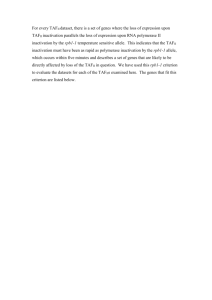

Trends in Food Science & Technology 66 (2017) 20e35 Contents lists available at ScienceDirect Trends in Food Science & Technology journal homepage: http://www.journals.elsevier.com/trends-in-food-scienceand-technology Review Mild processing applied to the inactivation of the main foodborne bacterial pathogens: A review Francisco J. Barba a, d, Mohamed Koubaa b, Leonardo do Prado-Silva c, Vibeke Orlien a, Anderson de Souza Sant’Ana c, * a Department of Food Science, Faculty of Science, University of Copenhagen, Rolighedsvej 26, 1958 Frederiksberg C, Denmark Sorbonne Universit es, Universit e de Technologie de Compi egne, Laboratoire Transformations Int egr ees de La Mati ere Renouvelable (UTC/ESCOM, EA 4297 TIMR), Centre de Recherche de Royallieu, CS 60319, 60203 Compi egne Cedex, France c ~o Paulo, Brazil Department of Food Science, University of Campinas, Campinas, Sa d Nutrition and Food Science Area, Preventive Medicine and Public Health, Food Sciences, Toxicology and Forensic Medicine Department, Faculty of Pharmacy, Universitat de Val encia, Avda. Vicent Andr es Estell es, s/n, 46100 Burjassot, Val encia, Spain b a r t i c l e i n f o a b s t r a c t Article history: Received 25 June 2016 Received in revised form 24 April 2017 Accepted 17 May 2017 Available online 19 May 2017 Background: Salmonella, Listeria monocytogenes, Escherichia coli O157:H7 and Campylobacter are the major bacterial pathogens associated with foodborne diseases and their inactivation is fundamental to ensure microbiologically safe products. Although efficient in generating safe foods with proper shelflives, pasteurization and commercial sterilization may result in numerous nutritional and sensory changes in foods. To address these disadvantages, mild processing methods (i.e., processing technologies for food preservation that apply mild temperature; <40 C) aiming to destroy microbial food contaminants have been developed. Scope and approach: This review emphasizes the main applications of mild technologies aiming to the inactivation of the four main pathogenic bacteria of relevance for food safety as well as their mechanisms of action. Key findings and conclusions: Mild processing technologies such as high pressure processing, ultrasounds, pulsed electric fields, UV-light, and atmospheric cold plasma may serve, in some conditions, as useful alternatives to commercial sterilization and pasteurization aiming to destroy foodborne pathogens. Each of these mild technologies has a specific mode of microbial inactivation and their knowledge is of foremost importance in the design and practical application aiming to produce high quality and safe foods. This is necessary to ensure that mild technologies are highly advantageous in comparison to conventional technologies not only for preservation of nutritional and sensorial aspects of foods but also to ensure their safety throughout shelf-life. © 2017 Elsevier Ltd. All rights reserved. Keywords: Food preservation High pressure processing Ultrasound Pulsed electric field UV-Light Atmospheric cold plasma Food safety Shelf-life Hurdle technology 1. Introduction Food preservation has greatly relied on the application of effective processes able to inactivate foodborne microorganisms. These processes are of paramount importance and formed the solid basis for the industrialization and commercialization of foods in large scale. Pathogenic microorganisms are normally the major targets of several industrial food processes because of the burden posed by foodborne diseases. Moreover, these microorganisms may * Corresponding author. Rua Monteiro Lobato, 80, 13083-862 Campinas, S~ ao Paulo, Brazil. E-mail address: and@unicamp.br (A.S. Sant’Ana). http://dx.doi.org/10.1016/j.tifs.2017.05.011 0924-2244/© 2017 Elsevier Ltd. All rights reserved. be able to adapt and withstand stressful conditions faced during food production and storage. The main traditional methods applied by industries for food preservation include the application of heat (pasteurization and sterilization), decrease of temperature (freezing and chilling), reduction of water activity (addition of salt and sugar, or drying) and addition of preservatives, among others. These methods may be very effective, if correctly designed and applied, in inactivating or ensuring pathogenic microorganisms will not grow and reach levels that will impair food safety. Nonetheless, these methods usually result in changes in nutritional, chemical/biochemical and sensorial properties of foods that reduce their acceptance by consumers. In addition, environmental and wellness concerns served F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 as basis for the development of novel food preservation methods (mild technologies) such as high pressure-based processes, pulsed light, among others, have been introduced into food industries (Georget et al., 2015; Jermann, Koutchma, Margas, Leadley, & Ros ~ a, Alvarez, n, & Raso, Polski, 2015; Koutchma, 2009; Saldan Condo 2014; Serment-Moreno, Barbosa-C anovas, Torres, & Welti-Chanes, novas, Torres, & 2014; Serment-Moreno, Fuentes, Barbosa-Ca Welti-Chanes, 2015). Despite this, it is the ability of a technology to efficiently destroy a microbial target that will determine its potential practical applications. Given this, the understanding of mechanisms and factors impacting on microbial inactivation by mild technologies, specially speaking about the main foodborne bacterial pathogens, is of foremost relevance for ensuring food safety. Therefore, in this paper a comprehensive review of literature on the key aspects of the application of mild technologies aiming to ensure the production of safe foods is presented. 2. Key microorganisms impacting on food safety Foodborne illnesses can be defined as any disease originated from consumption of foodstuffs contaminated with microorganisms or chemicals (Tauxe, Doyle, Kuchenmüller, Schlundt, & Stein, 2010). Foodborne diseases cause the illness of several millions of people around the world. For instance, in the United States, an estimated 76 million illnesses occur annually, with more than 5.2 million of the infections that are attributed to foodborne pathogens (Mead et al., 1999). These infections result in 128,000 hospitalizations and around 3000 deaths annually in the United States (CDC, 2010). Due to their high morbidity and mortality rates, foodborne illnesses have taken great attention worldwide (Tauxe et al., 2010). Salmonella spp., Listeria monocytogenes, Campylobacter spp., and Escherichia coli O157:H7 comprise the most important bacterial foodborne pathogens associated with foodborne diseases (Alocilja & Radke, 2003; Chemburu, Wilkins, & Abdel-Hamid, 2005). The Campylobacter species such as C. jejuni and C. coli have long been recognized as the most important pathogens in veterinary field. Moreover, Campylobacter spp. have received special attention due to their repetitive occurrence in some foods for human consumption. C. jejuni is nowadays considered as the first causative agent of human foodborne infection in developed countries (Rantsiou & Cocolin, 2016). For instance, it was reported that both C. coli and C. jejuni species cause the infection of approximately 2.4 million persons annually in the United States (CDC, 2011). Also, C. jejuni is the most commonly isolated species from fecal specimens, with almost 90% of the reported cases (Fitzgerald, 2015). Salmonella is the second most common bacterial pathogen involved in foodborne diseases after Campylobacter. After consuming contaminated foods, the symptoms (diarrhea, abdominal cramps, nausea, vomiting, fever, headache, and blood in the feces (Poppe, 2011) may appear usually after 12e72 h and last for 4e7 days. In most cases, Salmonella infections do not require hospitalization, but high risk groups (children, elderly and those who have weak immune system) are more prone to become ill and the illness might be more severe (Grant, Hashem, & Parveen, 2016). Salmonella infection cases are reported to be approximately 1.4 million in the United States of America annually, which result in approximately 16,000 hospitalizations and about 600 deaths (Cummings et al., 2010; Turner, 2010). In poultry industry, Salmonella and Campylobacter are considered as the major concerns compromising the safety of poultry products. It is widely recognized that chicken represents the major vehicle for these pathogens (Domingues, Pires, Halasa, & Hald, 2012; Greig & Ravel, 2009; Guo et al., 2011; Hermans et al., 2012; Newell et al., 2011). However, many other sources (raw or unpasteurized milk, eggs, meat, etc) have also been associated to salmonellosis (Gurtler et al., 2015; 21 Poppe, 2011; Wingstrand & Aabo, 2014). L. monocytogenes constitutes another major foodborne pathogen because of its psychrotrophic behavior (ability to grow below €, & Hirn, 1988; Walker, Archer, & Banks, 7 C) (Junttila, Niemela €limaa, Tilsala1990), under aerobic and anaerobic conditions (Va €rvi, & Virtanen, 2015) and in a modified atmosphere packTimisja aging (Swaminathan & Gerner-Smidt, 2007). In addition, this bacterium is able to grow in a broad pH range (4.0e9.6) (Farber & Peterkin, 1991), and at low water activity levels such as 0.9 (Nolan, Chamblin, & Troller, 1992; de Daza, Villegas, & Martinez, 1991). These features make L. monocytogenes a great concern in food industry that requires very effective control measures to be implemented along the food chain (Lambertz, Ivarsson, LopezValladares, Sidstedt, & Lindqvist, 2013). The disease caused by L. monocytogenes, i.e., listeriosis, is a severe foodborne disease that is associated with the consumption of fish, meat, dairy products, as well as fresh products. In fact, part of these food products have usually a long shelf-life, and their storage at low temperatures and in vacuum or modified atmosphere packages does not prevent the €limaa et al., 2015). Despite this, it growth of L. monocytogenes (Va should be highlighted that L. monocytogenes has also been associated to foodborne disease outbreaks linked to the consumption of wholesome foods that are not necessarialy commercialized at low temperature conditions, such as fruits. L. monocytogenes can be isolated not only from raw and processed foods but also from environmental sources. It is a ubiquitous bacterium of special concern for specific population groups (e.g. pregnant women, babies, the elderly and people with reduced immunity), for which the illness can be more severe and even evolute to death. The fourth main bacterial pathogen associated with foodborne diseases is E. coli O157:H7, which is mainly transmitted to food products, directly or indirectly, by the feces of cattle. Once contamination takes place during processing, foods reach humans and E. coli O157:H7 may cause the disease (Bari & Inatsu, 2014). This microorganism produces verocytotoxin or shiga-toxin (verocytotoxin-producing E. coli, or VTEC; Shiga-toxin producing E. coli, or STEC), which symptoms may include bloody diarrhea, hemolytic anemia, low platelet count and thrombocytopenia (Karmali, Gannon, & Sargeant, 2010). This type of pathogenic E. coli was identified for the first time in the late 1970s (Konowalchuk, Speirs, & Stavric, 1977) and their toxin structure (described as “Shiga-like” toxin) was recognized in 1983 to have similar structure and antigenicity as Shiga toxin produced by Shigella dysenteriae type 1 (O'Brien & LaVeck, 1983). VTEC strains involved in human diseases are especially found in cattle and foods of bovine origin (i.e. undercooked ground beef patties and unpasteurized milk) (Griffin & Tauxe, 1991; Rangel, Sparling, Crowe, Griffin, & Swerdlow, 2005). Other important foodstuff involved in VTEC outbreaks were well reviewed by Rangel et al. (2005) and include fresh products such as apple cider, spinach, lettuce, radish sprouts, alfalfa sprouts. The burden caused by these and other foodborne pathogens have motivated the food industry to apply strict and robust hygienic protocols to avoid food contamination, as well as to develop inactivation methods to destroy microorganisms likely present. A recent and important trend due to consumer's demands is that inactivation methods must also preserve the sensory and nutritional aspects of foods, while ensuring a proper shelf-life. 3. Key aspects in the design of processes to ensure microbiologically safe foods during shelf-life A food preservation method is considered as “ideal” when it allows improving the shelf-life (inactivation of pathogens and spoilage microorganisms), preserves the nutritional and 22 F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 organoleptic properties, does not leave residual traces in the final product, and is economically competitive to ensure the profitability novas, 2003). As of the food industry (Raso & Barbosa-Ca mentioned, diverse methods such as decreasing the temperature (e.g. chilling or freezing), decreasing either water activity or pH novas, 2003), use of salt, sugar and adding (Raso & Barbosa-Ca preservatives are widely used for food preservation. Currently, thermal treatment is the most extensively applied approach in food industry to destroy foodborne microorganisms. The concepts and key aspects of the application of thermal processing to inactivation of foodborne microorganisms, was recently well reviewed by Smelt and Brul (2014). Although efficient, heating causes losses of sensorial (texture, taste, flavor, and color) and nutritional quality attributes, such as ~ as & Paga n, 2005a). reduction of some bioactive compounds (Man Therefore, there is a growing interest for processes that can reduce the microbial load without increasing deteriorative reactions in order to minimize quality losses. Nevertheless, high temperature and/or long time are required in some foods to inactivate microorganisms (e.g. spores), which affects tremendously the organoleptic and nutritional food properties (Cardello, Schutz, & Lesher, 2007). In addition to affecting the organoleptic and nutritional attributes of food products, conventional heating treatments require high-energy consumption, which compromises with the final product value to guarantee the profitability of the food industry. Therefore, finding mild processing methods that maintain the nutritional and organoleptic properties of the food, ensure microbial inactivation in foods to prolong their shelf-life and to safeguarde public health is of paramount importance. In order to estimate the profitability of any new technology, it is necessary to calculate the benefit brought to the product, which is highly variable and difficult to estimate. In addition, the economic cost per ton of product associated with the use of the new technology in comparison with the conventional technology should be assessed. This cost mainly depends on: i) investment on equipment, ii) energy cost of the treatment, and iii) general production costs. The latter ones can be quite variable, as they depend on local conditions (e.g. rtolas, Alvarez, cost of water, electricity, labor, ingredients, etc) (Pue ~ Raso, & Maranon, 2013). Althought these are highly relevant parameters, the aspects related to microbial inactivation can be considered of chief importance. A technology with potential for food preservation can be decidedly efficient regarding the environmental, sensorial and nutritional aspects. Nonetheless, if that technology is not able to deliver a lethality of a target microorganism, it will hardly find vast practical applications in the food industry. Given this, there are some general and specific parameters that must be taken into account when the mild processing methods are developed, which are briefly outlined below. 