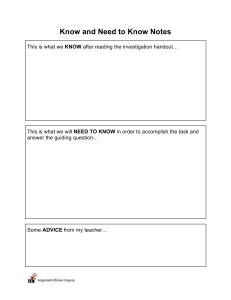

Content 1. Outline 2. Main Technique Parameter 3. Instruction for Switches on operating panel 4. Slitting system 5. Rewinding System 6. Operating instruction 7. Accessories and Electrical Diagrams 1 1. Outline This machine is the auxiliary product of the automatic die cutting machine. It is suitable for the narrow paper. It has function of auto meter counter, auto number counter and auto web guiding. It is well structured, fast, efficient, precise, easy to use and working steadily. 2. Main Technique Parameter (1) Slitting speed: 100m/min (2) Max. Web width: 320 mm (3) Max. Unwinding diameter: 600 mm (4) Max. Rewinding diameter: 200mm-500mm (5) Power of the Machine: 3kw (6) Size of the Machine: 1700×1200×1700 (7) Weight of the Machine: about 1200 kg 3. Instruction for Switches on operating panel 3.1. Panel instruction 1 计数/计米显示 3 速度显示 计数 计米 NUMBER METER 设置 选择 运行/START 风机/BLOWER 2 关/OFF 开/ON 电眼 调速/SPEED 速度 自动 停止/STOP 双 单 极性 4 电源/POWER 手动 7 5 6 2 1. Length and speed control part (see 3.3.3 and 3.3.4) 2. Web guiding control part 3. Main motor Starts 4. Main motor stops 5. Speed for main motor 6. Power: the switch of the head power 7. Blower: the switch to blow the waste away. 3.2. Control system 3.2.1 Web guiding part: 1). Brief introduction of web guiding: This system is composed of synchronous engine, ball bearing, transitional roller and photocell for web guiding and so on. The web guiding system do registration job well by photocells and the synchronous engine makes the ball bearing running to do web guiding job. 2). Picture for the panel: 3 3). Introduction for the switches on the panel (1). Dot move (“<”, “>”): To move paper guide roller to left and right when setting up the web guiding. (2). Electric eye: (see the following diagram) Select on single when using one photocell to setup the web guiding. Select on double when using two photocells to setup web guiding. (3). Photocell indication lights: These two indication lights are used for indicating the selection of the photocell is “single” or “double”. knife label Photocell tracking Single photocell label knife Photocell side tracking Single photocell side tracking knife lable Photocell tracking Photocell tracking double photocelss tracking 4 (4).Limited: Press the button to change the light “light” or “dark” for the photocells. (See following diagram). (5).Indication lights for limit selection: these two indication lights are used for indicating the selection of the photocells. (6). auto: to run on auto mode when setting web guiding. Photocell deep inside, light outside color color Photocell light color inside, deep color outside Photocell deep color inside, light color outside limit“ ” Photocell light color inside, deep color outside limit“ ” (7). Indication light for auto mode (8).Manual: To run on manual mode when setting web guiding. (9). Indication light for manual mode. (10). Speed adjusts for web guiding: “+”: To increase speed for web guiding motor (to move faster) “-”: To reduce speed for web guiding motor (to move slower). (11). Indication for speed. (12).Indication for the direction of synchronous engine. (13). Limit position indication light: this indication light is used for indicating that the web guiding have already in the effective area. (14). Power indication light. 3.3.2 Diagram for web guiding: 5 Moving bar Screw Limit switch Web guiding motor 3.3.3 meter/number counter and speed control part: Meter/number counter can accurately count the length and number of the materials, and can display the current speed on time, automatically slow down in advance, automatically stop while arrives to the number of previously setting, automatically stop while lack of material. Measuring principle see below: Being material Inspected Girth Magnets 2~3mm Hall switch Paste the magnets 计数状态,当计数传感器调置薄(已排废)位置时,绿灯亮,当 3.3.4 Panel setting instruction 6 计数/计米显示 速度显示 设置 计数 计米 NUMBER METER 选择 (1). Setup: Press the key of set (time-delay key) and it will be back in 5 seconds automatically. +: Press once to add one. -: Press once to subtract one. Clear: It becomes move key in the state of set. Press once to move one bit. It becomes clear key in the state of working. Number: Count the quantity of labels when in the state of number counting. Meter: Count the meter of paper when in the state of meter counting. (2). Attention: 1) Install the machine on the level ground properly. 2) Check the all joints parts are in good position or not, wipe off the machine. 3) Check all the parts whether they are reliably fixed and well fastened. 4) Lubricate such moving parts as every oil cup, oil hole, bearing, gear, and sprocket, etc. 5) Check whether all the connectors of electric appliances are well inserted and the power is correctly connected. Check electric board, electric route and fuse is in good position or not. To ensure all electric 7 appliances is good. 6) There should be no phenomenon of seizing-up after idling, and the running direction of motor should be the same as the mark direction. If find the running direction of motor, air fan, and compressor is wrong, just change the phase direction of power supply. 7) Te monitor, meter and potentiometer are adjusted strictly before delivery; please do not change it easily. 8) User should be familiar with every command switch on the electric panel and the operation function of the instrument. For further detail, please see the Function diagram of the control panel and photocell control operation instruction. 9) Power supply preparation: User should fix a power switch box near the machine, connect the power supply wire to the connector No: L1, L2, L3 (phase wire), and N (neutral wire) which on the machine electric control box, the PE connector should connect to the earth wire. 4. Slitting System This system is composed of up-side rotary knife, down-side rotary knife and the controller around the round knife. The longitudinal nuts control the length of the paper. The transverse nuts control the width of the paper. 5. Rewinding System This system is composed of air expand shaft, magnetic clutch and so on. And the tension is controlled by the magnetic clutch. 6. Operating Instruction Turn on power. Put paper according to the diagram of paper feeding. Charge enough gas to the air expand shaft. Turn on the correcting system. Adjust the position of the knives. Turn on the fan and turn on the main 8 engine slowly. Absorb the waste to wind pipe. Speed up the main engine after adjusting the winding tension in a suitable state. 7. Accessories and Electrical Diagrams Accessories List No. Name Unit Quantity 1 3# inner hexagonal die nut Piece 1 2 5# inner hexagonal die nut Piece 1 3 6# inner hexagonal die nut Piece 1 4 8# inner hexagonal die nut Piece 1 Piece 1 Memo 10# inner hexagonal die 5 nut 6 8” coeswrench Piece 1 7 12” coeswrench Piece 1 8 14-17 standing lever Piece 1 9 17-19 standing lever Piece 1 10 6# crossed wood screws Piece 1 11 6# straight wood screws Piece 1 9