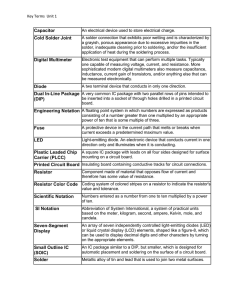

Course Code: GED1103 Course Name: Manufacturing Practices Laboratory Department of Electronics and Communication Engineering Name : RRN : BONAFIDE CERTIFICATE Certified that this is the bonafide record of the workdone by _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ R R N _ _ _ _ _ _ _ _ _ _ _ of I-semester B.Tech __________________________ in the course GED 1103 Manufacturing Engineering Practice Laboratory during the year 2021- 2022. Faculty in-charge Identifications and symbolic representation 1 of active and passive electronic components Soldering, 2 De-soldering & tracing of electronic circuits and checking its continuity 3 Assembly of A.C to D.C Circuits in Bread board Avg : Sign (100) Total (30) Viva (30) Performance (40) Execution Name of Experiment Date S. No. Index Identifications and symbolic representation of active and passive electronic components Ex.No :_____________ Date : _____________ Aim : To identify the symbolic representation of active and passive electronic components Theory: The electronic Components have terminals and each will have its own name and polarities. The Basic is Passive and Active components, R C L (Resistor, Capacitor, Inductor) are passive and Most of the Semiconductors are Active components. Resistor Resistor component gives resistance that is barrier to the current flow in a circuit. There are two different symbols are widely used in schematics that is Zigzag format (US style) and Rectangle shape, this will have two pins and three pins if variable resistor. Unit of resistor is Ohm Ω. Defining the value of resistor from its color bands: 1. First find the tolerance band, which is typically gold (5%) and sometimes silver (10%), and hold the resistor such that this band is at your right-hand side. 2. Starting from the other end, identify the first band at your left-hand side; write down the number associated with that color. Example: First band – BLUE- write down ‘6’. 3. Then identify the color band next to it. Example: Second band - RED, write down a '2' next to the ‘6’. 4. The first two bands are called digit band. 5. Now read the third or multiplier band and write down that number of zeros Example: Third band - GREEN, multiply the quantity indicated by the digit bands with 10^5. The resistance value of a sample resistor with a color code as ‘blue-red-green-gold” is 62*10^5 Ω = 6.2MegaΩ(1M Ω=10^6 Ω). Measurement of Resistance using Multimeter: • Switch on multi-meter • Switch to Ohmmeter • Enable “Auto Range” in order to get the maximum number of significant digits during measurement. • Hold the resistor in your left hand and connect one end of a banana-to-minigrabber cable to the instrument and the other end to the resistor. • Record the resistance value and the unit from the LCD screen Calculate Percentage Error: For a given resistor, we measure the difference between its nominal resistance and measured resistance in the percentage, which is called percentage error, given by PE = | NV − MV | *100 % NV , Where PE represents for percentage error, NV for nominated value and MV for measured value. Tabulation: Read the color codes of 2 resistors and identify their resistances. Resistor Color codes Nominated value Measured value Percentage of error 1 2 Capacitor The capacitor reacts as static energy storage some times, Non-polarized (two parallel line) capacitor have two equal plate separated by insulator and Polarized (one straight and one curved line) capacitor have positive and negative pins. Capacitor Value Calculation: Ex1: Let the number 104 is written on the capacitor Then, capacitor value is given by 104 = 10x104 x10−12 = 10−7 = 0.1µF. Ex2:223 = 22 ∗ 103 ∗ 10−12 = 22 ∗ 10−9 = 22𝑛𝐹 = 0.022µ𝐹. Inductor The Inductor reacts as magnetic storage element; it is represented as loopy coils, or curved bumps. This element doesn’t have polarities. Diode The Active devices are starts from diode, symbol represented with Triangle Arrow pressed up against a line. The diode have polarities called Anode(triangle pin) and Cathode(straight line) hence it should be identified for employment. Transistor This components transfers resistance between two circuits based on the layers it is called as NPN or PNP and also it is named as BJT (Bi Junction Transistor). Thyristor Thyristors are active device having more than two junction in layer structure and used in high voltage and high power applications. MosFET Metal oxide semiconductor field effect transistor is the expansion of MosFET, these are reacts as voltage control device having three terminals. Based on the diffusion it is classified as Depletion and Enhancement and depends on the channel it is classified as N and P channel MosFET. Logic Gate Logic Gates are comes in a Integrated Circuit (IC) format for an example IC7400 (four nand gates), The Logic operations are AND, OR, NOT, EXOR, NAND, NOR