3.1. General parameters of mild technology approaches to inactivate foodborne microorganisms, with special reference to pathogenic bacteria As alternative to thermal inactivation of foodborne pathogens, numerous methods were described in the literature. Among them, high pressure processing, pulsed electric fields, ultrasounds, UV light irradiation, and cold plasma can be considered the most relevant. Fig. 1 summarizes the technologies described in this review as well as their principles and mechanisms of microbial inactivation. In general, most studies performed are focused on the inactivation of Listeria spp., followed by pathogenic and non-pathogenic E. coli, Salmonella and in low numbers, by Campylobacter (see Suplementary Fig. 1). This may reflect the great concerns over the potential presence of L. monocytogenes in minimally processed foods considering that several foods treated by mild technologies will further require storage at low temperatures, which will not €limaa et al., 2015). prevent the growth of L. monocytogenes (Va Several studies deal with pathogenic and non-pathogenic E. coli likely because of their general spread and potential to contaminate foods through several routes, such as from raw materials, crosscontamination and food handling. 3.1.1. High pressure processing (HPP) HPP is an efficient preservation treatment applied to packaged solid or liquid food products with minimal modifications of the nutritional and sensorial attributes (Barba, Esteve, & Frígola, 2012; Barba, Terefe, Buckow, Knorr, & Orlien, 2015). HPP is based on the use of very high pressures (100e1000 MPa) for a temperature range from 20 to 60 C at short time (few seconds to 20 min) (Oey, Lille, Van Loey, & Hendrickx, 2008). Fig. 2 represents a schematic diagram of a HPP operating unit and the pressure range of HPP compared to other known pressure levels. The mechanisms of microbial inactivation by HPP are based on a combination of changes in the cell membranes (eg. structural changes in protein and membrane phospholipids which can alter membrane permeability and the function of membrane-bound proteins), cell walls, proteins and enzyme-catalyzed cellular functions (Patterson, 2014). In fact, HPP acts due to molecular volume changes, thus pressure favors chemical reactions and physical processes accompanied by a decrease in volume. In addition, the effects of compression of HPP treatments seem to be highly relevant in terms of microbial inactivation. It is known that compression of foods lead not only to ~ as & Pag shifts in temperature due to adiabatic heating (Man an, 2005b) but also in pH (Heremans, 1995). The isostatic principle ensures that pressure applied and pressure within the food should be equal. Nonetheless, a special attention should be paid to the fact that for heterogeneous foods (meats with bones, for instance), there might be pressure gradients, which will also result in nonuniform temperature distribution (Nair et al., 2016). Considering that temperature and pressure are key factors for microbial inactivation, variability in microbial inactivation at different locations of the foods can be observed (Nair et al., 2016). As such, during HPP several phenomena may occur simultaneously (e.g. disruption of cell walls and membranes, chemical reactions, enzyme activation or inactivation, and protein modification such as denaturation and gel formation) and thereby affecting the overall microbial load. A more detailed description of HPP processing is provided in the literature (Patterson, 2014). Moreover, by using HPP for food preservation, numerous benefits are attained including reduced thermal exposure and, thus, almost no sensory and nutritional changes (Georget et al., 2015) which gives the consumer an increased sensation of a fresh product (Ferrari, Maresca, & Ciccarone, 2010; Keenan et al., 2010). For these reasons, the food industry found interest in replacing conventional heating processes with high pressure processing. Especially, the HPP inactivation of the four major pathogen species cited above (Campylobacter, Salmonella, L. monocytogenes, and E. coli O157:H7) has drawn attention to numerous food products. In Supplementary Fig. 2, Box-and-Whisker plots illustrate the number of decimal reductions caused by HPP in Salmonella, Listeria spp. as well as pathogenic and non-pathogenic E. coli. The range of pressures used as well as the mean and standard deviation log10 CFU/mL or g caused by HPP to these microorganisms may vary enormously as affected by several factors such as food composition, bacterial strain and environmental conditions (temperature, for instance). When it comes to the application of HPP for microbial inactivation (Supplementary Fig. 3), it was found that most of the data available for Campylobacter spp. inactivation by HPP corresponded F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 23 Fig. 1. Chart of the non-conventional, mild technologies described in this review for the inactivation of pathogenic microorganisms in foods. HPP, high pressure processing; US, ultrasounds; PEF, pulsed electric fields. to chicken (n ¼ 6 studies), while for Salmonella the top studied food was ham (n ¼ 16 studies), followed by vegetables (n ¼ 14). For Listeria spp., most of the studies dealt with juice (n ¼ 14) and milk (n ¼ 12), while for pathogenic or non-pathogenic E. coli, the top studied foods were juice (n ¼ 14) and beef (n ¼ 9). 3.1.2. Pulsed electric fields Pulsed electric fields (PEF) is one of the utmost important mild technologies for food conservation. PEF technology involves the application of an electrical treatment during a very short period (from several ns to several ms) and using a pulse amplitude from 100 to 300 V/cm to 20e80 kV/cm (Koubaa et al., 2015) (Fig. 3). PEF processing induces the electroporation of the microbial membrane which results in the alteration of membrane permeability, temporary or permanently (Teissie, Golzio, & Rols, 2005). Generally, this permeabilization is dependent upon the cell geometry and size rtolas, Koubaa, & Barba, 2016). Numerous food industries (Pue already acquired PEF food processing equipment (Jaeger, Balasa, & Knorr, 2009; Mohamed & Amer Eissa, 2012), where different treatment chamber configurations are used to process up to € pfl, 2011). Equipment cost constitutes one of 10,000 L/h capacity (To the major issues limiting the industrialization of PEF technology (To€pfl, 2006). Fig. 3a represents a schematic diagram of industrial installation using PEF for food processing. This technology takes its advantages from its potential to permeabilize cell structure without damaging the treated tissue. Studying and understanding the changes occurring in the cell structure as a result of electric fields represent the keys to keep and increase the quality and shelf-life of minimally processed vegetables, respectively, thus maintaining the “fresh-like characteristics” (Gonzalez & Barrett, 2010). PEF treatments were studied for microbial inactivation mainly in milk, eggs, juice and buffer (Ait-Ouazzou et al., 2012, 2011,; Aitn, 2013; Ferna ndezOuazzou, Espina, Garcia-Gonzalo, & Paga Molina, Bermúdez-Aguirre, Altunakar, Swanson, & Barbosa~ a, C anovas, 2006; Jaeger, Meneses, et al., 2009; Monfort, Saldan n, Raso, & Alvarez, rez, Martínez-Lo pez, & Condo 2012; Pina-Pe ~ a, Minor-Pe rez, Raso, & Alvarez, Rodrigo, 2012; Saldan 2011). PEF conditions for microbial inactivation of Salmonella spp. (A), Listeria spp. (B) and pathogenic or non-pathogenic E. coli (C) are shown in Supplementary Fig. 4. The treatment seems to be promising for Salmonella spp. inactivation, while it seems to be generally less efficient for Listeria as well as pathogenic or non-pathogenic E. coli inactivation (Supplementary Fig. 4). 3.1.2.1. Electric field intensity. One of the most significant factors in PEF is the electric field. When applying an external electric (Ee) field across the cellular membrane, a potential difference occurs. The critical transmembrane potential, known also as critical electric field (Ec), corresponds to the highest value withstood by the membrane. When the Ee field exceeds the Ec value, the cellular membrane breaks down. The effectiveness of PEF is highly impacted by the type of microorganism as well as the environment and the differences of the electric field values (Qin, Barbosanovas, Swanson, Pedrow, & Olsen, 1998). Ca 3.1.2.2. Pulse waveform. Another influencing factor of microbial inactivation after PEF treatment is pulse waveform. There are two typical PEF pulse waveforms: exponential decay and square wave (Fig. 3b). Numerous works showed that enhanced microbial inactivation occurs when applying, with the same energy, pulses with square waves compared to exponential decay waves (Rodrigo, Ruíz, novas, Martínez, & Rodrigo, 2003; Zhang, MonsalveBarbosa-Ca lez, Qin, Barbosa-Ca novas, & Swanson, 1994). Depending on Gonza their polarity, pulses could also be classified as monopolar or bipolar (Fig. 3c). When applying bipolar pulses, reversal of the electric charge occurs by alternating positive and negative pulses. This treatment causes structural fatigue by changing the movement direction of charged ions in the cellular membrane, which increases its susceptibility to electrical breakdown, and accelerate the inactivation of microorganism (Ho, Mittal, Cross, & Griffiths, 1995). On the other side, when applying monopolar pulses, the inactivation of microorganism is less effective, as the same polarity is maintained. Furthermore, as monopolar pulses will separate the charged particles, a deposit will be formed on the electrode, which distorts the electric field. 3.1.2.3. Pulse width. Pulse width is a crucial parameter to optimize n, & Sala for effective microbial inactivation (Raso, Alvarez, Condo Trepat, 2000). Therefore, several studies have determined the optimum pulse width, and it was concluded that a pulse width of z2 ms leads to the highest microbial inactivation level, with the less consumed energy. Increasing the pulse width over this value is not systematically accompanied with greater inactivation of microorganisms. However, numerous studies showed that within a field intensity of 25e28 kV/cm, increasing the pulse width leads to increased inactivation of microorganisms (Abram, Smelt, Bos, & Wouters, 2003; € nner, 2001; Elez-Martínez, Aronsson, Lindgren, Johansson, & Ro -Herna ndez, Soliva-Fortuny, & Martín-Belloso, 2005). Escola 24 F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 Fig. 2. a. Schematic diagram of HPP operating unit for the inactivation of foodborne microorganisms. The packaged food is placed in a pressure vessel containing a pressuretransmitting liquid (usually water), and the pressure is produced by a hydraulic pump (as shown) or by a piston and is transmitted to the product instantaneously and uniformly. b. Pressure range of HPP among other known mechanisms and associated biological mechanisms with increased pressure. 3.1.3. Temperature PEF is generally accompanied with increased temperature, due to ohmic heating. This rise of temperature occurs proportionally to the treatment intensity (electric field and treatment time), allowing thus further inactivation of microorganisms through a synergetic effect (pulses-temperature) at 35e60 C. The main effects of temperature on microbial inactivation seem to be associated with an augmented permeability and fluidity of the microbial membrane and consequently its structural fatigue (Jayaram, Castle, & Margaritis, 1992). In fact, at low temperature conditions, phospholipids constituting the membrane of microorganisms are attached, which create a gel-shaped rigid arrangement ngora-Nieto, San-Martin, & Barbosa-Ca novas, 2005). (Sepulveda, Go Therefore, increasing the temperature will decrease the physical stability of the membranes, adopting a crystalline liquid appearance, and thus being more susceptible to PEF treatment. 