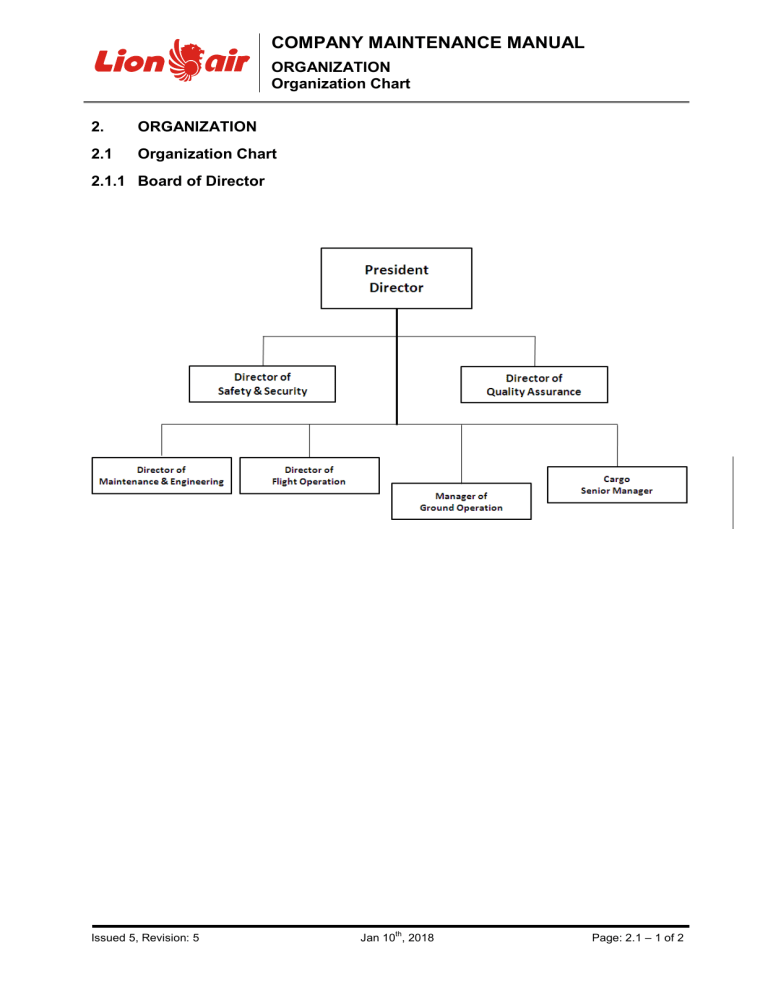

COMPANY MAINTENANCE MANUAL ORGANIZATION Organization Chart 2. ORGANIZATION 2.1 Organization Chart 2.1.1 Board of Director Issued 5, Revision: 5 th Jan 10 , 2018 Page: 2.1 – 1 of 2 COMPANY MAINTENANCE MANUAL ORGANIZATION Organization Chart 2.1.2 Maintenance and Engineering Department Organization Chart Notes: Instruction line a. All the names and addresses of the Management Personnel listed in the M & E Organization Chart will be submitted to the DGCA Office on a separate list at appendix 20.7 of the Company Maintenance Manual. b. In the case of any change in the assignment of Management Personnel in the listed position above, it will notify the Authority within at least 10 (ten) days include the name and address of the assigned person. c. The Company choose to rename managerial position listed in CASR 121.59 (a) (6), the rename managerial position is Chief Inspector to be Quality Control Manager d. For duty and responsibility of Assistant Manager and Chiefs, set out in manual level 2 Issued 5, Revision: 3 th Jun 08 , 2017 Page: 2.1 – 2 of 2 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities 2.2 Duties and Responsibilities 2.2.1 President Director The President Director is the head and representative of Lion Air. He is responsible for ensuring that all operations and maintenance activities are financed and carried out in compliance with the standards required by the regulations and the requirements defined by Lion Air. His responsibilities encompass the following: 1) Visible the Directors of Directorate, Head and Managers of Departments 2) Safety, Security and Quality Systems Responsible: a. Define policies b. Ensures, through the Director of Safety and Security and Director of Quality Assurance, to be pursued and pursuing corrective and preventive actions. c. Manage SMS that has continuity throughout the organization and ensures control of operations and management of safety and security outcomes. 3) Responsible of Security Systems implemented. 4) Management and operation of the market strategy. 5) Decision making high level PT. Lion Air 6) Financial control of Lion Air. 7) Delivering a company global strategy 8) Maintaining an organization that can deliver the respective and stated performance a. Position Purpose 1) Lead and direct the company in accordance with the company strategy 2) Has ultimate responsibility and accountability for the implementation and maintenance of safety management system 3) Has the authority to ensure the allocation of resources necessary to manage safety and security risk to aircraft operation 4) Outline the mission, policies and management systems and procedures in line with the company strategy and brand 5) Sustain the company in the long term 6) Achieve profitability 7) Ensure an effective management system is fully implemented and functional with a clear consistency and unity of purpose between corporate management and management in the operational areas. 8) Ensure an assignment of responsibility within the management system in all area of operations for maintaining ongoing compliance with: conditions and restrictions of the AOC applicable regulatory requirements standards established by the Company b. Accountability 1) Overall company operational performance, 2) Overall safety and security and for ensuring operations and maintenance are provided with necessary resources and conducted in accordance with standards of the Operator and requirements of the State and other applicable authorities, 3) Delivering a company global Strategy, 4) Maintaining an organization than can deliver on the respective and stated performance, 5) Meeting the obligations of a Foreign Air Operator Certificate (FAOC) holder (if any). Issued 5, Revision: 4 th Sep 30 , 2017 Page: 2.2 – 1 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities c. Authority President Director hold a full authority and financial control to make policy decisions, provide adequate resources, resolve safety and quality issues and, in general, ensure necessary system components are in place and functioning properly. President Director has full authority to delegate most or part of his duties to his subordinate by assigning person to perform a job specified to his satisfaction. However, the delegation of duty does not alleviate his overall responsibility. d. Direct Report 1) Director of Flight Operation (DO) 2) Director of Maintenance & Engineering (DE) 3) Director of Safety & Security (DS) 4) Director of Quality Assurance (DQ) 5) Manager of Ground Operation (GO) 6) Senior Manager of Cargo (CF) e. Responsibilities 1) Maintain a close liaison with higher regulatory authorities or government official with regard to AOC limitation and other operationally relevant issues, 2) Overall safety, profitability, legal operation and regulatory compliance, 3) Develop a corporate business strategy in line with the objective of the Company and ensure its effective implementation through executive leadership, 4) Construct mission, values, culture, management system/business units and provide adequate resources ( economic, human and technological ) to support the strategic planning, 5) Have a long term envision for company growth and productivity, 6) International consideration for networking and new ventures, 7) Safety of passengers and crew and staff to ensure the wellbeing of all person and properly under the jurisdiction of Lion Air, 8) Communication and the management of staff and passengers to ensure best possible services are provided in accordance with the airline charter and strategies, 9) Establish and monitor the effectiveness and robustness of systems, including safety policy, safety objectives and planning, 10) Monitor all delegated functions, the safety and compliance of Aircraft Operations, Maintenance & Engineering Operations, Ground (airport) Operations, Safety Systems, Security, Commercial and Corporate support services, 11) Monitor the day-to-day financial security of the operation and the overall company financial strategies, 12) Ensure that response to DGCA legislative issues meet the obligations of the AOC holder, 13) Ensure that responses to issues raised by international regulator meet the obligation of the Foreign AOC holder, 14) Ensure that all operations under the LION AIR AOC, including the Safety Management System, training and maintenance activities are financed and