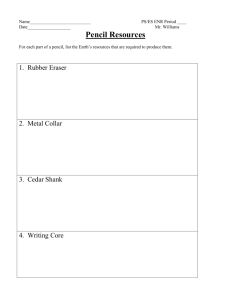

materials Review Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite Maciej Dutkiewicz 1, * , Hasan Erhan Yücel 2 1 2 3 * Citation: Dutkiewicz, M.; Yücel, H.E.; Yıldızhan, F. Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite. Materials 2022, and Fatih Yıldızhan 3 Faculty of Civil and Environmental Engineering and Architecture, Bydgoszcz University of Science and Technology, 85-796 Bydgoszcz, Poland Civil Engineering Department, Engineering Faculty, Niğde Ömer Halisdemir University, Niğde 51240, Turkey Civil Engineering Department, Engineering Faculty, Gaziantep University, Gaziantep 27310, Turkey Correspondence: macdut@pbs.edu.pl Abstract: Production of cement and aggregate used in cement-based composites causes many environmental and energy problems. Decreasing the usage of cement and aggregate is a crucial and currently relevant challenge to provide sustainability. Inert materials can also be used instead of cement and aggregates, similar to pozzolanic materials, and they have positive effects on cement-based composites. One of the inert materials used in cement-based composites is wollastonite (calcium metasilicate-CaSiO3 ), which has been investigated and attracted attention of many researchers. This article presents state-of-the-art research regarding fibrous concretes produced with wollastonite, such as mortars, conventional concrete, engineered cementitious composites, geopolymer concrete, selfcompacting concrete, ultra-high-performance concrete and pavement concrete. The use of synthetic wollastonite, which is a novel issue, its high aspect ratio and allowing the use of waste material are also evaluated. Studies in the literature show that the use of wollastonite in different types of concrete improves performance properties, such as mechanical/durability properties, and provides environmental–economic efficiency. It has been proven by studies that wollastonite is a material with an inert structure, and, therefore, its behavior is similar to that of a fiber in cementitious composites due to its acicular particle structure. Keywords: wollastonite; fibrous concrete; mechanical properties; durability properties 15, 6904. https://doi.org/10.3390/ ma15196904 Academic Editors: Nikolai Vatin and G. Murali Received: 10 August 2022 Accepted: 28 September 2022 Published: 5 October 2022 Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. Copyright: © 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https:// creativecommons.org/licenses/by/ 4.0/). 1. Introduction Concrete, which is the most used construction material thanks to its superior properties [1], increases production every year, and it is estimated that it reaches approximately 11 billion metric tons annually [2–4]. Cement, which constitutes 10–15% of concrete by volume [4,5], is the most expensive component of concrete and causes the main environmental and energy consumption problems [6,7]. For example, cement, which is responsible for over 5% of global CO2 emissions [8,9], generates approximately 50% of these emissions during the calcination phase of carbonate raw material [9–11]. Because global CO2 emissions reached approximately 30 billion tons with an increase of 2% in 2020 [12], along with the increasing global warming effect, production of cement must be reduced. In addition to this problem, environmental and energy problems in the supply and transportation of aggregate must be considered for concrete production. The usage of pozzolanic additives, such as fly ash, blast furnace slag and silica fume, which have binding properties, has been experimented with in many studies to reduce cement or aggregate production. These pozzolanic additives have enhanced the performance properties of concrete and have reduced devastating environmental problems in cement-aggregate production. Not only pozzolanic materials but also inert materials can be used as alternatives to cement or aggregates [13]. One of the most used inert materials is wollastonite. Wollastonite was discovered in 1886 by British chemist Sir Wollaston and was named after him [14,15]. Wollastonite, Materials 2022, 15, 6904. https://doi.org/10.3390/ma15196904 https://www.mdpi.com/journal/materials Materials 2022, 15, x FOR PEER REVIEW 2 of 20 Materials 2022, 15, 6904 2 of 18 production. Not only pozzolanic materials but also inert materials can be used as alternatives to cement or aggregates [13]. One of the most used inert materials is wollastonite. Wollastonite was discovered in which consists of two main basic components, 48.3% CaO and 51.7% SiO2 , has a molecular 1886 by British chemist Sir Wollaston and was named after him [14,15]. Wollastonite, weight of 116.2 [15–17]. The chemical composition of wollastonite is provided in Table 1. which consists of two main basic components, 48.3% CaO and 51.7% SiO2, has a molecular Small amounts of Al2 O3 , Fe2 O3 , MgO and Na2 O could also be available in the chemical weight of 116.2 [15–17]. The chemical composition of wollastonite is provided in Table 1. composition of wollastonite. Wollastonite is also called calcium metasilicate, and the Small amounts of Al2O3, Fe2O3, MgO and Na2O could also be available in the chemical chemical formula of this mineral is CaSiO3 [18]. A scanning electron microscopy (SEM) composition of wollastonite. Wollastonite is also called calcium metasilicate, and the image of wollastonite is shown in Figure 1. It is a white-colored natural mineral that chemical formula of this mineral is CaSiO3 [18]. A scanning electron microscopy (SEM) occurs as a result of a reaction between limestone and silica at 400 ◦ C–450 ◦ C, and it image wollastonite is shownshape in Figure 1. It is a white-colored natural that occurs has an of acicular or needle-like [13,14,19–21]. The melting pointmineral of wollastonite is as a result of the a reaction between limestone and silica at is 400 °C–450 °C, and hasrange an acic◦ C [15], 1540 modulus of elasticity of wollastonite approximately in itthe of ulartoor needle-like shape [13,14,19–21]. The melting in point of wollastonite 1540 °C [13]. [15], 300 530 GPa and the tensile stress is approximately the range of 2700 to is 4100 Mpa the modulus of elasticity of wollastonite is approximately in the range of 300 to 530 GPa Wollastonite has thermal stability, low dielectric constant, low dielectric loss, corrosion and the tensile stress is approximately in the range of 2700 to 4100 Mpa [13]. Wollastonite resistance and chemical inertness [22–25]. Therefore, wollastonite has a very wide usage has thermal dielectric low many dielectric loss, corrosion resistance and area, such asstability, ceramic,low dental, paintconstant, plastic and other fields [26–28]. Moreover, chemical inertness [22–25]. Therefore, wollastonite has a very wide usage area, such as wollastonite can enhance environmental sustainability and durability properties in cementceramic, dental, paint plastic and many other fields [26–28]. Moreover, wollastonite can based composites [13], and it has the capability to decrease the cost of cement-based enhance environmental durability properties in cement-based compocomposites. However, itssustainability availability isand limited because it is a natural mineral [14]; thus, sites [13], and it has the capability to decrease the cost of cement-based composites. Howresearchers have focused on production of synthetic wollastonite [7,13,29]. ever, its availability is limited because it is a natural mineral [14]; thus, researchers have focused on production of synthetic wollastonite [7,13,29]. Table 1. Chemical composition of wollastonite based on Ref. [7]. Chemical Analysis of (%) Table 1. Chemical composition wollastonite based on Ref. [7]. CaO Chemical Analysis (%) SiO2 CaO Al2 O3 SiO AlFe 2O 23O3 Fe2MgO O3 MgO SO3 SO3 K2 O K2O Na2 O Na2O TiO TiO2 2 Figure 1. SEM image of wollastonite. Wollastonite 44.55 Wollastonite 50.78 44.55 0.83 50.78 0.17 0.83 0.17 0.47 0.47 0.04 0.04 0.001 0.001 0.363 0.363 0.49 0.49 Materials 2022, 15, 6904 3 of 18 Wollastonite can be artificially synthesized with different materials. For example, it was produced with eggshell and silica [30], rice husk ash, silica ferrochrome, diatomite, quartz and calcined marble tailings in the literature [14,31]. Protection of natural wollastonite resources and use of waste material provide a significant advantage for synthetic wollastonite. There are three different methods for production of synthetic wollastonite. These methods are the wet method, which has lower than 200 ◦ C and high pressure; the solid-state reaction method, which involves reaction of silica with calcium oxide or calcium carbonate at a temperature higher than 800 ◦ C and liquid phase reaction method, which is higher than 1400 ◦ C [13]. Each method contains different advantages and disadvantages in itself. However, the aspect ratio of synthetic wollastonite with acicular particle structure is not as high as that of natural wollastonite. Therefore, a new technique that brings together the three-step process, which includes the mechanochemical process, hydrothermal process and solid-state reaction, was developed [13]. Wollastonite is available in nature with aspect ratios of 3:1 to 20:1 [32], but wollastonite with an aspect ratio of 23:1 [13] and even 44:1 [33] was developed in productions synthetically. Therefore, the use of synthetic wollastonites in cement-based composites or in different fields is precious and has a promising future to study. In recent years, many studies have been conducted on the use of both natural wollastonite and synthetic wollastonite in cement-based composites. Especially, the use of synthetic wollastonite is novel and contains valuable findings for future studies regarding cement-based composites because of the high aspect ratios of acicular particle structure. In this study, use of wollastonite in mortar, conventional concrete, engineered cementitious composites, geopolymer concrete, self-compacting concrete, ultra-high-performance concrete and pavement concrete was investigated. The effects of wollastonite usage in different cementitious composites on the physical, mechanical and durability properties were presented and discussed. In addition, general evaluations were conducted according to these discussions. Finally, suggestions were put forward regarding possible future research directions. 