having unique symbols. Based on the requirements we can choose two, three are more input output pin logic gates. Integrated Circuit The Integrated Circuits (IC) are represented in many ways but mostly with big arrow for operational amplifier or square box with pin functions. Switches Switches makes circuit connected or disconnected (ON or OFF), depends on the number of poles and throws it is classified. Other than this push button and toggle switches are also available in circuit diagram. Power Supply These are represents Power supply and bias details in circuit diagram. Symbol with + and – indicates DC (direct current) source and symbol with sin wave indicates AC (alternating current) source. Fuse The Fuse reacts as safety element to protect circuit against large current and sudden urges of current. The fuse are comes in different structure and different materials the basic symbol given here, PTC represents positive temperature coefficient (temperature dependent resistor) and it is also reacts as fuse. Transformer The Transformer is step down or step up the voltage and current, for electronic circuits we use Step down and isolation transformers mostly in some other case like inverter we use step up transformer. Transformer with two terminal secondary and three terminal (center tapped) secondary are illustrated. Relay The Relay are Electromagnetic Switches and makes or disconnects circuits when the relay coil gets energy. Depends on the pole and contact relays are classified. Relay Switch gives N/O (normally open) and N/C (normally close) terminals when the relay coil gets energy N/O becomes closed and N/C becomes opened terminals. Bread Board: A breadboard is used to make up temporary circuits for testing or to try out an idea. No soldering is required so it is easy to change connections and replace components. Parts will not be damaged so they will be available to re-use afterwards. Multimeter: A multimeter or a multitester, also known as a VOM (Volt-Ohm meter), is an electronic measuring instrument that combines several measurement functions in one unit. A typical multimeter may include features such as the ability to measure voltage, current and resistance. Multimeter may be used in analog or digital circuitsanalogmultimeters (AMM) and digital multimeters (often abbreviated DMM or DVOM). CRO: The cathode-ray oscilloscope (CRO) is a common laboratory instrument that provides accurate time and amplitude measurements of voltage signals over a wide range of frequencies. Its reliability, stability, and ease of operation make it suitable as a general purpose laboratory instrument. A cathode ray oscilloscope (CRO) is used to see the waveform of a repetitive electronic signal. The signal is amplified or attenuated as required and used to deflect an electron beam in the vertical direction. This electron beam is deflected in the horizontal direction at a suitable speed. The electron beam impinging on a phosphorescent screen enables the viewer to see the wave shape of the signal. Power Supply: Power supply is a reference to a source of electrical power. A device or system that supplies electrical or other types of energy to an output load or group of loads is called a power supply unit or PSU. The term is most commonly applied to electrical energy supplies, less often to mechanical ones, and rarely to others. Regulated power supply is a power supply containing means for maintaining essentially constant output voltage or output current under changing load conditions. The fixed voltage power supply is useful in applications where an adjustable output is not required. This supply is simple, but very flexible as the voltage it outputs is dependant only on the regulator and transformer you choose. Function Generator: A function generator is usually a piece of electronic test equipment or software used to generate different types of electrical waveforms over a wide range of frequencies. Some of the most common waveforms produced by the function generator are the sine, square, triangular and sawtooth shapes. Result: Soldering and De-soldering of electronic circuits and checking its continuity Ex.No :_____________ Date : _____________ Aim: To perform soldering and desoldering of a circuit and also to check its continuity. Apparatus Required: Soldering iron, solder, flux, wick or solder sucker, Resistors. Theory: 1. SAFETY PRECAUTIONS • Never touch the element or tip of the soldering iron. • Take great care to avoid touching the mains flex with the tip of the iron. • Always return the soldering iron to its stand when not in use. • Allow joints a minute or so to cool down before you touch them. • Work in a well-ventilated area. • Wash your hands after using solder. 1.1 soldering. Soldering is a process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, the filler metal having a relatively low melting point. The filler metal used in the process is called solder. 