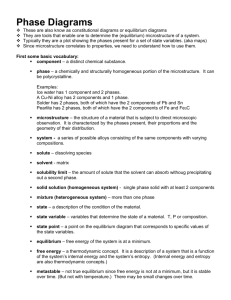

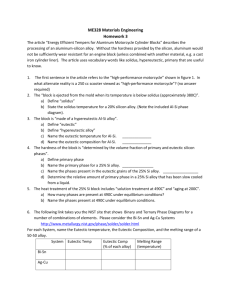

Phase Diagrams MT 2020 – Metals and Alloys Introduction • Many material properties are microstructure-sensitive • Phase diagrams are an important tool in studying how microstructure is developed • Phase diagrams can accurately predict the microstructures of metal alloys. Processing Structure Applications and Performance Properties Important definitions A phase is a specific arrangement of atoms in a regular repeating array, with a defined range of atomic compositions on each symmetrically unique site in the array. It is a chemically and structurally homogeneous portion of the microstructure. A component is a distinct chemical substance from which the phase is formed AluminumCopper Alloy Adapted from chapteropening photograph, Chapter 9, Callister, Materials Science & Engineering: An Introduction, 3e. b (lighter phase) a (darker phase) Single phase microstructure • A single-phase microstructure can be polycrystalline • However, each crystal grain differs only in crystalline orientation. • Each crystal has the same chemical composition. Single phase microstructure of pure molybdenum. Single phase microstructure Two phase microstructure • Solid solubility is limited for many material systems. • For certain compositions, the result is two phases, each richer in a different component. • A classic example is the pearlite structure in carbon steel. • The structure has alternating layers of ferrite and cementite. Two-phase microstructure of pearlite found in a steel with 0.8 wt.% C. Single Component Phase Diagram • The simplest chemical compound to consider is H2O. This has three common phases; vapour or steam, liquid water and solid ice. Single component phase diagram Single component phase diagram Phase and component • Phase must be distinguished from component. • A component is a distinct chemical substance from which the phase is formed. • For example two components Cu and Ni are components in the Cu and Ni continuous system where the elements are soluble in all proportions. • MgO and NiO form solid solutions in a way similar to that for Cu and Ni. Here, MgO and NiO are considered components. Degrees of Freedom • Degrees of freedom are the number of independent variables available to the system. • For example, a pure metal at precisely its melting point has no degrees of freedom. • At this condition, or state, the metal exists in two phases in equilibrium in solid and liquid phases simultaneously. • Any increase in temperature will change the state of the microstructure. • All of the solid phase will melt and become part of the liquid phase. • Similarly, even a slight reduction in temperature will completely solidify the material. Phase Rule • The phase rule is an important tool used for the quantitative treartment of systems in equilibrium. • It enables us to predict the conditions that must be specified for a system to exhibit equilibrium. • J. Willard Gibbs enunciated the phase rule in 1876 on the basis of Thermodynamic principles • This rule predicts qualitatively the effect of temperature, pressure and concentration on a heterogenous equilibrium. Phase Rule • Gibbs phase rule: In a heterogeneous system in equilibrium is not affected by gravity or by electrical and magnetic forces, the number of degrees of freedom(F) of the system is related to the number of component(C) and the number of phases(P) existing at equilibrium. • It is expressed mathematically as, F=C–P+2 where, F - number of degrees of freedom C - number of components P - number of phases 2 - additional variables of temperature and pressure Phase rule • For most materials involving condensed systems, the effect of pressure is slight, and we can consider pressure to be fixed at 1 atm. • In this case, the phase rule can be rewritten to reflect one less degree of freedom: F=C–P+1 where, F - number of degrees of freedom C - number of components P - number of phases 1 - additional variable of temperature Phase Rule Phase: • A gaseous mixture constitutes a single phase since gases are completely miscible. • Example : Air • Two or more liquids which are miscible with one another constitute a single phase as there is no bounding surfaces separating the different liquids. • Example : water and alcohol, chloroform and benzene constitute one phase system. • A system consisting of a liquid in equilibrium with its vapour constitute a two phase system • Example : H2O(l) H2O(g) Phase Rule Examples • Sulphur system • (a)monoclinic sulphur, (b)rhombic sulphur (c)liquid sulphur (d) sulphur vapour. (C = 1; P=4) • Water system • solid, liquid and vapour (C=1 ; P = 3) . • Salt + water system • Certain salts are capable of existing as hydrates with different number of water molecules of crystallization. The system is a two component.