2. Cement Paste and Mortar Cement paste consists of cement and water; mortar consists of cement, water and fine aggregate. Studies on cement paste or mortar were performed in the form of using wollastonite replacement of sand and/or cement. Doner et al. [34] used 5% and 10% wollastonite by mass replacement of cement in their study. Figure 2 shows the fracture toughness of wollastonite content. They observed that the use of 5% and 10% wollastonite increased the fracture toughness by 17.88% and 33.71%, respectively. The toughening effects of wollastonite usage result from the acicular nature of wollastonite that significantly bridge cracks at the micro-level. In this way, it delays microcrack coalescence. In a study where natural wollastonite from 0% to 15% by 3% increments was used instead of cement [35], the best mixture containing 3% wollastonite performed better than the control mixture for capillary water permeability and gas permeability. The compressive and flexural strengths of the mixtures are provided in Figure 3. The strength increase in the use of 3% wollastonite could be explained by the acicular particle structure and high modulus of elasticity of the wollastonite. The use of wollastonite at rates of 6% or more could cause deterioration of the microstructure and decrease in strength. In some studies, comparisons were performed by using wollastonite and an additional material. In a study in which the effect of wollastonite average particle size was taken into account, 3.5 µm and 9.0 µm average particle size wollastonite was used at a rate of 10%, 20%, 30%, 40% and 50% by mass in replacement of cement [36]. In addition, the results of wollastonite and limestone were compared by using limestone in the same proportions. The use of wollastonite decreased the workability of mortar mixes but increased cement hydration. Using 10% limestone reduced the compressive strength of the mortar by approximately 20%. For the same strength range, wollastonite-3.5 µm can be used in replacement of 40% cement. The use of wollastonite-3.5 µm instead of 30% of the cement reduced the 28-day compressive strength by only a rate of 10%. In other words, wollastonite can be used to replace high ratio of cement up to 30% in mixes without remarkably reducing strength. Dey et al. [28] took into Materials 2022, 15, 6904 4 of 18 account aspect ratio in addition to average particle size. They used 5% silica fume instead of cement to form a control mixture and also 5%, 10% and 15% wollastonite instead of cement; four grades of wollastonite fibers with average particle size ranging from 33 to 2000 µm, with aspect ratios varying from 3:1 to 20:1, were used. The results of the study showed that the wollastonite fibers moderately increased the compressive strength and also significantly increased the fracture strength and toughness and, finally, enhanced ductility. At optimum dosage, an increase in 28-day compressive strength up to 30%, an increase in flexural strength of up to 41% and an increase in toughness of up to 147% were observed compared to the control mixture. The crack results of this study are provided in Figure 4. C refers to coarse grades, F refers to fine grades and the number refers to the average particle size in Figure 4. Wollastonite increased crack growth resistance. This can be attributed to matrix packing and its bridging of microcracks that lead to delayed microcrack coalescence thanks to usage of wollastonite. Moreover, the optimum replacement was dependent on the wollastonite fiber type. In a study where wollastonite and additional material were evaluated instead of cement, Ransinchung and Kumar [20] investigated the effect of wollastonite, microsilica and combination of wollastonite + microsilica on cement-based composites. Wollastonite increased the initial–final setting time, and 10% wollastonite+7.5% microsilica combination provided the highest strength value. The combination of 15% wollastonite+7.5% microsilica also showed higher strength than the control mix. In a study in which wollastonite was used instead of both sand and cement, 10%, 20% and 30% wollastonite were used instead of sand and cement, thus forming seven mixtures including the control mixture [37]. The initial setting time increased by using wollastonite, but this increase had a negligible effect on cement replacement. The use of wollastonite up to 20% instead of sand increased the compressive and flexural strength. When using wollastonite instead of 20% sand, 28-day compressive strength increased by 45%, and flexural strength increased by 28% compared to the control mixture. The mechanical strength of using wollastonite instead of 30% sand was also higher than the control mixture. When using wollastonite instead of 10% cement, the compressive strength decreased by 12% and the flexural strength decreased by 2% compared to the control mixture. The strengths were much lower when wollastonite was used instead of 20–30% cement. The total shrinkage strain is displayed in Figure 5. Usage of wollastonite decreased the drying shrinkage with 30% cement replacement and 30% sand replacement at the rates of 47% and 44%, respectively. From the studies, the increase in strength and durability with the use of wollastonite was attributed to the effect of densifying the microstructure of the matrix and the filling effect of wollastonite. Leeman et al. [38] used carbonated wollastonite clinker instead of 30% of cement by weight. They found that this mixture increased the Si/Ca ratio by 15% compared to the control mixture4 but decreased Materials 2022, 15, x FOR PEER REVIEW of 20 the 28-day compressive strength by 7.8%. 10 mN/s 20 mN/s 30 mN/s Wollastonite content 10% 5% 0% 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 Fracture toughness, K1c (MPa-m0.5) Figure 2. Fracture toughness of wollastonite content based on Ref. [34]. Figure 2. Fracture toughness of wollastonite content based on Ref. [34]. ngth (MPa) 80 70 60 50 0.9 0% 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 Fracture toughness, K1c (MPa-m0.5) Materials 2022, 15, 6904 5 of 18 Figure 2. Fracture toughness of wollastonite content based on Ref. [34]. Compressive strength (MPa) 80 70 60 50 40 30 20 10 0 W 7 days Materials 2022, 15, x FOR PEER W=Natural wollastonite REVIEWSW= Synthetic wollastonite SW 7 days 0% 3% 6% W 28 days 9% 12% 15% SW 28 days 5 of 20 (a) 12 Materials 2022, 15, x FOR PEER REVIEW 6 of 20 Flexural strength (MPa) 10 of sand and cement, thus forming seven mixtures including the control mixture [37]. The initial setting time increased by using wollastonite, but this increase had a negligible effect on cement replacement. The use of wollastonite up to 20% instead of sand increased the 6 compressive and flexural strength. When using wollastonite instead of 20% sand, 28-day compressive strength increased by 45%, and flexural strength increased by 28% compared 4 to the control mixture. The mechanical strength of using wollastonite instead of 30% sand was also higher than the control mixture. When using wollastonite instead of 10% cement, 2 the compressive strength decreased by 12% and the flexural strength decreased by 2% compared to the control mixture. The strengths were much lower when wollastonite was 0 used insteadSW of 720–30% cement. The total shrinkage strain is displayed in Figure 5. Usage W 7 days days W 28 days SW 28 days of wollastonite decreased the drying shrinkage with 30% cement replacement and 30% W=Natural wollastonite 3% 6% sand 0% replacement at the9% rates12% of 47%15% and 44%, respectively. From the studies, the increase SW= Synthetic wollastonite in strength and durability with the use of wollastonite was attributed to the effect of den(b) sifying the microstructure of the matrix and the filling effect of wollastonite. Leeman et al. [38] used carbonated wollastonite clinker instead of 30% of cement by weight. They found Figure 3. (a) Compressive and (b) flexural strengths of natural wollastonite and synthetic wollastonite thatand this(b)mixture Si/Ca ratio by 15% and compared to wollasthe control mixture but Figure 3. (a) Compressive flexuralincreased strengths the of natural wollastonite synthetic basedbased on Refs. [13,35]. decreased the 28-day compressive strength by 7.8%. tonite on Refs. [13,35]. 8 Wollastonite fiber In some studies, comparisons were performed by using wollastonite and an addiControl 10% 15%average particle size was tional material. In a study in which the effect 5% of wollastonite taken into account, 3.5 µm and 9.0 µm average particle size wollastonite was used at a rate of 10%, 20%, 30%, 40% and 50% by mass in replacement of cement [36]. In addition, the F33 results of wollastonite and limestone were compared by using limestone in the same proportions. The use of wollastonite decreased the workability of mortar mixes but increased cement hydration. Using 10% limestone reduced the compressive strength of the mortar F55 by approximately 20%. For the same strength range, wollastonite-3.5 µm can be used in replacement of 40% cement. The use of wollastonite-3.5 µm instead of 30% of the cement reduced the 28-day compressive strength by only a rate of 10%. In other words, wollasC850 tonite can be used to replace high ratio of cement up to 30% in mixes without remarkably reducing strength. Dey et al. [28] took into account aspect ratio in addition to average particle size. They used 5% silica fume instead of cement to form a control mixture and C2000 also 5%, 10% and 15% wollastonite instead of cement; four grades of wollastonite fibers with average particle size ranging from 33 to 2000 µm, with aspect ratios varying from 3:1 Control to 20:1, were used. The results of the study showed that the wollastonite fibers moderately increased the compressive strength and also significantly increased the fracture strength 0 and toughness and, finally,5enhanced 10 ductility. At15optimum 20 dosage, an 25 increase in 30 28-day compressive strength up to 30%, an increase in flexural strength of up to 41% and an increase in toughness of up to 147% were observed to the control mixture. The Critical crackcompared length (mm) crack results of this study are provided in Figure 4. C refers to coarse grades, F refers to fine grades and the number thelength average particle size in Figure 4. Wollastonite Figure 4. refers Criticalto crack in cured 28 days based on Ref. [28]. Figure 4. Critical crack length in cured 28 days based on Ref. [28]. increased crack growth resistance. This can be attributed to matrix packing and its bridging of microcracks that lead to delayed microcrack coalescence thanks to usage of wollastonite. Moreover, the optimum replacement was dependent on the wollastonite fiber type. In a study where wollastonite and additional material were evaluated instead of cement, Ransinchung and Kumar [20] investigated the effect of wollastonite, microsilica and combination of wollastonite + microsilica on cement-based composites. Wollastonite increased 35 Materials 2022, 15, 6904 Materials 2022, 15, x FOR PEER REVIEW 6 of 18 7 of 20 Age (28 days) 30% cement 20% cement 10% cement 0% cement 30% sand 20% sand 10% sand 0% sand -400 -350 -300 -250 -200 -150 -100 -50 0 Total shrinkage strain (μm) Figure5.5. Total Total shrinkage shrinkage strain Figure strain based basedon onRef. Ref.