2023 Normal stress distribution-Saint Venant principle and stress concentration

advertisement

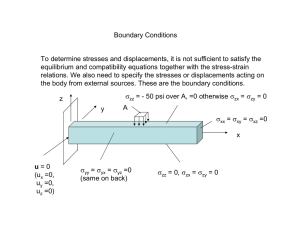

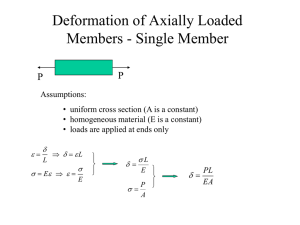

ENGINEERING STRENGTH OF MATERIALS II (MST21A) 1. Normal stress distribution 2. Sai nt Venant ’s pr i nci pl e 3. Stress concentration What you should know Before you start with this lecture, you should be able to do the following: 1. Draw a free body diagram 2. Apply the conditions for static equilibrium Expected outcomes Upon completion of this lecture, you should be able to do the following: 1. To represent the stress due to applied load on a section 2. To understand and use Saint Venant’s principle for calculation of stress applied on a section 3. To identify regions of stress concentration Background 1. Stress is a means of measuring the force distribution within a body 2. Strain is a means of measuring a body’s deformation 3. The mathematical relationship between stress and strain depends on the type of material from which the body is made. 4. If the material behaves in a linear elastic manner, then Hooke’s law applies, and there is a proportional relationship between stress and strain. 1. Normal stress distribution in axially loaded bars If a load P is applied at one free end of a prismatic bar, 1. The once horizontal and vertical grid lines drawn on the bar become distorted, and localized deformation occurs at each end 2. Throughout the midsection of the bar, the lines remain horizontal and vertical. Normal stress distribution in axially loaded bars • For axially loaded bars, we assume average UNIFORM STRESS over the cross-sectional area. • Considering the manner in which a rectangular bar will deform elastically when the bar is subjected to the force P applied along centroidal axis: its Stresses in axially loaded bars 3. A variation of stress distribution occur at sections a–a, b–b, and c–c, as shown. 4. If the material remains elastic, then the strains caused by this deformation are directly related to the stress in the bar through Hooke’s law, 𝜎 = 𝐸𝜀. Stresses in axially loaded bars 3. By comparison, the stress tends to reach a uniform value at section c–c, which is sufficiently removed (located far) from the end since the localized deformation caused by P vanishes. 4. The minimum distance from the bar’s end where this occurs can be determined using a mathematical analysis based on the theory of elasticity. 5. It has been found that this distance should at least be equal to the largest dimension of the loaded cross section. 6. Hence, section c–c should be located at a distance at least equal to the width (not the thickness) of the bar. 2. Saint-Venant’s principle 7. The fact that the localized stress and deformation behave in this manner is known as the Saint-Venant’s principle. 8. The Saint-Venant’s principle states that: The stress and strain produced at a point in a body, at a sufficient certain distance from the point of application of the external load P, will be the same as the stress and strain produced any applied external load that has the same statically equivalent RESULTANT, and being applied to the body within the same region. In other words, Saint-Venant’s principle states that if the forces acting on a small portion of an elastic body are replaced by a statically equivalent system of forces on the same portion of the surface, the effect upon the stresses in the body is negligible except in the immediate area affected by the applied forces. The stress field remains unchanged in areas of the body which are relatively distant from the surfaces upon which the forces are changed. Statically equivalent systems implies that the two distributions of forces have the same resultant force and moment. Add a Footer 1 10 0 Saint-Venant’s principle For example, if two symmetrically applied forces P / 2 act on the bar, the stress distribution at section c–c will be the same and therefore equivalent to 𝜎𝑎𝑣𝑔 = 𝑃 𝐴 3. Stress concentration in axially loaded bars 1. Discontinuities in a bar such as holes, grooves etc. result in a change of stress at these regions 2. Stresses may be higher in these regions 3. These regions of higher stress is known as stress concentrations 4. Stress concentrations can also occur at point loads application. at the point of Stress concentration in axially loaded bars Zone of stress concentration Simulation with The Finite Element Method (FEM) allows to visualize the stress distribution along the bar. The red color indicates zones (regions) with higher stress (Stress concentration) usually in transition zones such as corners, fillets or holes.