CAPSTONE PROJECT

REPORT

on

Prototyping a Piezoelectric tile and creating an efficient

Street Light System

Project Team Members Group 25:

EIC 7thSEMESTER

Prabhjas Singh- 101805005

Saatvik Sharma- 101805027

Sahil Walia- 101805053

Under the Guidance of

Dr.Gagandeep Kaur

Associate Professor, EIED

2022

Thapar Institute of Engineering and Technology

Electrical & Instrumentation Engineering Department

(Declared as Deemed-to-be-University u/s 3 of the UGC Act., 1956)

Post Bag No. 32, Patiala – 147004

Punjab (India)

DECLARATION

We hereby declare that project entitled "development of Prototype of a Piezoelectric tile is

an authentic record of our work carried out in the Electrical & Instrumentation Engineering

Department, Thapar Institute of Engineering and Technology, Patiala, under the guidance of

Dr. Gagandeep Kaur (Associate Professor) during March-December 2022.

Date: 28/11/22

S. No.

Name of the Student

Roll No.

1

Prabhjas Singh

101905122

2

3

Saatvik Sharma

Sahil Walia

102085007

101905053

Signature

Faculty Supervisors:

Dr. Gagandeep Kaur Signature

Signature

(Associate Professor)

Electrical & Instrumentation Engineering

Thapar Institute of Engineering & Technology

i

ACKNOWLEDGEMENT

We want to express our sincere gratitude to everyone who helped the project and convergence

come to a successful conclusion thanks to our supervisor Dr. Gagandeep Kaur, and all the

faculty & staff members of the Electrical and Instrumentation Engineering Department,

Thapar Institute of Engineering & Technology for generously extending their support and

for sparing their valuable time to guide us towards the completion of this project work.

We would like to place a special word of appreciation to Jaideep Sir, Department of Electrical

& Instrumentation Engineering, for allowing us to use their laboratories/tools. Also, we would

like to thank our classmates and all other respondents and group members whose responses

and coordination was of utmost importance for completing this project work.

S. No.

Name of the Student

Roll No.

1

Prabhjas Singh

101905122

2

3

Saatvik Sharma

Sahil Walia

102085007

101905053

ii

ABSTRACT

By the year 2040 the dependence on non-renewable electricity sources is estimated to increase

by a whopping 93% when compared to the levels of 2015. Currently, electricity usage has

become a norm for our civilization. Day by day, demand has grown for it. Modern technology

requires a significant amount of electrical power for its numerous activities. The primary

cause of pollution in the globe is the production of electricity. On the one hand, increased

concern over the gap between the supply and demand of power for the general population

has brought attention to the investigation of alternative energy sources and their sustainable

use. Essentially in this project, an attempt to counter this dependence on non-renewable

resources, a prototype of a piezoelectric tile has been created which further is used to create a

street light system which would run on the electricity generated via this tile. During the

night time, the intensity of the street lights would remain at 50% to save energy and

whenever a car or object is sensed by the sensors located in modules paced at the street

lights, the succeeding 2 street lights would be set to an intensity of 100% and after a delay

they would be set back to 50%.

As a result, the street lights would not lead to energy wastage and moreover in the future

these tiles can be commercialized for private usage once the prototype is efficiently and fully

made.

iii

TABLE OF CONTENTS

Page No.

DECLARATION

ii

ACKNOWLEDGEMENT

iii

ABSTRACT

iv

LIST OF TABLES

vii

LIST OF FIGURES

viii-ix

LIST OF ABBREVIATIONS

x

CHAPTER 1: INTRODUCTION TO PROJECT

1

1.1 INTRODUCTION

1

1.2 LITERATURE SURVEY

4

1.3 NEED ANALYSIS

2

1.4 AIM

3

1.5 OBJECTIVES

1.6 PROBLEM FORMULATION

1.7 EXPECTED DELIVERABLES

CHAPTER 2: THEORY, STANDARDS AND CONSTRAINTS

15

2.1. THEORY

18

2.3. ASSUMPTIONS AND CONSTRAINTS

21

CHAPTER 3: DESIGN METHODOLOGY

25

3.1. PROPOSED WORKFLOW/ METHODOLOGY

25

3.2. FLOW CHART

29

3.3. MATHEMATICAL ANALYSIS AND CALCULATIONS

29

CHAPTER 4: RESULTS AND DISCUSSION

34

4.1. HARDWARE RESULTS

35

4.2. PROPOSED OUTCOME

36

4.3.CONCLUSION

37

iv

CHAPTER 5: CONCLUSION AND FUTURE WORK

38

5.1. SUMMARY

38

5.2. FUTURE WORK

38

CHAPTER 6: PROJECT METRICS

39

6.1. CHALLENGES FACED AND TROUBLE SHOOTING

39

6.2. RELEVANT SUBJECTS

39

6.3. INTERDISCIPLINARY ASPECT

39

6.4. COMPONENTS AND COST ANALYSIS

40

6.5 TEAM ASSESSMENT MATRIX

40

6.6. WORK SCHEDULE (GANTT CHART)

40

REFERENCES

ANNEXURE

41

43

PLAGIARISM REPORT

44

v

LIST OF TABLES

Table

Caption

Page No.

1

Course learning outcomes of the subjects used in the project

7

2

Lists of components used

36

3

List of relevant Subjects

37

4

Team assessment matrix

37

5

Gantt chart of group

39

6.

Gantt chart of Prabhjas singh

39

7

Gantt chart of Saatvik Sharma

40

8

Gantt chart of Sahil walia

40

vi

LIST OF FIGURES

Fig.

Caption

Page No.

1

Arduino Uno Board

9

2

Piezoelectric sensor and its terminals

10

3

Simple bridge rectifier

10

4

Diagram of (a)Direct piezoelectric effect (b)Converse

19

piezoelectric effect.

5

simple piezoelectric sensor

19

6

Circuit representation of a simple ac-dc converter

20

7

The design of piezoelectric tile developed by Hwang li, the

27

prototype of piezoelectric energy

harvesting tile

.

