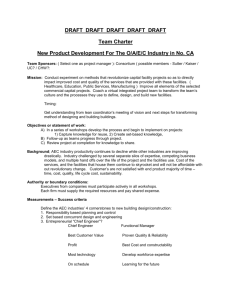

TECHNOLOGY CONCENTRATES Light-emitting diodes Chrome plating process M&T Chemicals, Inc., says it has developed a chrome plating process which combines the advantages of soluble and insoluble catalyst systems. The Rahway, N.J., firm, a subsidiary of American Can Co., says its Luma-Chrome process operates at low chromic acid concentrations with a soluble primary sulfate catalyst (sulfuric acid is the makeup), and a selfregulating insoluble secondary catalyst. M&T claims the process gives improved plating speeds and lower finishing costs. • Mercury in water High, but periodically varying, mercury levels in drinking water have been found in a survey of 24 Chicago-area communities conducted by Midwest College of Engineers, Chicago. MCE used flameless atomic absorption to find more than 18 p.p.b. mercury in one well in Aurora, III., and periodic levels higher than the recommended federal maximum of 5 p.p.b. in other suburban areas. • Long-lived foams A process for making high-expansion, long-lived, semiplastic foams has been developed by Douglas United Nuclear, Inc., Richland, Wash., at AEC's Hanford reactor. Designed to encapsulate radioactive noble gases in an emergency and prevent their escape, the foam's long-lived bubbles may also be suitable for control of particulate and gaseous industrial effluents, or protection of plants from frost, note project engineers Jim Mecca and H. F. Jensen. A foam made from polyethyjeneimine, polyvinyl alcohol, a surfactant, and water lasts almost 250 days. AEC has applied for a patent on the foaming process. • A new process for fabricating electronic display panels from thousands of tiny light-emitting semiconductor diodes—with application in computers, two-way communications, and eventually perhaps low-cost home display terminals— has been developed by Dr. Allen M. Barnett, Dr. Simeon V. Galginaitis, and Frederick K. Heumann at General Electric's research and development center, Schenectady, N.Y. The GE scientists can put as many as 2000 diodes and their interconnections on a coin-sized wafer of gallium phosphide by etching grooves into the wafer and growing in gallium phosphide containing an n-type dopant • Gaseous diffusion plants 0/7 from shale Elsewhere, AEC has contracted for additional electric power to bring its three gaseous diffusion plants back to full capacity. Currently, the plants—which produce enriched uranium reactor fuels— are operating at about 40% of capacity. AEC also plans a 10-year, $750 million production improvement and uprating program. • Oil has been successfully produced from large uncrushed oil shale boulders of up to 5 tons in two retorting tests made by the Bureau of Mines simulating underground conditions. Heating the shale at more than 900° F. released the oil for collection at the retort bottom. • Pollution instrumentation U.S. requirements for air pollution analysis instrumentation will grow to between $60 and $80 million yearly by 1980, according to a study by Arthur D. Little, Inc., Cambridge, Mass. The 260-page study assesses existing and needed technology, and identifies three principal instrumentation sectors and 12 subsectors. It concludes that only a few segments will reach annual sales of $10 million by 1980. In March, ADL will issue a similar study on water pollution equipment. C&EN projects a total pollution instrumentation market of at least $1 billion for the 1970's (C&EN, Feb. 15, page 78). • 22 C&EN MARCH 1, 1971 0/7 absorbent Electro-optic ceramics "Whiter whites" and "blacker blacks" characterize ferroelectric electrooptic ceramics made by a process developed by Dr. Gene H. Haertling, Sandia Laboratories, Albuquerque, N.M. Dr. Haertling says that the greater degree of blackwhite contrast (4000:1 compared to 1000:1) should make the materials useful in optical memory devices, as well as in display applications. The improved process is used to produce lanthanum-modified lead zirconate/lead titanate. • Sorboil, a fibrous material which may be useful for cleaning up oil spills, is being developed by Innova Corp., Seattle, Wash. Sorboil's inventor, G. Otto Orth, says that the material—made by hydrocarbon treatment of recycled waste such as shredded cardboard or old newsprint—has many times the oil absorbency of straw, and may be cheaper and more easily disposed of than some competitive oil absorbents. So far tested only in the laboratory, Sorboil may have other applications besides oil spill cleanup. A new company, Marlex Enviro-Systems, Ltd., Vancouver, B.C., will have sole marketing rights in Canada. •