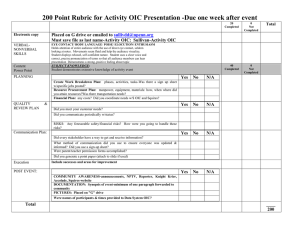

1 Appendix 1: SSA “Missing part” Root Causes Analysis Using Fishbone Chart Receiving Section Issue Section Storage Section Misplace Putaway/Pick TOs. Failed to write 5XXXXXXXXXX on parts Fake missing part: Dedicated parts Parts in VL06i, not in bins because falling out during transporting. Misplace incoming MROs. Put-away to/Pick the wrong parts to/from the wrong bins. Parts in the bin missing paperwork. Missing parts in SSA Unsecured turn-in paper blown away during transportation. Turn in/Shipping Section. Stock Control Section Print out duplicate TOs in the mornings. 2 Appendix 1: SSA “Missing part” Root Causes Using Fishbone Chart Analysis We can analogize the quality control measures in all Sections to a defense in depth/layered defense. “Missing parts’ result in two consequences: 1) Parts cannot be put away and Put-away TO cannot be closed and become overdue backlog. 2)Parts cannot be picked to satisfy customers’ demands. Pick TOs cannot be closed and become the overdue backlog. Receiving Section: First line of defense Errors Consequence Corrective/Short- ErrorTerm Actions proof/Preventive/Long Term Actions Pull out MROs and Missing MROs on Research under Train/daily reminder. misplaced them incoming parts supervisory Designate area for Work-in- guidance, locate Process (WIP) and mark parts or OIC may with conspicuous labels (lunch, end of day) take a loss if last resort fails. Remarks 3 Parts are properly Untrained Storage Research under Train/daily reminder: Parts Designated areas processed, but TOs personnel may supervisory without paper are supposed and redefining do not print out) misplace such parts. If guidance, locate to be properly researched parts physical because Stock NCOs are absent (sick, parts, or OIC may and the temp location flow are critical locations are blocked appointment), the parts take a loss if last 5xxxxxxxxx should be to prevent due to inventory could be sitting there resort fails written on the parts and Condition Code /admin block (E.g., idle /misplaced move to Storage Section so A and Code F/H Storage can do a bin-to-bin parts from mixing for walk-thru) up. 2)need to designate an area for such parts to prevent mixing with other parts Stock Control Section: 4 Errors Consequence Corrective/Short- ErrorTerm Actions Remarks proof/Preventive/LongTerm Actions Print out duplicate Chain reaction: Research under Issue Section print out pick it happened a TOs (Put-away/Pick) Duplicate picked supervisory list in SSA (not by the MP couple times in a parts flow to Issue guidance, locate clerk at MP) and SSA year, even by section and find no parts or OIC may soldier escort pick up and experienced matching record in take a loss mark off the list for each Soldier. the system. If it is item picked up-----very time issued anyway, then and manpower consuming this part will be short in the future Storage Section: 5 Errors Consequence Corrective/Short- Error-proof/Preventive/Long-Term Term Actions Actions misplace Fail to Put-away Research under NCOs develop a tracker to sign in/out Putaway/Pick TOs /Pick a part. supervisory Put-away/Pick TOs Chain reaction: guidance, locate Failure to put away parts or OIC may will cause failure take a loss Remarks to pick to satisfy a demand, resulting in Pick backlog Soldier put away parts The part will be Research under -Mark BOH container/drawers/bins -Repetitive work result into the wrong bin unavailable in the supervisory with conspicuous large letters in loss of focus future guidance, locate Ensure Soldier rest well before doing -Cold/wet weather and parts or OIC may put-away/pick outdoor work cause take a loss -Allow Soldiers to take small break distraction/fatigue/cold injury in Washington 6 -Offer refreshment such as hot chocolate from DFAC -Position supplies close to the BOH to reduce Soldiers’ moving distance that introduce possibility of errors. Soldiers pick the Wrong parts flow Research under wrong parts to Issue and get supervisory issued to customer guidance, put if Issue fails to parts back Storage catch the error or OIC may take a loss if parts can not be found Same as above Same as above 7 Issue Section: Alamo---last line of defense Errors Consequence Corrective/Short- ErrorTerm Actions proof/Preventive/LongTerm Actions Remarks 8 Dedicated parts: not real VL06i is not cleared daily Locate parts in the -Train Soldiers to utilize Print out all “missing” parts: parts are designated Dedicated Customer DODAAC for class II, in VL06i, but not in the “dedicated” DODAAC list IX, VII from GCSS. regular customer issue customer bin -Learn to print all customer Or ask NCOIC/OIC DODAAC List from GCSS for it. bin Parts in the bin missing Research under Train Storage Soldiers to Acquire sufficient paperwork---because supervisory spend time in attached supplies: stapler & Storage did not secure guidance, locate MROs to parts in a secured staples, packing tapes, the MROs, parts or OIC may way rubber bands Same as above take a loss Storage did not secure Individual part fell out and Research under -Train Storage Soldiers to multiple parts on the become a “orphan” part supervisory spend time in securing same MRO together and without paper guidance, locate multiple parts utilizing parts fell out during parts or reproduce ziplock bags, small boxes transportation to Issue paper, or OIC for small/tiny parts may take a loss 9 -NCOIC provide sufficient warehouse supplies -enforce using pallet-size plastic bin (NOT wooden pallet) to transport parts to prevent parts fall-out 10 Turn-in/Shipping Section: Errors Consequence Corrective/Short- ErrorTerm Actions Remarks proof/Preventive/LongTerm Actions Unsecured turn in paper Parts without paper cannot Research under -purchase better supplies to Print out all be processed or supervisory secure/attach waterproof DODAAC for class II, incorrectly processed as guidance, paperwork IX, VII from GCSS. FOI locate/reproduce -train/daily reminder Or ask OIC for it. paper Turn-in personnel did not Accept the wrong parts Research under -Train/daily reminder: do check NSN, qty and parts will not be supervisory not take shortcut. accepted by LRC guidance, reverse -for repetitive offender, turn-in and disciplinary action/transfer reprocess out 11 Turn in personnel did not Accept the wrong turn-in Research under Train Soldiers to utilize Tire utilize tire book for tire tire supervisory book turn in guidance, reverse turn-in, reprocess