[37]. [37]. Inaddition, addition, studies onon mortars were alsoalso carried In studies on onthe theuse useofofsynthetic syntheticwollastonite wollastonite mortars were carried out. Kalkan et al. [29] used 0%, 0.5%, 1%, 2%, 5%, 10%, 15% and 20% synthetic wollastonite out. Kalkan et al. [29] used 0%, 0.5%, 1%, 2%, 5%, 10%, 15% and 20% synthetic wollastonite insteadof ofcement. cement.The Theuse useofofwollastonite wollastonitereduced reducedthe theworkability, workability,and andthe theinitial initialand andfinal instead final setting times were delayed. Water absorption decreased up to 2% replacement. It setting times were delayed. Water absorption decreased up to 2% replacement. It enhanced enhanced at 2% replacement in the mechanical properties of mortars. Moreover, 5% reat 2% replacement in the mechanical properties of mortars. Moreover, 5% replacement placement can be a usable ratio and indicated higher strength than 0% replacement. The can be a usable ratio and indicated higher strength than 0% replacement. The increase in increase in flexural strength with the use of wollastonite was higher than the percent comflexural strength with the use of wollastonite was higher than the percent compressive pressive strength. Moreover, thermal conductivity decreased as replacement ratio instrength. Moreover, thermal conductivity decreased as replacement ratio increased. Yücel creased. Yücel and Özcan [13] formed a total of six mixtures, including a control mixture and Özcan [13] formed a total of six mixtures, including a control mixture and usage of and usage of wollastonite from 0% to 15% by 3% steps of increment replacing cement. wollastonite from 0% to 15% by 3% steps of increment replacing cement. Slump flow Slump flow diameter decreased with use of wollastonite. Figure 3 shows the compressive diameter decreased with use of wollastonite. Figure 3 shows the compressive and flexural and flexural strengths of synthetic wollastonite. The compressive and flexural strengths strengths wollastonite. Thetheir compressive and flexural strengths increased up to increasedofupsynthetic to 9% usage and reached maximum value at 9%. In addition, the me9% usage and reached their maximum value at 9%. In addition, the mechanical properties chanical properties of the 12% and 15% replacement mixtures provided better results than ofthe the 12% and 15% replacement mixtures fills provided betterstructure results than the control mixture. control mixture. Synthetic wollastonite the porous of cement and forms Synthetic wollastonite the porous of cement and andsynthetic forms a wollastonite more compact a more compact mortar fills [13,37,39]. When structure natural wollastonite mortar [13,37,39]. When to natural andthat synthetic wollastonite are compared, according Figurewollastonite 3, it is observed the optimum dosage are andcompared, rate of according to Figure is observed that the optimum dosage of increase are higher increase are higher 3, foritsynthetic wollastonite. The SEM imagesand andrate energy dispersive Xfor synthetic wollastonite. The SEM images and energy dispersive X-ray (EDX) analysis ray (EDX) analysis of synthetic wollastonite are presented in Figure 6. The acicular strucof synthetic wollastonite areispresented ininFigure acicular structure synthetic ture of synthetic wollastonite also shown Figure6.6. The The enhancement in the of mechanwollastonite is also shown in Figure 6. The enhancement in the mechanical properties ical properties can be explained by the physical property (acicular structure) of synthetic can be explained acting by the as physical (acicular structure) synthetic wollastonite acting wollastonite a fiber property in the matrix. Moreover, theseofresults supported that synas a fiber in the matrix. Moreover, these results supported that synthetic wollastonite thetic wollastonite is an inert material and, thus, does not show any chemical reaction.is an inert material thus, does any of chemical reaction. CaCOÖz to decrease CaCO to decrease withnot theshow addition synthetic wollastonite. and Güneş [7], 3 tendedand, 3 tended with theother addition of examined synthetic wollastonite. and Güneş [7], on the hand, examined on the hand, the effects of Öz synthetic wollastonite on other high-performance mortars. of five mixtures wereon formed: control mixture and usage of synthetic wolthe effectsAoftotal synthetic wollastonite high-performance mortars. A total of five mixtures lastonite at 3%, 6%, 9% and 12% of cement. Use of wollastonite reduced were formed: control mixture andratios usageinstead of synthetic wollastonite at 3%, 6%, 9% and 12% workability. compressive and flexural strengths increased up to The 9% usage. At 12%and ratios insteadThe of cement. Use of wollastonite reduced workability. compressive usage, the mechanical properties thoseusage, of the the control mix. Theproperties water flexural strengths increased up towere 9% worse usage.than At 12% mechanical sorptivity is of provided in Figure 7. The performance water in were worsecoefficient than those the control mix. The water sorptivityproperties coefficientofisthe provided sorptivity coefficient, rapid properties chloride permeability gas permeability, were Figure 7. The performance of the waterand sorptivity coefficient,which rapid chloride tested for durability, improved up to 9% usage. Thanks to the synthetic wollastonite filling permeability and gas permeability, which were tested for durability, improved up to 9% usage. Thanks to the synthetic wollastonite filling effect, the microstructure in the cement matrix condensed. Therefore, synthetic wollastonite reduced the water absorption of the Materials 2022, 15, x FOR PEER REVIEW Materials 2022, 15, 6904 Materials 2022, 15, x FOR PEER REVIEW 8 of 20 7 of 18 8 of 20 effect, the microstructure in the cement matrix condensed. Therefore, synthetic wollaston- material andmicrostructure provided pore discontinuity in condensed. the and cement [7,20,32,39]. While the Yücel iteeffect, reduced the water absorption of thematrix material provided pore discontinuity in theand the in the cement Therefore, synthetic wollastonite reduced thesynthetic water absorption of the material and pore in the it was cement [7,20,32,39]. While the Yücel and Özcanwas [13] provided 12% synthetic wollastonite mixture Özcan [13] 12% wollastonite mixture better than thediscontinuity control mixture, cement While the Yücel Özcan 12% synthetic wollastonite mixture was better than the control mixture, itand was worse than theGüneş control mixture in the study by to worse than[7,20,32,39]. the control mixture in the study by [13] Öz and [7]; this difference is due was better than thethis control mixture, wastoworse than control in thewollastonite study by Öz and Güneş [7]; difference is itdue theup w/c Usage of synthetic the w/c ratio. Usage of synthetic wollastonite toratio. athe 10% ratio mixture also indicates very valuable Güneş this difference is due to the w/c ratio.for Usage synthetic wollastonite upÖz toand a 10% ratio[7]; also indicates very valuable future studies. When the mortar usage is findings for future studies. When the usage offindings wollastonite onofcement paste and up to a 10% ratio also indicates very valuable findings for future studies. When the usage of wollastonite on cement and mortar examined, it is that wollastonite was examined, it is found that paste wollastonite wasisused instead offound sand and/or cement; further, of wollastonite on cement paste and mortar is examined, itwere is found thatwith wollastonite was + used instead of sand and/or cement; further, these uses tested wollastonite these uses were tested with wollastonite + different material combinations. In addition, used instead of sand and/or cement; further, these were that tested with wollastonite + material combinations. In addition, it is uses observed synthetically produced itdifferent is observed that synthetically produced wollastonites were also used. Cement paste or different material combinations. In addition, it is observed that synthetically produced wollastonites werehigher also used. Cementand paste or mortars that havewere higher mechanical and of mortars that have mechanical durability withand usage wollastonites were also used. Cement paste or mortarsproperties that have higherformed mechanical durability properties were formed with usage of natural or synthetic wollastonite. natural or synthetic wollastonite. durability properties were formed with usage of natural or synthetic wollastonite. Figure 6. SEM images and EDX analysis of synthetic wollastonite. Figure EDX analysis analysisof ofsynthetic syntheticwollastonite. wollastonite. Figure6.6.SEM SEMimages images and EDX 28 days 28 days (mm/ min ) Water sorptivity coefficient Water sorptivity coefficient (mm/ min0.5)0.5 0.05 90 days 90 days 0.05 0.04 0.04 0.03 0.03 0.02 0.02 0.01 0.01 0 0 0% 0% 3% 6% 9% 3% 6% Synthetic wollastonite content9% 12% 12% Synthetic wollastonite content Figure 7. The water sorptivity coefficient and synthetic wollastonite content based on Ref. [7]. Figure 7. The water sorptivity coefficient and synthetic wollastonite content based on Ref. [7]. 