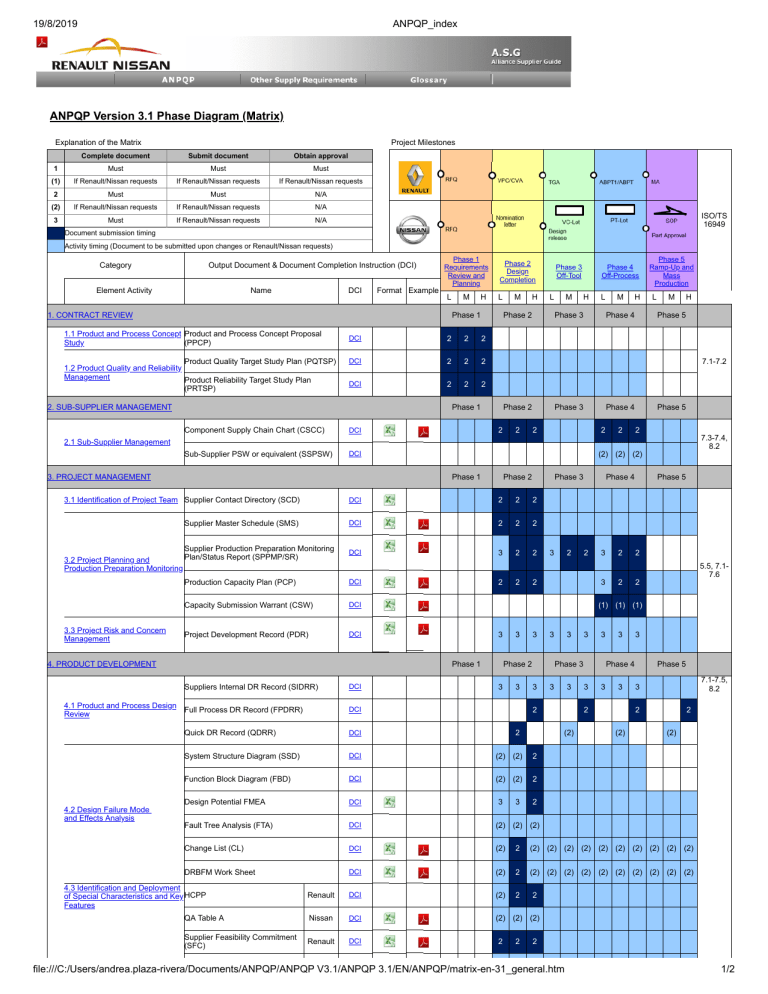

19/8/2019 ANPQP_index ANPQP Version 3.1 Phase Diagram (Matrix) Explanation of the Matrix Complete document Project Milestones Submit document Obtain approval 1 Must Must Must (1) If Renault/Nissan requests If Renault/Nissan requests If Renault/Nissan requests 2 Must Must N/A (2) If Renault/Nissan requests If Renault/Nissan requests N/A 3 Must If Renault/Nissan requests N/A ISO/TS 16949 Document submission timing Activity timing (Document to be submitted upon changes or Renault/Nissan requests) Category Output Document & Document Completion Instruction (DCI) Element Activity Name DCI Format Example Phase 1 Requirements Review and Planning L 1. CONTRACT REVIEW M H Phase 2 Design Completion L Phase 1 1.1 Product and Process Concept Product and Process Concept Proposal Study (PPCP) Product Quality Target Study Plan (PQTSP) 1.2 Product Quality and Reliability Management Product Reliability Target Study Plan (PRTSP) 2 2 2 DCI 2 2 2 DCI 2 2 2 DCI Sub-Supplier PSW or equivalent (SSPSW) DCI L M Phase 4 Off-Process H L Phase 3 M H Phase 4 Phase 5 Ramp-Up and Mass Production L M H Phase 5 7.1-7.2 Phase 1 Component Supply Chain Chart (CSCC) H Phase 2 DCI 2. SUB-SUPPLIER MANAGEMENT M Phase 3 Off-Tool Phase 2 2 2 Phase 3 Phase 4 2 2 2 Phase 5 2 7.3-7.4, 8.2 2.1 Sub-Supplier Management 3. PROJECT MANAGEMENT (2) (2) (2) Phase 1 Phase 2 Phase 3 3.1 Identification of Project Team Supplier Contact Directory (SCD) DCI 2 2 2 Supplier Master Schedule (SMS) DCI 2 2 2 DCI 3 2 2 Production Capacity Plan (PCP) DCI 2 2 2 Capacity Submission Warrant (CSW) DCI Project Development Record (PDR) DCI Supplier Production Preparation Monitoring Plan/Status Report (SPPMP/SR) 3.2 Project Planning and Production Preparation Monitoring 3.3 Project Risk and Concern Management 4. PRODUCT DEVELOPMENT 4.1 Product and Process Design Review 4.2 Design Failure Mode and Effects Analysis 3 2 Phase 4 2 Phase 5 3 2 2 3 2 2 5.5, 7.17.6 (1) (1) (1) 3 Phase 1 3 3 3 Phase 2 3 3 3 Phase 3 3 3 3 3 3 Phase 4 Full Process DR Record (FPDRR) DCI Quick DR Record (QDRR) DCI System Structure Diagram (SSD) DCI (2) (2) 2 Function Block Diagram (FBD) DCI (2) (2) 2 Design Potential FMEA DCI Fault Tree Analysis (FTA) DCI (2) (2) (2) Change List (CL) DCI (2) 2 (2) (2) (2) (2) (2) (2) (2) (2) (2) (2) DRBFM Work Sheet DCI (2) 2 (2) (2) (2) (2) (2) (2) (2) (2) (2) (2) Renault DCI (2) 2 QA Table A Nissan DCI (2) (2) (2) Supplier Feasibility Commitment (SFC) Renault DCI 2 3 2 3 2 3 3 7.1-7.5, 8.2 DCI 2 3 Phase 5 Suppliers Internal DR Record (SIDRR) 4.3 Identification and Deployment of Special Characteristics and Key HCPP Features 3 3 2 (2) 3 2 (2) 2 (2) 2 2 2 file:///C:/Users/andrea.plaza-rivera/Documents/ANPQP/ANPQP V3.1/ANPQP 3.1/EN/ANPQP/matrix-en-31_general.htm 1/2 19/8/2019 ANPQP_index QA Table