carried out to the standard required by DGCA under the Regulations and the Airline’s AOC, 15) Take the reasonable steps to ensure that AOC operations and related activities are conducted at all times with a reasonable degree of care and diligence, particularly including : Issued 5, Revision: 5 th Jan 30 , 2018 Page: 2.2 – 2 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities i. Adequate corporate management control and supervision of the conduct of staff and agents of the Company ii. Adequate system for communicating relevant information to relevant people in the Company 16) Chair the Safety Management Review meetings, 17) Review outstanding Safety Actions as part of the Safety Management Group, 18) State legislation, including Occupational Health and Safety legislation. f. Requirements: The President Director must: a. Knowledge of ICAO standard practices, Indonesian DGCA requirements, and other regulatory agency related to Lion Air operation. b. Has had at least five years management experience in the Airline Industry c. Knows the Operation Specification of Lion Air. d. Fluent in English e. Meet DGCA requirement, CASR 121.61 (a). g. Legislative Accountability The President Director has legislative accountability to DGCA as the holder of an AOC. h. Delegation of Duties DZ may delegate part or all of his duties to any of his sub ordinate; however, this delegation of duty in any way will not alleviate his overall responsibilities. To ensure management continuation, during his absence DZ shall delegate his duties and responsibilities to any one of his sub ordinates. The delegation of duties must be informed to assigned person and communicated to internal business counterparts via Inter Office Memo, email or other communication media. i. Nominated Delegate Anyone of his sub ordinates, in the event of an unplanned absence or suddenly out of communication. j. Meeting Chaired by President Director 1) Management Review Meting, 2) Executive Management Team, 3) Senior Management Team. Issued 5, Revision: 4 th Sep 30 , 2017 Page: 2.2 – 3 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities 2.2.2 Director of Maintenance and Engineering The Maintenance and Engineering (M&E) Director, as one of Board of Director (BoD) Lion Air and is the administrative head of all function Lion Air M&E Department. M&E Director oversees the operations of the home base and out stations. Accountability 1) Provide direction and objectives in support of long-term company plans. The goals and objectives are stated in terms of revenue to expenditure ratios, fleet flight hour’s requirements airplane utilization, schedule reliability airplane downtime, spares availability rates, and other performance factors. 2) Develop annual operating plans to assure the proper allocation of resources (Budgets, manpower and skill levels, material, facilities, and other required resources) The M&E Director bears the primary responsibility on the airworthiness of the aircraft, engines, and other component of Lion Air fleets. a. The Maintenance & Engineering Director responsibility: The M&E Director is responsible for the complete overall operations of the M&E Department, including ensuring the adequate housing & facilities for continued maintaining Airworthiness & Safety of the Aircraft thereof. 1) Assure that maintenance and engineering program carried out in accordance with the company objective and goal. 2) He is responsible for coordinating all technical activities to ensure a smooth functioning operation. 3) Assure that Lion Air aircrafts, engines, components and appliances, as well as operating procedures, comply with the regulatory authority rules and standard of airworthiness and safety. 4) Ensure that M&E Department operations comply with Company goals and objectives. Select, develop, motivate and appraise maintenance management personnel to ensure that M&E Department goals objectives are met. 5) Forecast human and financial resource needed to meet the demand of business. Plan for longrange requirements of licensed and unlicensed personnel and make plans for their training. 6) Develop the annual budget for M&E Department and exercises tight control over technical expenditures. 7) Set up a system for collection of cost data, including labor and material, to enable the proper costing and cost control of maintenance functions. Maintenance such economic records as may be required. 8) Ensure that long range plans for the development of overhaul and repair capabilities support Maintenance & Engineering goals and objectives. 9) Ensure the Subcontractors contracts are properly managed: Work scope definition, update and efficiency for the Company Continuous Airworthiness including the close monitoring of all AMO subcontractors and subcontractor production. 10) Ensure that technical operating plans adequately support Lion Air domestic and international operations. 11) Ensure that airplanes scheduled for flight operations meet flight schedules, and the aircraft utilization is maximal while adequate ground time is provided for maintenance. 12) Review and approve technical handling agreements at out stations where Lion Air does not have capabilities. Arrange for schedule and unscheduled outside maintenance of airplanes and components through approved Contract Agencies. Issued 5, Revision: 4 th Sep 30 , 2017 Page: 2.2 – 4 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities 13) Provide contract maintenance and engineering services to other operators seeking such service, and assure quality service provided. 14) Develop training program for all M&E Department personnel and third party personnel who take technical handling of Lion Air’s Airplane. 15) Ensure that all maintenance operations are conducted in a safe working environment. Therefore all maintenance personnel shall involve in Safety Management System to eliminate hazard in the conduct of maintenance operation. 16) As delegation of authority and assignment of responsibility within the management system for maintenance operations for liaison with regulatory authorities, original equipment manufacturers (OEMs) and other external entities relevant to maintenance operations. b. Authority: The Director of Maintenance & Engineering has the Authority to: 1) Act on behalf of Lion Air with respect to his area of responsibility. 2) Plan, direct, and manage Organization within the Directorate. 