2. SOLDERING ACCESSORIES 2.1 Soldering Iron A soldering iron is a tool used for applying heat to two adjoining metal parts such that solder may melt and flow between those parts, binding them securely and conductively. A soldering iron is composed of a heated metal tip and an insulated handle. Heating is often achieved electrically, by passing a current, supplied through an electrical cord or a battery, through a heating element The following are the different soldering iron types 1. Temperature-controlled iron. A soldering iron with electronic temperature control is highly recommended. Irons without temperature control can reach temperatures that are high enough to irreversibly damage the tips. Since temperature is not proportional to wattage with this type of iron, the wattage rating is relatively unimportant. A higher wattage iron results in a faster temperature recovery time between soldering operations (40 W to 60 W units seem to work well). 2. Non-temperature-controlled iron. A low wattage (10 W to 25 W) pencil-type (not gun-type) can be used but is not recommended. This type of iron must be unplugged when not in use to save the tips. The temperature is proportional to wattage and most of these types of soldering irons will reach temperatures that can destroy tips quickly. 3. Modified, non-temperature-controlled iron. A 10 W to 40 W pencil-type iron can be operated from a variac to limit the wattage (and therefore the temperature) and is a reasonable substitute for a temperature-controlled iron. However, a variac can cost more than a temperature controlled station and will yield less satisfactory results. 2.2 Solder Solder is an alloy (mixture) of tin and lead, typically 60% tin and 40% lead. It melts at a temperature of about 200°C. Coating a surface with solder is called ‘tinning’ because of the tin content of solder. Lead is poisonous and you should always wash your hands after using solder. Solder for electronics use contains tiny cores of flux, like the wires inside a mains flex. The flux is corrosive, like an acid, and it cleans the metal surfaces as the solder melts. This is why you must melt the solder actually on the joint, not on the iron tip. Without flux most joints would fail because metals quickly oxidise and the solder itself will not flow properly onto a dirty, oxidised, metal surface. The following are the different solder types 1. Rosin core. 60/40 Sn/Pb (M.P. 361-376°F) and 63/37 Sn/Pb (M.P. 361°F) solders are the most common types used for electronics assembly. These solders are available in various diameters and small diameters are most appropriate for small electronics work (0.02” - 0.05” dia. is recommended). 2. Lead-free. Lead-free solders are used as more environmental-friendly substitutes for leaded solder, but they are typically not as easy to use mainly because of their higher melting point and poorer wetting properties. 3. Silver. Silver solders are typically used for low resistance connections but they have a higher melting point and are more expensive than Sn/Pb solders. 4. Acid-core. NEVER USE ACID CORE SOLDERS FOR ELECTRONICS! They are intended for plumbing or non-electronics assembly work. The acidcore flux will cause corrosion of circuitry and can damage components. 2.3 Flux Flux is used to prepare the surfaces of the conductors prior to soldering. Flux removes oxidation from the conductors and maintains oxide-free surfaces at elevated temperature during the soldering process. This allows all surfaces to “wet” properly. The following are the different solder types 1. The most common flux used in hand soldering of electronic components is rosin, a combination of mild organic acids extracted from pine trees (some manufacturers use synthetic compounds). 2. Although fluxes can be obtained in liquid or paste form, they are typically contained in solders (rosin core) used for hand assembly of electronics. Fluxes labeled as “Acid” are strong acids (as opposed to the mild rosins) and should never be used for electronics assembly. 2.4 Sponge A sponge is required for keeping tips clean for best heat transfer. A clean soldering iron tip is one of the most important steps towards producing good solder joints.Most soldering stations come with sponges and sponge holders. 2.5 Tips Currently, most tips sold for electronics work are iron-clad copper and have long life spans. Iron-clad tips cannot be filed or sanded when they become oxidized; they must be replaced. Many tip shapes are available, but miniature needle or chisel point tips are best for most work. The tip shape should be chosen to provide the highest contact surface area for best heat conduction. Minimizing the shank length can increase the heat transfer from the iron (heater) to the tip. Copper tips can still be purchased but are not recommended because of their short life span and poor wetting properties. 