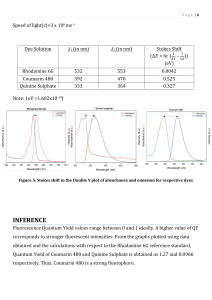

Preparative Biochemistry & Biotechnology ISSN: (Print) (Online) Journal homepage: https://www.tandfonline.com/loi/lpbb20 The influence of UV light on the course of fluorescent enzyme assays A. Samborski, P. Jankowski & R. Ostaszewski To cite this article: A. Samborski, P. Jankowski & R. Ostaszewski (2022): The influence of UV light on the course of fluorescent enzyme assays, Preparative Biochemistry & Biotechnology, DOI: 10.1080/10826068.2022.2119573 To link to this article: https://doi.org/10.1080/10826068.2022.2119573 Published online: 15 Sep 2022. Submit your article to this journal View related articles View Crossmark data Full Terms & Conditions of access and use can be found at https://www.tandfonline.com/action/journalInformation?journalCode=lpbb20 PREPARATIVE BIOCHEMISTRY & BIOTECHNOLOGY https://doi.org/10.1080/10826068.2022.2119573 The influence of UV light on the course of fluorescent enzyme assays A. Samborskia , P. Jankowskia , and R. Ostaszewskib a Institute of Physical Chemistry PAS, Warsaw, Poland; bInstitute of Organic Chemistry PAS, Warsaw, Poland KEYWORDS ABSTRACT Experiments were carried out to illustrate the effect of UV light on the course of the enzymatic reaction of the coumarin derivative. Only the pulsating light of the UV diode gives the correct results for the determination of the kinetic constants of the enzymatic reaction. The enzyme concentration limit was found where the description of the M-M model breaks. It was shown that the system determines the kinetic parameters of enzymatic reactions: Vmax—the maximum rate of reaction and KM—the Michaelis constant. This method produces kinetic constants calculated from the changes in enzyme product concentration using the Michaelis-Menten model. To verify the results, we used a statistical analysis that checks the correctness of the model used. Introduction Coumarins are nontoxic compounds that widely occur naturally in bacteria, plants, and fungi.[1,2] They are present in many natural sources such as essential oils, fruits, green tea, and other foods.[2] Coumarins play a primary role in plant nutrition and health.[3] Coumarin possesses an extensively conjugated system with electron-rich and charge transfer properties. The presence of the hydroxyl group in the 7-position of coumarin yields a highly fluorescent molecule whose derivatives are widely used as a fluorescence substrate[4] for serine and cysteine proteases[5] probes. Unfortunately, coumarin and its derivatives undergo photodimerization reaction (Scheme 1) upon UV light irradiation (<300 nm) in methanol, ethanol, and aqueous solutions.[6] Photodimerization reaction leads to the formation of four types of dimers: anti-head-to-head 5, syn head-to-head 6, syn head-to-tail 7, and anti-head-to-tail 8. This reaction is reversible and proceeds spontaneously in water and organic solvents. Coumarins are highly fluorescent compounds in the visible light range. These properties enable the application of coumarin molecules in numerous different fields such as laser dyes,[7] optical data storage,[8] drug delivery systems,[9] or organic light-emitting diodes (OLEDs).[10] We recently used the unique properties of coumarin derivatives to design a self-immolative coumarin-based fluorescent probe to detect salinary hydrogen sulfide[11] and small amounts of hydrogen peroxide.[12] We designed mixed carbonates containing coumarin as efficient fluorogenic probes for screening enzyme enantioselectivity[13] and selfimmolative coumarin fluorogenic probes for screening of hydrolytic activity of enzymes.[14] The designed coumarin peptidomimetics were cytotoxic agents on E. coli strains.