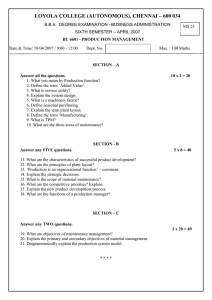

TPM Club India Autonomous Maintenance Pillar PILLAR Jishu Hozen or Autonomous Maintenance TPM Club India Autonomous Maintenance Pillar Reasons Why Autonomous Maintenance is Required No satisfactory increase in the performance record can be seen … • Confirmation of working conditions • Daily inspection • Periodical inspection Activities to keep record on equipment degradation Activities to prevent equipment degradation • Keep cleaning • Inspection • Additional tightening Preventive Maintenance Production Maintenance U.S style of PM Maintenance Department’s sole responsibility Activities to restore the machine conditions TPM Japanese style of PM • Frequent servicing • Solution of abnormality • Good communication TPM Club India Autonomous Maintenance Pillar Autonomous Maintenance •Inspect & lubricate daily •Replace parts and make repairs •Detect abnormalities early •Check precision I take care of my own machine TPM Club India Autonomous Maintenance Pillar Classification of Maintenance and Responsibility Implementation Classification Prevention Measurement Restoration Proper Operation Normal Operation Set-up and adjustment Cleaning, Address Latent Defects Preventive Maintenance Lubrication Daily Maintenance Retightening Operation Condition, Daily Inspection for Deterioration Minor Check Time – based Inspection Time based Maintenance Productive Maintenance Time – based Inspection Time – based Check Tend Check Predictive Maintenance Unscheduled Check Strength KAIZEN Corrective Maintenance (Reliability) Corrective Maintenance Lightening of Loading Accuracy Improvement Corrective Maintenance (Maintain-ability) Conditions Monitoring KAIZEN of Check Operation KAIZEN Of Check Operation Others Maintenance Prevention Breakdown Maintenance Check Quality KAIZEN MP Activities Planned Breakdown Maintenance Emergency Maintenance Earlier discovery of interior situation and positive and rapid report/remedy Sporadic Repair Assigned Operati Maintena on nce TPM Club India Autonomous Maintenance Pillar Relationship Between Forced Deterioration and Losses Example of Forced Deterioration Due to Inadequate Cleaning 1. Cause of failure Contamination by dirt or fallen matter in rotating parts, sliding parts, air and oil pressure systems, electrical control systems, sensors, etc. causes a drop in accuracy, misoperation or a failure due to wear, jamming, resistance, poor electrical conductivity, etc. 2. Cause of quality Direct contamination by foreign matter in products and misoperation of equipment results in quality defects. 3. Cause of forced Waste and dirt makes it difficult to inspect for deterioration looseness, cracks, play and out-of-oil conditions, resulting in forced deterioration. 4. Cause of speed Dirt increases frictional resistance and sliding losses resistance resulting in speed losses such as decreased performance and idling. TPM Club India Autonomous Maintenance Pillar Examples of Steps for Evolving Autonomous Maintenance Step Name 1 Initial clean-up All-around clean-up of dust and dirt, centering on equipment proper, and implementation of lubrication, and machine parts adjustment; discovery and repair of malfunctions in equipment 2 Measures against Sources Prevent causes of dust and dirt and scattering, improve places which are difficult to clean and lubricate and reduce the time required for clean-up and lubrication. 3 Formulation of clean-up and lubrication Formulate behavioral standards so that it is possible to steadily sustain standards clean-up, lubrication and machine parts adjustment in a short period (Necessary to indicate a time frame-work that can be used daily or periodically)…. 4 Overall inspection Training in check-up skills through check-up manuals; exposure and restoration of minor equipment defects through overall check-ups 5 Autonomous check-up Formulation and implementation of autonomous check-up sheets 6 Orderliness and tidiness Standardize various types of on-the job management items and devise complete systematization of up-keep management. • Standards for clean-up, check-ups and lubrication • Standards for physical distribution in the workplace • Standardization of data records • Standardization of die management, jigs and tools 7 All-out autonomous management Development of corporate policies and goals, and making improvement activities routine : Steadily record MTBF analysis, analyze these, and carry out equipment improvements TPM Club India Autonomous Maintenance Pillar Four Steps to Become An Operator Strong on Equipment And Autonomous Maintenance Autonomous Maintenance 7 steps 7 All-out autonomous