3.1.4. Ultrasounds Likewise, ultrasound was broadly applied for several food and non-food applications (e.g. decontamination, extraction of valuable compounds, etc). The basic mechanism of action of US to inactivate microorganisms was previously reviewed by several authors (Piyasena, Mohareb, & McKellar, 2003; Zinoviadou et al., 2015) and it is mainly based on cavitation phenomena, which promotes the formation of shock waves when the bubbles that are generated during the ultrasound processing collapse. These shock waves promote the generation of high temperatures and pressures, which are the main factors that result in microbial inactivation. The main processing parameters that influence ultrasound treatment are: i) power, ii) frequency (20 kHz-10 MHz), and iii) treatment time. Several studies have reported the huge potential of ultrasounds to inactivate microorganism (Zinoviadou et al., 2015). However, in most of the cases ultrasound does not allow achieving 5-log reduction of microorganisms when it is used alone, although the degree of inactivation differs depending on the targeted microorganism. However, interestingly, this technology presents a great versatility and can be combined with other techniques such as temperature (thermosonication), pressure (manosonication), pressure and temperature (manothermosonication), thus having a synergistic effect with all of them when they are used together. Therefore, this technology has the potential to be used to decrease the temperature used in heat treatments, pressure in high pressure processing, etc., thus allowing mild processing treatments, which can avoid the degradation of nutritional and quality parameters (Zinoviadou et al., 2015). F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 25 Fig. 3. a. Schematic diagram of industrial installation using PEF technology for the inactivation of microorganisms in food products. b. Exponential and square waves used in PEF treatments. c. Bipolar square wave. Research was done on L. monocytogenes, a number of strains of Salmonella spp., E. coli, S. aureus, B. subtilis and some other microorganisms. However, most data available in the literature is focused on the study of Listeria inactivation in milk (n ¼ 24). Less than two studies were conducted for each of Campylobacter spp., Salmonella spp. and E. coli, highlighting the potential use of this method for ensuring the safety of milk and dairy products (Allen et al., 2008; novas, 2008; Boysen & Bermúdez-Aguirre & Barbosa-Ca Rosenquist, 2009; Haughton, Lyng, Morgan, et al., 2012; Huang, Mittal, & Griffiths, 2006; Lee, Kim, Cadwallader, Feng, & Martin, ~ as, Paga n, Raso, Sala, & Condo n, 2000; Musavian, 2013; Man ~ as, Raso, & Krebs, Nonboe, Corry, & Purnell, 2014; Pag an, Man n, 1999). Condo 3.1.5. UV-light Ultraviolet (UV) light corresponds to the portion of the electromagnetic spectrum having wavelengths ranging between 100 and 400 nm. The formation of lesions in the genomic DNA of the organisms, by UV-B and UV-C radiation, represents the main cause of microorganisms' inactivation (Friedberg, Walker, & Siede, 1995; Harm, 1980). The presence of these lesions inhibits the DNA replication and therefore results in inactivating the microorganisms (Fig. 4) (Oguma et al., 2001). The first application of UV-light treatment at large scale was carried out in Marseille (France) in 1906, for the decontamination of drinking water (Masschelein & Rice, 2002). Nowadays, wide range of applications in food safety and food quality have been reported, including the treatment of apple cider (Koutchma, Keller, Chirtel, & n, Serrano, Monfort, Alvarez, Parisi, 2004), orange juice (Gaya & n, 2012; Tran & Farid, 2004), liquid egg products (Unluturk, Condo Atılgan, Handan Baysal, & Tarı, 2008), milk (Krishnamurthy, Demirci, & Irudayaraj, 2007), and honey (Fit et al., 2014). UV-light was described as an efficient method for the inactivation of a wide range of microorganisms including viruses (Eischeid, Meyer, & Linden, 2009), vegetative cells and bacterial spores, fungi mez-Lo pez, Devlieghere, Bonduelle, & Debevere, 2005), and (Go parasites (Hijnen, Beerendonk, & Medema, 2006). Due to this wide range of applications, UV-light could be used similarly for the disinfection of food-contacting surfaces, foods, and mez-Lo pez, Koutchma, & Linden, 2012). It was liquids in general (Go also demonstrated that the application of UV light improves the toxicological safety of foods by reducing the levels of mycotoxins (i.e. patulin) in apple cider (Dong et al., 2010), and by reducing the allergenicity of foodstuffs such as liquid peanut butter (Chung, Yang, & Krishnamurthy, 2008). UV-light has been extensively applied for the inactivation of E. coli (pathogenic or non-pathogenic) in juice (n ¼ 27 data) and milk (n ¼ 8 data). Less than two studies focused on the use of UVlight for the inactivation of Campylobacter spp., Salmonella spp. and Listeria spp. (Chun et al., 2009, Chun, Kim, Lee, Yu, & Song, 2010; 26 F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 Chun, Kim, Chung, Won, & Song, 2009; Crook, Rossitto, Parko, Koutchma, & Cullor, 2015; Haughton et al., 2011; Haughton, Lyng, Cronin, et al., 2012; Orlowska, Koutchma, Kostrzynska, & Tang, 2015; Yin, Zhu, Koutchma, & Gong, 2015). 3.1.6. Atmospheric cold plasma Plasma represents a neutral ionized gas constituted of particles that include free radicals, free electrons, positive and negative ions, quanta of electromagnetic radiation, as well as excited and nonexcited particles (Misra, Tiwari, Raghavarao, & Cullen, 2011). When plasma is generated at room pressure and temperature, it is termed atmospheric cold plasma (ACP). ACP technology is a novel approach dealing with the inactivation of microorganisms to improve the food safety, along with the preservation of the organoleptic properties (Ziuzina, Han, Cullen, & Bourke, 2015). The technology takes its advantages from its use of reduced water quantity, low processing temperatures, and low cost. The plasma agents mentioned above are responsible of the lethal action of microorganisms through the interaction with the biological material. The mechanism of action of ACP was shown to be due to the degradation of proteins, lipids, and cellular DNA (Mogul et al., 2003). Reactive species in plasma cause direct oxidative effects on the outer surface of microbial cells. It was shown that ACP is efficient to inactivate a wide range of microorganisms including bacteria (Nelson & Berger, 1989), spores (Feichtinger, Schulz, Walker, & Schumacher, 2003; KellyWintenberg et al., 1999; Lee, Paek, Ju, & Lee, 2006), and viruses (Terrier et al., 2009). The mechanisms of action were well reviewed in the literature (Misra et al., 2011). Plasma was mainly used to inactivate pathogenic or non-pathogenic E. coli in vegetable matrices (Baier et al., 2014, 2015). Table 1 presents some applications of mild technologies for the inactivation of the main bacterial pathogens in foods. 4. Combining mild technology processes for destruction of foodborne pathogens Even though some of mild technologies can be applied alone to achieve a determined destruction of a foodborne pathogen (for instance, 5 log10 CFU/g or mL reductions), given the necessity to reduce physical, biochemical, sensorial and nutritional changes in foods, a combination of processes is frequently applied. This combination allows the optimization of microbial inactivation while decreasing unwanted chemical and biochemical changes in the foods. Below, a detailed assessment is presented on the application of mild technologies (combined or not with other methods) aiming to destroy the main foodborne pathogens. This section will provide an overview of work done and will also serve as basis for identification of aspects demanding further investigations. 4.1. Campylobacter spp. 4.1.1. High pressure processing (HPP) alone or combined with other techniques The inactivation of C. jejuni (strains 35919 and 35921) by high pressure was studied by Solomon and Hoover (2004). It was found that the pressure resistance of the C. jejuni strains was affected by the substrate, i.e., a protective effect was observed when the HPP was applied in foods (ultra-high temperature (UHT) whole milk, e). This resulted in a UHT skim milk, soya milk and chicken pure need to increase the pressure in 50e75 MPa to achieve the similar log reductions. C. jejuni strains were found to present similar sensitivity to HPP as other Gram-negative foodborne pathogens (Jackowska-Tracz & Tracz, 2015), for which treatments of <10 min at 300-40 MPa at ambient temperature can reach >5 log reductions. The pressure inactivation of C. jejuni and C. coli seems to follow first-order kinetic order which allow the application of HPP at short times (1 min and 30 s) at ambient pressure and 70 C or at 450 MPa and 15 C and to achieve > 6 log reductions, respectively (Lori, Buckow, Knorr, Heinz, & Lehmacher, 2007). In another study, a reduction of 6 log10 cycles in the counts of C. jejuni inoculated in smoked salmon was obtained through treatments 200 MPa during 64.26 min, 300 MPa during 17.10 min, ski, Pe,conek, or 400 MPa for less than 5 min (Jackowska, Szczawin & Fonberg-Broczek, 2008). While Campylobacter are known to be sensitive to HPP and treatments combining pressure (600 MPa) and temperature (40 C) can result in >6 log reductions, the presence of pressure-resistant bacteria such as E. coli AW1.7 might hinder the effectiveness of the process. E. coli AW1.7 is one of the most pressure-resistant bacterial vegetative cells and for a process to Fig. 4. Mechanism of action of UV-light for microbial inactivation. F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 27 achieve 4.5 log CFU/g reductions in minced poultry meat, pressure €nzle, 2012). These of 600 MPa and 40 C are required (Liu, Betti, & Ga results indicate that a global assessment of the microbiota present in the foods and also the substrate per se should be considered for proper decisions to be made. Therefore, when dealing with mild processing technologies, it should be taken into account that the use of pre-established temperature/pressure binomials or combined treatments (Gunther, Sites, & Sommers, 2015) should be avoided and these should be established case by case to avoid food safety or spoilage issues. considered. However, the combination of treatments must be carefuly investigated as a synergistic effect between UV-light irradiation and other methods will not always be observed. For example, the combination of UV-light irradiation (0.048 J/cm2) and crust freezing (air temperature of 5 to 27 C and freezing times varying from 6 to 70 min) resulted in no synergistic in Campylobacter inactivation on raw chicken (Haughton, Lyng, Cronin, et al., 2012). 4.1.2. Ultrasound processing alone or combined with other techniques The application of ultrasounds aiming to destroy Campylobacter has been mainly focused enhancing the safety of poultry meats. Ultrasounds are more effective in inactivating this pathogen when combined with mild heat conditions. Campylobacter has been found to be sensitive to ultrasound processing, and particularly C. jejuni presents higher susceptibility to thermosonication compared to thermal or sonication treatments. A combined system of steam and US (SonoSteam) built in the evisceration area in a Danish broiler plant that works at conventional slaughter speeds of 8500 birds per hour was able to reduce the initial concentration of Campylobacter in about 1 log₁₀ CFU per broiler carcass (Musavian et al., 2014). Other authors evaluated the effects of steamultrasound to inactivate Campylobacter from broiler meat, observing a significant reduction of 2.5 log10 CFU per carcass (Boysen & Rosenquist, 2009). Thermosonication, thermal or sonication treatments result in up to 4.7, 1.4 and 3.2 log10 CFU reductions of C. jejuni in liquid media, respectively (Haughton, Lyng, Morgan, et al., 2012). The inactivation of Campylobacter seems to be generally more affected by thermosonication treatment in liquid matrices than the inoculated poultry products. In addition, the efficiency of the inactivation process is also affected by the intensity of the unit. Treatments done in high-intensity units (HI) (20,000 W/L) are more efficient in destroying Campylobacter than low-intensity unit (LI) (20 W/L) (Haughton, Lyng, Morgan, et al., 2012). Ultrasound can also be combined with other methods aiming to reduce the counts of Campylobacter in the plastic craters used for transportation of live poultry to abattoir. Ultrasound treatment (4 kW, 3e6 min) combined with temperature (65 C) and mechanical scrubbing may lead to at least 4 log10 reduction of C. jejuni (Allen et al., 2008). This treatment can be an alternative to the application of soaking (55 C), followed by scrubbing the craters for 90 s and further washing at 60 C for 15 s (Allen et al., 2008), showing that ultrasound and combined treatments with ultrasounds can also comprise alternatives for disinfection of processing premises or utensils. 