3) Develop and initiate actions to rectify quality related deficiencies resulting from Management Reviews, Quality Audit and Quality Control Inspection& Surveillance. c. Requirements: The Director of Maintenance & Engineering must: 1) Be thoroughly familiar with appropriate parts of the CASR and its applicable maintenance provisions. 2) Knows the policies and procedures outlined in the Company Maintenance Manual. 3) Knows the ACL of Lion Air. 4) Has had at least five years of experience in the maintenance and one year experience in supervisory capacity. 5) Management experience in aviation industry oriented with maintenance. 6) Holds an appropriate AME license or equivalent qualifications acceptable to the Director. d. Direct Report 1) Manager of Quality Control. 2) Manager of Planning & Technical Service 3) Manager of Fleet Maintenance Management 2.2.3 Planning & Technical Services Manager Planning & Technical Services Manager is responsible to Director of Maintenance & Engineering. She /He is responsible in providing direction to, and coordinating the activities of Planning & Technical Services organization and function. All scope of work, Planning & Technical Services functions include aircraft Production Planning, Maintenance Engineering, Technical Publication, and Technical Records are under Sub Contracted Company. Issued 5, Revision: 5 th Jan 30 , 2018 Page: 2.2 – 5 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities 2.2.3.1 Re s p o n s i b i l i t i e s a. Management 1) Responsible of the PTS Section: Select staffs and define individual tasks allocation and priorities, 2) Yearly Staff appraisal and proposal for improvement. 3) Evaluate and Propose Training Program for all subordinates in the Planning and Technical Services Division. 4) Define, writing, update and drive implementation of policies and procedures contained in this Planning and Technical Services Procedure Manual and other Company Manuals. 5) Develop the annual budget for the Planning and Technical Services Division and exercise tight control over expenditure. 6) Report to Director of M&E by sending routine PTS Monthly Report. b . M a i n t e n a n c e P r o g r a m( C A M P ) 1 ) Develop initial maintenance schedule which required by approval maintenance program (CAMP). 2) For new aircraft type, define Lion Air requirement for the new CAMP, and coordinate to Engineering for development. 3) Control and coordinate with BAT Maintenance Program for CAMP implementation and revisions according to applicable regulation and CMM. 4) Make sure that Task Card to comply CAMP is up to date referring to current manuals. 5) Developing and evaluation ETOPS performance and Maintenance Program c . E f f e ct i ve n e s s o f C A M P a n d r e l i a b i l i t y P r o g r a m: 1) Responsible to receive fleet Reliability monthly reports and participate in the monthly TRG (Technical Reliability Group) with BAT Departments: Review, analyses and coordinate improvement action plan to solve Aircraft problems. 2) Responsible for monitoring and validate the reliability correctives or improving action plan pointed out and analyzed during the RCB (Review Control Board) meeting for improvement of the Aircraft Reliability (And CAMP effectiveness) to maintain inherent level of flight safety as well as cost efficiency. 3) Initialize and organize regular 121 RCB Meeting in case of CAMP revision required following the reliability figures and analysis results, d . M a i n t e n a n c e Pl a n n i n g 1) Ensure that Long term, Midterm and short term planning are available and cover all scheduled maintenance items (Aircraft and Major Components). 2) Ensure to Scheduling maintenance, elementary work and servicing to be performed within the time constraints specified in the approved maintenance schedule; 3) Approve Work package of scheduled maintenance tasks which might be included specific inspections, modifications, deferred defect rectification etc. into a work package to match to the available downtime and manpower, 4) Manage and control BAT planning of aircraft scheduled checks to match the CAMP requirements and the company policy, 5) Monitoring and control of Data Base information’s updated by subcontractors in the TRAX Software (Maintenance subcontractor Software selected). e. Production Control Ensure that All Scheduled Maintenances are performed as schedule and comply in accordance with Company Manuals. Issued 5, Revision: 3 th Jun 08 , 2017 Page: 2.2 – 6 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities f . A i r wo r t h i n e s s D i r e c t i v e 1) Responsible to ensure AD tasks from analyses and review to AD implementation by BAT Department are efficient and match with all Airworthiness DGCA requirements and Lion Air contracts 2) Ensure to scheduling the accomplishment of Airworthiness Directives (ADs); 3) Control of Lion Air AD status produced by subcontractors, 4) Control of AD files records requested for each AD. 5) Initiate all requested corrective actions prior AD time limits 6 ) Prepare deviation file justification for Lion Air Quality Control to request DGCA Approval. g. Structural Repairs and Modi ficati ons 1) Approve Engineering Data Package and Form is used to proposed Major Repair and Modification to get approval from DGCA. 2) Register all structural defects 3) Responsible to obtain the DGCA approval for Major repairs (DAAO Form 21-9). 4) Responsible for obtaining and control of AMO subcontractor to present the proper files according to DGCA regulation and AMO contract. 5) Establish minimum modification standards for ETOPS components h. Short Term Escal ati on Responsible for collecting the file package from BAT Maintenance Planning to justify need and acceptability of STE request before Lion air QC and/or DGCA validation i . E n g i n e e r i n g A ct i vi t i e s, En g i n e e r i n g P r o d u c t , O p t i o n a l S B , 1) Ensuring that issue technical advises/orders such as Engineering Authorization, Engineering Report, Engineering Order, Engineering Evaluation and engineering information are prepared and issued to solve technical problems encountered within the production units and within the company operational regions to increase aircraft reliability, safety and cost effectiveness. 2) Decide for company interest to implement optional SB on the fleet. 3) Approve Engineering Data Package and Form is used to get Modification approval from DGCA. 4) Engines Fleet Data monitoring parameters follow up & monitoring for Airworthiness. 