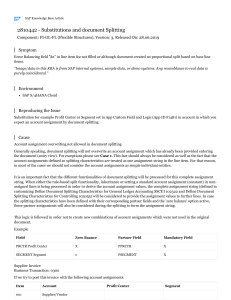

PRACTICE FOR GROUP WORK WEEK 2 Case 2.1 – ASSIGNING PLANTS TO PRODUCTS (BETTER PRODUCTS COMPANY) The Better Products Company has decided to initiate the production of four new products, using three plants that currently have excess production capacity. The products require a comparable production effort per unit, so the available production capacity of the plants is measured by the number of units of any product that can be produced per day, as given in the rightmost column of Table case 2.1. The bottom row gives the required production rate (number of units produced per day) to meet projected sales. Each plant can produce any of these products, except that Plant 2 cannot produce Product 3. However, the variable costs per unit of each product differ from plant to plant, as shown in the main body of the table. Management now needs to make a decision about which plants should produce which products. Product splitting, where the same product is produced in more than one plant, is permitted. Table case 2.1 – The Data for the Better Products Co. Problem Formulated as a Variant of a Transportation Problem Unit Cost Product Plant 1 2 3 Required production 1 2 3 4 $41 $40 $37 20 $27 $29 $30 30 $28 $27 30 $24 $23 $21 40 Capacity Available 75 75 45 Case 2.2 – ASSIGNING PLANTS TO PRODUCTS (BETTER PRODUCTS COMPANY) The Better Products Co. needs to assign three plants to produce four new products. The relevant data are given in Table case 2.2. Management had permitted product splitting (where the same product is produced in more than one plant). However, there are some hidden costs associated with product splitting that are not reflected in Table case 2.2, including extra setup, distribution, and administration costs. Therefore, management now has decided to have the problem analyzed again under the additional restriction that product splitting is prohibited. New Problem Statement: Given the data in Table case 2.2, minimize the total cost of assigning each plant to at least one new product where each product is to be produced in only one plant (no product splitting). Since there are three plants and four new products, two plants will produce one new product and a third plant will produce two. Only plants 1 and 2 have the capacity to produce two. Table case 2.2 – Data for the Better Products Co. Problem Cost ($/day) Product Plant 1 2 3 4 Total assignments 1 2 3 Total assigned 820 800 740 1 810 870 900 1 840 810 1 960 920 840 1 2 1 1