8

Schematic of curved piezoelectric smart paver tile

27

9

Structural outline of the system

30

10

flowchart of Step by step representation of the system

31

11

odel for equivalent piezoelectric energy harvester circuit with

32

bridge rectifier and output capacitor.

12

Piezoelectric Tile by PaveGen

33

13

Piezoelectric Schematic

34

14

A technology used by pavegen(UK), a company which brought

37

the idea of smart tiles into reality in 2019

15

Physical protype of the piezoelectric tile

38

vii

16

Diagram represents the proposed outcome which resembles real

38

world street light system where energy is generated from the

piezoelectric.

viii

CHAPTER 1

INTRODUCTION TO PROJECT

1.1 INTRODUCTION

Every year, demand for electricity is expected to rise as a result of population growth, economic

expansion overall.

The rising demand for power has put pressure on the cost and availability of all natural resources.

There are three different ways to produce electricity: peak, load, and intermediate. This load power

is required to keep the electrical grid powered up to meet ongoing consumer demand.

Energy scavenging is the most important concept and probably one of the most sought- after options

for electrical energy contentment. Energy scavenging is the capture of minute amounts of energy

from more than one surrounding energy sources, accumulation, and storage for later use. This process

has innumerous advantages, including the fact that it is inexpensive, safe, requires no maintenance,

is versatile, and can be used in a variety of situations. The energy of vibration is one of the renewable

sources of energy in our world. This concept can be used in everyday life to generate renewable

energy and reduce reliance on nonrenewable energy.

Compared to other energies, vibration energy produces electrical energy with a higher density. We

may readily find the vibration everywhere around us. Electrostatic, electromagnetic, and piezoelectric

processes can all be utilised to transform vibrational energy into electrical energy. Since they don't

need external power and have a steady energy density, piezoelectric materials are highly valued.

Piezoelectric materials may be employed as energy storage devices, which may be used to supply

power to the sensor. The piezoelectric substance can also transform mechanical stress into electrical

energy.

The unique property known as the piezoelectric effect making possible for materials to convert

mechanical energy into electrical energy and electrical energy into mechanical energy. Human

movement, wind, rain, tide, and waves can all trigger piezoelectric materials. The substance may

naturally possess this effect or it may be introduced to an already existing non-piezoelectric

substance.

Japan has already begun using the piezoelectric effect to generate electricity by placing specialised

floor tiles at the two busiest stations in its cities.

The use of tiles that have piezoelectric components components with a diameter of 28 millimetres

and disc form. It uses 40 of these components for every square metre. The floor employs the opposite

method to generate electricity by harnessing vibration power, just as a loudspeaker produces sound

by converting electric signals to vibrations

1

Tiles can be installed on pathways. As a result, every time a passerby steps on a mat, a small vibration

is produced that can be stored as energy. According to East Japan Railway, the energy generated by

a single passer is multiplied many times by the 400,000 people who use Tokyo station on an average

day, producing enough energy for electronic sign boards. A person who weighs 60 kg will only

produce 0.1 watt in the brief period of time it takes them to go two steps over a tile, but if they cover

a big area of floor space and thousands of individuals step or jump on them, a significant amount of

power can be produced. The energy produced by this generator is adequate to run automatic ticket

gates and electronic gates.

The piezoelectric effect is a special property that enables the conversion of mechanical energy to

electrical energy and vice versa. For piezoelectric materials, wind, rain, tide, and waves can all be

used as stimuli. This effect may be introduced to an existing non- piezoelectric material or

incorporated into the substance as an essential characteristic.

The distinctive flooring tiles in London that include 35 millimeter-diameter piezoelectric elements

inserted in them as well as disc-shaped components for loudspeakers. Each square metre uses 600 of

these elements. The floor uses a reverse mechanism to produce energy by using the vibration power,

whereas the loudspeaker makes sound by translating electrical pulses to vibrations.

1.2 LITERATURE SURVEY

In[1] using applications for piezoelectric, electromagnetic, and triboelectric devices to transform

mechanical energy into electricity in accordance with the first law of energy conversion.

In [2]. Piezoelectricity, which is the ability of materials to create electricity through mechanical

deformation, was discovered by the Curie brothers in 1880. The two categories of piezoelectric

technology are piezopolymer and piezoceramic. Despite being more adaptable, the former has

significant drawbacks, such as poor power conversion rates and

electromechanical

coefficients. They frequently have strong electromechanical coupling constants and high energy

conversion rates, although they are delicate..

In[3] The technology that received the greatest attention over the last ten years was piezoelectric

devices.

In[4]Due to its simplicity and convenience of use, Piezoelectric Energy Harvesting (PEEH)

has drawn increased interest in the field of energy harvesting technologies . Monomorphic,

bimorphic, stack, and membrane piezoelectric transducers can

capture

mechanical

all

be

utilised

to

energy

2

In[5]A typical energy harvester can't operate effectively in

every circumstance;

each

arrangement has advantages and limitations of its own. As a result, energy harvesters are

frequently created for a specific application and frequency range.

In[6]. For instance, piezoelectric devices installed in roads may be able to capture energy in the

form of pressure and mechanical energy under the tyres of moving vehicles.

In[7] When a coil moves through the magnetic field, creating a potential difference at both ends of

the coil, Faraday discovered electromagnetism in 1831. The magnetic flux change rate over time

determines the voltage induced in the coil Therefore, this caught the interest of researchers as a

useful method for electromagnetic energy harvesters (EMEHs).

In[8]When two materials with different polarities come into touch with one another, there is a

charge transfer that results, which is what causes the triboelectric effect. Surface detachment leads

to charge buildup electrostatic interaction induction effect once these two materials are connected

with metal, where electrodes are found at the two non-contacting ends. Charge moves in the

opposite way when these two surfaces come into touch once more

In[9]Triboelectric energy harvesting (TEEH), which is easily produced at the nanoscale size

and has a low operation frequency, is regarded as an advanced approach when compared to

piezoelectric and electromagnetic energy harvesting.

In[10]In recent times, it has been in demand, because it produces very high power density, high

conversion efficiency, and low operating frequency.