[15] This work was extended to create a modular microfluidic CONTACT R. Ostaszewski ryszard.ostaszewski@icho.edu.pl Authors contributed equally to this work. ß 2022 Taylor & Francis Group, LLC Enzymes assay; UV light; Michaelis-Menten model; Lambert function W(x) system to execute enzyme assays that determine the kinetic parameters (Vmax and KM) of the enzymatic reactions.[16] As a substrate, coumarin carbonate 1 was used, which upon enzyme-catalyzed reaction was transformed into alcohol 2, coumarin derivative 3 (7-hydroxy-4-methyl-2H-chromen-2one), and carbon dioxide. For calculating kinetic constants from the concentration of enzymatic product 3 changes via the Michaelis–Menten model, Lambert function W(x) was used. Our results pointed out that fluorogenic carbonate is an excellent probe for rapidly determining the kinetic parameters KM and kcat of hydrolases, such as lipases and esterases. The detailed analysis of data obtained during experiments determining the course of an enzyme-catalyzed reaction is complex and requires special attention. The mathematical model may help determine the Michaelis-Menten (M-M) parameters from experimental data.[17] The M-M model commonly used to determine kinetic parameters assumes that a single reaction catalyzed by an enzyme occurs. For enzymatic reactions of coumarin derivatives, their progress monitored by fluorescence spectroscopy reveals that additional responses can occur. Under UV irradiation, coumarin’s photodimerization may proceed according to general Scheme 1. This process will diminish coumarin’s concentration since dimers 5–8 are non-fluorescent compounds. For the reaction depicted in Scheme 2, UV light can lead to the dimers of 7-hydroxy coumarin 3 and diminish its concentration. The respective dimers formed may act as enzyme inhibitors that complicate experimental data interpretation. In our system, enzymatic reactions are tested using the fluorescence method with UV light. Coumarin, a component of the reaction product here, is destroyed by photodimerization. We decided to investigate how significant this effect is by carrying out several experiments to illustrate the Institute of Organic Chemistry PAS, Warsaw, Poland. 2 A. SAMBORSKI ET AL. Scheme 1. Photodimerization of coumarin 4. Scheme 2. The enzymatic reaction of carbonate 1. influence of UV light on the course of the enzymatic reaction. The enzymatic reaction product, we irradiated with UV light in different ways. We changed the sample’s exposure time from very short to continuous irradiated. In this way, we determined the optimal method of irradiation, which allowed us to minimize the impact of photodimerization on the determined kinetic constants of the reaction. This method can also be used in situations where we have photodimerization of other compounds. In this paper, we also specified the applicability range of the M-M theory, where the parameter was the concentration of the enzyme. To verify the obtained results, we used a statistical analysis—the chi-square test, which checks the correctness of the model used. Experimental Materials and methods The fluorogenic probe 1 was synthesized according to the procedure described in the literature.[18] We purchased commercial enzyme Lipase Candida Rugosa from Sigma-Aldrich (batch number: BCBV3825, powder, 67 kDa, enzymatic activity 6.2 U/mg). We prepared the enzyme stock solution for the enzymatic assay by dissolving 1 mg of the enzyme in 10 mL of PBS buffer (pH 7.4) and then diluting with the buffer to the desired concentration. All enzyme experiments we performed by adding 100 mL of substrate[1] solution (0.5 mM in CH3CN) to 5 mL of the enzyme solution in PBS buffer. After shaking, 2 mL of the reaction mixture, we transferred it to the cuvette placed in the experimental set-up. We performed the measurement at room temperature. The measuring