3. Conventional Figure 7. The water Concrete sorptivity coefficient and synthetic wollastonite content based on Ref. [7]. Concrete is formed by mixing cement, water, coarse aggregate, fine aggregate, chemical additives and mineral additives at a certain rate. The usage of wollastonite in concrete Conventional Concrete Concrete 3.3.Conventional Concreteisisformed formedby by mixing mixing cement, cement, water, water, coarse coarse aggregate, Concrete aggregate, fine fine aggregate, aggregate,chemchemical ical additives and mineral additives at a certain rate. The usage of wollastonite concretewas additives and mineral additives at a certain rate. The usage of wollastonite ininconcrete performed in three different ways: replacement of sand, cement and their combination. Kh [40] used 10%, 15% and 20% wollastonite by mass replacement of sand. A compressive toughness test, which is significant for quantitative analysis of the energy distributing ability of materials, was implemented for these mixtures. It was observed that the use of 15% wollastonite Materials 2022, 15, x FOR PEER REVIEW was performed in three different ways: replacement of sand, cement and their combina- 8 of 18 tion. Kh [40] used 10%, 15% and 20% wollastonite by mass replacement of sand. A compressive toughness test, which is significant for quantitative analysis of the energy distributing ability of materials, was implemented for these mixtures. It was observed that the increased 23–25% in 28-day results compared to the control mixture. This increase was use of 15% wollastonite increased 23–25% in 28-day results compared to the control mixobserved as 20% at 10% usage of wollastonite. In a study evaluating the durability properties, ture. This increase was observed as 20% at 10% usage of wollastonite. In a study evaluatAziza and Kh [41] used wollastonite replacement of 30% sand and found that it improved ing the durability properties, Aziza and Kh [41] used wollastonite replacement of 30% the durability by 32%. a studyproperties where wollastonite used in replacement sand and foundproperties that it improved the In durability by 32%. In awas study where wolof cement, 5% and 10% wollastonite were used [42]. It was determined that lastonite was used in replacement of cement, 5% and 10% wollastonite were used the [42].use It of 10% wollastonite increased the compressive toughness by 40% and the flexure toughness was determined that the use of 10% wollastonite increased the compressive toughness by by 32%. These values were increased 20% at 5% usage, respectively. In a20% study 40% and the flexure toughnessby by 21% 32%. and These values were increased by 21% and at where 5% w/b usage,ratio respectively. In into a study wherein theaddition w/b ratiotowas into account in addition the was taken account thetaken use of wollastonite replacement of to the use wollastonitestrength replacement of cement, strength increased cement, theofcompressive increased up tothe usecompressive of 10% wollastonite in all w/bup ratios [32]. to use ofstrength 10% wollastonite allto w/b [32].wollastonite Flexural strength upand to use of Flexural increasedinup useratios of 15% at 0.55increased w/b ratio increased up at 0.55 w/batratio to usePorosity of 10% wollastonite at 0.50 replacement and to15% usewollastonite of 10% wollastonite 0.50and andincreased 0.45 w/bup ratios. and wollastonite w/b ratios. Porosity andnoted wollastonite is provided in Figure 8. Asofnoted is0.45 provided in Figure 8. As in otherreplacement studies [7,13,20,32,39], the addition wollastonite in other studies [7,13,20,32,39], the addition of wollastonite resulted in reduced pores and resulted in reduced pores and densification of the concrete microstructure. It was found that densification of the concrete microstructure. It was found that 10–15% wollastonite sub10–15% wollastonite substitution instead of cement improves the durability properties of stitution instead of cement improves the durability properties of concrete, such as water concrete, suchporosity, as watercarbonation, permeability, porosity, carbonation, chloride andracorrosion, permeability, chloride diffusion and corrosion, in diffusion different w/b intios. different w/b ratios. 0% 5% 10% 15% 20% 25% 12 Total Porosity (%) Materials 2022, 15, 6904 9 of 20 10 8 6 4 2 0 w/b 0.55 w/b 0.50 w/b 0.45 Figure 8. Porosity and wollastonite replacement based on Ref. [32]. Figure 8. Porosity and wollastonite replacement based on Ref. [32]. In some studies for concrete, different material combinations were attempted, includIn some studies for concrete, different material combinations were attempted, ining wollastonite replacement of cement or replacement of cement+fine aggregate. Kalla et cluding wollastonite replacement of cement or replacement of cement+fine aggregate. al. [43] examined the effect of the combination of wollastonite and fly ash replacement of Kalla et al. [43]into examined of the combination of ash wollastonite and fly ash cement, taking accountthe theeffect w/b ratio. They used 40% fly (fixed ratio) instead of replacement of as cement, into account the25% w/b They used 40% ash (fixed ratio) cement, well as taking wollastonite from 0% to by ratio. 5% steps of increment in fly replacement instead of The cement, as well as wollastonite from 0%ofto55% 25% by 5% steps of increment in of cement. mechanical properties increased up to use combination wollastonite replacement of(40%) cement. increased tocombination use of 55% combination (15%) + fly ash at a The 0.55 mechanical w/b ratio andproperties increased up to use ofup 60% wollastonite (20%)(15%) + fly ash (40%) 0.50 and w/bw/b ratios. Additionally, permeability wollastonite + fly ashat(40%) at a0.45 0.55 ratio and increased up to 55– use of 60% 60%, carbonation resistance (20%) 45%, diffusion corrosion 45–55% and shrinkage recombination wollastonite + fly ash45–60%, (40%) at 0.50 and 0.45 w/b ratios. Additionally, sistance at the55–60%, rate of 55–60% wollastonite+fly combination enhancedcorrosion its durability permeability carbonation resistance ash 45%, diffusion 45–60%, 45–55% and properties.resistance It was found the usage of wollastonite + fly ash combination in the range shrinkage at that the rate of 55–60% wollastonite+fly ash combination enhanced its of 40–55% and wollastonite in the range of 5–15% affect the mechanical and durability durability properties. It was found that the usage of wollastonite + fly ash combination properties of concrete positively. The wollastonite + fly ash combination was investigated in the range of 40–55% and wollastonite in the range of 5–15% affect the mechanical and durability properties of concrete positively. The wollastonite + fly ash combination was investigated in replacement of both cement and sand in another study [39]. It was stated that the mixture of fly ash instead of 20% cement + wollastonite instead of 10% sand increased the 28-day compressive strength by 28% and flexural strength by 36% compared to the mixture using only fly ash in replacement of cement at 20%. In addition, it was stated that the combination of fly ash in replacement of 20% cement + wollastonite in replacement of 10% sand and only wollastonite in replacement of 10% sand showed higher mechanical strength compared to the control mixture (no fly ash and no wollastonite). Materials 2022, 15, 6904 9 of 18 Finally, it was found that the usage of wollastonite (single or in combination with fly ash) reduces water absorption, drying shrinkage and abrasion loss. These findings obtained from the studies [39,43] show that fly ash and wollastonite could be a preferable alternative material combination. In another study, the use of 10% wollastonite in replacement of cement was taken as a fixed ratio, and, furthermore, waste granite fine was used at a rate of 10%, 20%, 30%, 40% and 50% in replacement of fine aggregate [44]. A mix design of concretes is provided in Table 2. Indeed, the 20% waste granite fine + 10% wollastonite combination mixture, which provided the best results, increased the compressive strength by 5.7% compared to the control mixture, and the 10% waste granite fine + 10% wollastonite combination and 30% waste granite fine + 10% wollastonite combination mixtures showed superior mechanical properties compared to the control mixture. Further, the 10–20% and 30% waste granite fine + 10% wollastonite combination mixture showed superior durability properties compared to the control mixture, but other mixtures (40% and 50% waste granite fine+10% wollastonite combination) showed worse properties than the control mixture. According to the findings obtained from the studies [32,43,44], generally, 10% was found as the optimum ratio for the usage of wollastonite in replacement of cement. Moreover, the use of 10–15% wollastonite has positive effects on durability properties [32,39,44]. When usage of wollastonite on concrete is examined, it is observed that wollastonite was used instead of sand and/or cement; further, these uses were tested with wollastonite + different material combinations, similar to mortar. Moreover, it is observed that waste materials were used in concrete. The use of a combination of wollastonite and waste material is crucial for forming sustainable concrete due to the reduction in cement use and recycling of waste material. Table 2. Mix design of concrete (kg/m3 ) based on Ref. [44]. Mix W/b Ratio OPC * WF CA FA * WGF Water * SPDosage % 1 0.35 425 0 1298 628 0 148.75 1.25 2 0.35 382.5 42.5 1298 565.2 62.8 148.75 1.3 3 0.35 382.5 42.5 1298 502.4 125.6 148.75 1.5 4 0.35 382.5 42.5 1298 439.6 188.4 148.75 1.65 5 0.35 382.5 42.5 1298 376.8 251.2 148.75 1.9 6 0.35 382.5 42.5 1298 314 314 148.75 2.1 * WF = wollastonite fiber, WGF = waste granite fines, SP = high water reducing superplasticizer. 