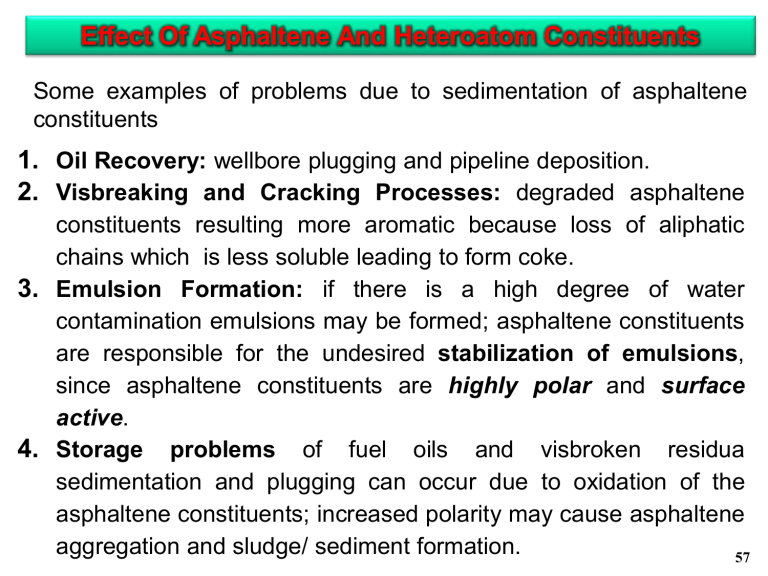

Effect Of Asphaltene And Heteroatom Constituents Some examples of problems due to sedimentation of asphaltene constituents 1. Oil Recovery: wellbore plugging and pipeline deposition. 2. Visbreaking and Cracking Processes: degraded asphaltene constituents resulting more aromatic because loss of aliphatic chains which is less soluble leading to form coke. 3. Emulsion Formation: if there is a high degree of water contamination emulsions may be formed; asphaltene constituents are responsible for the undesired stabilization of emulsions, since asphaltene constituents are highly polar and surface active. 4. Storage problems of fuel oils and visbroken residua sedimentation and plugging can occur due to oxidation of the asphaltene constituents; increased polarity may cause asphaltene aggregation and sludge/ sediment formation. 57 CRUDE OIL CLASSIFICATION Refinery deals with crudes of different origins, many methods established to group crude oils with similar characteristics. Crude oils can be classified into three or four groups depending on the relative ratio of the hydrocarbon classes that predominates in the mixture. The following describes three types of crudes: 1. Paraffinic: the ratio of paraffinic hydrocarbons is high compared to aromatics and naphthenes. Like Pennsylvanian 2. Naphthenic: the ratios of naphthenic and aromatic hydrocarbons are relatively higher than in paraffinic crudes. 3. Asphaltic: contain relatively a large amount of polynuclear aromatics, a high asphaltene content, and relatively less paraffins than paraffinic crudes. 58 PROPERTIES OF CRUDE OILS Crude oils differ in their properties according to origin and the ratio of the different components in the mixture. Lighter crudes generally yield more valuable light and middle distillates and are sold at higher prices. Crudes containing a high percent of impurities, such as sulfur compounds, are less desirable than low-sulfur crudes because of their corrosively and the extra treating cost. Corrosivity of crude oils is a function of many parameters among which are the type of sulfur compounds and their decomposition temperatures, the total acid number, the type of carboxylic and naphthenic acids in the crude and their decomposition temperatures. The following are some of the important tests used to determine the properties of crude oils Dr.Firas Salim Mohammed Al-Ghulami 59 Density, Specific Gravity and API Gravity Density is defined as the mass of unit volume of a material at a specific temperature. A more useful unit used by the petroleum industry is Specific Gravity, which is the ratio of the weight of a given volume of a material to the weight of the same volume of water measured at the same temperature. The API (American Petroleum Institute) gravity is another way to express the relative masses of crude oils. The API gravity could be calculated mathematically using the following equation: A low API gravity indicates a heavier crude oil or a petroleum product, while a higher API gravity means a lighter crude or product. Specific gravities of crude oils roughly range from 0.82 for lighter crudes to over 1.0 for heavier crudes (41 - 10 °API scale). 60 Salt Content The salt content expressed ppm NaCl (or in pounds/barrel) indicates the amount of salt dissolved in water. Water in crudes is mainly present in an emulsified form. A high salt content in a crude oil presents serious corrosion problems during the refining process. High salt content is a major cause of plugging heat exchangers and heater pipes. A salt content higher than 10 lb/1,000 barrels (expressed as NaCl) requires desalting. Dr.Firas Salim Mohammed Al-Ghulami 61 Sulfur Content Determining the sulfur content in crudes is important because the amount of sulfur indicates the type of treatment required for the distillates. To determine sulfur content. Convert all sulfur compounds in crude oil to SO2 by burning crude oil in enough amount of air, which is then further oxidized to SO3 and finally titrated with a standard alkali. Sulfur compounds can easily be hydro-desulfurized to hydrogen sulfide and the corresponding hydrocarbon. Dr.Firas Salim Mohammed Al-Ghulami 62 Pour Point The pour point of a crude oil or product is the lowest temperature at which an oil is observed to flow under the conditions of the test. Pour point data indicates the amount of long-chain paraffins (petroleum wax) found in a crude oil. Paraffinic crudes usually have higher wax content than other crude types. Handling and transporting crude oils and heavy fuels