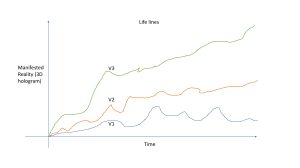

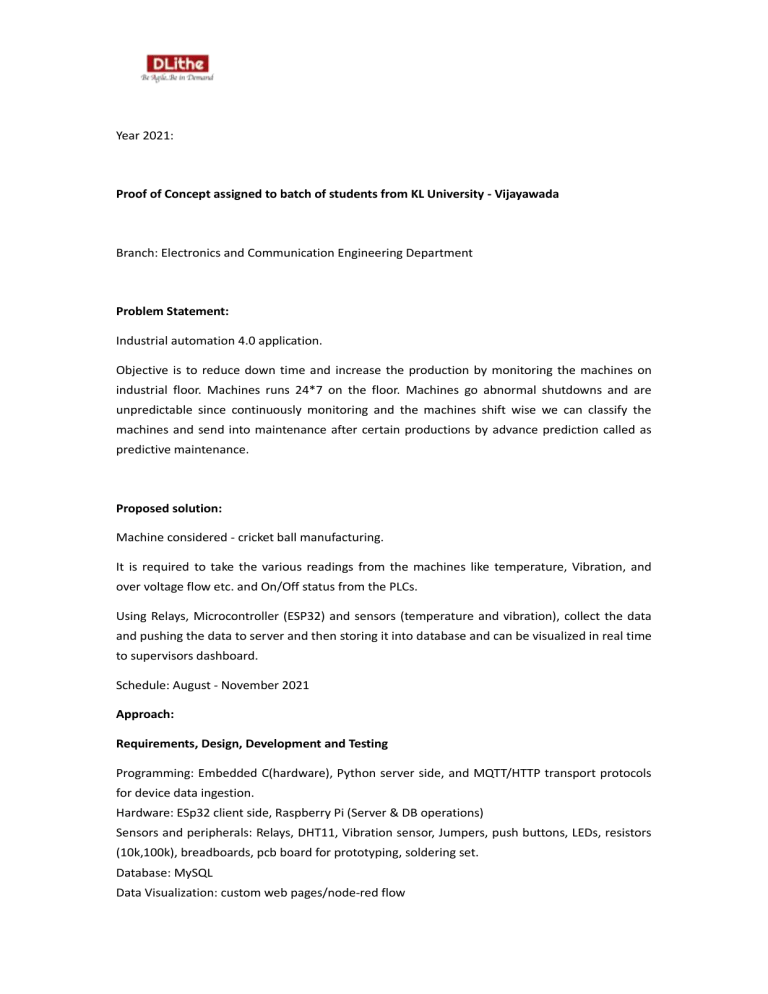

Year 2021: Proof of Concept assigned to batch of students from KL University - Vijayawada Branch: Electronics and Communication Engineering Department Problem Statement: Industrial automation 4.0 application. Objective is to reduce down time and increase the production by monitoring the machines on industrial floor. Machines runs 24*7 on the floor. Machines go abnormal shutdowns and are unpredictable since continuously monitoring and the machines shift wise we can classify the machines and send into maintenance after certain productions by advance prediction called as predictive maintenance. Proposed solution: Machine considered - cricket ball manufacturing. It is required to take the various readings from the machines like temperature, Vibration, and over voltage flow etc. and On/Off status from the PLCs. Using Relays, Microcontroller (ESP32) and sensors (temperature and vibration), collect the data and pushing the data to server and then storing it into database and can be visualized in real time to supervisors dashboard. Schedule: August - November 2021 Approach: Requirements, Design, Development and Testing Programming: Embedded C(hardware), Python server side, and MQTT/HTTP transport protocols for device data ingestion. Hardware: ESp32 client side, Raspberry Pi (Server & DB operations) Sensors and peripherals: Relays, DHT11, Vibration sensor, Jumpers, push buttons, LEDs, resistors (10k,100k), breadboards, pcb board for prototyping, soldering set. Database: MySQL Data Visualization: custom web pages/node-red flow Deliverable: 1. Hardware with integrated with software 2. Dashboard with reading ( real time) 3. Project Report