In[11]Despite the fact that these projects used piezoelectric tiles in various space functions,

regions, and installation techniques, they all had high occupancy densities that enabled

adequate energy production. Low

energy

conversion

rates

and

low

electromechanical

coefficients are just two of the examples' many flaws. However, they have significant energy

conversion rates and substantial electromechanical coupling constants despite being typically fragile.

.

In[12]In the previous decade, piezoelectric devices have been the most widely discussed

technology.

3

In[13]As a result of its ease of use and simple structure, Piezoelectric Energy Harvesting (PEEH)

has gained more attention in the field of energy harvesting technologies. To harvest mechanical

energy, various piezoelectric transducers such as monomorphic, bimorphic, stack, and membrane

can be used.

In[14]An energy harvester generally can't function well in all situations; each configuration has

its own benefits and restrictions. Because of this, energy harvesters are often made for a

particular use and operating frequency range.

In[15]When a coil moves through the magnetic field, creating a potential difference at both ends of

the coil, Faraday discovered electromagnetism in 1831. The magnetic flux change rate over time

determines the voltage induced in the coil. Researchers became interested in this as a viable method

of energy collecting, and electromagnetic energy harvesters (EMEHs) were created as a result.

In[16]The charge transfer that takes place when two materials with different polarities come into

contact is what causes the triboelectric effect. Electrodes are located at the two non-contacting

ends of the materials after they have been joined together with metal. The electrostatic induction

effect causes charge accumulation when surfaces become detached. Charge flows in opposite

directions when these two surfaces come into touch again.

In[17]Triboelectric energy harvesting (TEEH), which is easily

size and has a low operation frequency, is

regarded

as

an

produced

advanced

at

the nanoscale

approach

when

related to piezoelectric and electromagnetic energy harvesting.

In[18]Due to its high power density, excellent conversion ratio, and low operating frequency,

it has attracted a lot of interest recently.

In[19] Despite the fact that these projects used piezoelectric tiles in various space functions, regions,

and installation techniques, they all had high occupancy densities that allowed for adequate energy

production.

1.3 NEED ANALYSIS

4

The energy problem has become one of the most critical worldwide challenges in the last 20 years,

with the explosive growth of electronic gadget development playing a major role. Even if we have

high-capacity electrical energy generation sources like hydro/thermal power plants, it is now critical

to investigate renewable and sustainable energy sources. Numerous innovative energy harvesting

methods, including triboelectric, have been developed over the past ten years.

Due to their distinctive qualities, solar, thermoelectric, piezoelectric, and electromagnetic energy are

unrivalled. Piezoelectric materials stand out among them due to the wide range of sensing and

actuation applications they are used for. It is as a result of their effective solid-state coupling of

mechanical and electrical forces. To meet society's needs, hundreds of new piezoelectric materials

are being researched. These substances often fall within the ferroelectric category. These materials

are mostly insulators. These are broadly divided into categories based on their compositions, stages,

and structures.. Some of these materials belong to the family of BaTiO3, K0.5Na0.5NbO3,

Bi0.5Na0.5TiO3, Pb(Zr,Ti)O3, ZnO, and a few polymers.

PEH (piezoelectric energy harvesting) has been studied for many different types of mechanical

energy harvesting, including acoustics, water flow energy, wind energy, human motion, railway

tracks, and motorways. The typical energy outputs are alternating current and voltage, with current

on the order of microamperes and voltage in the range of a few volts (from piezoelectric). All of this

data imply that there is untapped potential for piezoelectric energy harvesting techniques and tools.

In the past, it has been asserted that shoes, tiles, sidewalks, roadways, limited power devices of

wireless sensors networks, and implanted devices all use piezoelectric energy harvesting technology.

1.4 AIM

Development of prototype of piezoelectric tile for energy Generation and creating a autonomous

street light system.

1.5 OBJECTIVES

•

Prototyping a piezoelectric tile and make all hardware connections.

•

Using the tile to create a smart street lighting system

1.6 PROBLEM FORMULATION

Several states in the nation are currently suffering power disruptions for several hours amid

the rampant surge in power demand caused by the ongoing heatwave and the worst electricity

shortfall in more than six years due to adequate coal supply to thermal plants.

5

During the first 27 days of April, electricity supply lagged behind demand by 1.88 billion

units, or 1.6%, according to Reuters. The country now has a total deficiency of 623

million units less electricity than it did in March!

Two out of every three households in the nation have admitted to experiencing power

disruptions, according to a Circles study.

Finally, The method for generating electricity using piezoelectric crystals to recover

tensional or vibrational energy is among the most promising options. The concept is

based on the positive piezoelectric effect of piezoelectric material: when the material

deforms as a result of external force (pressure or stress), a polarization phenomenon

occurs, enabling charges of varying polarities to collect on two opposing surfaces. The

charges disappear when the outside force is

withdrawn.

If

an

intermittent

external

force is continuously applied to piezoelectric material, charges will built will dissipate.

1.7 EXPECTED DELIVERABLES

•

•

•

Working prototype of a piezoelectric tile.

.

Delivering a non-renewable source for energy harvesting and generation.

Integration of prototype with arduino IDE to create an effecient street

light system.

1.8 CONCLUSION

In this chapter, Introduction to the project along along with the literature survey, need analysis

and other key aspects such as problem formulation were discussed and stated.

6

CHAPTER 2

THEORY, STANDARDS AND CONSTRAINTS

2.1 THEORY

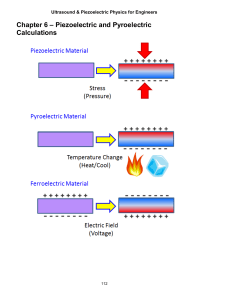

This chapter deals with overview of concepts such as Piezoelectric effect,Arduino microcontroller,

piezoelectric transducer, bridge rectifier and various concepts and components related to the project.

