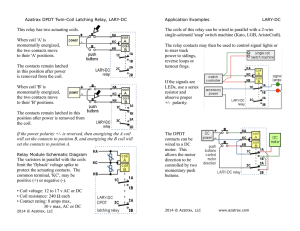

Industrial Power Protection & Controls June 2021 Pushbutton A pushbutton is a switch activated by finger pressure. Two or more contacts open or close when the button is depressed. Push-buttons are usually spring loaded so as to return to their normal position when pressure is re moved. Control relays A control relay is an electromagnetic switch that opens and closes a set of contacts when the relay coil is energized. The relay coil produces a strong magnetic field which attracts a movable armature bearing the contacts. Control relays are mainly used in low-power circuits. Power relays Power relays come as the ideal solution for all applications requiring small, low-noise relays or contactors at low costs. The power relays are suitable for basic controls and particularly for use in large-scale series devices and controls. They are ideal for applications which require only one auxiliary contact and no overload relay – and place increased requirements upon switching capacity, switching voltage and service life. They include time-delay relays whose contacts open or close after a definite time interval. Thus, a time-delay closing relay actuates its contacts after the relay coil has been energized. On the other hand, a time-delay opening relay actuates its contacts some time after the relay coil has been de-energized Thermal relays A thermal relay (or overload is a temperature sensitive device whose contacts open or close when the motor current exceeds a preset limit. The current flows through a small, calibrated heating element which raises the temperature of the relay. Thermal relays are inherent time-delay devices because the temperature cannot follow the instantaneous changes in current. Normally open and normally closed contacts Control circuit diagrams always show components in a state of rest, that is, when they are not energized (electrically) or activated (mechanically). In this state, some electrical contacts are open while others are closed. They are respectively called normally open contacts (NO) and normally closed contacts (NC) and are designated by the following symbols: Normally Open contact (NO) Normally Closed contact (NC) 1 Contactor A contactor is an electrically controlled switch used for switching a power circuit, similar to a relay except with higher current ratings. They are used to connect and break power supply lines running through power lines or repeatedly establish and interrupt electrical power circuits. These are used in light loads as well as in complex machine controls. It can be considered as an intersection point between the control circuit and power circuit because it is controlled by the control circuit, it also controls the circuit between power and loads. Contactors are used to control electric motors, lighting, heating, capacitor banks, thermal evaporators, and other electrical loads. Components of a Contactor The following three are crucial components of the contactor: 1. Coil or Electromagnet: This is the most crucial component of a contactor. The driving force that is required to close the contacts is provided by the coil or electromagnet of the contactor. The coil or electromagnet and contacts are protected by an enclosure. 2. Enclosure: Just like the enclosures used in any other application, contactors also feature an enclosure, which provides insulation and protection from personnel touching the contacts. The protective enclosure is made from different materials, such as polycarbonate, polyester, Nylon 6, Bakelite, thermosetting plastics, and others. Generally, the open-frame contactor features an additional enclosure, which protects the device from bad weather, hazards of explosion, dust, and oil. 3. Contacts: The current carrying task of the contactor is done by the contacts. There are different types of contacts in a contactor namely, contact springs, auxiliary contacts, and power contacts. Each type of contact has an individual role to play. The construction of a contactor. 2 Operating Principle of a Contactor An electromagnetic field is generated whenever current flows where the moving coils attract each other. A large amount of current is drawn initially by an electromagnetic coil; this current excites the electromagnet. The moving contact is pushed forward by moving core, as a result, the force created by the electromagnet holds the moving and fixed contacts together there by completing the circuit between the fixed contacts and the moving contacts. This permits the current to pass through these contacts to the load. When current is removed, the coil is de-energized and opens the circuit where the contactor coil gravity or spring moves back the electro-magnetic coil to its initial position and there is no flow of current in the circuit. The contacts of the contactors are known for their rapid open and close action. If contactors are energized with AC current, a small portion of the coil is the shaded coil, where the magnetic flux in the core is slightly delayed. This effect is too average as it prevents the core from buzzing at twice line frequency. There are internal tipping point processes to ensure rapid action so that contactors can open and closed very rapidly. From the block diagram below, the supply is given using a switch, that is when the switch is closed current flows through the contactor coil and attaches the moving core. The contactor attached to the moving core closes and the motor starts running. When the switch is released the electromagnetic energizes spring arrangement pause the moving coil back to its initial position and power supply to the motor is cut off. The block diagram of a contactor. 