management 6 Orderliness and tidiness 5 Autonomous check-up 4 General inspection 3 Formulation of clean-up and lubrication standards 2 Measures against sources of outbreaks 1 Initial clean-up Four steps to become an operator strong on equipment 4 Master how to repair the equipment Learn how to operate the equipment 3 with the required accuracy and how to evaluate the product quality 2 Study the mechanism and functions of equipment and machines Familiarize with the concept of equipment 1 maintenance and improvement and with how to put the idea into practical realization TPM Club India Autonomous Maintenance Pillar How to Concretely Develop “Jishu-Hozen” The outline is mentioned in the 1st through 3rd stages, but how to concretely develop the activities is as per Table IV-2. Table IV -2 Development of “Jishu-Hozen” (For equipment) 2nd Activities Target Guidance and promotion Equipment Operator • Prevention of forced deterioration caused by dust or dirt • Discovery and rectification of latent defects thorugh clean-up • Discovery of areas where clean-up and inspection are difficult • Removal of unnecessary things around equipment • Rationalization of lubrication • Formation of mind attachment to the equipment through touching and handling the equipment • Cultivation of the ability to identify equipment “fuguai” • Recognition of the importance of cleanup • Pointing out and guidance of the priority clean-up areas. • Instruction in the importance of clean-up (education) • Preparation of diagnosis sheets • Responsibilities in the operation and implementation of activities Counter• Implementation of countermeasures • Making the equipment • KAIZEN of nearby measures for against such sources as dust and dirt, cleaning and inspection items to practice and the causes and prevention of splashing of leaks easy through improvement to master the of forced of the sources of dust and application of the • Implementation of countermeasures deterioration dirt, and areas where KAIZEN method and against the areas where cleaning and and inspection and cleaning concept inspection are difficult (Operation improviding are difficult improvement for shortening the time • Enjoy the KAIZEN hard-to needed for cleaning and service) • Improvement of activities (Pleasure of access areas • Ranking the priority places for daily maintainability hand-made) inspection • Confirmed of KAIZEN and its effect • Concept and practice of equipment KAIZEN • How to prepare the criteria or standards • Implementation of visual control and instruction on device development • Complete elimination of dust and dirt, especially on equipment • Performance of lubrication and retightening, and discovery and rectification of slight equipment Initial cleandefects up (Cleaning • Removal of unnecessary things, orderliness and tidiness of tools and and jigs inspection © JIPM, 1987 * Trained operators to be proficient in equipment and reduction in failure rate 1st Category * Establish of basic conditions (cleaning, lubrication and retightening) Step TPM Club India Autonomous Maintenance Pillar How to Concretely Develop “Jishu-Hozen” (Contd.) Category Activities Target Equipment 3rd Preparation of tentative “JishuHozen” standards • Preparation of action criteria to • Keeping the 3 basic allow positive clean-up, lubrication elements of equipment and retightening maintenance within maintenance clean-up, shortest time lubrication and relighting • KAIZEN of inspection method and visual control • Mastering inspection skill, utilizing • inspection manuals • Discovery and restoration of general inspection • Preparation of autonomous inspection standards 4th General inspection • • Autonomou s inspection 5th Operator Guidance and promotion • Review clean-up, lubrication and • general inspection criteria and integrate them into comprehensive criteria to contribute to efficiency activities • • Preparation and implementation of autonomous inspection check sheets • Improvement of visual control and operability • Self-decision of criteria • Preparation of and its strict observance standards for technologies and • Each worker learns to be techniques aware of individual roles. • Clarification of procedures to study what the equipment must be Restoration of • Acquaintance of • Preparation of deterioration by inspection skill training text for exterior general general inspection • Understanding the inspection of equipment functions and • Planning of education equipment and mechanism and training schedule reliability • Mastering how to put • Execution of leader improvement. together data and how to training KAIZEN of areas use it • Follow-up