2.1.1

DIRECT PIEZOELECTRIC EFFECT

The direct impact of piezoelectricity is the capacity of a material to transform mechanical stress into

an electrical response, such as an electromagnetic field, electric current, or polarisation. This

property was initially proven by the Curie siblings in 1880 on single quartz crystals (SiO2). The

Curie brothers further proved indirect piezoelectricity after their initial discovery, showing that

particular crystals might undergo a mechanical reaction when exposed to an electric field. Despite

the fact that it was once thought that only a small number of particular crystals have this property, a

wide range of ceramics and composites, as well as other types of materials like polymeric, bone,

wood, and microorganisms, have all been discovered to possess piezoelectricity. Piezoelectricity has

an impact on non-earth-centered materials like zincite (ZnO), which has a non- centrosymmetric

hexagonal wurtzite-type crystal structure, and is not just restricted to spontaneous forms.

Large piezoelectric structures have been found in perovskite crystals, where one crystal can have

piezoelectric coefficients that are more than three orders of magnitude higher than those seen in the

quartz that the Curie brothers first demonstrated. A piezoelectric effect can be described

mathematically as an electromechanical connection. line relationships between a machine (e.g.,

pressure and hardness) and the amount of electric field (e.g., electric field and electric field).

The strain charge form of the piezoelectric constitutive rule is given, S = sT + dE, (1) D = dT +

∊TE.(2) On the other hand, in the stress charge form, T = CS - eE, (3) D = eS + ∊SE, (4) where, s, t,

e, and d are mechanical malfunctions, stress, electric field, and electricity. migration, respectively.

S, C, d, and e are compliance machines, durability, and piezoelectric coefficients ’strain charge

forms and strain-charge forms, respectively. While ∊T, and ∊S are metrics for dielectric clearance in

chronic stress and continuous stress, respectively.Crystalanisotropy is characterized by non-zero

coefficients, leading to differences in the crystallographic point groups' piezoelectric tensors.the

body.

7

2.1.2 EXTRINSIC CONTRIBUTION TO PIEZOELECTRICITY

Both internal and external contributions are present in the piezoelectric response. It is believed that

the internal contribution is caused by the lattice's impacts on the field, namely by the expansion of

the cell unit's recurrent polarisation and rotation during external field operation, which results in

full changes in both polarisation and cell unit type. In contrast, external donations are those that

do not occur in the lattice and are frequently attributed to the domain wall, phase boundary

nucleation, and growth under externally applied power fields and equipment. However, other

hysteretic phenomena, such as cellular dysfunction, can also affect the piezoelectric response.

2.1.3

ARDUINO UNO

The Arduino Unoin figure 2.1 is an open-source microcontroller board developed by Arduino.cc

that was first released in 2010. The board includes digital and analog input/output sets, (I/O)

pins that may be interfaced to various expansion boards (shields) and other circuits.The board

features 6 analog I/O pins, and 14 digital I/O pins, six of which can be used for PWM output. It can

be programmed using the Arduino IDE (Integrated Development Environment) with a type B

USB cable.

THE TECHNICAL CHARACTERISTICS OF ARDUINO UNO:

•

Input Voltage: 7 to 20 Volts

•

Digital I/O Pins: 14

•

PWM Pins: 6 (Pin # 3, 5, 6, 9, 10 and 11)[9]

•

UART: 1

•

I2C: 1

•

SPI: 1

•

Analog Input Pins: 6

•

DC Current per I/O Pin: 20 mA

•

DC Current for 3.3V Pin: 50 mA

•

Flash Memory: 32 KB of which 0.5 KB used by bootloader

•

SRAM: 2 KB

•

EEPROM: 1 KB

•

Clock Speed: 16 MHz

•

Length: 68.6 mm

•

Width: 53.4 mm

•

Weight: 25 g

•

ICSP Header: Yes

8

Fig 2.1 Arduino Uno Board

2.1.4 INVERSE PIEZOELECTRIC EFFECT

The term "inverse piezoelectric effect" describes how piezoelectric sensing devices would

mechanically deform or exert mechanical pressure in a certain direction when an electric field is

supplied in the direction of their polarisation. This deformation or pressure will vanish as soon as the

electric field is eliminated. It is possible for piezoelectric sensors to deform in terms of thickness,

length, volume, thickness shear, and plane shear. Because piezoelectric crystals come in a variety of

materials, some of them are more sensitive to one or more of the effects than to others. For instance,

some piezoelectric crystals are very sensitive to the thickness deformation and length deformation

effects of piezoelectricity, but not to volume deformationThe piezoelectric coefficients of the same

material in the positive and inverse piezoelectric effects are the same. Materials having positive

piezoelectric effect must also have inverse piezoelectric effect. The higher the piezoelectric

coefficient, the more effectively piezoelectric materials convert energy..

2.1.5

PIEZOELECTRIC TRANSDUCER

A piezoelectric transducer, also known as a piezoelectric sensor, is a device that uses the piezoelectric

effect to monitor changes in acceleration, pressure, strain, temperature, or force by converting

this energy into an electrical charge as in figure2.2. Further piezoelectric sensors are also used in

ultrasound imaging and even a current operating system and SDK. In this project one tile is of 1m x

1m, and 40 piezoelectric sensors were placed on the tile connected in parallel such that maximum

amount of energy can be generated through these sensors. One Transducer generates upwards of 2

volts when pressed

9

continuously resulting in a sub-par energy source on its own, however when 40 of them

wereconnected together a 12v battery could be charged easily.

Fig 2. 2 Piezoelectric sensor and its terminals

The terminals of a piezoelectric transducer are depicted in figure 2.2

2.1.6 BRIDGE RECTIFIER

Figure 2.3 depicts how AC power is transformed into a DC power using rectifiers. The

bridge rectifier is the most effective rectifier circuit available. Bridge rectifiers are a

particular kind of full-wave rectifier that effectively converts alternating (AC) current to

direct (DC) current by employing four or more diodes in a bridge circuit design.

Fig 2.3 Bridge rectifier

10

2.1.6 STREET LIGHT SYSTEM

After turning on the street lights at night using the generated power. One can create an autonomous

street light control system utilizing various sensors to save electricity because it wastes a lot of energy

when the lights are left on all night. For this, a Ultrasonic sensor as well as a PIR sensor are being

employed. Due to such an independent control system, the street lights are only turned ON when a car

or a personis present.

The PIR sensor is powered by the 5v regulated power source, though we can also use the Arduino's 5v

for this purpose. The PIR sensor's output pin is linked to pin number four on the Arduino. For ultrasonic

detection, use the module below. So, when someone passes in front of the laser, pin number 2 on the

Arduino is signaled.