3. NECESSARY TOOLS These are the recommended minimum complement of tools for soldering: 1. Miniature needle-nose pliers 2. Miniature side cutters 3. Wire strippers 4. Solder removal tool (“Solder Sucker”) 5. Water bottle 6. Safety glasses 4. MAKING SOLDERED JOINTS 4.1 Preparing the Soldering Iron •Place the soldering iron in its stand and plug in. The iron will take a few minutes to reach its operating temperature of about 400°C. • Dampen the sponge in the stand. The best way to do this is to lift it out the stand and hold it under a cold tap for a moment, then squeeze to remove excess water. It should be damp, not dripping wet. • Wait a few minutes for the soldering iron to warm up. You can check if it is ready by trying to melt a little solder on the tip. • Wipe the tip of the iron on the damp sponge. This will clean the tip. • Melt a little solder on the tip of the iron. This is called 'tinning' and it will help the heat to flow from the iron’s tip to the joint. It only needs to be done when you plug in the iron, and occasionally while soldering if you need to wipe the tip clean on the sponge. • You are now ready to start soldering! Please turn the page for further instructions... 4.2 Making Soldered Joints • Hold the soldering iron like a pen, near the base of the handle. Imagine you are going to write your name! Remember to never touch the hot element or tip. • Touch the soldering iron onto the joint to be made. Make sure it touches both the component lead and the track. Hold the tip there for a few seconds and... • Feed a little solder onto the joint. It should flow smoothly onto the lead and track to form a volcano shape as shown in the diagram below. Make sure you apply the solder to the joint, not the iron. • Remove the solder, then the iron, while keeping the joint still. Allow the joint a few seconds to cool before you move the circuit board. • Inspect the joint closely. It should look shiny and have a ‘volcano’ shape. If not, you will need to reheat it and feed in a little more solder. This time ensure that both the lead and track are heated fully before applying solder. 5. SOLDERING ADVICE FOR COMPONENTS Some components require special care when soldering. Many must be placed the correct way round and a few are easily damaged by the heat from soldering. Appropriate warnings are given in the table on the next page, together with other advice which may be useful when soldering. Components Resistors Pictures Soldering advice No special precautions are required. Connect either way round. Diodes Diodes must be connected the correct way round: a = anode, k = cathode. Use a heat sink with germanium diodes. IC holders Ensure the notch is at the correct end. (DIL sockets) Do not insert the IC at this stage to prevent it being damaged by heat. Presets (small No special precautions are required. variable On stripboard take care to ensure you resistors) insert them the correct way round. Capacitors, No special precautions are required. non-polarised Connect either way round. (less than 1μF) Take care to identify their value. Capacitors, Electrolytic capacitors must be connected the correct way round, they are marked electrolytic with + or - near one lead. (1μF and greater) LEDs LEDs must be connected the correct way round: a = anode, k = cathode. (Light Emitting Use a heat sink with small (3mm) LEDs. Diodes) Transistors Transistors have three leads and must be connected the correct way round. Use a heat sink clipped to each lead in turn between the joint and the transistor. Integrated When all soldering is complete, carefully Circuits insert ICs the correct way round in their (ICs or ‘chips’) holders. Make sure all the pins are lined up before pushing in firmly. 6.Desoldering Guide 1 Desoldering At some stage you will probably need to desolder a joint to remove or reposition a wire or component. There are two ways to remove the solder 1.1 With a desoldering pump (solder sucker) • Set the pump by pushing the spring-loaded plunger down until it locks. • Apply both the pump nozzle and the tip of your soldering iron to the joint. • Wait a second or two for the solder to melt. • Then press the button on the pump to release the plunger and suck the molten solder into the tool. • Repeat if necessary to remove as much solder as possible. • The pump will need emptying occasionally by unscrewing the nozzle. 