of where remedial action • Activation through education and and normal inspection KAIZEN activities training are difficult • Learning the importance • Preparation of Making inspection of education on general inspection efficient communication manual and check sheets Positively keeping the • Maintenance of one’s • Teaching how to restoration from own equipment by precisely analyze the deterioration by means oneself data of general inspection • Self-decision and strict • Effective equipment KAIZEN of equipment observance management and which has good maintenance • “Jishu-Hozen” is operability learning what the ideal * Through implementation and maintenance of inspection Step © JIPM, 1987 TPM Club India Autonomous Maintenance Pillar How to Concretely Develop “Jishu-Hozen” (Contd.) Activities Target Equipment • Picking the items to be managed 6th Standardization • Standardization of management items and systematization of maintenance management • Development of company policy/goals and quantitative analysis of KAIZEN activities Autonomous management 7th • Positive implementation of MTBF analysis and recording (Recording failure by visual control) and equipment KAIZEN Operator Guidance and promotion • KAIZEN of equipment reliability, maintainability and operability • Improvement of • Technical guidance to management technology promote standardization • Expansion of “JishuHozen” management • Revision of • Review and KAIZEN scope management of equipment standards and • Thoroughness of visual environment and thoroughness of control layout management • Kaizen of equipment reliability maintainability and operability through equipment KAIZEN by applying various data analysis • Keeping overall equipment efficiency at its best • Enhancement of goal • Technical assistance consciousness and for equipment thorough cost KAIZEN consciousness, including • Standardization of maintenance cost improved items • Acquirement of skill to • Education and perform minor repair by training in repair oneself skills • Acquisition of data recording and analyzing technique and KAIZEN technology © JIPM, 1987 * Making the strong structure which can perform “Jishu-Hozen management Category * KAIZEN activities, including those for problems related to equipment Step TPM Club India Autonomous Maintenance Pillar Step 1 - Initial Cleaning KEY POINTS • • • • Cleaning with Meaning Cleaning for no cleaning Inspection means finding problems Identification of abnormalities TPM Club India Autonomous Maintenance Pillar Any thing wrong here We’ll clean every nook and corner Anything we can fix right away, we will Cleaning is inspection TPM Club India Autonomous Maintenance Pillar Step 1 - Initial Cleaning : Activities Thorough cleaning of machines and identify White tag Red tag fuguai. Attaching tags for fuguais depending upon the nature. White tags for fuguais to be attended by the operatives. Red tags for fuguais to be attended by the specialists ( Maintenance personnel or subcontractor) Green tags for fuguais found in the similar type Green tag of machines also to be considered for JH machines. Fuguais will be linked to conditions which may lead to breakdown, defect and unsafe conditions. Do audit and get passed. Go for step 2. TPM Club India Autonomous Maintenance Pillar Table 4-6. Sample Manual on Exposing Seven Types of Abnormality Abnormality 1. Minor flaws • Contamination • Damage • Play • Slackness • Abnormal phenomena • Adhesion 2. Unfulfilled Basic Conditions • Lubrication • Lubricant supply • Oil level gauges • Tightening 3. Inaccessible Places • Cleaning • Checking • Lubricating • Tightening • Operation • Adjustment 4. Contamination Sources • Product • Raw Materials • Lubricants • Gases • Liquids • Scrap • Other Examples Dust, dirt, powder, oil, grease, rust, paint Cracking, crushing, deformation, chipping, bending Shaking, falling out, titling, eccentricity , wear, distortion, corrosion Belts, chains Unusual noise, overheating, vibration, strange smells, discoloration, incorrect pressure or current Blocking, hardening, accumulation of debris, peeling, malfunction Insufficient, dirty, unidentified, unsuitable or leaking lubricant Dirty, damaged, or deformed lubricant inlets, faulty lubricant pipes Dirty, damaged, leaking ; no indication of correct level Nuts and bolts : slackness, missing, cross-threaded, too long, crushed, corroded washer unsuitable, wing nuts on backward Machine construction, covers, layout, footholds, space Covers, construction, layout, instrument position and orientation, operating – range display Position of lubricant inlet, construction, height, footholds, lubricant