10-bit device that changes an analog voltage on a pin to a digital number. The system will link input voltages from 0-5V with values from 0-1023V to generate 5Vs for every 1024 units. The system will process the analog signal and convert it to digital value of 0 or 1. Also, the analog values from the alcohol sensor will be scaled to percentage, and this percentage is equivalent to the analog voltage values in ppm (part per million). The first condition is the intoxication stage; the second condition or the last stage is drunkenness stage. Each stage will be a condition to perform a task based on the level of alcohol. In the intoxication stage, the alarm will be OFF and the car engine will be ON. In stage two, the alarm will be ON, as well as the car engine. Finally, the driver is mentally and physically inactive in stage three, so the engine will be OFF while the alarm will be ON. Therefore, once the system detect alcohol in stage two the car will be stopped and the driver can park by the roadside. If the driver passes the drunkenness then another major situation is overtaking cars, so our sensor will help us to determine the distance of our vehicle to another with the help of Audrino. If the distance is less than 3ft LCD will show that distance and buzzer will also set ON at an interval. Else is system will again detect the distance at an interval of every 3mins. SOFTWARE IMPLEMENTATION The software design consists of a free running program which manipulates input from the Alcohol sensor and programming of the indicating unit, LCD display, DC motor, alarm unit. The program code is written on Arduino sketch and uploaded to ATMEGA328 microcontroller program memory using Arduino Uno development board. The hex file is generated using the Arduino sketch IDE environment. Below figure shows the device programming used for this research. SYSTEM DESIGN AND SIMULATION After generating the hex file from the Arduino sketch environment, the hex file was copied from the Arduino file directory and linked to the tinkercad for simulation. Each unit was also tested to ensure continuity and efficiency in the components before placing. 1. ALARM UNIT The alarm unit used a buzzer to produce sound whenever alcohol is detected. The purpose of the buzzer was to create awareness to passengers whenever alcohol is detected. The alarm unit is represented in figure below 2. ENGIN LOCKING UNIT The engine locking unit was built by the concept of using a DC motor to demonstrate as the car engine. The DC motor operate based on preset conditions; once the alcohol level goes above 40% the engine motor stops. The engine motor continues to run when the alcohol level goes below 39%.The DC motor is connected to pin 9 on the microcontroller and it operate from 1.5V to 6V. 3. ALCOHOL CHECKING STAGE In this stage, when the car is switched on the system measures the level of alcohol from the driver breath to check whether the driver is intoxicated, slightly drunk and whether if he is extremely drunk. Based on this, the microcontroller only locks the engine when the level exceeds 40% in which case car engine stops so that the driver can manage to stare the car to the road side 4. ALCOHOL DETECTION UNIT The alcohol sensor unit has four pins; test pin, vcc, dout and ground. The test pin is used to accept logic signals of 0 or 1 by using logic state pin as shown in figure 12. The buzzer is used to show when the sensor detect alcohol in the simulation, when the logic state is 1 then it goes on to indicate that alcohol is present and off to show the absence of alcohol. 5. DISTANCE DETECTION FOR COLLISION An Ultrasonic sensor has 4 pins; trig pin, echo pin, vcc and ground pin. This vcc and ground pins are used for power supply. And other pins are the functional pins. Tigger pin or trig pin actually sends the sonic waves and echo receives that wave after collisions with any object. In our system if no alcohol is detected then this sensing will go on. And it will indicate the distance if that is less than 3ft. 6. DISTANCE MEASUREMENT UNIT As the waves is sent from the trig pin, it will return after collision to the echo pin. So, the distance travelled by the waves is twice the distance from the object. This error is rectified while calculating the distance. Formula to be used, Speed= [(Distance/ Time)/2], here Time is measured by the data from Ultrasonic Sensor, Speed is of speed of light (i.e 3×10⁹ m/sec), from here we can get the Distance. The circuit diagram of our proposed alcohol detection system is RESULTS The results of our experiments are presented Table 1: Sensitivity level characteristics VOLTAGE (V) PPM(PART PER MILLION) PERCENTAGE(%) 0 0 0 0.5 100 10 1 200 20 1.5 300 30 2 400 40 2.5 500 50 3 600 60 3.5 700 70 4 800 80 4.5 900 90 5 1000 100 Table 2: Level Of Drunkenness VOLTAGE OUTPUT 200-300ppm 400-500ppm 1-1.5V 2-2.5V 20%-30% 40%-50% LCD DISPLAY NORMAL DRUNK ALARM OFF ON IGNITION SYSTEM ON OFF Table 3: Distance Detection System DISTANCE (FEET) 3< 3> LCD DISPLAY DISTANCE SYSTEM RUNNING ALERT ALARM ON DISCUSSION OFF We tested the sensor’s accuracy using a deodorant perfume to simulate its response to alcohol concentration level. To verify the functionality of our system, we employed breadboard ,Buzzer, Arduino sketch IDE, and tinkercad software. The final bread boarding of the entire system is shown in above figure. ALCOHOL SENSOR ACCURACY Accuracy is the measurement of an instrument to give equivalent value to the true value or the quantity being measured. The Blood Alcohol Content(BAC) is calculated by the given formula BAC= [(SenserValue/10)×(5.0/1024)]× 0.67. Here SenserValue is provided by the MQ-3 alcohol gas detector, Then its changed into float or decimal number. Again multiplied by 5 which is nothing other than then human weight constant. Its converted into digital value by dividing it with 1024. Then its multiplied by 0.67 for converting it into mg/L. If BAC value comes greater than 0.8 then it means high Drunkenness. DISTANCE SENSER ACCURACY The more accurate ultrasonic sensors can achieve 0.1 – 0.2% of the detected range under perfectly controlled conditions, and most good ultrasonic sensors can generally achieve between 1% and 3% accuracy. SENSITIVITY LEVEL CHARACTERISTICS The alcohol levels in ppm. The values in ppm correspond to the voltage and percentage. Our system displays the BAC to the driver. The values are the concentration level, that is, BAC level. The voltage values increase or decreases based on the resistance of the alcohol sensor. Using this table, the locking concept was achieved by programming instruction to the microcontroller to lock the car engine when the alcohol sensor reading is above 0.8. The microcontroller uses the analog voltage values coming from the sensor to determine whether the sensor reading is above the set limit. In essence, once the microcontroller receives analog value above 2V, it automatically compares it with the preset limit, if it is not the same the engine will stop. LEVEL OF DRUNKENNESS Experimental results were obtained based on the three pre-designated conditions for drunk driving. In intoxication stage, the car engine will be running as the driver can still control himself. Also in the slightly drunk state, the system will still allow the engine to run. Finally, in the drunken state, the driver will lose stability and cannot make decisions. In that case, the engine automatically locks off. COLLISION RANGE: In India the most frequent vehicle accidents is rare front accident. This happens due to misunderstanding between the driver. As a result accident increases so, according to vehicles related law it is said that all vehicles while running should have atleast 3ft between them. Our system obeys that rule and indicates when it is less than 3ft. CONCLUSION In this paper, we proposed a method to sense the presence of alcohol from the breath of drivers and curtail the catastrophic effects due to rear front accident, that costs lives of many people. The system was designed and implemented successfully via the use of Arduino Uno ATMEGA328 microcontroller and MQ-3 sensor with Ultrasonic Sensor. Experimental evaluation of the system showed that the alcohol sensor and Ultrasonic Sensor was able to deliver fast response when alcohol is detected as well as when it is not. Also, the ability of the alcohol sensor with Ultrasonic Sensor to operate over a long time is a feature of the proposed system.