To control the lights, two relays are utilized one can alter how many of these relays there

are.designating two pins for the motion sensor "PIR" and the ultrasonic module. The motion sensor is

attached to pin number 4 of the Arduino, while the trigger and echo pins of ultrasonic is connected to

pin numbers 12,13 respectively.

int duration, distance;

int trigPin=12,echoPin=13;

int motion = 4;

The relays are used to turn on and off the street lights. Pins 7 and 8 on the Arduino board are used

to connect two relays. Relays load1 and load2 are given these names.

int load1 = 7;

int load2 = 8;

Every Arduino and Mega 2560 contains at least two functions: void setup and void loop. The

absence of a void indicates that these functions do not return any values, whereas the absence of an

empty parenthesis indicates that these functions do not accept any arguments as input. When

the Arduino or Mega2560 is turned on rorestarted, the void setup() function is only called once.

void setup()

11

Serial.begin(9600); // activates the serial communication, while 9600 is the baud rate. This is only

used for the debugging purposes.

The sensors are set as the input, and relay are setas outputs.

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

pinMode(motion, INPUT);

pinMode(load1, OUTPUT);

pinMode(load2, OUTPUT);

the lights are turned OFF.

digitalWrite(load1, LOW);

digitalWrite(load2, LOW);

}

void loop()

{

The following condition means if the ultrasonic is activated then turn ON the lights connected with

the relay named load1.

if (distance >= 200 || distance <= 0)

{

Serial.println("no object detected");

digitalWrite(load1,LOW);

}

else {

Serial.println("object detected \n");

Serial.print("distance= ");

Serial.print(distance);

12

Serial.print("cm\n ");

digitalWrite(load1,HIGH);

delay(50);}

The following condition states that the lights connected to Load2 will turn on if motion is detected

if (distance >= 200 || distance <= 0)

{

Serial.println("no object detected");

digitalWrite(load1,LOW);

}

else {

Serial.println("object detected \n");

Serial.print("distance= ");

Serial.print(distance);

Serial.print("cm\n ");

digitalWrite(load1,HIGH);

delay(50);

}

if(digitalRead(motion) == HIGH)

{

Serial.println("motion");

digitalWrite(load2, HIGH);

delay(1000);

digitalWrite(load2, LOW);

delay(300);

}

else{

digitalWrite(motion, LOW);

}

}

13

2.2 ASSUMPTIONS AND CONSTRAINTS

•

By choosing a controller roll-off frequency much lower than the current prototype's 12.5

dB per decade and using an integrated interferometric fibre optic method to monitor

diaphragm motion, future efforts for the implementation of an ultrasonic transducer will

concentrate on increasing the achievable bandwidth well beyond 20 kHz. Since the

suggested system is linear, the necessary control action can be produced using an

analogue PID control technique. Long-term stability is resistant to environmental

disturbances because the associated Coulomb force is constant for a fixed electrodemembrane separation, polarisation voltage, and electrode area. The suggested transducer

may be employed as a sensing microphone for photoacoustic and photothermal

phenomena related to bio-photonics at high modulation frequencies, enabling the

execution of experiments with increased spatial resolution. By adjusting the plate

charge, it should be feasible to fine-tune the location of the conductors when employing

an electrostatic actuator.

•

In accordance with the data gleaned from the interferometric signal. The objective is to

lessen instability, which frequently restricts the stable travel distance of electrostatic

actuators. A high linearity, high bandwidth electrostatic actuator would be beneficial for

continuous wave laser.

•

One of the major constraints of using a piezoelectric sensor is the amount of voltage

generated from t, per sensor the maximum voltage generated is north of 5v volts when

pressed with force greater than 50N. the average force generated from a step when a

person walks is in the range of 20-70N hence for this purpose the tile was considered

optimal.

2.3 CONCLUSION

This chapter gave a brief overview to the various concepts for understanding this project

moreover it gave an in depth understanding of the various components used as shown in

fig.2.4 which shows the working and circuit of a bridge rectifier.

14

CHAPTER 3

DESIGN METHODOLOGY

3.1 INTRODUCTION TO THE CHAPTER

In this chapter, the design methodology along withe workflow model and flowchart will be

discussed extensively such that there is complete understanding of the project

.

3.1.1 PIEZOELECTRIC CRYSTAL

The piezoelectric crystal is first of all electrically neutral due to the dispersion of charges, which

results in an equal number of positive and negative charges. This symmetrical charge distribution

leads to zero net electric dipole. An electrical pulse is formed when the symmetry of the crystal is

broken by pressure or an external load, which causes net polarisation. Analytically, to maximise

power extraction, the rectified voltage in a full bridge rectification arrangement with a capacitor

attached for filtration should be half of the no-load value. The direct effect and the converse effect

are two possible piezo effects as a result. The direct action is explained by the crystal structure of

substances like quartz and rochelle salt, which generate electricity when pressure or load is applied.

The former enables us to use it as a sensor when an electrical signal is generated, whilst the latter

transforms it into an actuator and causes their state to change when an electrical signal is applied.

The following two linear successive equations can model both impacts,(direct and converse) easily

Direct Piezoelectric Effect S = sE .T+ d. E [1]

Converse Piezoelectric Effect D = d.T+εT.E [2] Where,

D = electric displacement vector, T = the stress vector

sE = matrix of elastic coefficients at constant electric field strength,

S = strain vector

εT = dielectric matrix at constant mechanical strain

E = electric field vector ; d = direct or converse piezoelectric effect

Secondly, In this project use of a rounded Piezoelectric transducer diaphragm(figure 3.2) has been

seen. A piezoelectric material must be stressed betwen its self-resonant frequency (SRF) ranges

in order to generate the greatest amount of charge.

15

Fig 3.1 (a)Direct piezoelectric effect (b)Converse piezoelectric effect.

The above diagram shows the direct and inverse Piezo electric effects and the charge concentration and

movement.

Fig 3.2 Piezoelectric sensor

The above figure shows the structure of a piezoelectric transducer mounted on a metal coin.

