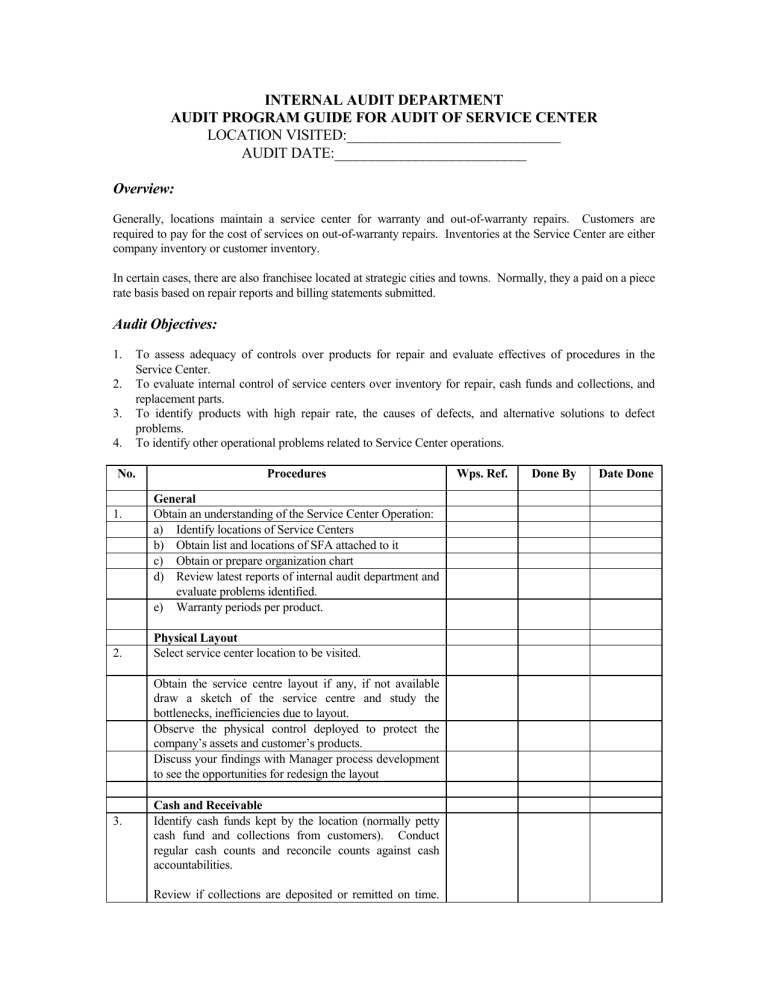

INTERNAL AUDIT DEPARTMENT AUDIT PROGRAM GUIDE FOR AUDIT OF SERVICE CENTER LOCATION VISITED:_____________________________ AUDIT DATE:__________________________ Overview: Generally, locations maintain a service center for warranty and out-of-warranty repairs. Customers are required to pay for the cost of services on out-of-warranty repairs. Inventories at the Service Center are either company inventory or customer inventory. In certain cases, there are also franchisee located at strategic cities and towns. Normally, they a paid on a piece rate basis based on repair reports and billing statements submitted. Audit Objectives: 1. 2. 3. 4. To assess adequacy of controls over products for repair and evaluate effectives of procedures in the Service Center. To evaluate internal control of service centers over inventory for repair, cash funds and collections, and replacement parts. To identify products with high repair rate, the causes of defects, and alternative solutions to defect problems. To identify other operational problems related to Service Center operations. No. 1. 2. Procedures General Obtain an understanding of the Service Center Operation: a) Identify locations of Service Centers b) Obtain list and locations of SFA attached to it c) Obtain or prepare organization chart d) Review latest reports of internal audit department and evaluate problems identified. e) Warranty periods per product. Physical Layout Select service center location to be visited. Obtain the service centre layout if any, if not available draw a sketch of the service centre and study the bottlenecks, inefficiencies due to layout. Observe the physical control deployed to protect the company’s assets and customer’s products. Discuss your findings with Manager process development to see the opportunities for redesign the layout 3. Cash and Receivable Identify cash funds kept by the location (normally petty cash fund and collections from customers). Conduct regular cash counts and reconcile counts against cash accountabilities. Review if collections are deposited or remitted on time. Wps. Ref. Done By Date Done Match collections and deposits for the last two weeks. Vouch petty cash expences to esure their accuaracy and compliancy to procedure Analyse expenses against prior year and identify unusual variances Obtain list of debtors and their aging and investigate reasons for long outstanding debtors Obtained list of completed repairs which were not invoiced. Calculate the aging and discuss with manger reason for not raising invoices. 4. Inventory Prepare flowcharts (or narrative) on: a) Control over parts inventory. b) Control of accountability over inventory for repair (both for company and customer inventory) d) Management reporting 5. Evaluate whether existing procedures provide adequate internal controls. Check if records are updated and kept in order. 6. Obtain monthly analysis of the following (by product line and by product): a) Inventory received for repair. b) Inventory repaired during the month. c) Inventory pending repair (with aging). Review available management reports. Generally, these will provide the required information and more. 7. Perform test count of service parts (10 to 15 items). Reconcile against inventory records. 8. Conduct count of selected items pending repair, repaired but not collected items and reconcile against accountability records. 