4. Engineered Cementitious Composite (ECC) Engineered cementitious composite (ECC) is defined as a special type of high-performance fiber concrete and shows strain hardening similar to a ductile material after the first crack and has approximately 300 to 500 times greater tensile strain capacity compared to conventional concretes. In a study conducted for ECC, synthetic wollastonites with different high aspect ratios were used instead of cement, fly ash and cement + fly ash [33]. The mini-v-funnel flow time values of ECCs are provided in Figure 9. Wollastonite with a 44:1 aspect ratio which was used as a cement replacement decreased workability. The decrease in the workability of the ECC is mainly caused by the interlocking of the acicular particle structure of wollastonite. The usage of synthetic wollastonite instead of fly ash or cement + fly ash enhanced the mechanical performance up to 6% in terms of compressive strength and flexural performance. Typical flexural strength and mid-span beam deflection curves are shown in Figure 10. Using synthetic wollastonite with a 44:1 aspect ratio exhibited behavior similar to a fiber compared to natural wollastonite. Therefore, a remarkable enhancement in ductility performance of ECCs was achieved. Finally, using wollastonite with a 44:1 aspect ratio showed better performance characteristics than wollastonite with a 30:1 aspect ratio. These findings show that a higher aspect ratio of synthetic wollastonite improves results. Therefore, synthetic wollastonite can be used because it has a higher aspect ratio than natural wollastonite. Although ECC shows Materials 2022, 15, 6904 strength and flexural performance. Typical flexural strength and mid-span beam deflection curves are shown in Figure 10. Using synthetic wollastonite with a 44:1 aspect ratio exhibited behavior similar to a fiber compared to natural wollastonite. Therefore, a remarkable enhancement in ductility performance of ECCs was achieved. Finally, using wollastonite with a 44:1 aspect ratio showed better performance characteristics than wol10 of 18 lastonite with a 30:1 aspect ratio. These findings show that a higher aspect ratio of synthetic wollastonite improves results. Therefore, synthetic wollastonite can be used because it has a higher aspect ratio than natural wollastonite. Although ECC shows superior performance characteristics compared to conventional concrete, it concrete, is costly due the polyvisuperior performance characteristics compared to conventional it is to costly due to the nyl alcohol (PVA) fiberfiber found in ECC and and absence of coarse aggregate [33].[33]. Wollastonite polyvinyl alcohol (PVA) found in ECC absence of coarse aggregate Wollastonite usable material material for producing without losing thethe performance isisaausable producingmore moreeconomical economicalECC ECC without losing performance characteristicsofofECC. ECC. characteristics Materials 2022, 15, x FOR PEER REVIEW Figure 9. Mini-v-funnel flow time values of ECCs based on Ref. [33]. Figure 9. Mini-v-funnel flow time values of ECCs based on Ref. [33]. 12 of 20 Figure 10. Typical flexural strength and mid-span beam deflection curve based on Ref. [33]. Figure 10. Typical flexural strength and mid-span beam deflection curve based on Ref. [33]. 5. Geopolymer Concrete 5. Geopolymer Concrete Geopolymer concrete is formed as a result of geopolymerization of aluminosilicate Geopolymer is formed as aslag result geopolymerization of aluminosilicate source materials concrete (such as fly ash, furnace andofmetakaoline) with sodiumor potassource materialsalkali (suchactivators as fly ash,[45,46]. furnace slag and metakaoline) sodiumor as potassiumsium-sourced Wollastonite was used as awith precursor (such fly ash slag or metakaolin), sand substitute or reinforcement with different material combinations in geopolymer concrete. When wollastonite was used instead of a precursor [47], usage of 10% wollastonite increased the strength properties in the range of 18–20%. In another study, in which wollastonite was used instead of both sand and a precursor [48], workability and setting time decreased with wollastonite. When wollastonite was used Materials 2022, 15, 6904 11 of 18 sourced alkali activators [45,46]. Wollastonite was used as a precursor (such as fly ash slag or metakaolin), sand substitute or reinforcement with different material combinations in geopolymer concrete. When wollastonite was used instead of a precursor [47], usage of 10% wollastonite increased the strength properties in the range of 18–20%. In another study, in which wollastonite was used instead of both sand and a precursor [48], workability and setting time decreased with wollastonite. When wollastonite was used instead of sand, use of 10% wollastonite increased the compressive strength by 17%, and use of 20% wollastonite increased the flexural strength by 43% compared to the control mixture. While usage of wollastonite instead of a precursor did not enhance the flexural strength, use of 10% wollastonite increased the compressive strength by approximately 17% compared to the control mixture. Bong et al. [49] used wollastonite instead of only sand and found that the setting time was reduced. Figure 11 shows the compressive and flexural strengths of the mold-cast geopolymers at 7 days, and a 10% replacement level was found as the optimum ratio, and, at this rate, the flexural strength increased by 54%, but the compressive decreased by 4% compared to the control mixture. The wollastonite was partially dissolved in the Materials 2022, 15, x FOR PEER REVIEW 13 of bonded 20 mixture because of an alkaline environment. Acicular wollastonite was partially to the geopolymer matrix, strengthened the matrix and enhanced the flexural strength. 0% 5% 10% 15% 20% 30% Flexural Compressive 0 10 20 30 40 50 60 70 Strength (MPa) Figure 11. Compressive and flexural strengths of the mold-cast geopolymers at 7 days based on Figure 11. Compressive and flexural strengths of the mold-cast geopolymers at 7 days based on Ref. [49]. Ref. [49]. In a study where wollastonite was used as a reinforcement, different material combiIn a study where wollastonite was used as a reinforcement, different material comnations were also tested in addition to wollastonite [50]. Substitution of metakaolin with binations were also tested in addition to wollastonite [50]. Substitution of metakaolin with 5% wollastonite, 5%tremolite tremolite and of short basalt reinforcement increased the 5% wollastonite, 5% and 2% 2% of short basalt fiber fiber reinforcement increased the compressive strength. In a study where polypropylene fiber, polyvinyl alcohol fiber and compressive strength. In a study where polypropylene fiber, polyvinyl alcohol fiber and wollastonite weretested, tested,usage usageofof polypropylene fiber, polyvinyl alcohol and wollaswollastonite were polypropylene fiber, polyvinyl alcohol fiber fiber and woltonite instead of of metakaolin 1% polypropylene polypropylenefiber fiber + 1% polyvinyl lastonite instead metakaolinwas wasexamined: examined: 1% + 1% polyvinyl al- alcohol coholand fiber15% andwollastonite 15% wollastonite 2% polyvinyl alcohol fibershowed showedthe thehighest highest comfiber + 2%+ polyvinyl alcohol fiber compressive pressive strengths [51]. Theof rates of increase 160%, respectively. It strengths [51]. The rates increase werewere 90%90% andand 160%, respectively. It also alsoinincreased creased flexural strength and sulfate attack resistance. In a study where wollastonite and flexural strength and sulfate attack resistance. In a study where wollastonite and glass fiber glassused fiber were used of metakaolin, use of wollastonite enhanced its viscosity were instead ofinstead metakaolin, use of wollastonite enhanced its viscosity and and mechanical mechanical properties [52]. Vishnu et al. [53] used wollastonite and graphene oxide in a properties [52]. Vishnu et al. [53] used wollastonite and graphene oxide in a self-compacting self-compacting geopolymer. It was found that wollastonite performed better with grageopolymer. It was found that wollastonite performed better with graphene. The improvephene. The improvement in the microstructure of the geopolymer matrix through mement in the microstructure of the geopolymer matrix through mechanical interlocking of chanical interlocking of unreacted wollastonite particles and bonding to the geopolymeric unreacted wollastonite and bonding to the geopolymeric gelproperties was attributed gel was attributed to theparticles improvement in the geopolymer’s performance [48]. to the improvement in the geopolymer’s performance properties [48]. Geopolymer has Geopolymer has attracted much attention in recent years as an alternative constructionattracted much attention in recent years as an alternative construction to concrete. material to concrete. The use of wollastonite in geopolymer can bematerial an applicable solution The use of geopolymerofcan be an applicable solutionand to overcome theperfordisadvantage towollastonite overcome theindisadvantage lower strength than concrete improve the mance of lowerfeatures. strength than concrete and improve the performance features. 