B 4.4 Engineering Product Specifications / Drawing Study and Completion 4.5 Special Characteristics Management Nissan (2) (2) (2) DCI Special Characteristics and Key Feature Diagram (SCKFD) DCI 3 3 3 Engineering Product Specifications and Engineering Drawings / CAD data DCI 1 1 1 Supplier Recommendations (SR) DCI Certificate of Certification (COC) /Conformity of Product (COP) DCI 5.2 Manufacturing Process Design 5.3 Tooling, Gauges and Facility Management 5.4 Process Capability Study and Improvement 5.5 Confirmation of Full Volume Conditions 5.6 Activities during Ramp-Up Phase 1 2 Phase 3 Control Plan (CP) DCI Process Flow Chart (PFC) DCI Floor Plan Layout (FPL) DCI 2 2 Work Instruction (WI) DCI Gauge Specification and Approval Sheet (GSAS) DCI 3 2 2 Process Capability Study Plan (PCSP) DCI 3 2 2 Process Capability Study Result (PCSR) DCI Full Volume Confirmation Audit Results (FVCAR) Phase 4 Phase 5 3 3 2 (2) (2) (2) 3 2 2 1 1 1 (2) (2) (2) 3 2 2 2 2 2 3 3 3 3 3 3 3 3 3 3 1 1 (2) 2 2 7.2-7.6, 8.5 (2) 2 2 DCI 3 3 3 Ram-Up Activity Plan (RUAP) DCI 3 2 2 Ramp-Up Activity Concern and Countermeasure Report (RUACCR) DCI - - Phase 1 Supplier Digital Test Report (SDTR) DCI Supplier Test Plan and Report (STPR) DCI Inspection Report (IR) DCI Appearance Approval Report (AAR) DCI (2) (2) (2) (2) (2) (2) Phase 2 Phase 3 Phase 4 Phase 5 (2) (2) (2) 2 2 2 2 2 2 2 2 2 7.3 (2) (2) (2) Phase 1 Part Submission Warrant (PSW) 2 2 Phase 2 Phase 3 Phase 4 1 DCI 8. NON CONFORMING PRODUCT MANAGEMENT 8D Concern and Countermeasure Report Summary (8D-CCR) 2 (2) (2) (2) (1) (1) (1) 7. PRODUCTION PART APPROVAL 8.1 Non Conforming Product Management Phase 2 DCI 6. PRODUCT CONFIRMATION 7.1 Production Part Approval 2 (2) (2) (2) Process Potential FMEA 5.7 Identification and Traceability 6.1 Design Verification and Product/Process Validation 2 (2) (2) (2) (2) (2) (2) 5. MANUFACTURING PROCESS DEVELOPMENT 5.1 Process Failure Mode and Effect Analysis 3 Phase 1 Phase 2 Phase 3 1 Phase 5 1 Phase 4 7.3, 7.5 Phase 5 (2) (2) (2) (2) (2) (2) (2) (2) (2) (2) (2) (2) 8.3, 8.5 DCI 9. CHANGE MANAGEMENT Phase 1 Phase 2 Phase 3 Phase 4 Phase 5 9.1 Design Change Management Design Change Request (DCR) DCI (1) (1) (1) (1) (1) (1) (1) (1) (1) 9.2 Process/Facility Site Change Process/Facility Site Change Request Management (PFCR) DCI (1) (1) (1) 10. LOGISTICS and PACKAGING 10.1 Logistics and Packaging Phase 1 Logistics and Packaging Data Sheet (LPDS) DCI 11. ENVIRONMENTAL REQUIREMENT 11.1 Environmental Requirement International Material Data System (IMDS) 2 2 2 Phase 1 DCI Phase 2 2 2 Phase 3 2 2 Phase 2 2 Phase 4 2 Phase 3 2 2 1 1 Phase 4 2 7.1-7.4, 8.5 Phase 5 1 7.4, 7.5 Phase 5 - Copyright © Renault / Nissan file:///C:/Users/andrea.plaza-rivera/Documents/ANPQP/ANPQP V3.1/ANPQP 3.1/EN/ANPQP/matrix-en-31_general.htm 2/2