5) Make sure that Aircraft Phase in process is correct input on TRAX. 6) Monitor BAT Engineering to prepare and submit an evaluation and recommendation include evidence of corrective action of SDR to QC Manager Lion Air. j. C o n t r a c t e d M a i n t e n a n ce a c t i vi t i e s t o t h i r d p a r t i e s 1) Maintenance contract negotiation and validation for airworthiness issue. 2) Monitor of the contracted AMO (CASR 145 approved) and All Aircrafts & Major component third party contract administration and revision. 3) Manage the DOA selection if requested and validation of the Lion Air contract with each DOA. 4) Maintaining contacts with other related parties t technical matters and to make decisions that are oriented to the company objectives and contract operator’s commitment 5) Negotiate and follow achievements of a Service Level Agreement for Lion Air subcontracted activities. Issued 5, Revision: 3 th Jun 08 , 2017 Page: 2.2 – 7 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities k . T e ch n i c a l p u b l i ca t i o n s 1) Monitoring that BAT Technical publications subcontractor ensure that all Aircraft Manufacturers Manuals needed for performing both the aircraft airworthiness management and maintenance tasks are provided, updated and controlled, including: Subscription management of technical publications, Surveillance of manufacturers publications issuance Receipt and registration of technical publications, Quarantine of non-valid Technical Publication, Storage on electronic and paper version, Distribution to the validated maintenance Bases, Out stations and all support entities from Lion Air and subcontractors, 2) Retention and dissemination of documentation received from external sources, to include manuals and documents from regulatory authorities and OEMs. 3) Revise/Develop PTS Form if required, and propose approval from QC. l . M a i n t e n a n c e r e co r d s 1) Ensure that the following maintenance records are maintained: Total time in service (hours, calendar time and cycles as appropriate) of the aircraft, engines and all life-limited components; Time in service (hours, calendar time and cycles, as appropriate) since last overhaul of aircraft, engines or its components subject to a mandatory overhaul life; Current status of compliance with all mandatory continuing airworthiness information; Appropriate details of modifications and repair; Current aircraft status of compliance with the Maintenance Program; Detailed maintenance records to show that all requirements for signing of a maintenance release have been met. 2) Retention of Maintenance Record Management iaw. CMM Requirement. m. T e ch n i c a l L o g ( AF M L ) 1) Define and validate the AFML format of information’s and attached procedures, 2) Monitoring of BAT Technical Record and AMO subcontractors for proper use of documents, n . C o f A r e n e wa l a n d a i r wo r t h i n e s s r e v i e w Responsible for control of Scheduling Planning and preparation of Airworthiness review documents for issuance Aircraft C of A renewal o . L e s so r r e l a t i o n s h i p f o r T e c h n i c a l R e c o r d s 1) Responsible for receiving Aircraft Lessor representatives for: Technical records Audit, Aircraft Audit and dedicated technical questions. PTS Tech records shall supply to Aircraft owner/lessor all aircraft technical records requested (Airworthiness dossier documents approved by Quality Control Division). 2 ) Responsible for data and document s of Aircraft Re-delivery, coordinate with BAT Technical Record. p . C o m mu n i ca t i o n Maintain liaison with regulatory authorities (DGCA), Original Equipment Manufacturers (OEMs) and other operationally relevant external entities. Issued 5, Revision: 0 th Jun 15 , 2015 Page: 2.2 – 8 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities q . S e r vi c e L e v e l A g r e e me n t 1) Review report of all SLA data’s and indicators and measure the subcontractors efficiency thru those indicators, 2) Manage the monthly SLA meeting to review subcontractor’s results for Lion Air Fleet, 3) Define and follow corrective action plan with subcontractors if required, 4) Reports to head of Lion Air Management and to subcontractors responsible for any disruption of services or permanent indicator deviation from subcontractor. r. N e w A i r cr a f t F l e e t . 1) Coordinate with BAT Engineering or Lion Air’s Operation or Procurement for aircraft technical initial definition. 2) For new aircraft, monitor and ensure production of Aircraft until delivery fulfills the required Technical Definitions. Note: Although Planning and Technical Services functions include aircraft Production Planning, Maintenance Engineering, Technical Publication, and Technical Records (AMO tasks) are contracted to Aircraft Maintenance Organization, however such delegation does not relieve him from the overall responsibilities. 2.2.3.2 Authority: The Planning & Technical Services Manager has the authority to: 1. Act on behalf of Lion Air with respect to his area of responsibility. 2. Plan, direct and manage the organization within the division. 3. Develop and initiate actions to rectify quality related deficiencies resulting from Management reviews, Quality Audit and Quality Control Inspection and Surveillance. 4. Approving repair schemes where manufacturer’s manuals and guidelines are adhered to, but that order engineering decision and directives are required to achieve completion of a task 5. Approving Engineering Authorization (EA), Engineering Information (EI), and other engineering technical advises/orders. 2.2.3.3 Requirement: In order to carry out those function it is required that the person holding this position shall have: 1. Be thoroughly familiar with appropriate parts of CASR and its applicable maintenance provisions. 