6. Self-Compacting Concrete Self-compacting concrete is a concrete that can be compacted without requiring any labor and fills the formwork homogeneously thanks to its self-flowing feature [54]. Jindal et al. [54] used wollastonite instead of sand and found that cohesiveness increased and Materials 2022, 15, 6904 12 of 18 6. Self-Compacting Concrete Self-compacting concrete is a concrete that can be compacted without requiring any labor and fills the formwork homogeneously thanks to its self-flowing feature [54]. Jindal et al. [54] used wollastonite instead of sand and found that cohesiveness increased and water absorption decreased. The use of wollastonite at rates of up to 30% increased the flexural strength, while it did not have a positive effect on compressive strength, but it is comparable to the control mixture. In the study where wollastonite was used instead of cement, a control mixture was formed by using slag instead of 20% cement. In addition to usage of slag, wollastonite was used from 5% to 25% by 5% steps [55]. The workability results of this study are provided in Figure 12. Workability decreased with usage of wollastonite. The acicular structure of wollastonite and the particle size of wollastonite smaller than the particle size of cement are the reasons for decreasing workability [13]. Materials 2022, 15, x FOR PEER REVIEW 14 of 20 Usage of 15% wollastonite increased compressive and flexural strength. In addition, its durability properties enhanced with the usage of wollastonite. In the study where the combination of wollastonite, flythe ashusage and of microsilica was studied, the use durability properties enhanced with wollastonite. In the study where theof almost equal amounts ofofwollastonite, flyash ashand and microsilica cement combination wollastonite, fly microsilica wasinstead studied, of theabout use of30% almost equal had a positive amounts wollastonite, strength fly ash andand microsilica instead of about 30% cement had a posieffect onofmechanical durability properties [56]. Although it is advantageous tive effect on mechanical strength without and durability properties [56].a Although it is advantato self-compacting concrete requiring labor, porous structure that could occur geous to self-compacting concrete without requiring labor, a porous structure that could may cause durability problems. The filling effect of wollastonite has a positive effect on occur may cause durability problems. The filling effect of wollastonite has a positive effect durability performance. It is observed that the durability properties of self-compacting on durability performance. It is observed that the durability properties of self-compacting concrete were improved with utilization of wollastonite in the studies. concrete were alsoalso improved with utilization of wollastonite in the studies. 760 Slump flow (mm) 740 720 700 680 660 640 0% 5% 10% 15% 20% 30% Wollastonite content (a) 14 12 V-funnel (sec) 10 8 6 4 2 0 0% 5% 10% 15% 20% 30% Wollastonite content (b) Figure (a)(a) Slump flowflow and (b) v-funnel of resultsofofresults wollastonite based on Ref.based [55]. on Ref. [55]. Figure12.12. Slump and (b) v-funnel of wollastonite 7. Ultra-High-Performance Concrete Ultra-high-performance concrete (UHPC) is defined as a type of concrete with very high strength and durability. Kwon et al. [57] used wollastonite, which has different aspect ratios, at 0%, 10%, 20% and 27% ratios instead of sand in UHPC. The tensile strength Materials 2022, 15, 6904 13 of 18 7. Ultra-High-Performance Concrete Ultra-high-performance concrete (UHPC) is defined as a type of concrete with very strength and durability. Kwon et al. [57] used wollastonite, which has different aspect 15 of 20 ratios, at 0%, 10%, 20% and 27% ratios instead of sand in UHPC. The tensile strength of 27% substitution of different types of wollastonite is shown in Figure 13. This increase could be due to bonding of the wollastonite microfibers and the mortar by a hydration reaction reaction in which liberated Ca(OH)2 reacts with SiO2 in the wollastonite microfibers and in which liberated Ca(OH)2 reacts with SiO2 in the wollastonite microfibers and forms forms C–S–H [20,57]. The mechanical properties (tensile strength, strain capacity and enC–S–H [20,57]. The mechanical properties (tensile strength, strain capacity and energy ergy absorption capacity) improved with the of wollastonite. The authors also stated absorption capacity) improved with the use ofuse wollastonite. The authors also stated that thatofuse of aaspect low aspect should be avoided. A high aspect emphasized use a low ratio ratio should be avoided. A high aspect ratioratio waswas alsoalso emphasized in in the study conducted ECC [33]. These findings show that a highaspect aspectratio ratioperforms performs the study conducted forfor ECC [33]. These findings show that a high betterin incementitious cementitious composites. composites. In used instead of of cebetter Inaastudy studywhere wherewollastonite wollastonitewas was used instead ment, wollastonite was tried instead of cement at a rate of 4%, 8% and 12% [21]. An incement, wollastonite was tried instead of cement at a rate of 4%, 8% and 12% [21]. An crease was observed in compressive strength, hydration process and cracking resistance; increase was observed in compressive strength, hydration process and cracking resistance; decreasewas wasobserved observedininlower lowershrinkage shrinkagestrains, strains,but butno nosignificant significantimprovement improvementwas was aadecrease observed in flexural strength. Soliman and Mehdi [58] examined the effect of wollastonite observed in flexural strength. Soliman and Mehdi [58] examined the effect of wollastonite cementsubstitute substituteas aswell wellas asthe theeffect effectofofshrinkage-reducing shrinkage-reducingadmixture. admixture.Wollastonite Wollastonite asasaacement increased the compressive strength and also mitigated the compressive strength decrease increased the compressive strength and also mitigated the compressive strength decrease caused by the use of shrinkage-reducing admixture. Zareei et al. [59] formed two mixture caused by the use of shrinkage-reducing admixture. Zareei et al. [59] formed two mixture groups:only onlyusing usingwollastonite wollastonite instead cement and also usage of wollastonite instead groups: instead of of cement and also usage of wollastonite instead of of cement+recycled waste ceramic aggregate instead of coarse aggregate. Workability, wacement+recycled waste ceramic aggregate instead of coarse aggregate. Workability, water ter absorption compressive strength decreased with wollastonite.Usage Usageofof absorption andand compressive strength decreased with thethe useuse of of wollastonite. wollastoniteenhanced enhancedthe thesplitting splittingtensile tensilestrength, strength,flexural flexuralstrength strengthand andmodulus modulusof ofelaselaswollastonite ticity of concrete. The use of minimum cement or aggregate with utilization of wollastonticity of concrete. The use of minimum cement or aggregate with utilization of wollastonite is valuable to obtain sustainable UHPC without losing theperformance performancecharacteristics characteristics isite valuable to obtain sustainable UHPC without losing the UHPC. ofofUHPC. high Materials 2022, 15, x FOR PEER REVIEW Wollastonite content and type 27%-C 27%-B 27%-A 0% 0 2 4 6 8 10 12 14 16 18 Tensile strength (MPa) Figure13. 13.Tensile Tensilestrength strengthofof27% 27%substitution substitutionofofdifferent differenttypes typesofofwollastonite wollastonite based Ref. [57]. Figure based onon Ref. [57]. 8.8.Pavement PavementConcrete Concrete Pavement Pavementisisthe thetop toplayer layerofofthe thesuperstructure superstructureand andforms formsaasmooth smoothrolling rollingsurface surface for forvehicles. vehicles.Due Dueto tothe thepositive positiveeffect effectofofwollastonite wollastoniteon onthe theperformance performanceproperties propertiesofof concrete, concrete,studies studieswere werecarried carriedout outon onits itsuse useininpavement. pavement.Ransinchung Ransinchungand andKumar Kumar[60] [60] used usedwollastonite wollastoniteinstead insteadofofcement cementinintheir theirstudy. study.The Theuse useofof10% 10%wollastonite wollastoniteincreased increased by by11% 11%and andthe theuse useofof20% 20%wollastonite wollastoniteincreased increasedby by5.2% 5.2%on onthe the28-day 28-daycompressive compressive strength compared to the control mixture. The use of 10% wollastonite increased the 28day flexural strength by 20.5% compared to the control mixture. The use of 20% and 30% for flexural strength also provided better results than the control mixture. The increase in flexural strength was higher than compressive strength. In another study, wollastonite Materials 2022, 15, 6904 14 of 18 , x FOR PEER REVIEW 16 of 20 strength compared to the control mixture. The use of 10% wollastonite increased the 28-day flexural strength by 20.5% compared to the control mixture. The use of 20% and 30% for found that wollastonite reduces the slump value of fresh concrete and increases its denflexural strength also provided better results than the control mixture. The increase in sity, abrasion resistance and compressive and flexural strength. It another was emphasized that flexural strength was higher than compressive strength. In study, wollastonite the combinationwas of wollastonite fly ash is also a usable findings of these used instead of+ sand, and, in addition, fly alternative. ash was used The instead of cement [61]. It was found that wollastonite reduces the slump value of fresh concrete and increases studies suggest that wollastonite could be a suitable material to be used in rigid pave-its density, abrasion resistance and compressive and flexural strength. It was emphasized ments [60,61] and that the combination of wollastonite + fly ash can be used in both conthat the combination of wollastonite + fly ash is also a usable alternative. The findings ventional concrete [39,43] andsuggest pavement [61], and, finally, indicated could be of these studies that wollastonite could beitawas suitable materialthat to beitused in rigid a suitable alternative material combination. Ransinchung et al. [27]+examined theused effect of pavements [60,61] and that the combination of wollastonite fly ash can be in both conventional concrete [39,43] and pavement [61], and, finally, it was indicated that it could wollastonite, microsilica and a combination of wollastonite + microsilica for pavement, be a suitable alternative material[20]. combination. Ransinchung et al. [27]in examined theand effect similar to the study conducted for mortar The percentage reduction chloride of wollastonite, microsilica and a combination of wollastonite + microsilica for pavement, wollastonite–microsilica replacement is shown in Figure 14. As a result of the saturated similar to the study conducted for mortar [20]. The percentage reduction in chloride and water absorption, rate of water absorption, coefficient absorption chloride wollastonite–microsilica replacement is shownof in water Figure 14. As a resultand of the saturated water absorption, rate of water absorption, coefficient water absorption and ion penetration durability