Concepts and engineering terms in Machine elements design (1)

advertisement

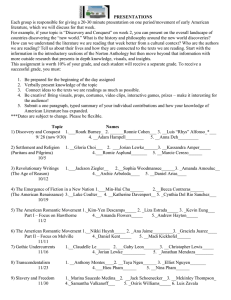

10/11/2021 Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Stress- What’s that mean? – Ứng suất là gì? • No applied force = Unloading MACHINE ELEMENTS DESIGN -CONCEPTS AND ENGINEERING TEMS- • One solid bar under effect of two opposite forces (loads) following its central axis = uniaxial loading period. • External forces occur internal forces due to the resistance phenomenon. (imagine in a cross section within the bar) Strength of Materials & Durable of Structure - Stress and Strain Faculty of Mechanical Engineering Dr. Anh-Duc PHAM– 0948 777 040 – ducpham@dut.udn.vn Left side • For equilibrium: External forces = internal forces Right side • STRESS: quantity to describes the distribution of internal forces within a body 2 1 2 Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Stress- What’s that mean? – Ứng suất là gì? Stress- What’s that mean? – Ứng suất là gì? • STRESS: • Tensile stress: Sketch objects. In SI: : in ANSI • Compressive stress: compress objects. • Normal stress: stress occurs when a member is loaded by an axial force. • For example: Strength of steel C30 (JIS: S30C) C30 = 570(Mpa) Diameter of pipe 40 (mm) Failure occurs when >C30 Square of pipe 1,256x10-3(m2) = Fext = Fext × F = 71.59 (kN) 3 3 * Stress of I beam more complex 4 4 10/11/2021 Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Stress & Strain correlation – Mối quan hệ ứng suất & sức căng Strain- What’s that mean? – Sức căng là gì? • STRAIN: quantity to describes the deformation occurring within a body = L • Stress & Strain: In section of Elastic deformation, this correlation is followed by HOOKE’s law: Elastic region = E. • Based on Stress&Strain graph, all important properties of material can be known (Strength, Young modulus, Ductility and Toughness. L Rise Run • STRESS and STRAIN show a correlation showing a property of material Plastic region 5 5 6 6 Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Shear Stress – Ứng suất cắt Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Shear Stress – Ứng suất cắt • Normal stress (): External forces affect to object in perpendicular to cross section • Shear strain ( ): change in angle in deformed process with shear stress. • Shear stress ( ): External forces affect to object in parallel to cross section = G. • At any point in body, stress state always includes Normal and Shear stresses. But values of those stresses can be different due to direction of applied force or analyzed cross-section. = *** Average value is due to that the internal forces will not be distributed evenly across the cross-section. Deformed 7 7 Hooke’s law for shear 8 10/11/2021 Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Faculty of Mechanical Engineering Dr. Anh-Duc PHAM True stress-strain curve – đặc tính thật của đường ứng suất và sức căng • Principle: Use Yield strength of material in chosen of design. (Elastic region). Knowing some important points of stressstrain curve to manufacturing and analysis elements. • True stress-strain curve (hooke’s law) is different with engineering curve • Reasons: Difference between cross-sections (necking phenomenon). Ultimate tensile strength Yield strength True stress-strain curve – đặc tính thật của đường ứng suất và sức căng Necking process Deformation Region. Engineering Necking phenomenon Elastic region Plastic region Manufacturing process 3 9 = = = (1 + ) = ln(1 + ) = Simulated engineering analysis = −1 3 10 Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Material properties – Đặc tính vật liệu Material selection: • Effected on strength of machine Machinablity Properties Understand material to: Performance • Ex: Welding, cutting There are three essential properties of material: Strength, Ductility, and Toughness • Suitable for machine purpose Avabilily • Supply and cost • Choose suitable type of material • Have a knowledge of limit strength of machine elements ( working area). • Repair and Re-design. • Maintenance. 3 11 12 10/11/2021 Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Material properties – Đặc tính vật liệu Converter among the world standards • Three main elastic constains: Young modulus Shear modulus Bulk modulus DIN: Deutsches Institut für Normung BSI Group: British Standards Institution ANSIANSI: American National Standards Institute AISI: The American Iron and Steel Institute ASME: The American Society of Mechanical Engineers CSA Group: Canadian Standards Association = = = (1 + ) = ln(1 + ) JISC: Japanese Industrial Standards Committee GB: Guobiao Simulated engineering analysis Manufacturing process = = −1 3 13 ISO: Int. Org. for Standardization ASTM International: Ame. Stand. for Testing & Materials 3 14 Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Faculty of Mechanical Engineering Dr. Anh-Duc PHAM Sample table Effects from common Alloyng Elements #1: Very high carbon steel (0.96%-2.1% carbon) Produced via a specialized process, very high carbon steel is extremely strong and capable of resisting localized deformation under high tensions. #2: High carbon steel (0.55%-0.95% carbon) Used until recently in railroad track applications, high carbon steel is quite strong, but does offer more ductility than very high carbon steels. Other examples of use include cutting and chiseling tools. #3: Medium carbon steel (0.3%-0.54% carbon) Used primarily in machine parts (i.e. gears, axels, bolts), medium carbon balances strength and hardness with ductility. #4: Low carbon steel (0.05%-0.25%) low carbon steel provides incredible strength relative to a lighter weight. • Iron alone is not enough…. - ELEMENTS THAT STRENGTHEN: chromium, vanadium, nickel, titanium, nitrogen & aluminum combo - ELEMENTS THAT INCREASE MACHINABILITY: Phosphorus, Chromium, Sulfur, Niobium (Columbium) - ELEMENTS THAT RESIST CORROSION: Phosphorus, Copper, Chromium, Nickel, Zirconium 3 15 3 16