1.2 With a solder remover wick (copper braid) • Apply both the end of the wick and the tip of your soldering iron to the joint. • As the solder melts most of it will flow onto the wick, away from the joint. • Remove the wick first, then the soldering iron. • Cut off and discard the end of the wick coated with solder. After removing most of the solder from the joint(s) you may be able to remove the wire or component lead straight away (allow a few seconds for it to cool). If the joint will not come apart easily apply your soldering iron to melt the remaining traces of solder at the same time as pulling the joint apart, taking care to avoid burning yourself. SERIES CIRCUITS Series circuits are sometimes called current-coupled or daisy chain-coupled. The current in a series circuit goes through every component in the circuit. Therefore, all of the components in a series connection carry the same current. There is only one path in a series circuit in which the current can flow.A series circuit's main disadvantage or advantage, depending on its intended role in a product's overall design, is that because there is only one path in which its current can flow, opening or breaking a series circuit at any point causes the entire circuit to "open" or stop operating. Current In a series circuit the current is the same for all elements. Resistors The total resistance of resistors in series is equal to the sum of their individual resistances: Parallel circuits If two or more components are connected in parallel they have the same potential difference (voltage) across their ends. The potential differences across the components are the same in magnitude, and they also have identical polarities. The same voltage is applicable to all circuit components connected in parallel. The total current is the sum of the currents through the individual components, in accordance with Kirchhoff’s current law. Voltage In a parallel circuit the voltage is the same for all elements. Resistors The current in each individual resistor is found by Ohm's law. Factoring out the voltage gives . To find the total resistance of all components, add the reciprocals of the resistances of each component and take the reciprocal of the sum. Total resistance will always be less than the value of the smallest resistance: . For only two resistors, the unreciprocated expression is reasonably simple: OBSERVATION: Series Circuit : Theoritical(NV) Practical (MV) 𝑅1 𝑅2 𝑅𝑇 = 𝑅1 + 𝑅2 Parallel Circuit: Theoritical(NV) Practical (MV) R3 R4 RR RT = 3 4 R3 + R4 Result: Thus, a simple series and parallel connection of resistor is performed using soldering. ASSEMBLY OF A.C TO D.C CIRCUITS IN BREAD BOARD Ex.No :_____________ Date : _____________ Aim To construct a Half wave rectifier , an A.C to D.C Circuit in Bread Board and observe its output response. Apparatus Required: S. Item Description Specification No. Quantity in Nos. 1 PN diode 1N4007 1 2 Resistor 1 KΩ\1W 1 3 Transformer (0-230)V\ (6-0-6) V – 250 1 mW 4 Bread Board -- 1 5 CRO with BNC Dual trace\15 MHz 1 Probe 6 Connecting wires Sufficient length few 7 Multi meter Sony \ Philips make 1 Theory: The process of converting alternating voltage/current to direct voltage/current is called rectification. An electronic device that offers a low resistance to current in one direction and a high resistance in the other direction is capable of converting a sinusoidal waveform into a unidirectional waveform. Diodes have this characteristic, which makes it a useful component in the design of rectifiers. In order to achieve a constant/pure DC voltage at the output, filtering should be done to the pulsating DC output of the rectifier. Half Wave Rectifier (HWR) The half-wave rectifier circuit using a semiconductor diode (D) with a load resistance RL but no smoothing filter is given in the figure. The diode is connected in series with the secondary of the transformer and the load resistance RL. The primary of the transformer is being connected to the ac supply mains. During positive half cycle of secondary voltage (input voltage), the diode D1 is forward biased and D2is reverse biased. The diode D1 conducts and current flows through load resistor RL. During the positive half cycle, the diode is under forwarding bias condition and it conducts current to RL (Load resistance). A voltage is developed across the load, which is the same as the input AC signal of the positive half cycle. Alternatively, during the negative half cycle, the diode is under reverse bias condition and there is no current flow through the diode. Only the AC input voltage appears across the load and it is the net result which is possible during the positive half cycle. The output voltage pulsates the DC voltage. Circuit Diagram: PROCEDURE: 1. Make the Connections as per the circuit diagram. 2. Connect the primary side of the transformer to ac mains and the secondary side to the rectifier input. 3. Observe input and output waveforms with the help of CRO. 4. Note down the readings for voltage and frequency of input and output waveforms. * Further a capacitor of 10 µF and a regulator IC 7805 is addad to the circuit to get a perfect DC voltage from a pulsating DC across the resistor. OBSERVATION TABLE: Observation Amplitude (V) Time Period (ms) Input Output across resistor RESULT: Thus AC to DC Circuit is constructed using bread board and its output waveform is obtained.