experiments, it was stated that up to of 15% wollastonite andchloride 7.5% ion penetration durability experiments, it was stated that up to 15% wollastonite and 7.5% microsilica enhance its durability properties. The use of wollastonite in concrete pavemicrosilica enhance its durability properties. The use of wollastonite in concrete pavements ments provides advantages in terms of cost, strength and durability. The use of wollasprovides advantages in terms of cost, strength and durability. The use of wollastonite in tonite in pavement concrete is crucial ininorder reduceitsits high compared to flexible pavement concrete is crucial order to to reduce high costcost compared to flexible pavement pavement and toand make its use widespread. to make its use widespread. Wollastonite (w) and Microsilica (m) 7 days 28 days 15% w + %7.5 m 10% w + %7.5 m 10% w + %5 m 15% w 0% 0 10 20 30 40 Percentage reduction in chloride (%) at 25–35 mm w.r.t. 10–20 mm Figure 14. Percentage reduction in chloride and replacement based on Figure 14. Percentage reduction in wollastonite–microsilica chloride and wollastonite–microsilica replacement based on Ref. [27]. Ref. [27]. Wollastonite uses and different are summarized in Table 3. Some studies are Wollastonite uses and different effects areeffects summarized in Table 3. Some studies are provided to show the effect of using wollastonite on different properties. It is observed that provided to show the effect of using wollastonite on different properties. It is observed both natural and synthetic wollastonite enhance the mechanical and durability properties that both naturalofand syntheticcomposites. wollastonite the mechanical and durability cement-based It hasenhance been determined that wollastonite is a material propthat can erties of cement-based composites. It has been determined that wollastonite is a material be used instead of both aggregate and cement for sustainable concrete production. that can be used instead of both aggregate and cement for sustainable concrete production. Table 3. Usage and different effects of wollastonite in the literature. rature Wollastonite Replacement 5–10% instead of cement Effect of Wollastonite Increment about 34% fracture toughness Materials 2022, 15, 6904 15 of 18 Table 3. Usage and different effects of wollastonite in the literature. Study in Literature Wollastonite Replacement Effect of Wollastonite [34] 5–10% instead of cement Increment about 34% fracture toughness [35] 0–15% instead of cement Increment about 12% compressive and increment about 6% flexural strength [36] 0–50% instead of cement Decrease in workability and increment in cement hydration [28] 5–15% instead of cement Increment in crack growth resistance and ductility [37] 10–30% instead of cement and sand Increment in initial setting time and decrease about 47% drying shrinkage [7] 0–12% instead of cement (synthetic wollastonite) Increment about 8% compressive and increment about 11% flexural strength; decrease about 15% water sorptivity coefficient, about 4% rapid chloride permeability and about 25% gas permeability [32] 0–25% instead of cement Decrease in porosity, water permeability, chloride diffusion and carbonation depth [43] 0–25% instead of cement Increment in resistance against corrosion 9. Conclusions Decreasing the usage of cement and aggregate is a crucial and currently relevant challenge. As an alternative to cement and aggregate, pozzolanic materials have been used for many years and have positive effects on cement-based composites. Not only pozzolanic materials but also inert materials can be used instead of cement and aggregate. One of the inert materials used in cement-based composites is wollastonite, which has two main basic components (CaO and SiO2 ). Wollastonite (calcium metasilicate-CaSiO3 ) has been Investigated by many researchers for approximately the last two decades. Moreover, artificially synthesized wollastonite is a novel and high-quality inert material because of the higher aspect ratio and the possibility of production by using different materials. This study systematically presented the use of natural and synthetic wollastonite in cement-based composites. The use and effects of wollastonite in cement-based composites are as follows: • • • • • • In the use of cement paste and mortar of wollastonite, rates of 3–10% usage instead of cement demonstrated a positive effect, while this rate increased up to 30% in sand. Wollastonite and different material combinations also provided applicable results. The use of synthetic wollastonite instead of cement by up to 10% for improving the performance characteristics of mortar is crucial for sustainability. In the range of 10–15%, use of wollastonite instead of cement enhanced the mechanical and durability properties of conventional concrete. The positive effect of using a combination of fly ash and wollastonite up to 60% was also available in the studies. Superior performance characteristics of engineered cementitious composite (ECC) are further enhanced with wollastonite, and 6% wollastonite substitution was stated as the optimum ratio. In addition, synthetic wollastonite with high aspect ratios of 44:1 and 33:1 was tested. The synthetic wollastonite with an aspect ratio of 44:1 showed better performance than 33:1. The effect of high aspect ratio was observed on ECC. Wollastonite was used instead of a precursor and sand in geopolymer concrete. The low mechanical property disadvantage of geopolymer was partially eliminated with the utilization of wollastonite. Strength increases were achieved with the use of 10–20% instead of sand. Positive performance properties were obtained from self-compacting concrete produced with wollastonite, both alone and in combination with different materials, up to 30% replacement. In ultra-high-performance concrete, the usage of wollastonite 27% instead of sand and up to 12% instead of cement increased the performance properties. Wollastonite can also increase sustainability without losing its performance properties. Materials 2022, 15, 6904 16 of 18 • Only wollastonite and different material combinations were tested in pavements. Positive effects were observed in the use of up to 15% wollastonite. It has been proven by studies that wollastonite is a material with an inert structure, and, therefore, it behaves similar to a fiber in cementitious composites due to its acicular particle structure. The use of wollastonite in cement-based composites both improves mechanical-durability properties and reduces the use of cement and aggregate, therefore providing more sustainable production. Especially regarding synthetic wollastonite’s high aspect ratio and different material usage possibilities, its use up to 10% instead of cement is promising. In future studies, some durability tests (freeze–thaw, corrosion, etc.) of using wollastonite can be performed for all cementitious composites. The effect of synthetic wollastonite on different cement-based composites (except mortar and ECC) and use of synthetic wollastonite instead of sand can be studied. Moreover, the life cycle assessment of cementitious composites produced with synthetic wollastonite can be investigated. Finally, synthetic wollastonite and different pozzolanic material combinations can be tested. Author Contributions: Conceptualization, M.D., H.E.Y. and F.Y.; validation, M.D. and H.E.Y.; formal analysis, M.D., H.E.Y. and F.Y.; investigation, H.E.Y., M.D. and F.Y.; writing—original draft preparation, H.E.Y. and F.Y.; writing—review and editing, M.D., H.E.Y. and F.Y.; supervision, M.D. and H.E.Y.; funding acquisition, M.D. and H.E.Y. All authors have read and agreed to the published version of the manuscript. Funding: This research received no external funding. Institutional Review Board Statement: Not applicable. Informed Consent Statement: Not applicable. Data Availability Statement: Not applicable. Acknowledgments: The authors gratefully acknowledge the support of the research by the project “Pre-implementation works-increasing Technology Readiness Level” implemented by the Consortium PBŚ, SC PBŚ and SC UEP as part of the “INKUBATOR INNOWACYJNOŚCI 4.0”. Conflicts of Interest: The authors declare no conflict of interest. References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Erdoğan, T.Y. Beton; ODTÜ Geliştirme Vakfı Yayıncılık ve İletişim: Ankara, Turkey, 2007. Bhasya, V.; Bharatkumar, B.H. Mechanical and Durability Properties of Concrete Produced with Treated Recycled Concrete Aggregate. ACI Mater. J. 2018, 115, 209–217. [CrossRef] Jalil, A.; Khitab, A.; Ishtiaq, H.; Bukhari, S.H.; Arshad, M.T.; Anwar, W. Evaluation of Steel Industrial Slag as Partial Replacement of Cement in Concrete. Civ. Eng. J. 2019, 5, 181–190. [CrossRef] Arif, R.; Khitab, A.; Kırgız, M.S.; Khan, R.B.N.; Tayyab, S.; Khan, R.A.; Anwar, W.; Arshad, M.T. Experimental Analysis on Partial Replacement of Cement with Brick Powder in Concrete. Case Stud. Constr. Mater. 2021, 15, e00749. [CrossRef] Kumar Mehta, P.; M Monteiro, P.J. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw Hill: New York, NY, USA, 2017. Kannan, D.M.; Aboubakr, S.H.; EL-Dieb, A.S.; Reda Taha, M.M. High Performance Concrete Incorporating Ceramic Waste Powder as Large Partial Replacement of Portland Cement. Constr. Build. Mater. 2017, 144, 35–41. [CrossRef] Öz, H.Ö.; Güneş, M. The Effects of Synthetic Wollastonite Developed with Calcite and Quartz on High Performance Mortars. Struct. Concr. 2021, 22, E257–E272. [CrossRef] Chen, W.; Liu, W.; Geng, Y.; Ohnishi, S.; Sun, L.; Han, W.; Tian, X.; Zhong, S. Life Cycle Based Emergy Analysis on China’s Cement Production. J. Clean. Prod. 2016, 131, 272–279. [CrossRef] Huang, H.; Guo, R.; Wang, T.; Hu, X.; Garcia, S.; Fang, M.; Luo, Z.; Maroto-Valer, M.M. Carbonation Curing for WollastonitePortland Cementitious Materials: CO2 Sequestration Potential and Feasibility Assessment. J. Clean. Prod. 2019, 211, 830–841. [CrossRef] Humphreys, K.; Mahasenan, M. Towards a Sustainable Cement Industry: Climate Change; Substudy 8; World Business Council for Sustainable Development (WBCSD): Geneva, Switzerland, 2002. Mikulčić, H.; Klemeš, J.J.; Vujanović, M.; Urbaniec, K.; Duić, N. Reducing Greenhouse Gasses Emissions by Fostering the Deployment of Alternative Raw Materials and Energy Sources in the Cleaner Cement Manufacturing Process. J. Clean. Prod. 2016, 136, 119–132. [CrossRef] Materials 2022, 15, 6904 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 17 of 18 Atmaca, A.; Atmaca, N. Carbon Footprint Assessment of Residential Buildings, a Review and a Case Study in Turkey. J. Clean. Prod. 2022, 340, 130691. [CrossRef] Yücel, H.E.; Özcan, S. Strength Characteristics and Microstructural Properties of Cement Mortars Incorporating Synthetic Wollastonite Produced with a New Technique. Constr. Build. Mater. 