3.1.2 BRIDGE RECTIFIER AND ARDUINO MODULE

Since the resultant output from the piezoelectric tiles is in ac we have made use of a bridge rectifier

circuit which will allow us to store the current in dc.

A rectifier is required to change the alternating current (AC) from PEH into direct current (DC),

which is then used to drive electrical applications. Full bridge (FB) rectifiers are frequently utilized

in PEH circuits. But in low voltage circuits, the diode forward voltage in rectifiers suffers from non 16

negligible power loss as shown in figure 3.3. Even still in this project we shall be using a simple

bridge rectifier circuit for simplicity and efficiency.

Fig 3.3 Simple ac-dc converter

Basically, 40 bridge rectifiers were used which rectified the AC generated from the Piezoelectric tile

into direct current and as the ICs within step down the voltage to collect readings, this DC module

behaves like a voltage transformer. This dc is stored in a battery which upon charging gives a

constant source of current and voltage to the Arduino board which is used create the street light

system.

3.1.3

CANTILEVER TYPE AND CURVED TYPE PEH

One of the most popular types of energy extractors, including those used in energy harvesting

tiles, is the cantilever piezoelectric one. Steps on the tile cause a mechanical load to be transferred

to the cantilever beam that has embedded piezoelectric material. An electrical output is produced

when the cantilever beam is bent because the axial tension on the piezoelectric material. By

contrasting the output of the cantilever type piezoelectric harvester with a single-electrode mode

triboelectric energy harvester of equivalent size, the cantilever type harvester's superiority was

made clear. The power density

was

of

the

piezoelectric

harvester

found.

17

Fig 3.4 the prototype of piezoelectric energy harvesting tile,

For straightforward cantilever-based piezoelectric energy harvesters (figure3.4),a fixture for

restricting one end of the beam is typically needed. Additionally, a stopper is typically added

to avoid excessive deformation and damage to the piezoelectric material. Because they are more

compact and produce more power than cantilever harvesters, curved piezoelectric components

have been researched for use as energy harvesters inside smart tiles. These are easily

positioned inside the tile in simply supported boundary conditions due to their curved design,

eliminating the need for additional fittings at the ends.

Fig 3.5 Curved piezoelectric smart paver tile

18

3.1.4

WORKING METHODOLOGY

Fig 3.6 Structural outline of the system

Figure 3.6 shows the working methodology of the project.Piezoelectric transducers are used to

convey electrical energy. Because the mechanical vibration and energy produced by the

piezoelectric disc in the ceramic tile are directly inversely proportional, the output increases when

more pressure (weight) or force is applied to the disc at once. Therefore, investigation was

done to ascertain where on the floor the front and rear of the tile were positioned. When pressure

is exerted from within the foot to the piezoelectric discs, mechanical energy is produced.

Mechanical energy is converted into electrical impulses by the piezoelectric transducers. Due to

variations in vibrations brought on by various amounts of pressure applied, the electric voltage

produced as a result of a potential difference of the charges is an AC voltage; therefore, a bridge

rectifier circuit is used to convert the AC voltage to DC voltage, which can then be used in

electronic devices. An ineffective energy harvester is created by a direct connection between a

battery and a rectifier, which results in a constant VREC. A DC-DC power converter is

incorporated into the circuit to adaptively modify the rectified voltage in relation to the

piezoelectric open-circuit voltage, hence increasing the circuit's harvesting power. The

aforementioned statistics show a structural breakdown of all the processes that take place in our

setup.

3.2 FLOWCHART

The flowchart of this project is given in figure 3.7, which shows how the project synthesis is carried.

19

Fig .3.7 Project flowchart

3.3 MATHEMATICAL ANALYSIS AND CALCULATION

The mathematical analysis and all the conclusions drawn from them will be discussed here:

3.3.1 FORMULATING THE EQUATION FOR RESONANCE FREQUENCY OF THE

VIBRATING PIEZOELECTIRC TRANSDUCER.

Piezoelectric diaphragms or bender plates, which are comprised of a piezoelectric plate (PZT) with

electrodes on both sides and are bonded to a metal with conductive adhesive, are the transducers

utilised in this model. Helmholtz's equation provides the value of these diaphragms' resonant

frequency.

the pressure change p produced by a small volume change ΔV (assume a resonator)

now substitute for F and m. [4],[5].

20

Therefore, the restoring force is directly related to the displacement. This is the prerequisite for simple

harmonic motion, which has a frequency equal to half of the square root of the proportionality

constant, so:-

3.3.2 EQUATION FOR ENRGY HARVESTING

Fig3.8 simulation model

The above given figure (figure 3.8) shows the model of the circuit and the charging circuit as well.

Fig3.9 Piezoelectric Tile by PaveGen

The below shown image (figure 3.10) is of an already existing piezo tile which acts as a base of

our simulation, the below constructed tile has been referred from :-.

21

8

Fig.3.10 Piezoelectric Tile Schematic

Figure.3.13 was referred by Yung Soo Kim, Joo-Hyong Kim and Jaehwan Kim, reseachers form Japan

who created this schematic for a piezoelectric tile .

Fig.3.11 Piezoelectric tile created by pavegen(UK)

22

CHAPTER 4:

RESULTS

In this chapter, the physical diagram along with the hardware model and its results will be discussed.

4.1 PHYSICAL DESIGN

The connections shown below are of the piezoelectric tile where the white wires signify the AC output

of the tile which acts as input for the bridge rectifier which after rectifying are given to the charging

circuit which allow the street light sensors to be powered.

Fig. 4.1 Tile Circuitry

4.2

OUTPUT MODEL

The output model of the project is given in figure 4.2. which clearly depicts the project

deliverables and the tile as well as the lighting system circuitry.

23

Fig 4.2 Street light circuitry

4.3 CONCLUSION

In this chapter, the expected output after the construction of the piezo tile is observed and furthermore

the light system was seen the being connected to the charging circuit. Figure4.2 shows the circuit

model of the charging circuit interface with the Arduino sensor.