outlet, space Covers, construction, layout, size, footholds, space Machine layout : position of valves, switches, and levers : footholds Position of pressure gauges, thermometers, flow meters, moisture gauges, vacuum gauges, etc. Leaks, spills, spurts, scatter, overflow Leaks, spills, spurts, scatter, overflow Leaking, split, and seeping lubricating oils, hydraulic fluids, fuel oil,etc. Leaking compressed air, gases, steam, vapors, exhaust fumes etc. Leaking split and spurting cold water, hot water, half-finished products, cooling water, waste water etc. Flashes, cuttings, packaging materials, and nonconforming product Contaminants brought in by people, fork-lift trucks, etc. and infiltrating through cracks in buildings TPM Club India Autonomous Maintenance Pillar Table 4-6. Sample Manual on Exposing Seven Types of Abnormality : Contd... Abnormality 5. Quality Defect Sources • Foreign matter • Shock • Moisture • Gain size • Concentration • Viscosity 6. 7. Unnecessary and Nonurgent items • Machinery • Piping equipment • Measuring instruments • Electrical equipment • Jigs and tools • Spare parts • Makeshift repairs Unsafe Places • Floors • Steps • Lights • Rotating machinery • Lifting gear • Other Examples Inclusion, infiltration and entrainment of rust, chips, wire scraps, insects etc. Dropping, jolting, collision, vibration Too much, too little, infiltration, defective elimination Abnormalities in screens, centrifugal separators, compressed – air separators etc. Inadequate warming, heating, compounding, mixing, evaporation, stirring, etc. Inadequate warming, heating, compounding, mixing, evaporation, stirring etc. Pumps, fans, compressors, columns, tanks, etc. Pipes, hoses, ducts, valves, dampers, etc. Temperatures, pressure gauges, vacuum gauges, ammeters, etc. Wiring, piping, power leads, switches, plugs etc. General tools, cutting tools, jigs, molds, dies, frames, etc. Standby equipment, spares, permanent stocks, auxiliary materials, etc. Tape, string, wire, metal plates, etc. Unevenness, ramps, projections, cracking, peeling, wear (steel deckplates) Too steep, irregular, peeling anti-slip covering, corrosion, missing handrails Dim, out of position, dirty or broken covers, not properly explosion-proofed Displaced, fallen off or broken covers, no safety or emergency stop devices Wires, hooks, brakes, and other parts of cranes and hoists Special substances, solvents, toxic gases, insulating materials, danger signs, protective clothing etc. TPM Club India Autonomous Maintenance Pillar Identification of forced deterioration TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar EXAMPLE OF ABNORMALITY ( LOOSE FITTINGS ) TPM Club India Autonomous Maintenance Pillar EXAMPLE OF ABNORMALITY ( LEAKAGES ) TPM Club India Autonomous Maintenance Pillar ABNORMALITY TAGS White Tags Removed by Line Operators Red Tags Removed by Skilled Person TPM Club India Worn-out Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar ELIMINATION OF FORCED DETERIORATION Before After TPM Club India Autonomous Maintenance Pillar ELIMINATION OF FORCED DETERIORATION Before After TPM Club India Autonomous Maintenance Pillar Step 2 - Measures against Sources KEY POINTS • Stop contamination at source • Minimise (localise) contamination • Easy to Clean, Lubricate, Retighten & Lubricate • Uncover to discover • Take counter measure against Forced deterioration TPM Club India Autonomous Maintenance Pillar EASY TO CLEAN Means easy to clean, collect, dispose & inspect Use of localised guards TPM Club India Autonomous Maintenance Pillar Step 2 : Countermeasure for the causes of Forced Deterioration and Improving and Hard-to Access Areas Purposes : • Eliminate sources generating dirt, dust and stains, prevent splashing and flying and improve places that are hard to access, oil and check to shorten the time needed for cleaning, oiling and inspection • Learn approach to equipment KAIZEN and achieve tangible results © Understand evils of dirt, stains, dust and foreign matter Gather quan-tified data © Why do they generate ? © Learn how to think of KAIZEN © Find places with dirt, stains, dust and foreign matter accumulated © Analyze dirt, stains, dust and foreign matter material, shape and composition © Analysis of generating sources • Do they generate in a prior processes ? • Do they generate in one’s own process ? • Are they generated by machining ? • Are they generated by equipment ? • Do they come form the outside the plant ? © • • • • © What are hard-to-access areas • Time-consuming places • Places difficult to do © What type of work is performed? • Cleaning, oiling, inspection • Which tools are