2019, 223, 165–176. [CrossRef] Nair, N.A.; Sairam, V. Research Initiatives on the Influence of Wollastonite in Cement-Based Construction Material—A Review. J. Clean. Prod. 2021, 283, 124665. [CrossRef] Zheng, Y.; Wang, C.; Zhou, S.; Luo, C. The Self-Gelation Properties of Calcined Wollastonite Powder. Constr. Build. Mater. 2021, 290, 123061. [CrossRef] Maxim, L.D.; McConnell, E.E. A Review of the Toxicology and Epidemiology of Wollastonite. Inhal. Toxicol. 2008, 17, 451–466. [CrossRef] Saxena, S.K.; Kumar, M.; Chundawat, D.S.; Singh, N.B. Utilization of Wollastonite in Cement Manufacturing. Mater. Today Proc. 2020, 29, 733–737. [CrossRef] Ahmad, F.; Ullah, S.; Oñate, E.; Al-Sehemi, A.G.; Yeoh, G.H. An Investigation on Thermal Performance of Wollastonite and Bentonite Reinforced Intumescent Fire-Retardant Coating for Steel Structures. Constr. Build. Mater. 2019, 228, 116734. [CrossRef] Paul, F.K. Mineral Descriptions-Wollastonite, Optical Mineralogy, 4th ed.; McGraw Hill: New York, NY, USA, 1977. Ransinchung RN, G.D.; Kumar, B. Investigations on Pastes and Mortars of Ordinary Portland Cement Admixed with Wollastonite and Microsilica. J. Mater. Civ. Eng. 2010, 22, 305–313. [CrossRef] Soliman, A.M.; Nehdi, M.L. Effect of Natural Wollastonite Microfibers on Early-Age Behavior of UHPC. J. Mater. Civ. Eng. 2012, 24, 816–824. [CrossRef] Harabi, A.; Chehlatt, S. Preparation Process of a Highly Resistant Wollastonite Bioceramics Using Local Raw Materials: Effect of B2 O3 Additions on Sintering and Mechanical Properties. J. Therm. Anal. Calorim. 2013, 111, 203–211. [CrossRef] Obeid, M.; Mont, M.; Schneider, J.; Rodrigues, A.; Obeid, M.M. Crystallization of Synthetic Wollastonite Prepared from Local Raw Materials. Int. J. Mater. Chem. 2014, 4, 79–87. [CrossRef] Shamsudin, R.; ’Atiqah Abdul Azam, F.; Abdul Hamid, M.A.; Ismail, H. Bioactivity and Cell Compatibility of β-Wollastonite Derived from Rice Husk Ash and Limestone. Materials 2017, 10, 1188. [CrossRef] He, Z.; Shen, A.; Lyu, Z.; Li, Y.; Wu, H.; Wang, W. Effect of Wollastonite Microfibers as Cement Replacement on the Properties of Cementitious Composites: A Review. Constr. Build. Mater. 2020, 261, 119920. [CrossRef] Low, N.M.P.; Beaudoin, J.J. Flexural Strength and Microstructure of Cement Binders Reinforced with Wollastonite Micro-Fibres. Cem. Concr. Res. 1993, 23, 905–916. [CrossRef] Ransinchung, G.D.; Kumar, B.; Kumar, V. Assessment of Water Absorption and Chloride Ion Penetration of Pavement Quality Concrete Admixed with Wollastonite and Microsilica. Constr. Build. Mater. 2009, 23, 1168–1177. [CrossRef] Dey, V.; Kachala, R.; Bonakdar, A.; Mobasher, B. Mechanical Properties of Micro and Sub-Micron Wollastonite Fibers in Cementitious Composites. Constr. Build. Mater. 2015, 82, 351–359. [CrossRef] Kalkan, Ş.O.; Yavaş, A.; Güler, S.; Torman Kayalar, M.; Sütçü, M.; Gündüz, L. An Experimental Approach to a Cementitious Lightweight Composite Mortar Using Synthetic Wollastonite. Constr. Build. Mater. 2022, 341, 127911. [CrossRef] Vichaphund, S.; Kitiwan, M.; Atong, D.; Thavorniti, P. Microwave Synthesis of Wollastonite Powder from Eggshells. J. Eur. Ceram. Soc. 2011, 31, 2435–2440. [CrossRef] Emrullahoǧlu, S.B.; Emrullahoǧlu, C.B.; Emrullahoǧlu, Ö.F. Syntetic Wollastonite Production from Raw and Tailing Materials. Key Eng. Mater. 2004, 264–268, 2485–2488. [CrossRef] Kalla, P.; Rana, A.; Chad, Y.B.; Misra, A.; Csetenyi, L. Durability Studies on Concrete Containing Wollastonite. J. Clean. Prod. 2015, 87, 726–734. [CrossRef] Yücel, H.E.; Öz, H.Ö.; Güneş, M.; Kaya, Y. Rheological Properties, Strength Characteristics and Flexural Performances of Engineered Cementitious Composites Incorporating Synthetic Wollastonite Microfibers with Two Different High Aspect Ratios. Constr. Build. Mater. 2021, 306, 124921. [CrossRef] Doner, S.; Lyngdoh, G.A.; Nayak, S.; Das, S. Fracture Response of Wollastonite Fiber-Reinforced Cementitious Composites: Evaluation Using Micro-Indentation and Finite Element Simulation. Ceram. Int. 2022, 48, 15493–15503. [CrossRef] Öz, H.Ö.; Yücel, H.E.; Güneş, M.; Malkoç, B. The Effects on High Performance Mortars of Natural Wollastonite. NOHU J. Eng. Sci. 2020, 9, 966–974. [CrossRef] Khan, R.I.; Ashraf, W. Effects of Ground Wollastonite on Cement Hydration Kinetics and Strength Development. Constr. Build. Mater. 2019, 218, 150–161. [CrossRef] Abdel Wahab, M.; Abdel Latif, I.; Kohail, M.; Almasry, A. The Use of Wollastonite to Enhance the Mechanical Properties of Mortar Mixes. Constr. Build. Mater. 2017, 152, 304–309. [CrossRef] Leemann, A.; Winnefeld, F.; Münch, B.; Läng, F. Carbonated Wollastonite—An Effective Supplementary Cementitious Material? J. Microsc. 2022, 286, 120–125. [CrossRef] [PubMed] Mathur, R.; Misra, A.K.; Goel, P.; Mathur, R.; Misra, A.K.; Goel, P. Influence of Wollastonite on Mechanical Properties of Concrete. J. Sci. Ind. Res. 2007, 66, 1029–1034. Kh, K. Research of Light-Weight Concrete Properties on Base Wollastonite Addition. Middle Eur. Sci. Bull. 2021, 8. [CrossRef] Aziza, K.; Kh, K.; Aziza, K. Durability Characteristics of Concrete Admixed with Wollastonite Mineral. Eur. J. Life Saf. Stab. 2021, 5, 9–13. Materials 2022, 15, 6904 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 54. 55. 56. 57. 58. 59. 60. 61. 18 of 18 Kuldasheva, A.; Saidmuratov, B.; Kuldashev, H. The Use of Wollastonite Fiber to Enhance the Mechanical Properties of Cement Compositions. Int. J. Progress. Sci. Technol. 2020, 22, 37–45. Kalla, P.; Misra, A.; Gupta, R.C.; Csetenyi, L.; Gahlot, V.; Arora, A. Mechanical and Durability Studies on Concrete Containing Wollastonite-Fly Ash Combination. Constr. Build. Mater. 2013, 40, 1142–1150. [CrossRef] Kumar Mandrawalia, A.; Gaur, A. Compressive and Sorptivity Characteristic of Concrete Modified with Wollastonite Fibre and Waste Granite Fines. Mater. Today Proc. 2021, 42, 1012–1016. [CrossRef] Atiş, C.D.; Görür, E.B.; Karahan, O.; Bilim, C.; Ilkentapar, S.; Luga, E. Very High Strength (120 MPa) Class F Fly Ash Geopolymer Mortar Activated at Different NaOH Amount, Heat Curing Temperature and Heat Curing Duration. Constr. Build. Mater. 2015, 96, 673–678. [CrossRef] Choi, Y.C.; Park, B. Effects of High-Temperature Exposure on Fractal Dimension of Fly-Ash-Based Geopolymer Composites. J. Mater. Res. Technol. 2020, 9, 7655–7668. [CrossRef] Hemalatha, P.; Ramujee, K. Influence of Nano Material (TiO2 ) on Self Compacting Geo Polymer Concrete Containing Flyash, GGBS and Wollastonite. Mater. Today Proc. 2021, 43, 2438–2442. [CrossRef] Bong, S.H.; Nematollahi, B.; Xia, M.; Nazari, A.; Sanjayan, J. Properties of One-Part Geopolymer Incorporating Wollastonite as Partial Replacement of Geopolymer Precursor or Sand. Mater. Lett. 2020, 263, 127236. [CrossRef] Bong, S.H.; Nematollahi, B.; Xia, M.; Ghaffar, S.H.; Pan, J.; Dai, J.G. Properties of Additively Manufactured Geopolymer Incorporating Mineral Wollastonite Microfibers. Constr. Build. Mater. 2022, 331, 127282. [CrossRef] Ren, D.; Yan, C.; Duan, P.; Zhang, Z.; Li, L.; Yan, Z. Durability Performances of Wollastonite, Tremolite and Basalt Fiber-Reinforced Metakaolin Geopolymer Composites under Sulfate and Chloride Attack. Constr. Build. Mater. 2017, 134, 56–66. [CrossRef] Guo, L.; Wu, Y.; Xu, F.; Song, X.; Ye, J.; Duan, P.; Zhang, Z. Sulfate Resistance of Hybrid Fiber Reinforced Metakaolin Geopolymer Composites. Compos. Part B Eng. 2020, 183, 107689. [CrossRef] Archez, J.; Texier-Mandoki, N.; Bourbon, X.; Caron, J.F.; Rossignol, S. Influence of the Wollastonite and Glass Fibers on Geopolymer Composites Workability and Mechanical Properties. Constr. Build. Mater. 2020, 257, 119511. [CrossRef] Vishnu, N.; Kolli, R.; Ravella, D.P. Studies on Self-Compacting Geopolymer Concrete Containing Flyash, GGBS, Wollastonite and Graphene Oxide. Mater. Today Proc. 2021, 43, 2422–2427. [CrossRef] Jindal, A.; Ransinchung, R.N.G.D.; Kumar, P. Behavioral Study of Self-Compacting Concrete with Wollastonite Microfiber as Part Replacement of Sand for Pavement Quality Concrete (PQC). Int. J. Transp. Sci. Technol. 2020, 9, 170–181. [CrossRef] Gouse Mohiuddin, M.D.; Malagavelli, V.; kumar Balguri, P. Influence of Wollastonite-GGBS on Properties of Ternary Blended Self Compacting Concrete. Mater. Today Proc. 2022, 62, 3027–3032. [CrossRef] Sharma, S.K. Properties of SCC Containing Pozzolans, Wollastonite Micro Fiber, and Recycled Aggregates. Heliyon 2019, 5, e02081. [CrossRef] Kwon, S.; Nishiwaki, T.; Choi, H.; Mihashi, H. Effect of Wollastonite Microfiber on Ultra-High-Performance Fiber-Reinforced Cement-Based Composites Based on Application of Multi-Scale Fiber-Reinforcement System. J. Adv. Concr. Technol. 2015, 13, 332–344. [CrossRef] Soliman, A.M.; Nehdi, M.L. Effects of Shrinkage Reducing Admixture and Wollastonite Microfiber on Early-Age Behavior of Ultra-High Performance Concrete. Cem. Concr. Compos. 2014, 46, 81–89. [CrossRef] Zareei, S.A.; Ameri, F.; Shoaei, P.; Bahrami, N. Recycled Ceramic Waste High Strength Concrete Containing Wollastonite Particles and Micro-Silica: A Comprehensive Experimental Study. Constr. Build. Mater. 2019, 201, 11–32. [CrossRef] Ransinchung, G.D.; Kumar, P.N. Laboratory Study on Use of Wollastonite Micro-Fibers for Abrasion Resistance of Pavement Quality Concrete. In Proceedings of the International Conference on Engineering and Information Technology “ICEIT2012”, Toronto, ON, Canada, 17–18 September 2012. Kumar, R. Wollastonite Mineral Fibre in Manufacturing of an Economical Pavement Concrete. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016.