24

CHAPTER 5

CONCLUSION AND FUTURE WORK

5.1 CONCLUSION

For the time being, an attempt has been made to developed a system to build a smart street system

which works on its own without any non-renewable energy source, and a piezoelectric tile

has

been created and its implementation in the real world The constraints and assumptions associated

with this model have been verified. These outcome values remain within permissible limits.

Moreover the use of such a piezoelectric tile in the future can surely utilize the energy generated

from a step and use it for various purposes..

5.2 FUTURE WORK

In the upcoming days, the aim to pick up this prototype unit to a stage for testing and actual trials.

To make the device this efficient and in order for the device to be able to used more accessibly we

will incorporate various IOT components which can allow for this device to used for private as well

as public settings. (e.g., an Nvidia jetson nano developer board). The goal is to to make this device

become present all around us to ensure our environmental resources are consume judicially and we

reduce humanity’s dependency on non-renewable resources and to make the Indian streets fully

automated and powered via our piezoelectric tile system.

25

CHAPTER 6

PROJECT METRICS

6.1 CHALLENGES FACED AND TROUBLESHOOTING

During the entire process, starting from project planning to final testing of our hardware model, there

were various challenges we faced. Initially, we faced a problem with analyzing the novelty of our

model, but with the help of our mentors and the process of literature survey, we were able to identify

the novelty of our project. Another major challenge we faced was improving the accuracy of our tile

and genration model, but with the process of regular testing, we were able to achieve a consistent and

accurate working model.

6.2 RELEVANT SUBJECTS

UG Courses used in the project are tabulated below:

Table 6.1 course learning outcomes of the subjects used in the project

S. No.

Subject Code

Subject

1

UEI407

Signals & Systems

2

UEI501

Control Systems

3

UEI610

Fundamentals of Microcontrollers & Microprocessors

4

UTA014

Engineering Design 2

5

UEI701

Data Acquisition & System Design

6

UEI704

Soft Computing Techniques

7

UTA013

Engineering Design 1

8

UEI608

Biomedical Instrumentation

6.3 INTERDISCIPLINARY ASPECT

In our project, An attempt to cover various parameters has been done. It required in-depth

knowledge of principle of piezoelectricty, soldering and network analysis

,Arduino

programming, and different sensors for the proper functioning of the model developed. Some

essential components in the project included: the interfacing of different sensors, construction of

the piezoelectric tile, and linking the model with street lights

26

6.4 COMPONENTS USED

Here table number 6.2 indicates the final list of all the components used.

Table 6.2 Lists of components used

S.

No.

Name of the Component(s)

Cost

Status

1.

Arduino uno R2

1086/-

Purchased

2.

Piezoelectric crystals

900/-

Purchased

3.

Battery 12v

750/-

Purchased

4.

PIR Sensor – HC-SR501

120 /-

Purchased

5.

diode

300/-

Purchased

6.

Soldering kit

600/-

Purchased

7.

Tile material

350/-

Purchased

8.

Connecting wires and PCB board

300/-

Purchased

9.

Street simulation hardware material

200/-

Purchased

Grand Total

3606 /-

27

6.5 TEAM ASSESSMENT MATRIX

Table 6.3 Team Assessment Matrix

Evaluation of

Evaluation

By

Prabhjas

Singh

Saatvik

Sharma

Sahil Walia

Prabhjas Singh

5

5

5

Saatvik Sharma

5

5

5

Sahil walia

5

5

5

28

6.6 WORK SCHEDULE

Table 6.4 Gantt chart of group

February

March

May

July

August

October

December

Project idea discussion and finalisationFebruar2y8

Literature review

Research on piezoelectric tiles and charging circuit

circuit modelling and hardware design

65

April

51

June

hardware development

tile Assembly

21

March

122

209

April

March

Arduino code for smart street light

20

June

y

Development of tile with connectins and soldering

Integration between hardware and Software

61

ptember

Testing and Modification

40

November

Result Evaluation

November

1-9

1-9

Final Report and Documentation

November

1-10

Table 6.5 Gantt chart of Prabhjas Singh

February

March

May

July

August

October

December

Project idea discussion and finalisationFebruar2y8

Literature review

Research on piezoelectric tiles and charging circuit

21

March

April

65

circuit modelling and hardware design

hardware development

tile Assembly

Arduino code for smart street light

Development of tile with connectins and soldering

Integration between hardware and Software

Testing and Modification

51

June

April

March

June

May

122

209

20

61

September

November

40

Result Evaluation

November

1-9

1-9

Final Report and Documentation

November

1-10

29

Table 6.6 Gantt chart of Saatvik Sharma

February

March

May

July

August

October December

Project idea discussion and finalisationFebruar2y8

Literature review

Research on piezoelectric tiles and charging circuit

March 21

April

circuit modelling and hardware design

65

51

June

hardware development

April

March

tile Assembly

Arduino code for smart street light

122

209

20

June

May

Development of tile with connectins and soldering

Integration between hardware and Software

61

September

Testing and Modification

Result Evaluation

40

November

Final Report and Documentation

November

1-9

1-9

November

1-10

Table 6.7 Gantt chart of Sahil Walia

February

March

May

July

August

October

December

Project idea discussion and finalisationFebruar2y8

Literature review

Research on piezoelectric tiles and charging circuit

March 21

April

circuit modelling and hardware design

hardware development

tile Assembly

Arduino code for smart street light

Development of tile with connectins and soldering

Integration between hardware and Software

Testing and Modification

65

June

April

March

June

May

51

122

209

20

61

September

November

40

Result Evaluation

November

1-9

1-9

Final Report and Documentation

November

1-10

30

REFERENCES

1. C. Keawboonchua and T. G. Engel, Factors Affecting Maximum Power Generation in

Piezoelectric Pulse Generator Vol.1,

2. C. T. G. Engel, W. C. Nunnally, and N. B. VanKirk, Compact kinetictoelectrical energy

conversion, Proc 11th IEEE Int. Pulsed Power Cod., Baltimore,MD, 1997,

3. T. G. Engel, C. Keawboonchuay, and W. C. Nunnally, Energy conversion and high power

pulse production using miniature piezoelectric compressors, IEEE Trans. Plasma Science.,

vol 28, no. 5,

4. C. Keawboonchuay, Exploration of high power piezoelectric kinetic to electrical enera

converter, Master’s Thesis, University of MissouriColumbia, May, 2000.