used ? • Can work be performed in a visible state ? • How are results checked? • Visual examination hand…. © Devise countermeasures • Goal time • Improvement method Devise countermeasures Eliminate generating sources Prevent splashing and flying Prevent instrusion and attaching Schedule, operators in charge, plan Present daily cleaning and inspection goal time • Eliminate • Focus Restoration and KAIZEN •Prevent splashing and flying Check results of KAIZEN measures Reexamine tentative cleaning standard Matters pointed out Clean in accordance with tentative cleaning standard Autonomous audit KAIZEN records Reexamine tentative standard prepared in step 1 and tentative standard improved afterward Check if cleaning can be finished accurately within time specified in tentative standard and remove “EFU” Circle activity report, application for plant audit Plant audit © JIPM, 1987 Passed •……… •……… •……… Activities board TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar Minimise Contamination TPM Club India Autonomous Maintenance Pillar Modify equipment to make cleaning easier TPM Club India Autonomous Maintenance Pillar Install covers and inspection windows to make checking easier TPM Club India Autonomous Maintenance Pillar SOURCE OF CONTAMINATIONS TPM Club India Autonomous Maintenance Pillar IDEA FOR ELIMINATING FORCED DETERIORATION TPM Club India THEME: Autonomous Maintenance Pillar KAIZEN LOSS NO MACHINE: LOSS STRUCTURE: To reduce Cleaning time BENCH MARK 30 Sec TARGET 5 Sec 8A Cleaning Time Reduction COUNTERMEASURE: Before Oi lC Cleaning the contaminated material deposited in the magnet takes more time hu Contaminated material te KAIZEN START TEAM: IDEA: To provide a polythene paper on the magnet to collect contaminated material PROBLEM: 13B5SL S.Ravindharan V.Mohan P.Comarasen K.Patchaiappan 15.03.2001 KAIZEN FINISH 16.03.2001 BENEFITS : After Oi lC hu Contaminated material te Polythene Magnet Paper Magnet • Time saving / month = 533 min • Timings saving / Year = 6396 min • Effortless activity Oil tank Remove magnet & cleaning by brush with diesel then fix magnet ANALYSIS: WHY 1 Cleaning the magnet takes more time Oil tank No cleaning remove Polythene paper and fix new polythene paper HORIZONTAL DEPLOYMENT : RESULT: WHY 2 WHY 3 Iron particles not coming out easily from magnet Due to magnetic property Sec 30 Before After 30 Sec BETTER 15 5 Sec 0 Area Status Socket 13 Hex 15 Special 13 TPM Club India THEME: Autonomous Maintenance Pillar KAIZEN LOSS NO. To Reduce Cleaning Time inside the machine area in rolling machine BENCH MARK 8A LOSS STRUCTURE: Cleaning Time Reduction CGR17H TEAM: J. Srinivasan KAIZEN START 03-06-2001 S.Jayaraman 3 min / shift IDEA: To provide gaurds in the product discharge chute & providing conveyor “Zero” TARGET MACHINE: PROBLEM: COUNTERMEASURE: Before Krishnamoorthy D.Sivakumar KAIZEN FINISH 21-06-2001 G. Devanathan BENEFITS : After Gaurd Time saving = 3 Min / Shift Man hours saved per year = 15 hours Time taken for cleaning inside the machine area is more Other Benefits No Spill Over of Products Tray Product spillover ANALYSIS: WHY 1 Cleaning time Problem : Cleaning time is more WHY 2 WHY 3 Products get Basic design is more in spilled over inside the inside the machine area machine area in rolling and oil leakage machine from chute No oil leakage Oil S-Conveyor Oil Pit RESULT: HORIZONTAL DEPLOYMENT : mts 3 min / shift 3 Better of chute No of rolling machines Identified : 9 Nos. Implemented : 6 Nos. Zero 0 Before After Target Date 25-09-2001 TPM Club India Autonomous Maintenance Pillar EXAMPLES OF LOCALISED CONTAINMENT Before After TPM Club India Autonomous Maintenance Pillar Usage of localised guards TPM Club India Autonomous Maintenance Pillar Eliminate cleaning by fabricating chute for collecting disposable waste. After Before TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar Actions to eliminate dust falling on the floor TPM Club India Autonomous Maintenance Pillar Easy to lubricate TPM Club India Autonomous Maintenance Pillar Countermeasures against source of contamination Oil Localisation Before After Localised gaurds The return oil flow from the feed drive gears splash and spread all around the open space inside the machine there by getting contaminated. To avoid the contamination, the return oil flow is channalised from the feed drive gears directly to the lubrication tank TPM Club India Autonomous Maintenance Pillar Easy to Lubricate Before Machine cover After Machine cover Grease points Pulley In TM19B tapping machine the plummer block bearings (2 nos in every spindle and there are 4 spindles) are lubricated once