is difficult at temperatures below their pour points. Long-chain n-paraffins ranging from C16 – C60, are responsible for near-ambient temperature precipitation. In middle distillates, less than 1% wax can be sufficient to cause solidification of the fuel. Dr.Firas Salim Mohammed Al-Ghulami 63 Ash Content This test indicates the amount of metallic constituents in a crude oil. Defined, the ash left after completely burning an oil sample usually consists of stable metallic salts, metal oxides, and silicon oxide. The ash could be further analyzed for individual elements using Atomic Absorption Spectroscopic techniques (AAB). Conradson Carbon Residue % The Conradson Carbon Residue test gives an indication of the amount of carbonaceous material formed by a gas oil when this is burned in a limited supply of air. Specifically, as an indicator to detect the presence of excessive amounts of higher-boiling materials which might cause excessive carbon formation in pressure jet burners. 64 Reid Vapor Pressure (RVP) The Reid Vapor Pressure (RVP) of a product is the vapor pressure determined in a volume of air four times the liquid volume at 37.8 °C (100°F). This property provide two things: Measures the vapor-lock tendency of a motor gasoline in which excessive vapors are produced in the fuel line causing interruption of the supply of liquid fuel to the engine. Indicates the explosion and evaporation hazards of the fuel. Dr.Firas Salim Mohammed Al-Ghulami 65 Flash Point The flash point of a liquid hydrocarbon is the lowest temperature at which sufficient vapors are produced above the liquid such that spontaneous ignition will occur if a spark is present. Flash point indicates the fire and explosion potential of a fuel. A low flash point fuel is a higher fire hazard. It is an important specification for gasoline and naphtha related to safety in storage and transport in high temperature environments. Bottom Sediment and water (BS & W) Indicate the concentrations of aqueous contaminants, present in the crude either originally or picked up by the crude during handling and storage. When extracted petroleum from an oil reservoir, the crude oil will contain some amount of water and suspended solids from the reservoir formation. 66 Dr.Firas Salim Mohammed Al-Ghulami The water content can vary greatly from field to field, and may be present in large quantities for older fields, or if oil extraction is enhanced using water injection technology. The residual content of these unwanted impurities is measured as BS&W. Bottom Sediment and Water up to 0.5% are considered to be acceptable. The centrifuge methods are still employed, but many laboratories prefer the Dean and Stark adaptor A weighed amount, corresponding to approximately 100 mL of oil, is placed in the flask with 25 mL of dry toluene. The flask is heated gently until the 25 mL of toluene has distilled into the graduated tube. The water distilled with the toluene separates to the bottom of the tube where the volume is recorded as milliliter, or the weight as milligram, or per cent. Dr.Firas Salim Mohammed Al-Ghulami 67 To determine the sediment in petroleum or in a petroleum product, the method involves solvent extraction using a Soxhlet Extractor. The higher the bottom sediment and water content, the higher sludge and deposit formation rates can be expected in the stored crude oil. 68 Dr.Firas Salim Mohammed Al-Ghulami CRUDE OILS crude oils are not used directly as fuels or as feedstocks for the production of chemicals. This is due to the complex nature of the crude oil mixture and the presence of some impurities that are corrosive or poisonous to processing catalysts. Crude oils are refined to separate the mixture into simpler fractions that can be used as fuels, lubricants, or as intermediate feedstock to the petrochemical industries. A general knowledge of this composite mixture is essential for establishing a processing strategy. Dr.Firas Salim Mohammed Al-Ghulami 69 Crude Oil Types Versus Demand Gasoline Gasoline 5 - 15 % 20 - 30 % Distillate 20 - 25% Distillate 25 - 35% Heavy Fuel Oil 60 - 75% Heavy Fuel Oil 35 - 55% Light Crude Product Composition Heavy Crude Product Composition Dr.Firas Salim Mohammed Al-Ghulami Naturally occuring hydrocarbon molecules do not meet customer needs. The refining processes must adjust the molecules, reshape them and remove contaminants to ensure they meet requirements for: - end use performance - environmental performance Gasoline 40 - 45% Distillate 30 - 35% Heavy Fuel Oil ~10% Asphalt ~5% Other ~5 -10% Example Product Demand 70