9. Note down long-outstanding items not repaired and obtain reasons why they remain unrepaired (refer to aging). Determine time needed to repair damaged inventory and review whether repair turnover rate is acceptable? What should be done to expedite repair? Select items repaired during the year. Calculate the number of days from the time that the unit is received until it is repaired. Also determine date when the customer picked up the unit. 2 Are there items already repaired but not yet picked up by the customer? How long have they been in the service center? 10. Assess condition of the repair area. Is it clean, organized, and orderly? Are items for repair properly tagged so that defects are readily identified? Check whether repaired items segregated from unrepaired items. Also review whether company inventory segregated from customer inventory. 3 No. 11. Procedures Identify products with high quality problems. Relate the units of products sent for repair during the year against unit sales. Evaluate seriousness of recall percentages and determine need for additional procedures. Prepare a pareto list of quality problems. What did the location do to solve the problems? 12. Review procedures over repairs done by subcontractors. How are subcontractors paid? Review billings and payments and perform required tests at head office. 13. Determine the total warranty repairs during the previous year and current year. Obtain an analysis by product line. 14. Obtain P&L of service center. If none is available, identify all income and expense related to the Service Center operations. Are there areas where costs can be saved? 1. 2 . 3 4 5 6 7 8 9 SFA Work Discuss the nature of the SFA operation with Obtain list of SFAs attached to the Service centre and check the SFA agreements to identify expired agreements. Ensure that adequate SD is maintained for each SFA Look at the coverage of the SFA and service centers and assess the adequacy of the resources to cover the area. Check SFAs are available for all kind of product categories and if not; check whether servce center has resources to cover the gap. Analyse SFA jobs and payments for last 6 months Investigate repeated repairs and investigate the reason for repeat repairs and parts consumed to ensure no misappropriation exist. Select 7 SFAs covering following criteria; a) High voulume b) Lowers volume c) High volume of labour only jobs d) High % of jobs with spareparts e) Pending jobs and other criteria you may think appropriate Visit the above slected SFAs and do a physical observation of the location to determin cleanliness, due care for the products and resources to carry out jobs with the expectation of the company. Also check Nameboard and uniform for staff were provided Assess the technical background of the staff working under SFA 4 Wps. Ref. Done By Date Done Carryout physical verification of finished products and agree with pending jobs and undelivered jobs. Check whether inventories are insured adequately. Analyse the pending jobs and investigate any aging items Analysie locally purchased items and check if SFA is purchaseing items available in service centers. Analyse payable to and receivable from SFA and investigate any aging items Check sample of labour only jobs and contact the customers to ensure a job was done for them. Check whether Service Center Management had vsited SFA and SFA had called for the regular meetings with SC. Review minutes of meetings if available and ensure they were properly followed up. Discuss with SFA about improvement opprtunities 5