system consists of a box made of black polypropylene with a holder for measuring cuvettes inside (Figure 1). It was equipped with a UV diode (365 nm) illuminating the sample and a diode for calibrating the measurement of light detection. In addition, we kit equipment with a temperature control system. We performed fluorescence measurement with a QEPro spectrophotometer (Ocean Optics) connected to the measuring box using an optical fiber. We created a computer program to control the diode lighting and analyze the data obtained from the spectrophotometer. Method of calculation of the kinetic parameters vmax and KM To estimate the enzyme kinetic parameters Vmax and KM, we measure the fluorescence intensity signal proportional to the PREPARATIVE BIOCHEMISTRY & BIOTECHNOLOGY 3 Figure 1. Scheme of the experimental setup for determining the kinetic parameters of the enzymatic reaction. product concentration P(t). We use the known solution of the differential M-M equation[19–23] in terms of the Lambert function W ðxÞ :[24] S0 S0 Vmax t (1) PðtÞ ¼ S0 KM W exp KM KM where S0 is the initial substrate concentration. To estimate the parameters Vmax and KM, we created a numerical code to fit our results to the M-M equation (16). In this code, we use the nonlinear least-squares routines (Levenberg-Marquardt[25,26]), with the initial estimation of Vmax and KM that we obtained through linearization of the M-M equation:[27] PðtÞ KM S0 ln (2) ¼ Vmax t S0 PðtÞ t We prepared a calibration curve based on five different dilutions of the product solution with buffer to find the relation between the fluorescence intensity and the product concentration P(t). Figure 2. The fluorescence intensity (450 nm) of the product vs time, under various modes of illumination of the UV diode. Results and discussion As described in the introduction, the enzymatic reaction product degrades under the influence of UV radiation. In our experiment, the kinetic parameters of the enzymatic reaction are determined by measuring the fluorescence of product 3 (excitation 365 nm). To check the possible effect of UV on the experiment results, we performed a few experiments with different ways of exposing the product solution (7-hydroxy coumarin) to UV radiation. We established the time of the product irradiated and the time between exposures: (1 s, 9 s), (2 s, 8 s), (5 s, 5 s), (1 s, 5 s), (1 s, 1 s). In the end, we continuously irradiated the product. We showed the results in Figure 2. Only for the exposition 1 s and break 9 s the fluorescence intensity remained constant over time—blue line. For other parameters of the expositions, the fluorescence intensity of the product decreased with time, as the same for continuously light. Figure 3. The intensity vs time for the LED pulsed and continuous light. To make sure that the way the diode is turned on does not affect the intensity of the emitted UV light, we compared the intensity of the diode illumination for the wavelength of 365 nm for continuous (red line) and pulsed light (blue line): Figure 3. 4 A. SAMBORSKI ET AL. Figure 4. The intensity vs. time for Csub¼0.5[mM], Cenz¼0.02[mg/mL]: the blue line – the LED pulsed lighting on for 1 s with an interval of 10 s: Vmax ¼ 9.1 102 ± 2.83 103 [mM/s], KM ¼ 31. ± 1.12 [mM], v2 ¼ 16.99, and v2crit ¼ 154.54; the red line – the product was continuously irradiated by UV light: we cannot find the optimal parameters Vmax and KM. Figure 5. The experimental results (squares) and fitting curve (line) for the product concentration of enzymatic reaction: Csub¼0.5[mM], Cenz ¼ f0.1, 0.08, 0.06, 0.04, 0.02, 0.01, 0.005g [mg/mL]. The parameters: v2 and the critical value v2crit determined, which describes the correct fit of the experimental data to the assumed model. Table 1. The kinetic parameters obtained from the reaction for the enzyme CRL with fluorogenic probe 1. Enzyme concentration [mg/mL] 1. 