a week. This activity takes 20 minutes since the lub points are inside and machine covers to be removed and again assembled. It is also difficult to do this activity as the grease points are in “Hard to access” areas. Pulley Grease points The grease points have been brought out by means of tubes and greasing is done even when the machine is running. In addition to avoidence of loss of time,. It is also safe to carry out this activity like this. TPM Club India Autonomous Maintenance Pillar DIFFICULT TO LUBRICATE - EASY TO LUBRICATE Before Difficult to Lubricate the oil to gear box After Easy to Lubricate the oil to gear box TPM Club India Autonomous Maintenance Pillar Easy to Retighten TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar Easy to Inspect TPM Club India THEME: Autonomous Maintenance Pillar KAIZEN LOSS NO. LOSS STRUCTURE: To reduce Inspection time BENCH MARK TARGET MACHINE: 8A 2 sec / Day PROBLEM: Inspection Time Reduction COUNTERMEASURE: Before KAIZEN START TEAM: J. Sriram 10.05.2001 Karunairaja IDEA: To bring the pressure gauge for K.O. system outside the machine for easy inspection 30 sec / Day 10B3S After Franklin KAIZEN FINISH 25.05.2001 Sivakumar Ramalingam BENEFITS : Time saving = 28 sec / Day Man hours saved per year = 15 hours Inspection is very difficult and taking more time in the pressure gauge for K.O. system Pressure gauge Inside the M/c Difficult to Inspect ANALYSIS: WHY 1 Inspection is very difficult and it is taking Problem : Inspection is difficult WHY 2 WHY 3 Pressure gauge By machine kept inside the design Pressure gauge Outside the M/c Other Benefits Inspection becomes easy Easy to Inspect RESULT: HORIZONTAL DEPLOYMENT : Sec. 30 sec / change 30 Better No of Areas machine Identified 15 : 5 Nos. moretime in pressure gauge for K.O. system 2 sec / Day 0 Before After Implemented : 5 Nos. TPM Club India THEME: Autonomous Maintenance Pillar KAIZEN LOSS NO MACHINE: LOSS STRUCTURE: To reduce Inspection time 8A BENCH MARK 10 Sec / Inspection TARGET 1 Sec / Inspection PROBLEM: IDEA: To provide oil level visual indicator outside the gear box COUNTERMEASURE: Before 19.03.2001 Jayaraman Devanathan Krishnamoorthy Sivakumar KAIZEN FINISH 31.03.2001 BENEFITS : After Dip Stick Max To check the oil level in gear box is very difficult & take more time KAIZEN START TEAM: Inspection Time Reduction Lock screw 17B3S Gear Box Gear Box • Time saving / month = 270 Sec • Timings saving / Year = 3240 Sec • Effortless activity Min * Unlock Screws * Remove Dip stick * Inspect * Assy dip stick * Lock screw ANALYSIS: WHY 1 Inspection the oil level takes more time * Inspect Only HORIZONTAL DEPLOYMENT : RESULT: WHY 2 WHY 3 Method of inspection is difficult Basic machine design Sec 10 Before After Area 10 Sec Socket BETTER 5 Special 1 Sec 0 Hex Status ` ` ` 8/13 11/15 7/13 TPM Club India Autonomous Maintenance Pillar Easy to Clean & Inspect Before Motor Inside The 10b3s forging machine was fully covered which makes difficult to clean & inspect in the motor, fly wheel area After Motor Outside The C’measure was taken by opening the side cover of the machine & an See thru sheet was provided which makes easy to clean and inspect, the motor and flywheel. TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar DIFFICULT TO INSPECT- EASY TO INSPECT Before Difficult to Inspect the belt condition After Easy to Inspect the belt condition TPM Club India Autonomous Maintenance Pillar Rearranging cables / hoses for easy inspection Before After TPM Club India Autonomous Maintenance Pillar Step 3: Formulation of cleanup and lubrication standards • Learn the structure and functions of your own equipment (training by leader) • Test your understanding and then actually inspect the equipment • Correct new problems found • Establish through visual controls to help control equipment conditions TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar Step 3 : Preparation of Tentative “Jishu-Hozen” Standards Purposes : • Basic conditions of activities to prevent equipment deterioration -- Maintenance and management of cleaning, lubrication and retightening • Action standard allowing accurate maintenance of basic conditions quickly is prepared by oneself • New ideas for visual control (Steps 1 and 2) List of slight defects found Kaizen records Check goal time © • • • • • Cleaning and inspection Clarify places Clarify method Clarify standard Clarify troubleshooting Clarify period © • Set goal time • • • • • Lubricating Lubrication places, lubrication types, lubrication levels, tools Clarify period Identify lubrication work trouble and problems KAIZEN Set goal time Prepare