4.2.1. High pressure processing (HPP) alone or combined with other techniques The use of HPP aiming to destroy Salmonella in foods of animal origin as well as in fresh and processed produce has been investigated. The impact of single- and multiple-cycle HPP treatments on the inactivation of S. Enteritidis in chicken breast fillets was ~ ez investigated by Morales, Calzada, Rodríguez, De Paz, and Nun (2009). The findings indicated that an increase in the number of cycles, resulted in an increased inactivation of S. Enteritidis in chicken breast fillets (treatment at 300 MPa and 12 C): 0.6 log10 CFU/g to 3.3 log10 CFU/g for a 0 min cycle to a 20 min cycle, respectively. In addition, an increase in the number of cycles resulted in an augment in the number of injured cells of S. Enteritidis. Furthermore, the increase of pressure from 300 to 400 MPa resulted in up to 5 log10 CFU/g reductions in the counts of S. Enteritidis (Morales et al., 2009). The use of low temperature (4e6 C) during HPP treatment (450 MPa during 10 min) of ground chicken (95% lean) caused 5 log10 CFU/g of Salmonella spp. cocktail. The combination of lower pressures and one cycle of 15 min (250 or 350 MPa) reduced Salmonella counts in 0.5 log10 or 1.7 log10 CFU/g, respectively. On the other hand, the use of several cycles (3 cycles; 5 min per cycle) at 250 and 350 MPa resulted in 1.3 and 3.3 log10 CFU/g reduction of Salmonella counts, respectively (Sheen, Cassidy, Scullen, Uknalis, et al., 2015). Another factor that seems to affect the inactivation efficiency of HPP is the temperature of treatment. For instance, HPP treaments applied to raw chicken breast fillets at temperatures of 35 to 30 C and pressure of 300 and 400 MPa, resulted in 2e4 log10 CFU/g of Salmonella Typhimurium (DMST 28913), respectively (Tananuwong, Chitsakun, & Tattiyakul, 2012). In addition to chicken meat, Salmonella is also a major problem in beef meat. In this way, the potential application of high pressure treatments on the inactivation of S. Enteritidis was investigated (de Alba, Bravo, & Medina, 2012). The counts of S. Enteritidis were reduced by 3.7 and 5.9 log10 CFU/g after a processing at 450 MPa during 5 and 10 min, respectively. The study of HPP inactivation in specific food matrixes is relevant because food composition is known to exert a protective effect bol, Aymerich, Monfort, & on the microorganisms (Garriga, Gre Hugas, 2004). In processed meat products such as dry-cured ham, Salmonella inactivation by HPP was optimized through a response surface approach (Bover-Cid, Belletti, Garriga, & Aymerich, 2012). A model that allows the determination of optimum processing conditions as influenced by pressure (347e852 MPa), holding time (2.3e15.75 min), and temperature (7.6e24.4 C) was proposed. In addition to pressure and time, the interaction of temperature with pressure and time is also relevant for Salmonella inactivation by HPP. Through the model, processors can select pressure, time and temperature conditions and further verify whether legal lethality standards are achieved. HPP has also been studied as postprocessing treatment for the inactivation of foodborne pathogens such as Salmonella in meat products. According to Garriga et al. (2004), a HPP treatment at 600 MPa for 6 min at 31 C is capable to reduce the risks associated with the presence of Salmonella in 4.1.3. UV-light alone or combined with other techniques As for ultrasound, studies dealing with UV-light irradiation are mainly focused on inactivation of Campylobacter in chicken meat and chicken processed products. Studies included the use of UVlight irradiation in raw chicken (Chun et al., 2010) and in final products (Chun et al., 2009). There were also studies aiming to assess the inactivation efficiency of Campylobacter by the application of UV-light irradiation alone or combined with other methods. For instance, in chicken breasts and in ready-to-eat sliced ham, UVlight irradiation processes at dosis of 8 kJ/m2 and 5 kJ/m2, respectively, led no more than 1.7 log10 CFU/g reductions of C. jejuni (Chun et al., 2009, 2010). Therefore, given the limited inactivation effectiveness of the UV-light irradiation, if the application demands more than 1.5e2.0 log10 CFU/g of Campylobacter, the combination of UV-light irradiation treatment with other methods should be 4.2. Salmonella spp. F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 28 Table 1 Some examples of application of mild technologies for the inactivation of the main bacterial pathogens in foods. Technology Parameters HPP PEF UV-light Campylobacter spp. Salmonella spp. Listeria spp. E. coli Time (min) Dose (MPa) Food 0.50e64.26 200e450 UHT whole milk Poultry meat Smoked salmon 1.00e15.75 250e852 Meat products Tomato Pepper Strawberry puree 1.00e40.00 103e600 Beef; Ground beef; Beef jerky RTE meats LWE Alfafa seeds Fruit juice Source Solomon & Hoover, 2004 Lori et al., 2007 Jackowska et al., 2008 Liu et al., 2012 Garriga et al., 2004 Morales et al., 2009 Maitland et al., 2011 Tananuwong et al., 2012 Sheen et al., 2015a,b de Alba et al., 2012 Neetoo & Chen, 2012 Toledo et al., 2012 Bover-Cid et al., 2012 Huang et al., 2013 1.00e30.00 100e600 Buffer Orange juice Pear nectar Yogurt RTE salads Liquid whole eggs (LWE) Dry-cured-ham Beef carpaccio Hayman et al., 2008 Guerrero-Beltr an et al., 2011a novas, & WeltiGuerrero-Beltr an, Barbosa-Ca Chanes, 2011b Evrendilek & Balasubramaniam, 2011 Stratakos et al., 2016 de Alba et al., 2015 Luscher et al., 2004 Lee et al., 2003 Other information e With US and thermal treatment e Time (min) e Dose (kV per m) e Food e 11.6 106 25.00e30.00 Skim milk LWE Source e rez et al., 2012 Pina-Pe Monfort et al., 2012a,b,c Other information e e 9.90 105-5.00 106 25.00e38.90 Buffer Skim milk LWE ndez-Molina et al., 2006 Ferna ~ a et al., 2011 Saldan Espina et al., 2014 Nisin (100e200 mg/mL) Lemon EO (200 mg/L) 2.10 107 30.00e37.60 Buffer Raw milk Fruit juice Jaeger et al., 2009a,b Ait-Ouazzou et al., 2011, 2012, 2013 e Time (min) Dose 0.13e0.53 0.192 J/cm2 0.048 J/m2 0.002e5.00 kJ/m2 Sliced ham Chicken breast; Raw Chicken Skim milk Haughton et al., 2011 Haughton, et al., 2012a,b Chun et al., 2009 Chun et al., 2010 e e 1600-1950 J/L 0.55e13.70 200-5000 J/L 4.00e23.80 5-290 mJ/cm2 Whole milk UHT milk Apple Juice Milk Crook et al., 2015 Crook et al., 2015 Orlowska et al., 2015 Yin et al., 2015 e e e e e 5.00e30.00 24 kHz e e e Skim milk Milk þ 1% fat Whole milk novas, 2008 Bermúdez-Aguirre & Barbosa-Ca e e With thermal treatment e 0.50e2.00 5 Argon [L/min] þ 0,1% O2 Corn salad Corn salad leaves Cucumber Apple Tomato Baier et al., 2014, 2015 e Food Source Other information US Time (min) Dose Food Source Other information Plasma Microorganisms 3.00e6.00 4 kW 30.00e40.00 kHz Poultry meat Broiler carcasses Allen et al., 2008 e Musavian et al., 2014 With thermal treatment Time (min) e Dose (kV per m) e Food e e e e e e e Source Other information e e e e e e Morales et al., 2008 Gill and Ramaswamy (2008) Black et al., 2010 Neetoo et al., 2009 Lowder et al., 2014 Sheen et al., 2015a,b Monfort et al., 2012a,b,c Espina et al., 2013 Cherrat et al., 2014 Scheinberg et al., 2014 Guerrero-Beltr an et al., 2011a Guerrero-Beltr an et al., 2011b e F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 meat products. In this study, Salmonella was not detected in meat products submitted to HPP treatment (600 MPa for 6 min at 31 C) after storage at refrigerated conditions (4 C) after 120 days (Garriga et al., 2004). Several studies have also been done on the application of HPP to destroy Salmonella in fresh and processed produce. According to Maitland, Boyer, Eifert, and Williams (2011), HPP can be applied as a post-harvest approach to reduce low loads of Salmonella in diced and whole tomatoes. These authors reported that pressures of 350, 450, and 550 MPa during 2 min resulted in 0.5, 2.2 and 3.7 log10 CFU/g of Salmonella, respectively. The practices applied after harvest may also be important in impacting Salmonella inactivation. ~o Neetoo and Chen (2012) showed that wetting and soaking Jalapen and Serrano peppers affected Salmonella inactivation by HPP. The increase in pressure from 300 to 500 MPa and the use of soaking ~ o and Serrano and wetting increased Salmonella inactivation Jalapen peppers as compared to unwetted produce (Neetoo & Chen, 2012). The application of wetting and soaking seems to enhance the inactivation efficiency of HPP due to increase in water activity of produce tissues (Neetoo & Chen, 2012). HPP has also been applied aiming to inactivate Salmonella in processed fruits and vegetables. The combination of HPP and freezing on the inactivation of Salmonella spp. inoculated in strawberry puree was evaluated by Huang, Ye, and Chen (2013). Freezing at 18 C during 12 weeks followed by a HPP process (450 MPa during 2 min at 21 C) resulted in >5.5 log CFU/g in the counts of Salmonella spp. in strawberry puree. Treatments of 600 MPa for 5 or 8 min led to 5.9 and 6.5 log10 cycles of Salmonella rez spp. in Spanish potato omelet (tortilla de patatas) (Toledo, Pe lvez, 2012). Pulido, Abriouel, Grande, & Ga 4.2.2. Pulsed electric fields treatment alone or combined with other techniques Studies dealing with the application of pulsed electric field technology for Salmonella inactivation commonly consider the combination with other methods. Despite this, the number of decimal reductions caused by this technology seem to be limited. For instance, the effect of the combination between PEF (10, 20, and 30 kV/cm at treatment times ranging between 60 and 3000 ms) and cinnamon (1, 2.5 and 5% (w/v)) on the fate of S. Typhimurium in rez et al., 2012). Even though skim milk (SM) was studied (Pina-Pe the results indicated the synergistic effect of PEF and cinnamon, the number of decinal reductions was not superior to ~2 log10 cycles using a PEF treatment of 30 kV/700 ms in SM supplemented with 5% cinnamon. Another example of PEF combined with other methods ~ a, et al. for inactivation of Salmonella is the study by Monfort, Saldan (2012). PEF was combined with heat (52e60 C for up to 3.5 s) and additives (EDTA or triethyl citrate (TC)) aiming to enhance the inactivation of Salmonella in liquid whole egg (LWE). The combined treatments resulted not only in the decrease of heat resistance of Salmonella serovars tested, but also in the reduction of the heat treatment time in up to 92 times depending on the condition. In this study, a variability in terms of inactivation efficiency of Salmonella serovars was reported. Amongst the seven Salmonella serotypes tested, Salmonella Senftenberg and Salmonella Enteritidis 4396 were shown to be less affected by the combined treatment ~ a, et al., 2012) highlighting the importance applied (Monfort, Saldan to consider the strain variability in the design of processes based on mild technologies. A PEF (25 kV/cm; 200 kJ/kg) treatment followed by pasteurization (60 C/3.5 min), in presence of 1% TC or 10 mM EDTA, represents a promising alternative to industrial ultrapasteurization which may reaches up to 70e71 C/1.5 min (Monfort, Sagarzazu, et al., 2012). 29 4.2.3. Ultrasound processing alone or combined with other techniques As for PEF, the inactivation efficiency of ultrasound is enhanced through the combination with other methods. For instance, Salmonella Enteritidis inactivation in liquid whole egg (LWE) as affected by ultrasound, PEF, heat and hydraulic high pressure was studied. The treaments applied resulted in additive effects rather than synergism. The best combination was hydraulic high pressure followed by ultrasound treatment, which led to ~3 log10 CFU/mL reduction of Salmonella in LWE (Huang et al., 2006). Similarly, resistance to manosonication and monothermosonication in LWE of three Salmonella serovars (S. Enteritidis, S. Typhimurium, and S. ~ as et al., 2000; Pag Senftenberg) was studied (Man an et al., 1999; n, & Sala, 1998). Results demonstrated that S. Raso, Pag an, Condo Senftenberg showed the highest resistance among the three studied serovars. Nonetheless, treating LWE with manothermosonication at 60 C was effective to reduce S. Senftenberg 775 W by 3 log10 CFU/mL, compared to only 0.5 log10 CFU/mL when n et al., using conventional heating at the same temperature (Paga 1999). 4.2.4. UV-light alone or combined with other techniques The combination of UV-light with mild temperatures was applied to destroy S. enterica serovars (Gay an, Serrano, Raso, n, 2012). Results showed that the required doses Alvarez, & Condo to cause reduction of 99.99% of the initial load ranged from 18.03 to 12.75 J/mL for S. enterica serovar Typhimurium STCC 878, and S. enterica serovar Enteritidis ATCC 13076, respectively. It was also shown that UV-tolerance was unaffected by the pH and water activity of the treated medium, whereas an exponential decrease was noticed by increasing the absorption coefficient. UV-light and heating presented an inactivating synergistic effect when simultaneously applied. However, these effects were mainly observed when UV-light is applied after the heat treatment (UV-H). The proposed combination of UV-light and heat treatments was found to be a promising alternative in food industry for the pasteurization of liquid foods with high UV absorptivity, such as fruit juices. In meat products such as ready-to-eat (RTE) sliced ham a dose needed to reduce the initial microbial load of S. enterica serovar Typhimurium by 90% through UV-light irradiation (1000e8000 J/ m2) was 2.39 J/m2 (Chun et al., 2009). The highest dose used (8000 J/m2) was efficient to reduce the counts of S. Typhimurium by 2.0 log10 CFU/g, respectively. In chicken breast, an UV-light treatment with doses varying from 0 to 5 kJ/m2 resulted in no more than 1.3 log10 CFU/g of S. enterica serovar Typhimurium (Chun et al., 2010). UV-light treatment (0.192 J/cm2) caused upt to 1.3 and 4.2 log10 CFU/cm2 of S. enterica serovar Enteritidis on raw chicken fillet and packaging and surface materials (Haughton et al., 2011). 4.3. Listeria spp. 4.3.1. High pressure processing (HPP) alone or combined with other techniques HPP has been used alone or combined with different methods aiming to destroy L. moncoytogenes. HPP process combined with mint essential oil was investigated for the inactivation of L. monocytogenes and L. innocua in a yogurt drink (ayran) (Evrendilek & Balasubramaniam, 2011). A HPP treatment (600 MPa, 300 s) caused > 5 log10 CFU/g in the initial load of L. monocytogenes and L. innocua, while the addition of mint essential oil boosted the inactivation of L. monocytogenes and L. innocua by more than 6 log10 CFU/mL. In addition, when the combined process was used HPP pressure values of 100e300 MPa were enough to obtain similar inactivation of L. monocytogenes and L. innocua. When coriander essential oil was added to active packaging and combined 30 F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 with HPP (500 MPa for 1 min), resulted in a synergistic effect and led to reduction in the counts of Listeria below the limit of quantification during 60 days of storage at 4 C. On the other hand, the growth of Listeria was slowed down but not completely inhibited when the RTE chicken breast was stored at 8 C. This study showed that active packaging combined with in-package HPP treatment could be used as an approach to reduce the risk of L. monocytogenes in RTE chicken without changing the organoleptic and sensory properties. The addition of Stevia rebaudiana Bertoni extracts that contain high amounts of natural antimicrobials (0e2.5% w/v) to a fruit extract matrix led to increase in the inactivation of L. monocytogenes by HPP treatment (300e500 MPa, 5e15 min). Up to 5 log10 CFU/g log reductions of L. monocytogenes were obtained when combining HPP (453 MPa, 5 min) with 2.5% (w/v) of Stevia (Barba, Criado, Belda-Galbis, Esteve, & Rodrigo, 2014). HPP treatments (200e600 MPa/5e20 min/20e40 C) caused more than 4 log10 CFU/g reduction of L. monocytogenes inoculated in Queso Fresco (Tomasula et al., 2014). Nonetheless, as L. monocytogenes is psychrotrophic microorganism, the use of other preservation method is needed to avoid its growth during chilled storage of Queso Fresco (Tomasula et al., 2014). In this way, an approach to inhibit L. monocytogenes in RTE foods comprises the combination of HPP and protective cultures. This approach may be very useful to overcome failures in the cold chain that could allow the growth of L. monocytogenes. This strategy has been studied in salads with pH values of 4.3 and 5.6, added of a protective culture (Weissella viridescens), treated through HPP (400 MPa during 1 min), following storage at 4 and 12 C. While HPP caused 4.0 and 1.5 log10 CFU/g reductions of L. monocytogenes in RTE salad with pH 4.3 and 5.6, respectively (Stratakos et al., 2016), W. viridescens was able to inactivate/inhibit L. monocytogenes during storage of RTE salads depending on the pH and storage temperature. A HHP treatment with a post-processing barrier to inhibit further growth of pathogens was studied by de Alba, Bravo, and Medina (2015). The combination of HPP (450 MPa, 10 min) with lactoperoxidase (LP) system or lactoferrin (LF) failed to enhance the inactivation and inhibition of L. monocytogenes growth in sliced dry-cured-ham during storage for 60 days at 8 C (de Alba et al., 2015). In another study, Bravo, de Alba, and Medina (2014) reported that a HHP (450 MPa, 5 min) combined with lactoperoxidase system (LPOS) or activated lactoferrin (ALF) applied in cured beef carpaccio was effective only against S. Enteritidis and E. coli O157:H7 (Bravo et al., 2014). 