8. 6. 4. 2. 1. 5. 1 10 102 102 102 102 102 103 Vmax [mM/s] 1 2 2.89 10 ± 1.75 10 1.79 101 ± 3.69 103 1.8 101 ± 6 103 1.46 101 ± 3.65 103 9.1 102 ± 2.83 103 2.32 102 ± 5.79 104 4.54 103 ± 6.25 105 The results showed that the intensity values are similar and constant in time. Therefore, we assumed that the observed changes in the fluorescence intensity in the previous experiments were related to the degradation of the product. Hence, the conclusion is that pulsed illumination with the UV diode should be used when determining the fluorescence intensity of the enzymatic reaction product. We verified this by performing two measurements for the same set of enzymatic reaction parameters Figure 4. We can see that the product fluorescence intensities for the continuous and pulsating lighting of the LED are different. For a constant, we get the lowered values. Using our numerical code for the continuous lighting results, we cannot find the optimal parameters Vmax and KM. Opposite, for the pulsating lighting, we got the convergence of the procedure. Therefore, we should use pulse light of the UV diode to correctly determine the kinetic constants of the enzymatic reaction using fluorescence. We used these experimental data and fit them into the M-M equation. In the next step, we decided to check whether the measurement method we used was also effective for low enzyme concentrations. We made a series of measurements of enzymatic reactions for the substrate and the enzyme using the pulse UV LED. In the experiment, we established a constant substrate concentration (Csub ¼ 9.8 mM), while we changed the KM [mM] kcat [1/s] v2 v2crit 2.69 10 ± 1.93 1.93 101 ± 5.04 101 2.32 101 ± 9.46 101 2.37 101 ± 7.2 101 3.1 101 ± 1.12 1.68 101 ± 5.48 101 1.65 ± 6.97 102 0.194 0.15 0.2 0.245 0.305 0.156 0.061 9.74 2.21 1.02 101 3.16 1.69 101 2.47 102 2.51 102 7.44 101 5.95 101 5.95 101 7.53 101 1.55 102 1.55 102 2.1 102 1 concentration of the enzyme: Cenz ¼ f0.1, 0.08, 0.06, 0.04, 0.02, 0.01, 0.005g [mg/mL]. Figure 5 and Table 1. The graph shows the experimental data and the curves obtained by fitting the M-M model.[16] For the concentration of enzyme 0.02 < Cenz<0.1 [mg/mL], we see that our model corroborates with the experimental results and provides a reasonable estimate of the kinetic parameters: Vmax, KM; (v2 < v2crit that is, the theoretical curve describes the experimental results). For low enzyme concentrations Cenz<0.02 [mg/mL], the graphs show a deviation from the M-M model; (v2 > v2crit it means that the assumed theoretical curve badly describes our experiment, with a significance level of 0.95, see Table 1). It suggests the existence of a limit in the enzyme concentration where the description by the M-M model collapses. (the hypothesis H0 that the M-M model good describes the enzymatic reaction should be rejected). The parameters: v2 and the critical value v2crit also determined, which describe the correct fit of the experimental data to the assumed model. Conclusions Coumarins are naturally occurring fluorescent compounds. The high fluorescence of coumarin solutions and biocompatibility make them valuable substrates for enzymatic PREPARATIVE BIOCHEMISTRY & BIOTECHNOLOGY assays.