2. Knows the policies and procedures outlined in the Company Manual; 3. Experience on aircraft maintenance at least five years, and one year of which must have been in a supervisory capacity; 4. Training on various Aircraft Type Rating Level III, at least one of Aircraft operate by Lion Air; 5. Management experience in the respective work field. Issued 5, Revision: 5 th Jan 30 , 2018 Page: 2.2 – 9 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities 2.2.4 Fleet Maintenance Management Manager Fleet Maintenance Management Manager is responsible to the Director of Maintenance & Engineering. Set up coordination with other division within the Company to resolve problems related to aircraft in-service operation. Establish policies and procedures to approve, to control, to monitor and to program of unscheduled maintenance and deferred maintenance activities, including deferred maintenance item referring to MEL/CDL that is necessary to ensure timely correction of aircraft problems and provides necessary technical assistance to support in-service operation. Managing the daily movement and scheduling of each aircraft schedule for flight and assisting the line maintenance activity to achieve the smooth operation. 2.2.4.1 Responsibility: The Fleet Maintenance Management Manager is responsible for: a. Management - Responsible of the FMM Section: Select staffs and define individual tasks allocation and priorities, control of efficiency of FMM Division, - Yearly Staff appraisal and proposal for improvement. - Evaluate and Propose Training Program for all subordinates in the Fleet Maintenance Management (FMM) Division. - FMM Manager and staff shall attend requested Training and Safety courses, - Define, writing, update and drive implementation of policies and procedures contained in this FMM Procedure Manual and other Company Manuals. - Develop the annual budget for the FMM Division, - Report to Director of M&E by sending routine FMM Monthly Report. - Ensure proper dispatch of aircraft with regards to conformity with type design, requirement of other applicable operating rules. b. MCC BAT control and monitoring/ Repetitive discrepancies, - Maintenance Control Center functions are contracted from BAT AMO, - Control and monitoring of Daily Aircraft status issued by MCC for Lion Air A/C Operational Status (AOG, Serviceable or Phase check), - Receipt of immediate notification (SMS) for any aircraft on AOG, - Monitor and control all parts robbing (cannibalization) from one aircraft to another particularly the units removed from an AOG aircraft. - Aircrafts on AOG status: Monitoring and control for initial MCC organization for spares delivery and authorized personnel’s to implement correctives actions according AMM procedures and deliver RTS,(Ref CMM 10.3) - Daily communication and coordination on Aircraft readiness status with MCC and IOCC (Lion Air Integrated Operations Control Center), - Daily check of MCC aircraft technical status and control for repetitive discrepancies to be identified and treated by MCC as DMI, - Control and monitor technical dispatch reliability and deferred maintenance activities, including repetitive problem correction, Navigation Data Base (NDB FMC) update Control and aircraft appearance. c. DMI control and monitoring, - Deferred Maintenance Items Management functions are contracted to BAT MCC. MCC DMI list is communicated daily to Lion Air M&E FMM. - Control and monitoring of Deferred Maintenance Item status issued by MCC for Lion Air fleet, - Control for MCC implementation of Lion Air MEL and DMI escalation procedure for Lion Air QC validation, d. Lion Air M&E representatives and communication/coordination with PTS and QC - In case of regulation deviation request from MCC, coordination with Lion Air QC, - Practical organization of Lessor ramp inspection of A/C on CGK (Access and A/C Issued 5, Revision: 2 th May 27 , 2016 Page: 2.2 – 10 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities availability), - monitoring LM personnel to update the navigation data base which will be conducted every 28 days in accordance with the aircraft maintenance manual. e. Pilots and Cabin crew feedback for maintenance and A/C Status, - Receipt of regular feedback from Lion air crews about A/C Status and subcontractor procedures, - Decision and monitoring for correctives actions to be implemented, - Meeting with Chief Pilot and Chief Flight Attendant. f. Cabin maintenance control and monitoring, - MCC Cabin maintenance service is contracted to manage all cabin findings reported, - Random checks of Cabin Maintenance Log and NSRDI for corrective actions to be implemented, - For any repetitive findings a corrective action plans is initialized and monitored, g. Aircraft cleaning control and monitoring - Internal and external aircraft cleaning is subcontracted to LAS (Lion Airport Services) - Definition and monitoring for Aircraft cleaning work scope (Int. and Ext.) of subcontractor, - Collect the findings and request for corrective actions, h. ETOPS status, - Responsible of Coordinate and monitor the ETOPS status of the aircraft, - Receipt of conversant with ETOPS release Conversant with ETOPS release criteria i. Ferry flights permits - In case of any Maintenance Operational discrepancies not covered under MEL, Lion Air M&E shall request a ferry flight permit, MCC BAT is immediately requesting a decision and ferry permit to Lion Air M&E and IOCC, - Organization and coordination with Pilots, MCC and IOCC to address of all flying conditions requested and documents for transmission to Lion Air QC (Lion Air QC is in charge to get the ferry permit from DGCA). j. Service Difficulty Reports (SDR) - Control for Incidents and accidents immediate reporting to Lion Air Director of M&E and Manager. - From MCC daily information of Lion Air M&E for Aircraft Status; Identification and control for “Malfunctions of Aircraft systems” requiring a Special Maintenance correctives actions to be performed before next flights and all information’s to be reported on a Service Difficulty Report Format (SDR). The Lion Air M&E QC are controlling the SDR document before DGCA transmission. k. Safety Assessment of Foreign Aircrafts “SAFA Program” - Dedicated aircraft identification and preparation to be qualified, - Monitoring of all preparation work package, - After SAFA inspection, control and monitor for findings treatments before next flights, 2.2.4.2 Authority: The Fleet Maintenance Management Manager has the authority to: 1. Act on behalf of Lion Air with respect to his area of responsibility. 2. Plan, direct and manage the organization within the division. 3. Develop and initiate actions to rectify quality related deficiencies resulting from Management reviews, Quality Audit and Quality Control Inspection and Surveillance. 