4.3.2. Pulsed electric fields treatment alone or combined with other techniques PEF was also effective to inactivate different Listeria strains in food products when applied either alone or in combination with other techniques. The energy required by PEF to inactivate L. innocua inoculated in 0.2% skim milk (SM) was lower than that consumed by thermal pasteurization. It was demonstrated that the energy densities required to reduce the microbial load by 3 log10 CFU/g reductions were of 120, 212, and 270 kJ/L, which correspond to input voltages of 30, 35, and 40 kV, respectively ndez-Molina et al., 2006). (Ferna Even though PEF can be combined with other methods, it seems temperature will hold the main influence on the inactivation of ~a microorganisms. Through a response surface approach, Saldan et al. (2011) found that the increase in temperature from 4 to 50 C during PEF treatment resulted in an increase of the inactivation of L. monocytogenes by 3 log10 CFU/g cycles. Further, the combination of PEF, with low pH (3.5), nisin (200 mg/mL) and mild temperature (50 C) caused up to 5.5 log10 CFU/g reductions in the populations of L. monocytogenes. The combination of PEF (25 kV/cm and 100 kJ/kg) followed by heat (60 C, 3.5 min) applied to LWE supplemented with 200 mL/L of lemon EO resulted in inactivation of 4 log10 cycles of L. monocytogenes. On the other hand, individually processes resulted in inactivation of <1.5 log10 cycles of this bacterium. A synergism was reported, which could comprise an alternative to industrial ultrapasteurization at lower temperature to provide microbiologically safe LWE products (Espina, Monfort, Alvarez, n, 2014). This study also reported that the García-Gonzalo, & Paga inactivation efficiency of a combined process with PEF and mild heat will be dependent upon the EO applied (Espina et al., 2014). It is known that food componentes influence the antimicrobial activity of natural compounds. 4.3.3. Ultrasound processing and UV-light alone or combined with other techniques The inactivation efficiency of ultrasound treatment combined with heat treatment seems also to be affected by food composition. Bermúdez-Aguirre and Barbosa-C anovas (2008) found that increasing the fat content in milk decreased L. innocua inactivation. While 2.5 log reductions of L. innocua was observed in whole milk (3.47% of fat), in fat free milk up to 4.9 log reductions were observed after 30 min of treatment. The results obtained can be related to the influence of food composition on the efficiency of ultrasound treatment. Fat is known to reduce the penetration of ultrasound and also to impact on energy distribution. In addition, as cavitation is very important for the inactivation through ultrasound, different solid contents in milk will result in different boiling point of the product, which affects cavitation and microbial inactivation (Earnshaw et al., 1995). The importance of cavitation for microbial inactivation has been corroborated by Bermúdez-Aguirre, Mawson, and Barbosa-C anovas (2011). These authors reported that while thinning in cell walls was observed in heat-treated samples, in the samples submitted to thermo-sonication, the formation of pores through the cell membranes was observed. After 10 and 30 min of sonication breakage lines and broken cells were observed, respectively (Bermúdez-Aguirre et al., 2011). The effect of UV-light in a thin-film turbulent flow combined with heat on the inactivation of milkborne microorganisms was investigated and this treatment was also reported to be feasible for milk processing (Crook et al., 2015). L. monocytogenes was found to be the most UV resistant microorganism amongst seven tested (L. monocytogenes, Serratia marcescens, S. Senftenberg, Y. enterocolitica, A. hydrophila, E. coli, and S. aureus), as exposure to UV-light at 2000 J/L was needed to cause 5 log10 reduction of this bacterium inoculated in whole milk. 4.4. Escherichia coli 4.4.1. High pressure processing (HPP) alone or combined with other techniques The application of single-cycle high-pressure treatment of 400 MPa (12 C) for 1 min and 20 min for the inactivation of E. coli O157:H7 in ground beef resulted in 0.82e4.38 log10 CFU/g reductions, respectively. On the other hand, applying multiple-cycle treatments resulted 4.38 and 4.96 log10 CFU/g reductions at 400 MPa (12 C) for four 1-min and three 5-min cycles, respectively ~ ez, 2008). A HPP treatment at (Morales, Calzada, Avila, & Nun 600 MPa with a holding time of 3 min applied in RTE meats (Hungarian salami and All Beef salami) was able to reduce E. coli O157:H7 load by more than 4 log10 CFU/g (Gill & Ramaswamy, 2008). The combination of a HPP treatment of ground beef at 400 MPa for 10 min followed by freezing enhanced the inactivation of E. coli O157:H7 (Black, Hirneisen, Hoover, & Kniel, 2010). Another study showed that previous freezing (35 C) followed by a HPP treatment at 551 MPa pressure for 4 min resulted in 1.7 log10 CFU/g F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 reduction of E. coli O157:H7 inoculated in beef semitendinosus (Lowder, Waite-Cusic, & Mireles DeWitt, 2014). HPP treatments have also been studied aiming to inactivate E. coli O157:H7 in fermented/dried meat products such as Genoa salami. HPP treatments at 600 MPa or at 483 MPa for 1e12 min caused additional inactivation of E. coli O157:H7 inoculated in Genoa salami that reached 5.8 log10 CFU/g reduction (Porto-Fett et al., 2010). The combination of HPP and boiling water seems to be an alternative for E. coli O157:H7 inactivation during beef jerky processing as a treatment at 550 MPa and during 60 s result in up to 4.4 log10 CFU reductions per strip of this bacterium. E. coli O157:H7 was found to be more sensitive to the treatment than S. aureus and L. monocytogenes (Scheinberg, Svoboda, & Cutter, 2014). Heterogeneity in HPP resistance of STEC has been shown by Sheen, Cassidy, Scullen, & Sommers (2015). These authors found D10 values (HPP conditions necessary to cause 1 cyle reduction in a target microorganism count) for 39 STEC strains varying from 0.89 to 25.7 min when subjected to HPP (350 MPa, 4 C, up to 40 min) in ground beef (80% lean). This reinforces the need of proper assessment of microbial target strains used in the design of mild technologies-based processes for microbial inactivation. An error in selecting an appropriate strain may severely impact on the lethality of the process and further on public health. HPP has also been used to destroy E. coli O157:H7 in vegetables, such as alfafa seeds. A treatment at 600 MPa at 40 C caused 5 log10 CFU reductions of E. coli O157:H7 inoculated in alfafa seed samples. Other treatments with reduced pressure values or increased time resulted in similar lethal effects on E. coli O157:H7, i.e., 550 MPa for 2 min and 40 C, 300 MPa for 2 min and 50 C, and 400 MPa for 5 min and 45 C. Nonetheless, considering the effects for seeds's germination, the first treatment (550 MPa for 2 min and 40 C) was considered the most appropriate for practical applications (Neetoo, Pizzolato, & Chen, 2009). 4.4.2. Pulsed electric fields, ultrasound processing and UV-light alone or combined with other techniques Fewer studies on the use of pulsed electric fields, ultrasound and UV-light for E. coli inactivation, including pathogenic types, have been found in comparison to HPP, for instance. This can be related to characteristics of food matrixes in which pathogenic E. coli has an importance or due to the fact that other technologies (HPP, for instance), are more efficient from both microbial inactivation and economical points of view. Despite this, as for other technologies, the combination of PEF and EO has been evaluated for inactivation of E. coli O157:H7 with increase in the treatment efficiency depending on combination of hurdles and also on the type EO. Generaly, up to 5 log10 CFU/mL reductions can be obtained as influenced by several factors (Ait-Ouazzou et al., 2011, 2012, 2013; ~ a, Monfort, Condo n, Raso, & Alvarez, Saldan 2012). A manothermosonication treatment (400 kPa/59 ºC) of 1.4 min caused 5 log10 reductions of E. coli in apple cider while 3.7 min and 15.9 min were needed to achieve the same reduction through thermosonication and sonication alone, respectively (Lee et al., 2013; Ugarte-Romero, Feng, Martin, Cadwallader, & Robinson, 2006). UV-light combined or not with dimethyl dicarbonate (DMDC) (25, 50, and 75 mg/L), and heat (55 C) were used for inactivation of n, Raso, Condo n, & E. coli in commercial apple (Gouma, Gaya Alvarez, 2015). A synergistic effect between the techniques was observed and it was found that the addition of 75 mg/mL of DMDC followed by UV-light and heat at 55 C caused 5 log10 CFU/mL reductions of E. coli in commercial apple after only 1.8 min (Gouma et al., 2015). The type of monochromatic UV-light wavelengths (222, 254, and 282 nm) was found to influence on the inactivation of E. coli 31 O157:H7 in bovine milk. Yin et al. (2015) reported higher inactivation of this bacterium when treatment was done using UV-light at the wavelength of 254 nm, when compared inactivation obtained at 222 and 282 nm (Yin et al., 2015). 4.4.3. Atmospheric cold plasma Cold plasma, known also as non-thermal atmospheric-pressure plasma, was efficiently applied to inactivate different microorganisms. For instance, this technique was used for the treatment of fresh fruits and vegetables (Baier et al., 2014). In some produce items, non-thermal atmospheric-pressure plasma treatment can result in up to 4.7 log10 CFU reductions of E. coli. The inactivation efficiency seems to vary depending on the produce item (Baier et al., 2015). Non-thermal atmospheric-pressure plasma seems to be a promising and very cost-effective technology for microbial inactivation. 5. Conclusions As can be seen in Suplementary Fig. S5, HPP is the most studied mild processing technology applied for microbial inactivation followed by UV-light. The superior HPP data may based on three facts; the pressure-induced killing of bacteria was discovered already in the 19th century, HPP can be applied to a diverse range of foods, and HPP seems to be more efficient to destroy foodborne microorganisms. Contrary, the few numbers of data dealing with plasma inactivation of foodborne microorganisms seems to be due to a more recent application of this technology for food processing. As such, several developments and barriers have to be overcome so this technology can be widely applied. The mild processing technologies HPP, PEF, US, UV-light, and ACP constitute efficient alternatives to conventional heat inactivation methods (sterilization and pasteurization). Nonetheless, the choice of a mild technology for food processing demands careful analysis weighting the installation cost, the energy consumption, environmental issues, impact on and of food formulation, the complementarity with existing equipment and the effectiveness of the technology, combined or not, to deliver a specified destruction of the microbial target which will affect product's safety and shelflife. Through this review it was possible to notice that a few limited number of studies deal with the determination of inactivation kinetics of target microorganisms subjected to a specific mild technology. Despite this, the determination of inactivation of kinetics is of major relevance for the design of a preservation method aiming to ensure a specified destruction of a microbial target. Once the changes in the environmental conditions over the inactivation kinetic parameters are estimated, a preservation process can be safely designed and further validated. However, most studies dealing with microbial inactivation by mild technologies have focused on the determination of the number of decimal reductions rather than inactivation kinetics associated with a specific formulation and processing conditions. Conversely, this seems not adequate as it does not allow readily comparisons regarding foodborne pathogens' resistance to a specified condition. In addition, the determination of the number of decimal reductions do not permit to intuitively assess the impact of environmental conditions in the rate of inactivation kinetics, which is very important as most large scale processes work under dynamic (variable) conditions. Furthermore, for foods subjected to mild processing, not only microbial inactivation is relevant, but also the presence of injured cells due to sublethal inactivation. Because of this, special attention should be taken for the development of more robust food formulations throught he concept of hurdle technology. These formulations should be able to inhibit the growth of any injured cells possibly present in the product after mild processing and prone to 32 F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 reach levels that may result in public health issues. These facts also shed light on the significance of assessing the robustness of food formulations through challenge tests for proper decision-making regarding the best formulation for a specific mild technology of food preservation. Another key point regarding microbial inactivation through mild technologies is the ability to accurately determine the inactivation kinetic parameters. This is even more relevant to minimal processing because a lack of precision may greatly impact on survival of a target microorganism that will further cause severe public health issues. In this way, variability in microbial inactivation is a phenomena that really matters for the safety of mild processed foods (Aryani, den Besten, Hazeleger, & Zwietering, 2015; Koutsoumanis, Lianou, & Gougouli, 2016; Lianou & Koutsoumanis, 2013a, 2013b). Therefore, the variability in microbial inactivation (Koutsoumanis et al., 2016) and the recovery of injured microorganisms deserve great attention. Finally, in an era of consumer's demands for mild processed foods, an advanced knowledge of microbial ecology (of raw materials, food formulations, environment of food processing), storage and commercialization conditions along with data on microbial behavior in foods (inactivation and growth) seem to be even more important for the production of shelf-stable and safe foods. Acknowledgements F.J. Barba was supported from the Union by a postdoctoral Marie Curie Intra-European Fellowship (Marie Curie IEF) within the 7th European Community Framework Programme (http://cordis. europa.eu/fp7/mariecurieactions/ief_en.html) (project number 626524 dHPBIOACTIVE d Mechanistic modeling of the formation of bioactive compounds in high pressure processed seedlings of Brussels sprouts for effective solution to preserve healthy compounds in vegetables). L.P.