[27] This is due to the fact that fluorescence changes upon coumarin concentration allow for monitoring the progress of chemical and enzymatic reactions. However, under the influence of UV radiation, the photodimerization of coumarins occurs. Our experiments have noticed that we do not get the correct experimental results with continuous UV light irradiation of the enzyme sample. To check the influence of UV light on the course of the reaction, we changed the time of the product irradiated and the time between exposures. The fluorescence intensity remains constant over time for the exposition 1 s and breaks 9 s. For other parameters of the expositions, the fluorescence intensity of the product decreased with time. Therefore for the sample’s exposure 1 s, we can ignore the destructive effect of photodimerization on the kinetic constants of the enzymatic reaction. With pulsed lighting, we got results that we can correctly interpret. We used this method to study CRL enzymes. We showed that we could accurately determine the parameters of the enzymatic reactions. We used the Michaelis–Menten model to describe the enzymatic kinetics by determining the reaction’s kinetic parameters Vmax—the maximum rate of reaction and KM—the Michaelis constant. The statistical analysis gives us information about the scope of application of a given model to describe the phenomenon. Here we used the chi-square test (v2), which checks the correctness of the model used. If v2 > v2crit hypothesis H0 that the model describes correctly enzymatic reaction should be rejected.[28] For the enzymatic concentration Cenz < 1 102 [mg/mL], we obtained that v2 > v2crit which means that the assumed theoretical curve badly describes the experiment. It suggests that we found the enzyme concentration limit below which the description by the M-M model collapses. [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] Funding This work was supported from the National Science Centre, Poland project OPUS No. 019/33/B/ST4/01118. [15] ORCID A. Samborski P. Jankowski R. Ostaszewski http://orcid.org/0000-0001-8088-3891 http://orcid.org/0000-0002-0426-9221 http://orcid.org/0000-0002-3032-196X References [1] [2] [3] Lei, L.; Xue, Y. B.; Liu, Z.; Peng, S. S.; He, Y.; Zhang, Y.; Fang, R.; Wang, J. P.; Luo, Z. W.; Yao, G. M.; et al. Coumarin Derivatives from Ainsliaea fragrans and Their Anticoagulant Activity. Sci. Rep. 2015, 5, 13544. DOI: 10.1038/srep13544. Venugopala, K. N.; Rashmi, V.; Odhav, B. Review on Natural Coumarin Lead Compounds for Their Pharmacological Activity. Biomed Res. Int. 2013, 2013, 963248. DOI: 10.1155/ 2013/963248. Robe, K.; Izquierdo, E.; Vignols, F.; Rouached, H.; Dubos, C. The Coumarins: Secondary Metabolites Playing a Primary Role in Plant Nutrition and Health. Trends Plant Sci. 2021, 26, 248–259. DOI: 10.1016/j.tplants.2020.10.008. [16] [17] [18] [19] [20] 5 Sun, X-y.; Liu, T.; Sun, J.; Wang, X-j Synthesis and Application of Coumarin Fluorescence Probes. RSC Adv. 2020, 10, 10826–10847. DOI: 10.1039/c9ra10290f. Breidenbach, J.; Bartz, U.; Gutschow, M. Coumarin as a Structural Component of Substrates and Probes for Serine and Cysteine Proteases. Biochim. Biophys. Acta. Proteins Proteom. 2020, 1868, 140445. DOI: 10.1016/j.bbapap.2020.140445. Ciamician, G.; Silber, P. Chemische Lichtwirkungen. Ber. Dtsch. Chem. Ges. 1902, 35, 4128–4131. DOI: 10.1002/cber. 19020350450. Miluski, P.; Kochanowicz, M.; Zmojda, J.; Dorosz, D. Energy Conversion in 7-(Diethylamino)Coumarin Doped PMMA Fluorescent Fibre. Opt. Quant. Electron. 2017, 49, 132. DOI: 10. 1007/s11082-017-0971-1. Iliopoulos, K.; Krupka, O.; Gindre, D.; Salle, M. Reversible Two-Photon Optical Data Storage in Coumarin-Based Copolymers. J. Am. Chem. Soc. 2010, 132, 14343–14345. DOI: 10.1021/ja1047285. Samanta, P.; Kapat, K.; Maiti, S.; Biswas, G.; Dhara, S.; Dhara, D. pH-Labile and Photochemically Cross-Linkable Polymer Vesicles from Coumarin Based Random Copolymer for Cancer Therapy. J. Colloid Interface Sci. 2019, 555, 132–144. DOI: 10. 