4. FMM Manager scheduled vacancies will be back up & covered by Assistant Manager of fleet Management, Issued 5, Revision: 3 th Jun 08 , 2017 Page: 2.2 – 11 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities 2.2.4.3 Requirements: In order to carry out those function it is required that the person holding this position shall have: 1. Be thoroughly familiar with appropriate parts of CASR and its applicable maintenance provisions 2. Knows the policies and procedures outlined in the Company Manual; 3. Experience on aircraft maintenance at least five years, and one year of which must have been in a supervisory capacity; 4. Training on various Aircraft Type Rating Level III, at least one of Aircraft operate by Lion Air; 5. Have capability of troubleshooting on various aircraft system. 2.2.5 Quality Control Manager Quality Control Manager is responsible to the Director of M&E Quality Control functions includes Quality Control Certification, Quality Control standards and Quality Control Surveillance, airworthiness and certification, qualification personnel, quality control Inspection, aircraft inspection, material inspection, workshop, non-destructive testing and calibration, safety, and investigation. Ensure that all aircraft operated by Lion Air comply with the regulatory authority rules and standard concerned airworthiness and safety. a. Responsibility: 1) Supervise inspection activities delegated to AMO subcontractors at the maintenance base and all line stations facilities. 2) Provide direction to, and coordinating the activities of M&E Quality Control organization and function. 3) Initiating, writing, and submitting Company Maintenance Manual including revisions and fetch approval from Authority. 4) Maintain for the approval of the Air Operator Certificate from the local authority, assuring the currency of the Aircraft Registration, Certificates of Airworthiness and other operational approval certificate of all Lion Air Fleet, maintain current file pertinent of Civil Aviation Safety Regulations, Operation Specifications, all Technical Documents for Maintenance, and Airworthiness Directives. 5) Ensure that Lion Air aircraft and operating procedures comply with regulatory authority rules and Lion Air standard concerning airworthiness and safety. 6) Control that Certificate of Airworthiness, Certificate of Registration and other certificate or approval that required for aircraft operation are current. 7) Control the proper implementation of policy and procedure set forth in the Company Maintenance Manual. Assure that all divisions as well as all Contractors and Vendor comply with this manual. 8) Develop the annual budget for Quality Control Division and exercises tight control over technical expenditures. 9) Establish the Quality Control Certification, Quality Control Standard, Quality Control Surveillance and Quality Control Inspector policies. 10) Planning airworthiness policy, aircraft maintenance procedures, and Quality Control program. Issued 5, Revision: 5 th Jan 30 , 2018 Page: 2.2 – 12 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities 11) Arranges Technical Coordination Meeting in regard of significant issues arising from the maintenance operations Quality Control program- Maintenance Review Board (MRB). 12) Controlling that Airworthiness Directive is performed within the compliance date. 13) Monitor and ensure the performance of contracted maintenance provider, vendors or Suppliers to confirm satisfactory quality, required quantity of product comply with CASR and necessary specification, tracking the repairable and routable items, and to assure the accuracy record 14) Maintain an approved direct Lion Air M&E subcontractor’s list: Aircrafts and Main Components (Engine, APU and LG) subcontractors under direct control of Lion Air M&E. 15) Ensure the reliability control program executed effectively and efficiently to improve maintenance standards. 16) Control and evaluating statistic and analysis of performance reliability investigation against aircraft accident, serious incident, monitor vital technical defect and preventive action, repair, and withdrawal of C of A for flight safety consideration. 17) Submitting reports of defects and/or un-airworthy conditions in accordance with CASR 121.703 Service Difficulty Report ( SDR ) 18) Conducting incident/accident investigations. Reporting serious incident and accident to regulatory authority and to assist accident investigations. 19) Review and sign the application of AMOC prior to submit to DGCA. 20) Directing and controlling the performance, qualification of quality Control inspectors. 21) Maintain a current listing of all certifying Authorized personnel including Required Inspection Item Authorization holder and their license. 22) Maintain oversight over the qualifications and licensing of all Maintenance and Engineering personnel, administration, records and curriculum of technical training for all Maintenance and Engineering organizations. 23) Develop training requirements for maintenance & engineering, and inspection personnel to comply with current aviation authority regulation and company policy. Training program will include initial and recurrent aircraft system, inspector training, continuing airworthiness and training procedures. 24) Providing direction to, and coordinating with the activities of Subcontractors Training section and function in regard to providing, developing, and coordinating training for all technical training aspects for maintenance & engineering, and inspection personnel, includes third party personnel who maintain Lion Air airplanes. 25) Ensure that contracted maintenance organization who maintains Lion Air’s Aircraft and/or component for providing required training to their Authorized maintenance personnel. 26) Control and ensure Continuous Airworthiness Maintenance Program (CAMP) Applicable to each aircraft type in accordance with current regulation. 27) Responsible of Control and coordinate ETOPS authorization and Establish / oversee ETOPS criteria and procedures. 