-Silva and A.S. Sant’Ana are grateful to CNPq (Conselho Nacional de Desenvolvimento Científico e Tec~o de gico) (Grant #302763/2014-7) and CAPES (Coordenaça nolo Aperfeiçoamento de Pessoal de Nível Superior) (PROEX/CAPES #3300301702P1) for the financial support for the projects undertaken at the Laboratory of Quantitative Food Microbiology, University of Campinas, Brazil. Appendix A. Supplementary data Supplementary data related to this article can be found at http:// dx.doi.org/10.1016/j.tifs.2017.05.011. References Abram, F., Smelt, J. P. P. M., Bos, R., & Wouters, P. C. (2003). Modelling and optimization of inactivation of Lactobacillus plantarum by pulsed electric field treatment. Journal of Applied Microbiology, 94(4), 571e579. Ait-Ouazzou, A., Cherrat, L., Espina, L., Loran, S., Rota, C., & Pagan, R. (2011). The antimicrobial activity of hydrophobic essential oil constituents acting alone or in combined processes of food preservation. Innovative Food Science and Emerging Technologies, 12(3), 320e329. Ait-Ouazzou, A., Espina, L., Cherrat, L., Hassani, M., Laglaoui, A., Conchello, P., et al. (2012). Synergistic combination of essential oils from Morocco and physical treatments for microbial inactivation. Innovative Food Science and Emerging Technologies, 16, 283e290. Ait-Ouazzou, A., Espina, L., Garcia-Gonzalo, D., & Pag an, R. (2013). Synergistic combination of physical treatments and carvacrol for Escherichia coli O157:H7 inactivation in apple, mango, orange, and tomato juices. Food Control, 32(1), 159e167. Allen, V. M., Burton, C. H., Wilkinson, D. J., Whyte, R. T., Harris, J. A., Howell, M., et al. (2008). Evaluation of the performance of different cleaning treatments in reducing microbial contamination of poultry transport crates. British Poultry Science, 49(3), 233e240. Alocilja, E. C., & Radke, S. M. (2003). Market analysis of biosensors for food safety. Biosensors & Bioelectronics, 18(5e6), 841e846. € nner, U. (2001). Inactivation of Aronsson, K., Lindgren, M., Johansson, B. R., & Ro microorganisms using pulsed electric fields: The influence of process parameters on Escherichia coli, Listeria innocua, Leuconostoc mesenteroides and Saccharomyces cerevisiae. Innovative Food Science & Emerging Technologies, 2(1), 41e54. Aryani, D. C., den Besten, H. M. W., Hazeleger, W. C., & Zwietering, M. H. (2015). Quantifying variability on thermal resistance of Listeria monocytogenes. International Journal of Food Microbiology, 193, 130e138. €rgen, M., Ehlbeck, J., Knorr, D., Herppich, W. B., & Schlüter, O. (2014). Baier, M., Go Non-thermal atmospheric pressure plasma: Screening for gentle process conditions and antibacterial efficiency on perishable fresh produce. Innovative Food Science & Emerging Technologies, 22, 147e157. Baier, M., Janssen, T., Wieler, L. H., Ehlbeck, J., Knorr, D., & Schlüter, O. (2015). Inactivation of Shiga toxin-producing Escherichia coli O104:H4 using cold atmospheric pressure plasma. Journal of Bioscience and Bioengineering, 120(3), 275e279. Barba, F. J., Criado, M. N., Belda-Galbis, C. M., Esteve, M. J., & Rodrigo, D. (2014). Stevia rebaudiana Bertoni as a natural antioxidant/antimicrobial for high pressure processed fruit extract: Processing parameter optimization. Food Chemistry, 148, 261e267. Barba, F. J., Esteve, M. J., & Frígola, A. (2012). High pressure treatment effect on physicochemical and nutritional properties of fluid foods during storage: A review. Comprehensive Reviews in Food Science and Food Safety, 11(3), 307e322. Barba, F. J., Terefe, N. S., Buckow, R., Knorr, D., & Orlien, V. (2015). New opportunities and perspectives of high pressure treatment to improve health and safety attributes of foods. A review. Food Research International, 77(4), 725e742. Bari, M. L., & Inatsu, Y. (2014). Escherichia coli O157 j E. coli O157:H7. In C. A. B. Lou Tortorello (Ed.), Encyclopedia of food microbiology (2nd ed., pp. 735e739). Oxford: Academic Press. novas, G. V. (2008). Study of butter fat content Bermúdez-Aguirre, D., & Barbosa-Ca in milk on the inactivation of Listeria innocua ATCC 51742 by thermo-sonication. Innovative Food Science & Emerging Technologies, 9(2), 176e185. novas, G. V. (2011). Study of Bermúdez-Aguirre, D., Mawson, R., & Barbosa-Ca possible mechanisms of inactivation of Listeria Innocua in thermo-sonicated milk using scanning electron microscopy and transmission electron microscopy. Journal of Food Processing and Preservation, 35(6), 767e777. Black, E. P., Hirneisen, K. A., Hoover, D. G., & Kniel, K. E. (2010). Fate of Escherichia coli O157:H7 in ground beef following high-pressure processing and freezing. Journal of Applied Microbiology, 108(4), 1352e1360. Bover-Cid, S., Belletti, N., Garriga, M., & Aymerich, T. (2012). Response surface methodology to investigate the effect of high pressure processing on Salmonella inactivation on dry-cured ham. Food Research International, 45(2), 1111e1117. Boysen, L., & Rosenquist, H. (2009). Reduction of thermotolerant Campylobacter species on broiler carcasses following physical decontamination at slaughter. Journal of Food Protection, 72(3), 497e502. Bravo, D., de Alba, M., & Medina, M. (2014). Combined treatments of high-pressure with the lactoperoxidase system or lactoferrin on the inactivation of Listeria monocytogenes, Salmonella Enteritidis and Escherichia coli O157:H7 in beef carpaccio. Food Microbiology, 41, 27e32. Cardello, A. V., Schutz, H. G., & Lesher, L. L. (2007). Consumer perceptions of foods processed by innovative and emerging technologies: A conjoint analytic study. Innovative Food Science & Emerging Technologies, 8(1), 73e83. CDC. (2010). CDC Reports 1 in 6 get sick from foodborne illnesses each year. Centers for Disease Control and Prevention. http://www.cdc.gov/media/pressrel/2010/ r101215.html Accessed on September 10th, 2016. CDC. (2011). Vital signs: Incidence and trends of infection with pathogens transmitted commonly through food e foodborne diseases active surveillance network, 10 U.S. Sites, 1996-2010. Morbidity and Mortality Weekly Report, 60, 749e755. Chemburu, S., Wilkins, E., & Abdel-Hamid, I. (2005). Detection of pathogenic bacteria in food samples using highly-dispersed carbon particles. Biosensors and Bioelectronics, 21(3), 491e499. Cherrat, L., Espina, L., Bakkali, M., Pag an, R., & Laglaoui, A. (2014). Chemical composition, antioxidant and antimicrobial properties of Mentha pulegium, Lavandula stoechas and Satureja calamintha Scheele essential oils and an evaluation of their bactericidal effect in combined processes. Innovative Food Science & Emerging Technologies, 22, 221e229. Chung, S.-Y., Yang, W., & Krishnamurthy, K. (2008). Effects of pulsed UV-light on peanut allergens in extracts and liquid peanut butter. Journal of Food Science, 73(5), C400eC404. Chun, H., Kim, J., Chung, K., Won, M., & Song, K. B. (2009). Inactivation kinetics of Listeria monocytogenes, Salmonella enterica serovar Typhimurium, and Campylobacter jejuni in ready-to-eat sliced ham using UV-C irradiation. Meat Science, 83(4), 599e603. Chun, H. H., Kim, J. Y., Lee, B. D., Yu, D. J., & Song, K. B. (2010). Effect of UV-C irradiation on the inactivation of inoculated pathogens and quality of chicken breasts during storage. Food Control, 21(3), 276e280. Crook, J. A., Rossitto, P. V., Parko, J., Koutchma, T., & Cullor, J. S. (2015). Efficacy of ultraviolet (uv-c) light in a thin-film turbulent flow for the reduction of milkborne pathogens. Foodborne Pathogens and Disease, 12(6), 506e513. €hn, Y. T., McDonough, P. L., & Siler, J. D. Cummings, K. J., Warnick, L. D., Elton, M., Gro (2010). The effect of clinical outbreaks of salmonellosis on the prevalence of fecal Salmonella shedding among dairy cattle in New York. Foodborne Pathogens and Disease, 7(7), 815e823. de Alba, M., Bravo, D., & Medina, M. (2012). High pressure treatments on the inactivation of Salmonella Enteritidis and the characteristics of beef carpaccio. F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 Meat Science, 92(4), 823e828. de Alba, M., Bravo, D., & Medina, M. (2015). Inactivation of Listeria monocytogenes and Salmonella Enteritidis in dry-cured ham by combined treatments of high pressure and the lactoperoxidase system or lactoferrin. Innovative Food Science & Emerging Technologies, 31, 54e59. de Daza, M. S. T., Villegas, Y., & Martinez, A. (1991). Minimal water activity for growth of Listeria monocytogenes as affected by solute and temperature. International Journal of Food Microbiology, 14(3), 333e337. Domingues, A. R., Pires, S. M., Halasa, T., & Hald, T. (2012). Source attribution of human campylobacteriosis using a meta-analysis of case-control studies of sporadic infections. Epidemiology and Infection, 140(6), 970e981. Dong, Q., Manns, D. C., Feng, G., Yue, T., Churey, J. J., & Worobo, R. W. (2010). Reduction of patulin in apple cider by UV radiation. Journal of Food Protection, 73(1), 69e74. Newell, D. G., Elvers, K. T., Dopfer, D., Hansson, I., Jones, P., James, S., Gittins, J., Stern, N. J., Davies, R., Connerton, I., Pearson, D., Salvat, G., & Allen, V. M. (2009). UV disinfection of adenoviruses: Molecular indications of DNA damage efficiency. Applied and Environmental Microbiology, 75(1), 23e28. ndez, J., Soliva-Fortuny, R. C., & Martín-Belloso, O. Elez-Martínez, P., Escol a-Herna (2005). Inactivation of Lactobacillus brevis in orange juice by high-intensity pulsed electric fields. Food Microbiology, 22(4), 311e319. n, R. (2013). SynEspina, L., García-Gonzalo, D., Laglaoui, A., Mackey, B. M., & Paga ergistic combinations of high hydrostatic pressure and essential oils or their constituents and their use in preservation of fruit juices. International Journal of Food Microbiology, 161(1), 23e30. n, R. (2014). CombiEspina, L., Monfort, S., Alvarez, I., García-Gonzalo, D., & Paga nation of pulsed electric fields, mild heat and essential oils as an alternative to the ultrapasteurization of liquid whole egg. International Journal of Food Microbiology, 189, 119e125. Evrendilek, G. A., & Balasubramaniam, V. M. (2011). Inactivation of Listeria monocytogenes and Listeria innocua in yogurt drink applying combination of high pressure processing and mint essential oils. Food Control, 22(8), 1435e1441. Farber, J. M., & Peterkin, P. I. (1991). Listeria monocytogenes, a food-borne pathogen. Microbiological Reviews, 55(3), 476e511. Feichtinger, J., Schulz, A., Walker, M., & Schumacher, U. (2003). Sterilisation with low-pressure microwave plasmas. Surface and Coatings Technology, 174e175, 564e569. ndez-Molina, J. J., Bermúdez-Aguirre, D., Altunakar, B., Swanson, B. G., & Ferna Barbosa-C anovas, G. V. (2006). Inactivation of Listeria Innocua and Pseudomonas Fluorescens by pulsed electric fields in skim milk: Energy requirements. Journal of Food Process Engineering, 29(6), 561e573. Ferrari, G., Maresca, P., & Ciccarone, R. (2010). The application of high hydrostatic pressure for the stabilization of functional foods: Pomegranate juice. Journal of Food Engineering, 100(2), 245e253. Fit, N., Chirila, F., Nadas, G., Negrea, O., Bobis, O., & Marghitas, L. (2014). Assessment of the antimicrobial effect of honey, treated by heat and ultraviolet radiation. Bulletin of University of Agricultural Sciences and Veterinary Medicine Cluj-napoca. Veterinary Medicine, 71(2), 449e454. Fitzgerald, C. (2015). Campylobacter. Clinics in Laboratory Medicine, 35(2), 289e298. Friedberg, E. C., Walker, G. C., & Siede, W. (1995). DNA repair and mutagenesis. Washington, D.C.: ASM Press. bol, N., Aymerich, M. T., Monfort, J. M., & Hugas, M. (2004). Microbial Garriga, M., Gre inactivation after high-pressure processing at 600 MPa in commercial meat products over its shelf life. Innovative Food Science & Emerging Technologies, 5(4), 451e457. n, E., Serrano, M. J., Monfort, S., Alvarez, n, S. (2012a). Combining Gaya I., & Condo ultraviolet light and mild temperatures for the inactivation of Escherichia coli in orange juice. Journal of Food Engineering, 113(4), 598e605. n, E., Serrano, M. J., Raso, J., Alvarez, n, S. (2012b). Inactivation of Gaya I., & Condo Salmonella enterica by UV-C light alone and in combination with mild temperatures. Applied and Environmental Microbiology, 78(23), 8353e8361. Georget, E., Sevenich, R., Reineke, K., Mathys, A., Heinz, V., Callanan, M., Rauh, C., & Knorr, D. (2015). Inactivation of microorganisms by high isostatic pressure processing in complex matrices: A review. Innovative Food Science and Emerging Technologies, 27, 1e14. Gill, A. O., & Ramaswamy, H. S. (2008). Application of high pressure processing to kill Escherichia coli O157 in ready-to-eat meats. Journal of Food Protection, 71(11), 2182e2189. mez-Lo pez, V. M., Devlieghere, F., Bonduelle, V., & Debevere, J. (2005). Factors Go affecting the inactivation of micro-organisms by intense light pulses. Journal of Applied Microbiology, 99(3), 460e470. mez-Lo pez, V. M., Koutchma, T., & Linden, K. (2012). Ultraviolet and pulsed light Go processing of fluid foods. In P. J. Cullen, B. K. Tiwari, & V. P. Valdramidis (Eds.), Novel thermal and non-thermal technologies for fluid foods (pp. 185e223). San Diego: Academic Press. Gonzalez, M. E., & Barrett, D. M. (2010). Thermal, high pressure, and electric field processing effects on plant cell membrane integrity and relevance to fruit and vegetable quality. Journal of Food Science, 75(7), R121eR130. n, E., Raso, J., Condo n, S., & Alvarez, Gouma, M., Gaya I. (2015). Influence of dimethyl dicarbonate on the resistance of Escherichia coli to a combined UV-Heat treatment in apple juice. Frontiers in Microbiology, 6. http://dx.doi.org/10.3389/ fmicb.2015.00501. Grant, A., Hashem, F., & Parveen, S. (2016). Salmonella and Campylobacter: Antimicrobial resistance and bacteriophage control in poultry. Food Microbiology, 53(Part B), 104e109. 