5. G. K. Ottman, H. F. Hofmann, A. C. Bhatt, and G. A. Lesieutre, Adaptive piezoelectric energy

harvesting circuit for wireless remot power supply, IEEE Trans. Power Electron., vol. 17, no.

Sep. 2002

6. E. Lefeuvre, A. Badel, C. Richard, L. Petit, and D. Guyomar, “A comparison between several

vibration-powered piezoelectric generators for standalone systems,” Sens. Actuators A, Phys.,

vol. 126, no. 2,Feb. 2006.

7. E. Lefeuvre, A. Badel, C. Richard, L. Petit, and D. Guyomar, “A comparison between several

vibration-powered piezoelectric generators for standalone systems,” Sens. Actuators A, Phys.,

vol. 126, no. 2,, Feb. 2006.

8. G. K. Ottman, H. F. Hofmann, and G. A. Lesieutre, “Optimized piezoelectric energy

harvesting circuit using stepdown converter in discontinuous conduction mode,” IEEE Trans.

Power Electron., vol. 18, no. 2, Mar. 2003.

31

9. S. Roundy, P.K. Wright, J. Rabaey, A study of low level vibrations as a power source for

wireless sensor nodes, Computer Communication,vol. 13, no. 5, May. 2012.

10. C.B. Williams, R.B. Yates, Analysis of a micro-electric generator for Micro systems,

11. Sensors and Actuators, vol. 11, no. 2, Mar. 2010.

12. D. Shen, J.H. Park, J. Ajitsara, S.Y. Choe, H.C. Wikle III, D.J. Kim, The design, fabrication

and evaluation of MEMS PZT cantilever with an integrated Si proof mass for vibration energy

harvesting, Journal of Microelectronics and Microengineering, vol. 09, no. 1, Jan. 2003.

13. . [13] S. Roundy, P.K. Wright, A piezoelectric vibration based generator for wireless

electronics, Smart Materials and Structures, vol. 18, no. 2, Jun. 2003.

14. M. Marzenkicki, Y. Ammar, S. Ammar, S. Basrour, Integrated based harvesting system

including a MEMS generator and a power management circuit, Sensor and Actuators A, vol.

18, no. 1 Mar. 2007.

15. Y.B. Jeon, R. Sood, J.H. Jeong, S.G. Kim, MEMS power generator with transverse mode thin

films PZT, Sensors and Actuators vol. 4, no. 3, Jun, 2007.

16. G. Poulin, E. Sarraute, and F. Costa, “Genaration of electric energy for portable devices:

Comparative study of an electromagnetic and a piezoelectric system,” Sens. Actuator A,

Phys.,

17. N. Elvin, A. Elvin, and D. H. Choi, “A self-powered damage detection sensor,” J. Strain Anal.

Eng. Des., vol. 38, no. 2, Mar. 2011.

18. S. R. Anton and H. A. Sodano, “A review of power harvesting using piezoelectric materials

(2003-2006),” Smart Mater. Struct., vol. 16, no. 3, Jun. 2007.

19. A. Tabesh and L. G. Frechette, “An improved small-deflection electromechanical model for

piezoelectric bending beam actuators and energy harvesters,” J. Micromech Microeng., vol.

18, no. 10, Oct. 2008..

20. Yogesh K. Ramadass and Anantha P. Chandrakasan, An Efficient Piezoelectric Energy

Harvesting Interface Circuit Using a Bias-Flip Rectifier and Shared Inductor, IEEE Journal

Of Solid-State CircuitsVol. 45, No. 1, January 2010.

21. Pisharody Harikrishnan G, An Optimal Design for Piezoelectric Energy Harvesting System,

IEEE PESvol. 18, no. 2, Feb. 2006.

32

ANNEXURE

CODE FOR STREET LIGHT SYSTEM

int motion = 4;

int duration,distance;

int trigPin=12,echoPin=13;

int load1 = 7; int load2 = 8;

void setup()

{

Serial.begin(9600);

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

pinMode(motion, INPUT);

pinMode(load1, OUTPUT);

pinMode(load2, OUTPUT);

digitalWrite(load1, LOW);

digitalWrite(load2, LOW);

}

void loop()

{

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

duration = pulseIn(echoPin, HIGH);

distance = (duration/2) / 29.1;

if(distance >= 200 || distance <= 0) {

Serial.println("no object detected");

digitalWrite(load1,LOW);

}

33

else{

Serial.println("object detected \n");

Serial.print("distance= ");

Serial.print(distance);

Serial.print("cm\n ");

digitalWrite(load1,HIGH);

delay(50);

}

if(digitalRead(motion) == HIGH)

{

Serial.println("motion");

digitalWrite(load2, HIGH);

delay(1000);

digitalWrite(load2, LOW);

delay(300);

}

else {

digitalWrite(motion, LOW);

}

}

34

PLAGIARISM REPORT

Take print out of the first page of the plagiarism report

35

Title

ORIGINALITY REPORT

19

%

SIMILARITY INDEX

17%

20%

%

INTERNET SOURCES

PUBLICATIONS

STUDENT PAPERS

PRIMARY SOURCES

www.electroniclinic.com

1

Internet Source

2

Rania Rushdy Moussa, Walaa S.E Ismaeel,

Madonna Makram Solban. "Energy generation in

public buildings using piezoelectric flooring tiles;

a case study of a metro station", Sustainable Cities

and Society,2021

5%

4

Publication

3

Saurav Sharma, Raj Kiran, Puneet Azad, Rahul

Vaish. "A review of piezoelectric energy

harvesting tiles: Available designs and future

perspective", Energy Conversion and

Management, 2022

4

Publication

4

Syed Umaid Ahmed, Arbaz Sabir, Talha Ashraf,

Muhammad Ali Haider, Farha Perveen,Zafeer

Farooqui, Riaz Uddin. "Energy Harvesting through

Floor Tiles", 2019 International Conference on

Innovative

Computing (ICIC), 2019

Publication

Exclude matches

<8

2

words

36