28) Responsibility to initialized Quality Control Spot Checks and dedicated organization control where Lion Air M&E has identified potential or disfunctioning. The M&E Quality Control supervise plan results will be continuously shared with Lion Air Quality Assurance Directorate. Issued 5, Revision: 3 th Jun 08 , 2017 Page: 2.2 – 13 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Duties and Responsibilities b. Authority: The Quality Control Manager has the authority to: 1) 2) 3) 4) 5) 6) 7) 8) 9) c. Act on behalf of Lion Air with respect to his area of responsibility. Plan, direct and manage the organization within the division. Determine required actions after incidents or accidents. Act as a liaison functions between Lion Air and Aviation Regulatory Authority and other foreign governmental agencies in all aspect affecting quality and airworthiness of aircraft, products and services. Issuing authorization to maintenance personnel that issuing airworthiness release for Lions Air fleet. Approve limited Short Term Escalation of scheduled maintenance, and Ferry/Special Flight programs. Initiating, review, and submit Company Maintenance Manual to obtain approval from authority. Change or reject corrective actions of AMO Sub-Contractor audit and Surveillance finding. Remove contracted maintenance provider, vendor or supplier that fails to maintain required standards or unsatisfactory service. Requirement: In order to carry out those function it is required that the person holding this position must: 1) Be thoroughly familiar with appropriate parts of CASR and its applicable maintenance provisions 2) Knows the policies and procedures outlined in the Company Manual. 3) Knows the ACL of Lion Air. 4) Experience of aircraft maintenance at least three years on similar type of Aircraft operate by the Company, and one year of which must have been as a Maintenance Inspector; 5) Holding a valid Aircraft Maintenance Engineer License (AMEL) at least one of Aircraft operates by Lion Air; meet DGCA requirement. 6) Holds an appropriate AME license which has been valid for at least five years and knows the maintenance part of the air carriers company operations manual and ACL, and the applicable maintenance provisions of this part. 2.2.6 Delegation of Duty To ensure managerial continuity is maintained when operational managers, including any nominated post-holder (s), are absent from the workplace, there shall be delegation of duties throughout the company for managerial position and functional to qualified assistant as necessary. The list of substitutes for delegated contained in CMM chapter 20.11. On the list of delegate duties (CMM Chap. 20.11), the sequence number of nominated delegation of duties are use if management personnel in the event of an unplanned absence or suddenly out of communication. Therefore at the time of absence, Operational Manager shall designated his/her representative and inform this delegation to all necessary business counterparts and all structural member in the Company. This notification shall be conveyed through written notification via email or internal office memo; however such delegation does not relieve him from the overall responsibilities. Issued 5, Revision: 5 th Jan 30 , 2018 Page: 2.2 – 14 of 14 COMPANY MAINTENANCE MANUAL ORGANIZATION Contract Organization 2.3 Contract Organization 2.3.1 General Lion Air as Air Operator Certificate (AOC) Holder may arrange negotiation and administering maintenance contract to the DGCA Approved Maintenance Organization (AMO) or other Air Operator Certificate Holder to maintain the aircraft, aircraft engines, and component in an airworthy condition (see reference CMM Chapter 16). Lion Air will not operate their fleet unless the Aircrafts are maintained and release to service by an Approved Maintenance Organization (AMO). Lion Air establishes the procedure to ensure each maintenance organization that performs maintenance for Lion Air procedure completed. (a) Each maintenance organization shall sign contract agreement to maintenance Lion Air fleet that is required by Lion Air Company Maintenance Manual. (b) Lion Air Quality Assurance shall ensure is maintenance organizations that perform maintenance for Lion Air fleet by audit and surveillance. As outline in CASR 121.379: (a) Lion Air may make arrangements with other persons to perform maintenance, preventive maintenance, or an alteration as provided in Lion Air continues airworthiness maintenance program and Lion Air Maintenance manual. (b) Lion Air may approve any Aircraft, airframe, aircraft engine, or appliance for return to service after maintenance, preventive maintenance, or alterations that are performed under 121.379(a). However in the case of major repair or major alteration, the work must have been done in accordance with technical data approved by the Director. 2.3.2 Contract a. General In order to initiate Contract Maintenance with an Approved Maintenance Organization (AMO), Lion Air shall conduct review to all contract agreement associated with aircraft, engines, and major components. Prior to contract maintenance arrangement, Quality Control will coordinate with Quality Assurance to continue conduct Quality Surveillance to ascertain that the contracted agency has adequate capability to perform the work and meet the Indonesian Civil Aviation Safety Regulations requirements. In addition, through the audit, Quality Control Division will ensure that the maintenance organization that performs maintenance for the Lion Air provides for the use and guidance of relevant maintenance personnel a Maintenance Procedures Manual (MPM) which fulfills with the following requirement: 1) Holds a Certificate of an Approved Maintenance Organization or Repair Station’s and has Indonesian DGCA approval. 2) The Contracted Maintenance Organization has an independent Quality Control Program. 3) Have list of certificate number, rating and limitation, description of work scope authorized contracted person or organization including their procedures. 4) Have a line and base maintenance facilities, with appropriate tools and equipment. 5) Have devices that used to tracking all maintenance history that has been performed including planning bulletin boards, task card files, current maintenance document references or other computer system usage. The contracted maintenance organization has a process for periodic review of the Quality Control program by the Quality Manager or the person assigned managerial responsibility 6) Issued 5, Revision: 3 th Jun 08 , 2017 Page: 2.3 – 1 of 3 COMPANY MAINTENANCE MANUAL ORGANIZATION Contract Organization for the program for the purpose of ensuring compliance with current requirements of the CAMP and the CMM. 7) The Contracted Maintenance Organization has process to amend their Maintenance Procedure Manual (MPM) as necessary to keep the information contained therein up to date, and has a process to furnish copies of all amendment to the MPM promptly to all organizations or persons to whom the manual has been issued. 