33 Greig, J. D., & Ravel, A. (2009). Analysis of foodborne outbreak data reported internationally for source attribution. International Journal of Food Microbiology, 130(2), 77e87. Griffin, P. M., & Tauxe, R. V. (1991). The epidemiology of infections caused by Escherichia coli O157:H7, other enterohemorrhagic E. coli, and the associated hemolytic uremic syndrome. Epidemiologic Reviews, 13, 60e98. n, J. A., Barbosa-C Guerrero-Beltra anovas, G. V., & Welti-Chanes, J. (2011a). High hydrostatic pressure effect on natural microflora, Saccharomyces cerevisiae, Escherichia coli, and Listeria Innocua in navel orange juice. International Journal of Food Engineering, 7(1). http://doi.org/10.2202/1556-3758.2166. n, J. A., Barbosa-Ca novas, G. V., & Welti-Chanes, J. (2011b). High Guerrero-Beltra hydrostatic pressure effect on Saccharomyces cerevisiae, Escherichia coli and Listeria innocua in pear nectar. Journal of Food Quality, 34(6), 371e378. Gunther, N. W., Sites, J., & Sommers, C. (2015). The effects of high-pressure treatments on Campylobacter jejuni in ground poultry products containing polyphosphate additives. Poultry Science, 94, 2297e2302. http://dx.doi.org/10.3382/ ps/pev199 [Epub 2015 Jul 27]. Guo, Chuanfa, Hoekstra, Robert M., Schroeder, Carl M., Pires, Sara Monteiro, Ong, Kanyin Liane, Hartnett, Emma, Naugle, Alecia, Harman, Jane, Bennett, Patricia, Cieslak, Paul, Scallan, Elaine, Rose, Bonnie, Holt, Kristin G., Kissler, Bonnie, Mbandi, Evelyne, Roodsari, Reza, Angulo, Frederick J., & Cole, Dana (2011). Application of bayesian techniques to model the burden of human salmonellosis attributable to U.S. Food commodities at the point of processing: Adaptation of a Danish model. Foodborne Pathogens and Disease, 8(4), 509e516. Gurtler, J. B., Hinton, A., Jr., Bailey, R. B., Cray, W. C., Jr., Meinersmann, R. J., Ball, T. A., et al. (2015). Salmonella isolated from ready-to-eat pasteurized liquid egg products: Thermal resistance, biochemical profile, and fatty acid analysis. International Journal of Food Microbiology, 206, 109e117. Harm, W. (1980). Biological effects of ultraviolet radiation. Cambridge, Eng.; New York: Cambridge University Press. Haughton, P. N., Lyng, J., Cronin, D., Fanning, S., & Whyte, P. (2012a). Effect of crust freezing applied alone and in combination with ultraviolet light on the survival of Campylobacter on raw chicken. Food Microbiology, 32(1), 147e151. Haughton, P. N., Lyng, J. G., Cronin, D. A., Morgan, D. J., Fanning, S., & Whyte, P. (2011). Efficacy of UV light treatment for the microbiological decontamination of chicken, associated packaging, and contact surfaces. Journal of Food Protection, 74(4), 565e572. Haughton, P. N., Lyng, J. G., Morgan, D. J., Cronin, D. A., Noci, F., Fanning, S., et al. (2012b). An evaluation of the potential of high-intensity ultrasound for improving the microbial safety of poultry. Food and Bioprocess Technology, 5(3), 992e998. Hayman, M. M., Kouassi, G. K., Anantheswaran, R. C., Floros, J. D., & Knabel, S. J. (2008). Effect of water activity on inactivation of Listeria monocytogenes and lactate dehydrogenase during high pressure processing. International Journal of Food Microbiology, 124(1), 21e26. Heremans, K. (1995). High pressure effects on biomolecules. In D. A. Ledward, D. E. Johnston, R. G. Earnshaw, & A. P. M. Hasting (Eds.), High pressure processing of foods (pp. 81e97). Nottingham, UK: Nottingham University Press. Hermans, David, Pasmans, Frank, Messens, Winy, Martel, An, Van Immerseel, Filip, Rasschaert, Geertrui, Heyndrickx, Marc, Van Deun, Kim, & Haesebrouck, Freddy (2012). Poultry as a host for the zoonotic pathogen Campylobacter jejuni. Vector Borne and Zoonotic Diseases (Larchmont, N.Y.), 12(2), 89e98. Hijnen, W. A. M., Beerendonk, E. F., & Medema, G. J. (2006). Inactivation credit of UV radiation for viruses, bacteria and protozoan (oo)cysts in water: A review. Water Research, 40(1), 3e22. Ho, S. y., Mittal, G. s., Cross, J. d., & Griffiths, M. w. (1995). Inactivation of Pseudomonas fluorescens by high voltage electric pulses. Journal of Food Science, 60(6), 1337e1340. Huang, E., Mittal, G. S., & Griffiths, M. W. (2006). Inactivation of Salmonella enteritidis in liquid whole egg using combination treatments of pulsed electric field, high pressure and ultrasound. Biosystems Engineering, 94(3), 403e413. Huang, Y., Ye, M., & Chen, H. (2013). Inactivation of Escherichia coli O157:H7 and Salmonella spp. in strawberry puree by high hydrostatic pressure with/without subsequent frozen storage. International Journal of Food Microbiology, 160(3), 337e343. Jackowska-Tracz, A., & Tracz, M. (2015). Effects of high hydrostatic pressure on Campylobacter jejuni in poultry meat. Polish Journal of Veterinary Sciences, 18(2), 261e266. ski, J., Pe,conek, J., & Fonberg-Broczek, M. (2008). Possibility Jackowska, A., Szczawin of Campylobacter jejuni inactivation in smoked salmon by high-pressure treatment. High Pressure Research, 28(2), 127e132. Jaeger, H., Balasa, A., & Knorr, D. (2009a). Food industry applications for pulsed electric fields. In Electrotechnologies for extraction from food plants and biomaterials (pp. 181e216). New York: Springer. Jaeger, H., Meneses, N., & Knorr, D. (2009b). Impact of PEF treatment inhomogeneity such as electric field distribution, flow characteristics and temperature effects on the inactivation of E. coli and milk alkaline phosphatase. Innovative Food Science & Emerging Technologies, 10(4), 470e480. Jayaram, S., Castle, G. S., & Margaritis, A. (1992). Kinetics of sterilization of Lactobacillus brevis cells by the application of high voltage pulses. Biotechnology and Bioengineering, 40(11), 1412e1420. Jermann, C., Koutchma, T., Margas, E., Leadley, C., & Ros-Polski, V. (2015). Mapping trends in novel and emerging food processing technologies around the world. Innovative Food Science and Emerging Technologies, 31, 14e27. 34 F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 €, S. I., & Hirn, J. (1988). Minimum growth temperatures of Junttila, J. R., Niemela Listeria monocytogenes and non-haemolytic Listeria. The Journal of Applied Bacteriology, 65(4), 321e327. Karmali, M. A., Gannon, V., & Sargeant, J. M. (2010). Verocytotoxin-producing Escherichia coli (VTEC). Veterinary Microbiology, 140(3e4), 360e370. Keenan, D. F., Brunton, N. P., Gormley, T. R., Butler, F., Tiwari, B. K., & Patras, A. (2010). Effect of thermal and high hydrostatic pressure processing on antioxidant activity and colour of fruit smoothies. Innovative Food Science & Emerging Technologies, 11(4), 551e556. Kelly-Wintenberg, K., Hodge, A., Montie, T. C., Deleanu, L., Sherman, D., Roth, J. R., Tsai, P., & Wadsworth, L. (1999). Use of a one atmosphere uniform glow discharge plasma to kill a broad spectrum of microorganisms. Journal of Vacuum Science & Technology a, 17(4), 1539e1544. Konowalchuk, J., Speirs, J. I., & Stavric, S. (1977). Vero response to a cytotoxin of Escherichia coli. Infection and Immunity, 18(3), 775e779. Zlabur, -Soto, Elena, Sic Koubaa, Mohamed, Rosello Jana, Re zek Jambrak, Anet, Brn ci c, Mladen, Grimi, Nabil, Boussetta, Nadia, & Barba, Francisco J. (2015). Current and new insights in the sustainable and green recovery of nutritionally valuable compounds from Stevia rebaudiana Bertoni. Journal of Agricultural and Food Chemistry, 63, 6835e6846. Koutchma, T. (2009). Advances in ultraviolet light technology for non-thermal processing of liquid foods. Food and Bioprocess Technology, 2(2), 138e155. Koutchma, T., Keller, S., Chirtel, S., & Parisi, B. (2004). Ultraviolet disinfection of juice products in laminar and turbulent flow reactors. Innovative Food Science & Emerging Technologies, 5(2), 179e189. Koutsoumanis, K. P., Lianou, A., & Gougouli, M. (2016). Last developments in foodborne pathogens modeling. Current Opinion in Food Science, 8, 89e98. Krishnamurthy, K., Demirci, A., & Irudayaraj, J. M. (2007). Inactivation of Staphylococcus aureus in milk using flow-through pulsed UV-light treatment system. Journal of Food Science, 72(7), M233eM239. Lambertz, S. T., Ivarsson, S., Lopez-Valladares, G., Sidstedt, M., & Lindqvist, R. (2013). Subtyping of Listeria monocytogenes isolates recovered from retail ready-to-eat foods, processing plants and listeriosis patients in Sweden 2010. International Journal of Food Microbiology, 166(1), 186e192. Lee, D. U., Heinz, V., & Knorr, D. (2003). Effects of combination treatments of nisin and high-intensity ultrasound with high pressure on the microbial inactivation in liquid whole egg. Innovative Food Science and Emerging Technologies, 4(4), 387e393. Lee, H., Kim, H., Cadwallader, K. R., Feng, H., & Martin, S. E. (2013). Sonication in combination with heat and low pressure as an alternative pasteurization treatment effect on Escherichia coli K12 inactivation and quality of apple cider. Ultrasonics Sonochemistry, 20(4), 1131e1138. Lee, K., Paek, K., Ju, W.-T., & Lee, Y. (2006). Sterilization of bacteria, yeast, and bacterial endospores by atmospheric-pressure cold plasma using helium and oxygen. Journal of Microbiology (Seoul, Korea), 44(3), 269e275. Lianou, A., & Koutsoumanis, K. P. (2013a). Evaluation of the strain variability of Salmonella enterica acid and heat resistance. Food Microbiology, 34(2), 259e267. Lianou, A., & Koutsoumanis, K. P. (2013b). Strain variability of the behavior of foodborne bacterial pathogens: A review. International Journal of Food Microbiology, 167(3), 310e321. €nzle, M. G. (2012). High pressure inactivation of Escherichia Liu, Y., Betti, M., & Ga coli, Campylobacter jejuni, and spoilage microbiota on poultry meat. Journal of Food Protection, 75(3), 497e503. Lori, S., Buckow, R., Knorr, D., Heinz, V., & Lehmacher, A. (2007). Predictive model for inactivation of Campylobacter spp. by heat and high hydrostatic pressure. Journal of Food Protection, 70(9), 2023e2029. Lowder, A. C., Waite-Cusic, J. G., & Mireles DeWitt, C. A. (2014). High pressureelow temperature processing of beef: Effects on survival of internalized E. coli O157: H7 and quality characteristics. Innovative Food Science & Emerging Technologies, 26, 18e25. Luscher, C., Balasa, A., Frohling, A., Ananta, E., & Knorr, D. (2004). Effect of highpressure-induced ice I-to-ice III phase transitions on inactivation of Listeria innocua in frozen suspension. Applied and Environmental Microbiology, 70(7), 4021e4029. Luscher, C., Schlüter, O., & Knorr, D. (2005). High pressure-low temperature processing of foods: Impact on cell membranes, texture, color and visual appearance of potato tissue. Innovative Food Science & Emerging Technologies, 6(1), 59e71. Maitland, J. E., Boyer, R. R., Eifert, J. D., & Williams, R. C. (2011). High hydrostatic pressure processing reduces Salmonella enterica serovars in diced and whole tomatoes. International Journal of Food Microbiology, 149(2), 113e117. ~ as, P., & Pag Man an, R. (2005a). Microbial inactivation by new technologies of food preservation. Journal of Applied Microbiology, 98(6), 1387e1399. ~ as, P., & Paga n, R. (2005b). Microbial inactivation by new technologies of food Man preservation. Journal of Applied Microbiology, 98(6), 1387e1399. ~ as, P., Paga n, R., Raso, J., Sala, F. J., & Condo n, S. (2000). Inactivation of Salmonella Man enteritidis, Salmonella typhimurium, and Salmonella senftenberg by ultrasonic waves under pressure. Journal of Food Protection, 63(4), 451e456. Masschelein, W., & Rice, R. G. (2002). Ultraviolet light in water and wastewater sanitation. Boca Raton, Fla: Lewis Publishers. Mead, P. S., Slutsker, L., Dietz, V., McCaig, L. F., Bresee, J. S., Shapiro, C., Griffin, P. M., & Tauxe, R. V. (1999). Food-related illness and death in the United States. Emerging Infectious Diseases, 5(5), 607e625. Misra, N. N., Tiwari, B. K., Raghavarao, K. S. M. S., & Cullen, P. J. (2011). Nonthermal plasma inactivation of food-Borne pathogens. Food Engineering Reviews, 3(3e4), 159e170. Mogul, R., Bol’shakov, A. A., Chan, S. L., Stevens, R. M., Khare, B. N., Meyyappan, M., et al. (2003). Impact of low-temperature plasmas on Deinococcus radiodurans and biomolecules. Biotechnology Progress, 19(3), 776e783. Mohamed, M. E. A., & Amer Eissa, A. H. (2012). Pulsed electric fields for food processing technology. In A. H. Amer Eissa (Ed.), Structure and function of food engineering. InTech. Monfort, S., Ramos, S., Meneses, N., Knorr, D., Raso, J., & Alvarez, I. (2012a). Design and evaluation of a high hydrostatic pressure combined process for pasteurization of liquid whole egg. Innovative Food