1016/j.jcis.2019.07.069. Kotchapradist, P.; Prachumrak, N.; Sunonnam, T.; Tarsang, R.; Namuangruk, S.; Sudyoadsuk, T.; Keawin, T.; Jungsuttiwong, S.; Promarak, V. N-Coumarin Derivatives as Hole-Transporting Emitters for High Efficiency Solution-Processed Pure Green Electroluminescent Devices. Dyes Pigm. 2015, 112, 227–235. DOI: 10.1016/j.dyepig.2014.06.032. Zaorska, E.; Konop, M.; Ostaszewski, R.; Koszelewski, D.; Ufnal, M. Salivary Hydrogen Sulfide Measured With a New Highly Sensitive Self-Immolative Coumarin-Based Fluorescent Probe. Molecules 2018, 23, 2241. DOI: 10.3390/molecules23092241. Wilk, M.; Ostaszewski, R. Efficient Assay for the Detection of Hydrogen Peroxide by Estimating Enzyme Promiscuous Activity in the Perhydrolysis Reaction. ChemBioChem 2021, 22, 1464–1469. DOI: 10.1002/cbic.202000770. Zadlo, A.; Koszelewski, D.; Borys, F.; Ostaszewski, R. Evaluation of Pseudoenantiomeric Mixed Carbonates as Efficient Fluorogenic Probes for Enantioselectivity Screening. Chembiochem 2016, 17, 71–76. DOI: 10.1002/cbic.201500509. _ ˛dło-Dobrowolska, A.; Szczygieł, M.; Koszelewski, D.; Za Paprocki, D.; Ostaszewski, R. Self-Immolative Versatile Fluorogenic Probes for Screening of Hydrolytic Enzyme Activity. Org. Biomol. Chem. 2016, 14, 9146–9150. DOI: 10. 1039/C6OB01488G. Kowalczyk, P.; Wilk, M.; Parul, P.; Szymczak, M.; Kramkowski, K.; Raj, S.; Skiba, G.; Sulejczak, D.; Kleczkowska, P.; Ostaszewski, R. The Synthesis and Evaluation of Aminocoumarin Peptidomimetics as Cytotoxic Agents on Model Bacterial E. coli Strains. Materials (Basel) 2021, 14, 5725. DOI: 10.3390/ma14195725. Jankowski, P.; Samborski, A.; Ostaszewski, R.; Garstecki, P. Evaluation of Droplet-Based Microfluidic Platforms as a Convenient Tool for Lipases and Esterases Assays. Prep. Biochem. Biotechnol. 2019, 49, 727–734. Choi, B.; Rempala, G. A.; Kim, J. K. Beyond the MichaelisMenten Equation: Accurate and Efficient Estimation of Enzyme Kinetic Parameters. Sci. Rep. 2017, 7, 17018. DOI: 10.1038/ s41598-017-17072-z. Zadlo, A.; Koszelewski, D.; Borys, F.; Ostaszewski, R. Mixed Carbonates as Useful Substrates for a Fluorogenic Assay for Lipases and Esterases. ChemBioChem 2015, 16, 677–682. DOI: 10.1002/cbic.201402528. Corless, R. M.; Gonnet, G. H.; Hare, D. E. G.; Jeffrey, D. J.; Knuth, D. E. On the LambertW Function. Adv. Comput. Math. 1996, 5, 329–359. DOI: 10.1007/BF02124750. Goudar, C. T.; Harris, S. K.; McInerney, M. J.; Suflita, J. M. Progress Curve Analysis for Enzyme and Microbial Kinetic Reactions Using Explicit Solutions Based on the Lambert W 6 [21] [22] [23] [24] A. SAMBORSKI ET AL. Function. J. Microbiol. Methods 2004, 59, 317–326. DOI: 10. 1016/j.mimet.2004.06.013. Goudar, C. T.; Sonnad, J. R.; Duggleby, R. G. Parameter Estimation Using a Direct Solution of the Integrated MichaelisMenten Equation. Biochim. Biophys. Acta. 1999, 1429, 377–383. DOI: 10.1016/S0167-4838(98)00247-7. Schnell, S.; Maini, P. K. A Century of Enzyme Kinetics: Reliability of the KM and Vmax Estimates. Comments Theor. Biol. 2003, 8, 169–187. Schnell, S.; Mendoza, C. Closed Form Solution for TimeDependent Enzyme Kinetics. J. Theor. Biol. 1997, 187, 207–212. DOI: 10.1006/jtbi.1997.0425. Barry, D. A.; Barry, S. J.; Culligan-Hensley, P. J. Algorithm 743: WAPR–a Fortran Routine for Calculating Real Values of the W [25] [26] [27] [28] -Function. ACM Trans. Math. Softw. 1995, 21, 172–181. DOI: 10.1145/203082.203088. Marquardt, D. W. An Algorithm for Least-Squares Estimation of Nonlinear Parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. DOI: 10.1137/0111030. Press, W. H.; Teukolsky, S. A.; Vetterling, W. T.; Flannery, B. P. Numerical Recipes. 3rd ed.; Cambridge University Press, Cambridge, 2007. Robinson, J. A.; Characklis, W. G. Simultaneous Estimation ofV Max, K m, and the Rate of Endogenous Substrate Production (R) from Substrate Depletion Data. Microb. Ecol. 1984, 10, 165–178. DOI: 10.1007/BF02011423. Ross, S. M.; Introductory Statistics. Elsevier Science, Burlington, MA, 2010.