standard © Utilize visual control Cleaning, lubrication and inspection Guidance items Maintenance department Lubrication manual Lubrication training © Study what is wrong with existing standards © Study why they could not be followed Difference with goal time KAIZEN KAIZEN records Implement and confirm Activity records Autonomous audit Circle activity report and plant audit application Plat audit Passed •……… •……… •……… •……… •……… Activities board Passed * * * © JIPM, 1987 TPM Club India Autonomous Maintenance Pillar Cleaning and Lubricating Inspection 1) Lubrication 1) Clarify Places Places,Types,Levels,tools 2) Clarify method 2) Clarify Period 3) Clarify Standard 3) Identify lubrication work trouble & problems, Make 4) Clarify Troubleshooting 5) Clarify Period Lubrication Manual 4) Kaizen Set Goal time TPM Club India Autonomous Maintenance Pillar MAJOR GUIDELINES TO PREPARE JH STANDARDS • Study the existing M/C check sheet & Analyse the reasons, why is it not maintained and used effectively. • All the cause and problems should be addressed & rectified while preparing new standards • Set Goal time for all activities put together-Cleaning, Lubrication, Inspection & Retightening, set it separately for D,W,M & Y activities • Consider Stratification of Fuguais & see to that no Fuguai is missed, which needs to be addressed in standards to prevent Forced deterioration TPM Club India • Autonomous Maintenance Pillar Clarify place, method, standard, troubleshooting, period, tool, frequency etc. So that no ambiguity and subjectivity remains in mind while taking decision for any point in the standard • The standards should be rational and should consider all points necessary to maintain its basic operating conditions and prevent equipment deterioration. • Bring in More VISUAL CONTROLS so during inspection decision can be made easily & correctly by the person about check points. • Revise the standards after implementing any Kaizen TPM Club India Autonomous Maintenance Pillar VISUAL CONTROLS Activity CLEAN LUB INSPECTION Symbol Tools I S NOC TPM Club India Autonomous Maintenance Pillar COLOUR CODE FOR FREQUENCY TPM Club India Autonomous Maintenance Pillar DAILY INSPECTION ROUTE BEFORE STEP-3 9 1 8 7 6 2 5 3 4 Machine - Shigiya 138 - Grinding Machine TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar JISHU-HOZEN CHECK SHEET POINT NO. 3 HYDRAULIC TANK FRONT,LUB TANK,FRL AND WORK HEAD BACK MACHINE : C P BORING CELL : CONNECTING ROD SL. NO CHECK ITEM D 1 HYDRAULIC TANK FRONT 1a Outer body 1b Pipe Joints W M STND. VALUE 1 2 3 4 5 6 7 8 9 PLANT : ENGINE PLANT 10 11 MONTH : JANUARY 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 No dirt & dust No Leak btwn. Max & Min. 1c Oil level indicator 1d Oil pressure Gauge 2 LUBRICATION TANK 2a Tank outer body 2b Level indicator 2c El. Jn. Wiring 2d Lub Pipe joints in Green Zone No dirt & dust btwn. Max & Min. 3M No Leak Checked By : Sign. Of Supervisor REVISION NO. LEGENDS - ( ) - OK , ( 1 ) - NOT OK , 2 ( ) - NOT OK,RECTIFIED BY SELF , 4 3 ( ) - NOT OK, INFORMED SUPERVISORP, ( ) - PLANNED. TPM Club India Autonomous Maintenance Pillar TENTATIVE CLEAN LUB INSPECT STANDARDS Jishu - Hozen ( Tentative Cleaning, Lubrication and Inspection ) Standards Cell : Nozzle Cell Equipment description : Micromatic OD Grinding Machine Illustration Tail stock Classification Inspection No. 1 Equipment number : M12045 Place or section Tailstock Standards With in the indicated Cirlce name : NOZH 1 Method Visual value range Cleaning 2 Tailstock Free from mist & dust Waste cloth Inspection 3 Table Lubrication With in the indicated Visual value range Inspection 4 Loader Pistion No Damage Tools and Time Cycle handling N I N Remove the 3mm Pistion block Allenkey sec (month) Person in charge 2 W OP 30 W OP 2 W OP 1200 1 M OP During During operation stoppage b b b b Keys : D : Daily; W : Weekly; SC : Setting change; PM : Maintenance staff; OP : Operator. TPM Club India Autonomous Maintenance Pillar Aiders : Visual controls TPM Club India Indication marks for nuts & bolts Autonomous Maintenance Pillar Indication for valve controls TPM Club India Operational range on indicators Autonomous Maintenance Pillar Direction flow indicators TPM Club India Fan to indicate the function of Chiller Unit Autonomous Maintenance Pillar Arrow sign for indicating the rotating direction of Motor TPM Club India Color code for Lubrication oil Autonomous Maintenance Pillar Display of sub equipment name TPM Club India Autonomous Maintenance Pillar TPM Club India Autonomous Maintenance Pillar ONE POSITION INSPECTION Hydraulic tank Lube oil tank Before – Hydraulic tank and