(C=2 , P = 1) • The composition of each phase of the hydrates is described in terms of the anhydrous salt and water. e.g., Na2SO4 + water Phase diagram of complete solid solution • The simplest phase diagram we can consider is that of a complete solid solution • In this case, we have two metals of similar size and crystal structure that form a single continuous phase in both liquid and solid states but have different melting points Tm(A) Tm(B) • Therefore there are only two phases – the Liquid and the Solid phase. A pure solution of either A or B would have a single melting point, Tm(A) or Tm(B) • For in-between compositions, like C(x), on cooling, the liquid phase will first cool with a single composition, till the liquidus line is reached. At this point it will split into 2 phases, the solid S which is relatively pure in A, and liquid of composition C(x) • As the alloy cooled down in the two-phase field, the alloy would solidify, with both the solid and liquid phases increasing in B, but the fractions of phases would change with more solid being formed, so that the overall composition is the same. • The solid phase would follow the limit of solubility of S with temperature - the solidus, while the liquid phase L would follow the liquidus. All Liquid Crystallites of Solid in a matrix of Liquid Polycrystalline Solid Degrees of Freedom: F = C – P + 1 F=2–1+1=2 F=2–2+1=1 F=1–2+1=0 F=2–1+1=2 Cooling curve of A-B alloy • From the cooling curves of an alloy, such as seen above, the liquidus and solidus temperatures can be identified, which allows us to determine the phase diagram experimentally Criteria for Solid Solubility Simple system (e.g., Ni-Cu solution) Crystal Structure electroneg r (nm) Ni FCC 1.9 0.1246 Cu FCC 1.8 0.1278 • Both have the same crystal structure (FCC) and have similar electronegativities and atomic radii (W. Hume – Rothery rules) suggesting high mutual solubility. • Ni and Cu are totally soluble in one another for all proportions. Cu-Ni Phase Diagram • Phase diagram: Cu-Ni system. • System is: T(ºC) 1600 1500 L (liquid) -- binary i.e., 2 components: Cu and Ni. -- isomorphous i.e., complete solubility of one component in another; a phase field extends from 0 to 100 wt% Ni. Cu-Ni phase diagram 1400 1300 a (FCC solid solution) 1200 1100 1000 0 20 40 60 80 100 wt% Ni Cu-Ni Phase Diagrams: Determination of phase(s) present • Rule 1: If we know T and Co, then we know: -- which phase(s) is (are) present. A(1100ºC, 60 wt% Ni): 1 phase: a B(1250ºC, 35 wt% Ni): 2 phases: L + a 1600 L (liquid) B (1250ºC,35) • Examples: T(ºC) 1500 1400 1300 A(1100ºC,60) 1100 1000 a (FCC solid solution) 1200 Adapted from Fig. 9.3(a), Callister & Rethwisch 8e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys, P. Nash (Ed.), ASM International, Materials Park, OH (1991). Cu-Ni phase diagram 0 20 40 60 80 100 wt% Ni The phase diagram shows the phases that will form at equilibrium, that is, at the lowest energy state the system can be in. If the atoms are sufficiently mobile, given enough time equilibrium will always be obtained. Therefore phase diagrams are the most important tool we have for understanding how microstructures form in materials. However, care should be taken when using equilibrium phase diagrams as they tell us only what is favourable to occur; we require an understanding of kinetics (diffusion) to understand what happens and how fast. Microstructure development during cooling of a solid solution alloy. Eutectic Phase diagrams Eutectic phase diagrams are used when the alloying elements are not completely soluble with each other, but can only take a limited amount of each other. In this situation you have Metals A and B again, but then you have the A atoms preferring an α phase, and the B atoms preferring a β phase. You can therefore get α phase solids, β phase solids and two phase α + β solids. You also have a eutectic point where the liquid solidifies into the two solid phases (α + β) immediately. Solidification of Single phase alloys In this diagram, you have liquid solidifying into a an α phase solid. Solidification and solid-state precipitation in a two-phase alloy. Here you have a liquid solidifying to an α phase solid, but as it is cooled further, it enters the α + β phase, so β starts forming around the grain boundaries of the α crystals. Solidification of the Eutectic Alloy At the Eutectic point, the liquid solidifies straight into a α + β phase. The structure consists of α and β phase as lamellae (plate like structures) Solidification Sequence in a near eutectic alloy Close to the Eutectic point, the liquid solidifies straight into a liquid + α phase. Then past the eutectic temperature, the liquid around the crystals solidifies into a eutectic solid with α and β phase as lamellae Pb – Sn Phase Diagram An example of a eutectic phase diagram showing the Pb – Sn system • (a) A Hypoeutectic alloy (40wt.% Sn), showing dendrites of primary Pb in a Pb-Sn eutectic, • (b) a eutectic Pb-Sn alloy, • (c) a hypereutectic alloy (80wt.% Sn) with dendrites of primary Sn in a Pb-Sn eutectic, • (d) the Pb-Sn binary eutectic phase diagram