8) Contract arrangement with the maintenance organization for maintaining of Aircrafts, Engines and Major Components shall be in accordance with Approved Subcontractor’s list issued by M&E Quality Control, which shall be updated every twelve months (see reference CMM Chapter 16). 9) In the case Aircraft and Major Components maintenance is required to be performed at outside the state of Operator by a maintenance organization that has not hold a DGCA approval; Lion Air will seek confirmation from DGCA that the intended Maintenance Organization holds approval from the Authority that has agreement with the DGCA. Upon receiving confirmation Lion Air will conduct assessment to assure Lion Air requirement is fulfilled. 10) General description of the scope of work authorized under the organization’s terms of approval and general description of the organization’s facilities and the organization procedures and quality or inspection system, Names and duties of the responsible personnel. Names and duties of the person or persons whose responsibilities are to ensure that maintenance is carried out according to related manual. 11) Description of the procedures used to establish the competence of maintenance personnel, the methods used for the completion and retention of the company maintenance records, including procedures for retaining back-up records and the procedure for preparing the maintenance release and the circumstances under which the release is to be signed. 12) Process for authorizing personnel to sign the maintenance release and the scope of their authorization. 13) Description of any additional procedures for complying with the company maintenance procedures and requirements, the procedures for complying with the service information reporting requirements and the procedure for receiving, amending and distributing within the maintenance organization, all necessary airworthiness data. 14) Refer to CASR 121.367 which requiring maintenance, preventive maintenance, and alterations are to be performed in accordance with the certificate holder’s manual, all contracted Approved Maintenance Organization (AMO) performing maintenance of Lion Air Aircraft is required to follow Lion Air CMM training requirements – Reference CMM Chapter 12. The Training for contracted AMO Maintenance personnel can either be conducted by Lion Air Trainer or by distributing the intended training material to the contracted AMO Quality Assurance Department. Then it will be the AMO Quality Assurance Department responsibility to conduct training to their maintenance personnel. 15) The Contracted Maintenance Organization has managers who, if applicable, are acceptable to the relevant authorities and have the responsibility for the management and supervision of maintenance organizations. 16) Have appropriate post holder with responsibilities for ensuring the maintenance organization is in compliance with the requirements for an approved maintenance organization as accepted by the authority 17) The contracted Maintenance Organization has a training and qualification program for auditors used in the QA program. AMO Auditor training qualifications described in more details in CMM Chapter 12.3.3 Issued 5, Revision: 3 th Jun 08 , 2017 Page: 2.3 – 2 of 3 COMPANY MAINTENANCE MANUAL ORGANIZATION Contract Organization b. Lion Air Sub Contractors The Lion Air Maintenance and Engineering Department has contracts with BAT and GMF, as follows: BAT AMO for all Aircraft, Engines and components Maintenance according their DGCA approved scope of work, ref.: - 039/JT/DE/XI/2014 Amdt.III - 010/BAT/Agreement/JT/XI/2014 Amdt. III, Garuda Maintenance Facilities, ref.: - GMF/PERJ./DB-3222/2015 Malindo Airways Sdn. Bhd. - SGHA Annex B1.0, 1 March 2017 Issued 5, Revision: 5 th Jan 30 , 2018 Page: 2.3 – 3 of 3 COMPANY MAINTENANCE MANUAL ORGANIZATION Communication System 2.4 Communication System Lion Air has a communication system that enables and ensures an exchange of operationally relevant information including maintenance deficiencies and other significant issue throughout the management system and the areas where operations, maintenance, and activities are conducted, including AMO/MRO; OEM’s / Manufactures; Vendors and Suppliers. Methods of communication will vary according to the size and scope of the different departments, e.g. meetings, forums, intranet, Inter Office Memo’s, email, ops bulletins, standing order, Short Message Service (SMS), Safety Recommendation, etc. An effective, uncomplicated and easy to use communication system shall exist within the operational departments to enable and ensure an exchange of relevant information, throughout all areas of the organization. The system shall include progress report management, supervisory front line personnel coordination management. The communication systems used in the organization are: E-mail: Used for all communications from management to groups of people, to the complete organization, or to individuals, Used for reporting of anything that might be required for ensuring safety, to another individual or groups of persons, Used by the companies internal communication system to inform about any warning, vacancy, coming up events, etc., that are important for all or the majority of the people within the company, Used to report, on a daily basis, the aircraft Technical/operational status, punctuality; Facsimile: Quality Control Division within the maintenance organization has a fax machine that can be used in case e-mail or other means are not possible. Internet: Updated and approved Technical publications of Manufacturers, OEM., Access to Manufacturers and Authorities web-sites, TRAX software access Intranet: Updated and approved versions of procedure manuals are available online, On-line status of aircraft fleet is available to all departments, and secured for updating TRAX software access Mobile Telephone: Used by all people for urgent or other needs. All people have access to telephony, Each operational manager is always accessible by mobile phone and can be contacted any time for consultation and decision. Meetings: Several meetings are used as a way of communicating information within the organization. Issued 5, Revision: 0 th Jun 15 , 2015 Page: 2.4 – 1 of 1