Lubrication tank in different position. After – Hydraulic tank and Lubrication tank in one position. TPM Club India Autonomous Maintenance Pillar Initial Clean-up ( Cleaning is Inspection) ( Cleaning with meaning) (Doing with purpose) Taking countermeasure for forced deterioration and improving hard to access area Preparing tentative standards for cleaning and lubrication TPM Club India Autonomous Maintenance Pillar Example of Activities Board Leader Sub leader Circle Members Section and Subsection Goals and Measures Policies Kobetsu-Kaizen Themes ! Reason for Selection Understand Present status Analysis Troubleshooting and Schedule Accomplishment Indices Overall Efficiency Availability Non Defe-ctive Rate Performance Rate Rework Defect Minor Stoppag e Speed Failure Acceptance Effect Prevention of Recurrence, Remaining problems Jishu-Hozen Activity Schedule Number of Suggestions * Fuguai List Efu Attaching Removing and One-Point Lesson List of Doubts Actual Work Meetings Activities “Good to Find” Corner Photo Before Before Source : Our TPM © JIPM, 1994 TPM Club India Autonomous Maintenance Pillar Concept of “Jishu-Hozen” Change in concept Step 0 Motivation Step 1 Step 2 Step 3 Change equipment Step 4 Step 5 Effect Reduced defects and failures • Think and act • Rectify “Fuguai” • Process of actions is head-spring of motives • Cleaning is inspection • Inspection is a step to find “Fuguai” • “Fuguai” should and could be restored or improved • Why does forced deterioration occur ? • Needs of “Jishu-Hozen Enhance ability to find and improve “Fuguai” Defects and failures are the shame of the Production shop Step 6 Step 7 Effect Operator’s Change Zero defects and failures are realized Production shop changes Change in activities • Positive challenge for KAIZEN. • Thoroughness of maintenance and management • Restoration and KAIZEN are a kind of success. • Success is a pleasure as a result of achievement (Unless success can be expected, the operators will not change their mind.) • Bottom up from circle activities • Autonomous KAIZEN by operators TPM Club India Autonomous Maintenance Pillar Keypoints for Autonomous Maintenance Success and Check Points of Controller Roles 1. Introductory education…………….…….. Is TPM well understood ? 2. Cooperation between Divisions………. Are the assistance and cooperation of other divisions towards the production division satisfactory ? 3. Main Body of Circle Activities………….. Are the overlapping small group activities adopted ? 4. The work itself ………………………….. Has the concept of “Autonomous Maintenance is the work itself “ been established 5. Practice – First ………………………..…. Instead of insisting on forms and theroy, are people learning by experience ? 6. Education & Training……………………. Are training education and training done in accordance with the step 7. Substantial effect………………………… Are substantial effects obtained in accordance with the steps ? 8. The matters to be observed shall………. be decided by oneself Is there the capacity to decide by oneself ? 9. Autonomous Maintenance……………… Diagnosis Are the diagnosis and guidance of the controller adequate? 10. Model Selection………………………….. Is the selection of the model adequate ? Is the guidance of the controller good ? 11. Rapid Processing of ………………..…… Plant Is the processing of non-conformity points and improvements done rapidly ? 12. Make it Thorough………………………… Aren’t the steps merely followed by formality? TPM Club India Autonomous Maintenance Pillar Step 4 : General Inspection Purposes : • Understand structures, functions, principles and proper approach of equipment • Learn skills to inspect principal functions and parts comprising equipment • Thoroughly inspect principal functional parts comprising equipment and actualize and restore latent defects Preparations • Cut model • Inspection item list • Flow chart • Schematic diagram Training implementation © Identify subjects © Prepare teaching materials © Prepare training program © Instructors © Leaders © Each machine element 6 subjects - 2 subjects General inspection implementation 8. Machining conditions 7. Safety 6. Electric 5. Drive 4. Pneumatic 3. Hydraulic Inspection 2. Lubrication Analysis of results 1. Bolts and nuts Training Prepare 1- point lessons Transmission of education General inspection manual Comprehension check Skill check Prepare tentative inspection standard for each subject Restore and improve © Visual control Items pointed out Autonomous audit for each subject Plant audit for each subject Circle activity report Application for plant audit See data for each subject •……… •……… Hydraul ic fuguai Activities board Passed © JIPM, 1987