Science & Emerging Technologies, 14, 1e10. n, S., Raso, J., & Alvarez, Monfort, S., Sagarzazu, N., Condo I. (2012b). Liquid whole egg ultrapasteurization by combination of PEF, heat, and additives. Food and Bioprocess Technology, 6(8), 2070e2080. ~ a, G., Condo n, S., Raso, J., & Alvarez, Monfort, S., Saldan I. (2012c). Inactivation of Salmonella spp. in liquid whole egg using pulsed electric fields, heat, and additives. Food Microbiology, 30(2), 393e399. ~ ez, M. (2008). Inactivation of Escherichia coli Morales, P., Calzada, J., Avila, M., & Nun O157:H7 in ground beef by single-cycle and multiple-cycle high-pressure treatments. Journal of Food Protection, 71(4), 811e815. ~ ez, M. (2009). Inactivation of Morales, P., Calzada, J., Rodríguez, B., De Paz, M., & Nun Salmonella Enteritidis in chicken breast fillets by single-cycle and multiple-cycle high pressure treatments. Foodborne Pathogens and Disease, 6(5), 577e581. Musavian, H. S., Krebs, N. H., Nonboe, U., Corry, J. E. L., & Purnell, G. (2014). Combined steam and ultrasound treatment of broilers at slaughter: A promising intervention to significantly reduce numbers of naturally occurring campylobacters on carcasses. International Journal of Food Microbiology, 176, 23e28. ~ o, A. M., Schaffner, D. W., & Karwe, M. Nair, A., Maldonaldo, J. A., Miyazawa, Y., Cuitin (2016). Numerical simulation of stress distribution in heterogeneous solids during high pressure processing. Food Research International, 84, 76e85. ~o Neetoo, H., & Chen, H. (2012). High pressure inactivation of Salmonella on Jalapen and Serrano peppers destined for direct consumption or as ingredients in Mexican salsa and guacamole. International Journal of Food Microbiology, 156(3), 197e203. Neetoo, H., Pizzolato, T., & Chen, H. (2009). Elimination of Escherichia coli O157:H7 from Alfalfa seeds through a combination of high hydrostatic pressure and mild heat. Applied and Environmental Microbiology, 75(7), 1901e1907. Nelson, C. L., & Berger, T. J. (1989). Inactivation of microorganisms by oxygen gas plasma. Current Microbiology, 18(4), 275e276. Newell, D. G., Elvers, K. T., Dopfer, D., Hansson, I., Jones, P., James, S., et al. (2011). Biosecurity-based interventions and strategies to reduce Campylobacter spp. on poultry farms. Applied and Environmental Microbiology, 77(24), 8605e8614. Nolan, D. A., Chamblin, D. C., & Troller, J. A. (1992). Minimal water activity levels for growth and survival of Listeria monocytogenes and Listeria innocua. International Journal of Food Microbiology, 16(4), 323e335. Oey, I., Lille, M., Van Loey, A., & Hendrickx, M. (2008). Effect of high-pressure processing on colour, texture and flavour of fruit- and vegetable-based food products: A review. Trends in Food Science & Technology, 19(6), 320e328. Oguma, K., Katayama, H., Mitani, H., Morita, S., Hirata, T., & Ohgaki, S. (2001). Determination of pyrimidine dimers in Escherichia coli and Cryptosporidium parvum during UV light inactivation, photoreactivation, and dark repair. Applied and Environmental Microbiology, 67(10), 4630e4637. Orlowska, M., Koutchma, T., Kostrzynska, M., & Tang, J. (2015). Surrogate organisms for pathogenic O157:H7 and non-O157 Escherichia coli strains for apple juice treatments by UV-C light at three monochromatic wavelengths. Food Control, 47, 647e655. O'Brien, A. D., & LaVeck, G. D. (1983). Purification and characterization of a Shigella dysenteriae 1-like toxin produced by Escherichia coli. Infection and Immunity, 40(2), 675e683. n, R., Man ~ as, P., Raso, J., & Condo n, S. (1999). Bacterial resistance to ultrasonic Paga waves under pressure at nonlethal (manosonication) and lethal (manothermosonication) temperatures. Applied and Environmental Microbiology, 65(1), 297e300. Patterson, M. F. (2014). Food technologies: High pressure processing. In Y. Motarjemi (Ed.), Encyclopedia of food safety (Vol. 3: Foods, materials, technologies and risks (pp. 196e201). Waltham: Academic Press. rez, M. C., Martínez-Lo pez, A., & Rodrigo, D. (2012). Cinnamon antimicrobial Pina-Pe effect against Salmonella typhimurium cells treated by pulsed electric fields (PEF) in pasteurized skim milk beverage. Food Research International, 48(2), 777e783. Piyasena, P., Mohareb, E., & McKellar, R. C. (2003). Inactivation of microbes using ultrasound: A review. International Journal of Food Microbiology, 87(3), 207e216. Poppe, C. (2011). Pathogens in milk j Salmonella spp. In J. W. Fuquay (Ed.), Encyclopedia of dairy sciences (2nd ed., pp. 93e98). San Diego: Academic Press. Porto-Fett, A. C. S., Call, J. E., Shoyer, B. E., Hill, D. E., Pshebniski, C., Cocoma, G. J., et al. (2010). Evaluation of fermentation, drying, and/or high pressure processing on viability of Listeria monocytogenes, Escherichia coli O157:H7, Salmonella spp., and Trichinella spiralis in raw pork and Genoa salami. International Journal of Food Microbiology, 140(1), 61e75. rtolas, E., Alvarez, ~o n, I. M. de (2013). Aplicacio n industrial de Pue I., Raso, J., & Maran ctricos de alto voltaje para la pasteurizacio n de alimentos: Revilos pulsos ele n de su viabilidad te cnica y comercial. CyTA - Journal of Food, 11(1), 81e88. sio rtolas, E., Koubaa, M., & Barba, F. J. (2016). An overview of the impact of elecPue trotechnologies for the recovery of oil and high-value compounds from vegetable oil industry: Energy and economic cost implications. Food Research F.J. Barba et al. / Trends in Food Science & Technology 66 (2017) 20e35 International, 80, 19e26. novas, G. V., Swanson, B. G., Pedrow, P. D., & Olsen, R. G. (1998). Qin, B.-L., Barbosa-Ca Inactivating microorganisms using a pulsed electric field continuous treatment system. IEEE Transactions on Industry Applications, 34(1), 43e50. Rangel, J. M., Sparling, P. H., Crowe, C., Griffin, P. M., & Swerdlow, D. L. (2005). Epidemiology of Escherichia coli O157:H7 outbreaks, United States, 1982e2002. Emerging Infectious Diseases, 11(4), 603e609. Rantsiou, K., & Cocolin, L. S. (2016). Campylobacter: Species detection. In (Eds.), Encyclopedia of food and health (pp. B. Caballero, P. M. Finglas, & F. Toldra 609e613). Oxford: Academic Press. n, S., & Sala Trepat, F. J. (2000). Predicting inactivation of Raso, J., Alvarez, I., Condo Salmonella senftenberg by pulsed electric fields. Innovative Food Science & Emerging Technologies, 1(1), 21e29. Raso, J., & Barbosa-C anovas, G. V. (2003). Nonthermal preservation of foods using combined processing techniques. Critical Reviews in Food Science and Nutrition, 43(3), 265e285. n, S., & Sala, F. J. (1998). Influence of temperature and Raso, J., Pag an, R., Condo pressure on the lethality of ultrasound. Applied and Environmental Microbiology, 64(2), 465e471. Rodrigo, D., Ruíz, P., Barbosa-C anovas, G. V., Martínez, A., & Rodrigo, M. (2003). Kinetic model for the inactivation of Lactobacillus plantarum by pulsed electric fields. International Journal of Food Microbiology, 81(3), 223e229. ~ a, G., Alvarez, n, S., & Raso, J. (2014). Microbiological aspects related Saldan I., Condo to the feasibility of PEF technology for food pasteurization. Critical Reviews in Food Science and Nutrition, 54(11), 1415e1426. ~ a, G., Minor-Pe rez, H., Raso, J., & Alvarez, Saldan I. (2011). Combined effect of temperature, pH, and presence of nisin on inactivation of Staphylococcus aureus and Listeria monocytogenes by pulsed electric fields. Foodborne Pathogens and Disease, 8(7), 797e802. ~ a, G., Monfort, S., Condo n, S., Raso, J., & Alvarez, Saldan I. (2012). Effect of temperature, pH and presence of nisin on inactivation of Salmonella typhimurium and Escherichia coli O157:H7 by pulsed electric fields. Food Research International, 45(2), 1080e1086. Scheinberg, J. A., Svoboda, A. L., & Cutter, C. N. (2014). High-pressure processing and boiling water treatments for reducing Listeria monocytogenes, Escherichia coli O157:H7, Salmonella spp., and Staphylococcus aureus during beef jerky processing. Food Control, 39, 105e110. ngora-Nieto, M. M., San-Martin, M. F., & Barbosa-Ca novas, G. V. Sepulveda, D. R., Go (2005). Influence of treatment temperature on the inactivation of Listeria innocua by pulsed electric fields. LWT - Food Science and Technology, 38(2), 167e172. novas, G., Torres, J. A., & Welti-Chanes, J. (2014). Serment-Moreno, V., Barbosa-Ca High-pressure processing: Kinetic models for microbial and enzyme inactivation. Food Engineering Reviews, 6(3), 56e88. novas, G., Torres, J. A., & WeltiSerment-Moreno, V., Fuentes, C., Barbosa-Ca Chanes, J. (2015). Evaluation of high pressure processing kinetic models for microbial inactivation using standard statistical tools and information theory criteria, and the development of generic time-pressure functions for process design. Food and Bioprocess Technology, 8(6), 1244e1257. Sheen, S., Cassidy, J., Scullen, B., & Sommers, C. (2015a). Inactivation of a diverse set of shiga toxin-producing Escherichia coli in ground beef by high pressure processing. Food Microbiology, 52, 84e87. Sheen, S., Cassidy, J., Scullen, B., Uknalis, J., & Sommers, C. (2015b). Inactivation of Salmonella spp in ground chicken using high pressure processing. Food Control, 57, 41e47. Smelt, J. P. P. M., & Brul, S. (2014). Thermal inactivation of microorganisms. Critical Reviews in Food Science and Nutrition, 54(10), 1371e1385. Solomon, E. B., & Hoover, D. G. (2004). Inactivation of Campylobacter jejuni by high hydrostatic pressure. Letters in Applied Microbiology, 38(6), 505e509. Stratakos, A. C., Linton, M., Tessema, G. T., Skjerdal, T., Patterson, M. F., & Koidis, A. (2016). Effect of high pressure processing in combination with Weissella viridescens as a protective culture against Listeria monocytogenes in ready-to-eat salads of different pH. Food Control, 61, 6e12. Swaminathan, B., & Gerner-Smidt, P. (2007). The epidemiology of human listeriosis. 35 Microbes and Infection/Institut Pasteur, 9(10), 1236e1243. Tananuwong, K., Chitsakun, T., & Tattiyakul, J. (2012). Effects of high-pressure processing on inactivation of Salmonella Typhimurium, eating quality, and microstructure of raw chicken breast fillets. Journal of Food Science, 77(11), E321eE327. Tauxe, R. V., Doyle, M. P., Kuchenmüller, T., Schlundt, J., & Stein, C. E. (2010). Evolving public health approaches to the global challenge of foodborne infections. International Journal of Food Microbiology, 139, S16eS28. Teissie, J., Golzio, M., & Rols, M. P. (2005). Mechanisms of cell membrane electropermeabilisation: A minireview of our present (lack of?) knowledge. Biochimica et Biophysica Acta, 1724, 270e280. le my, M., Bouscambert-Duchamp, M., Kurtz, P., Terrier, O., Essere, B., Yver, M., Barthe VanMechelen, D., Morfin, F., Billaud, G., Ferraris, O., Lina, B., Rosa-Calatrava, M., & Moules, V. (2009). Cold oxygen plasma technology efficiency against different airborne respiratory viruses. Journal of Clinical Virology, 45(2), 119e124. rez Pulido, R., Abriouel, H., Grande, M. J., & Ga lvez, A. (2012). InactiToledo, J., Pe vation of Salmonella enterica cells in Spanish potato omelette by high hydrostatic pressure treatments. Innovative Food Science & Emerging Technologies, 14, 25e30. Tomasula, P. M., Renye, J. A., Van Hekken, D. L., Tunick, M. H., Kwoczak, R., Toht, M., Leggett, L. N., Luchansky, J. B., Porto-Fett, A. C. S., & Phillips, J. G. (2014). Effect of high-pressure processing on reduction of Listeria monocytogenes in packaged Queso Fresco. Journal of Dairy Science, 97(3), 1281e1295. € pfl, S. (2011). Pulsed Electric Field food treatment - scale up from lab to industrial To scale. Procedia Food Science, 1, 776e779. € pfl, S. (2006). Pulsed Electric Fields (PEF) for permeabilization of cell Membranes in To food- and bioprocessing applications, process and equipment design and cost analysis. Berlin: Berlin University of Technology. Tran, M. T. T., & Farid, M. (2004). Ultraviolet treatment of orange juice. Innovative Food Science & Emerging Technologies, 5(4), 495e502. Turner, C. W. (2010). Microbiology of ready-to-eat poultry products. In I. GuerreroLegarreta, & Y. H. Hui (Eds.), Handbook of poultry science and technology (pp. 507e515). Hoboken: John Wiley & Sons, Inc. Ugarte-Romero, E., Feng, H., Martin, S. E., Cadwallader, K. R., & Robinson, S. J. (2006). Inactivation of Escherichia coli with power ultrasound in apple cider. Journal of Food Science, 71(2), E102eE108. Unluturk, S., Atılgan, M. R., Handan Baysal, A., & Tarı, C. (2008). Use of UV-C radiation as a non-thermal process for liquid egg products (LEP). Journal of Food Engineering, 85(4), 561e568. €limaa, A.-L., Tilsala-Timisja €rvi, A., & Virtanen, E. (2015). Rapid detection and Va identification methods for Listeria monocytogenes in the food chain e a review. Food Control, 55, 103e114. Walker, S. J., Archer, P., & Banks, J. G. (1990). Growth of Listeria monocytogenes at refrigeration temperatures. The Journal of Applied Bacteriology, 68(2), 157e162. Wingstrand, A., & Aabo, S. (2014). Microbiological safety of meat j Salmonella spp. In M. Dikeman, & C. Devine (Eds.), Encyclopedia of meat sciences (2nd ed., pp. 367e375). Oxford: Academic Press. Yin, F., Zhu, Y., Koutchma, T., & Gong, J. (2015). Inactivation and potential reactivation of pathogenic Escherichia coli O157:H7 in bovine milk exposed to three monochromatic ultraviolet UVC lights. Food Microbiology, 49, 74e81. lez, A., Qin, B.-L., Barbosa-Ca novas, G. V., & Zhang, Q., Monsalve-Gonza Swanson, B. G. (1994). Inactivation of Saccharomyces cerevisiae in apple juice by square-wave and exponential-decay pulsed electric fields. Journal of Food Process Engineering, 17(4), 469e478. Zinoviadou, Kyriaki G., Galanakis, Charis M., Brn ci c, Mladen, Grimi, Nabil, Boussetta, Nadia, Mota, Maria J., Saraiva, Jorge A., Patras, Ankit, Tiwari, Brijesh, & Barba, Francisco J. (2015). Fruit juice sonication: Implications on food safety and physicochemical and nutritional properties. Food Research International, 77(Part 4), 743e752. Ziuzina, D., Han, L., Cullen, P. J., & Bourke, P. (2015). Cold plasma inactivation of internalised bacteria and biofilms for Salmonella enterica serovar typhimurium, Listeria monocytogenes and Escherichia coli. International Journal of Food Microbiology, 210, 53e61.