3 Types of Contactors These are classified based on three factors; The load being used. The current capacity. The power rating. 1. Knife Blade Switch It is the first contactor used to control an electric motor in the late 1800s. It consists of a metal strip, which acts as a switch in connecting and disconnecting the connection. This switch had a lever for pulling the switch down or pushing it up. But the disadvantage of this method is that it switching process since it caused the contacts to wear out quickly, since it was difficult to manually open and close the switch fast enough to avoid arcing. As a result of this, the soft copper switches underwent corrosion, which further made them vulnerable to moisture and dirt. Over the years, the size of the motors increased which further created the need for larger currents to operate them, which leads to high physical damage. 2. Manual Contactor Since the knife blade switch became potentially dangerous to use, another contactor device, which offered a number of features that were missing in the knife blade switch was developed. This device was referred to as a manual controller. These features included: Safe to operate Non-exposed unit, which is properly encased Physically smaller size Single break contacts replaced with double break contacts As their name implies, double break contacts can open the circuit in two places at the same time. Thus, even in smaller space, it allows you to work with more current. Double break contacts divide the connection in such a way that it forms two sets of contacts. The switch or button of the manual controller is not operated remotely and is attached to the controller physically. 4 The power circuit is engaged once the manual controller is activated by an operator. Once activated, it carries the electricity to the load. Soon, manual contactors replaced knife blade switches completely, and even today different variations of these types of contactors are being used. 3. Magnetic Contactor The magnetic contactor does not require human intervention and operates electromechanically. This is one of the most advanced designs of a contactor, which can be operated remotely. Thus, it helps eliminate the risks involved in operating it manually and putting operating personnel in potential danger. Only a small amount of control current is required by the magnetic contactor to open or close the circuit. This is the most common type of contactor used in industrial control applications. Difference between AC Contactors and DC Contactors AC Contactors DC Contactors They are designed for the contactors with selfextinguishing arc is drawn whenever the contact opens They don’t use freewheel diode Separation time is less They are specially designed to suppress electrical arching when there is switching in the DC circuit. They use freewheel diode Separation time is higher if the load is heavy a shunt load is attached to the main contact. 5 Advantages of a Contactor Disadvantages of a Contactor Fast switching operation Suitable for both AC and DC devices Simple in construction. High load capacity Low power consumption In the absence of magnetic-filed, the coil may burn Aging of components causes corrosion of materials when exposed to moisture. Absence of overload protection Application of Contactors 1. Lighting Control Contactors are often used to provide central control of large lighting installations, such as an office building or retail building. To reduce power consumption in the contactor coils, latching contactors are used, which have two operating coils. One coil, momentarily energized, closes the power circuit contacts, which are then mechanically held closed; the second coil opens the contacts 2. Electric Motor Starter Contactors can be used as a magnetic starter. A magnetic starter is a device designed to provide power to electric motors. It includes a contactor as an essential component, while also providing power-cutoff, under-voltage, and overload protection. 3. Vacuum contactor Vacuum contactors utilize vacuum bottle encapsulated contacts to suppress the arc. This arc suppression allows the contacts to be much smaller and use less space than air break contacts at higher currents. As the contacts are encapsulated, vacuum contactors are used fairly extensively in dirty applications, such as mining. Vacuum contactors are only applicable for use in AC systems. 4. Mercury relay 5. Mercury-wetted relay How to Choose a Correct Replacement for a Contactor? Firstly, one should check the coil voltage, which is a voltage used to energize the contactor. Checking for auxiliary contacts available, that is how many open and closed nodes are used in the contactor. Checking the rating which is mentioned in a table format on it. 6 Control of Electric Motor with Contactor When a relay is used to switch a large amount of electrical power through its contacts, it is designated by a special name: contactor. Contactors typically have multiple contacts, and those contacts are usually (but not always) normally-open, so that power to the load is shut off when the coil is de-energized. Perhaps the most common industrial use for contactors is the control of electric motors. The top three contacts switch the respective phases of the incoming 3-phase AC power, typically at least 480 Volts for motors 1 horsepower or greater. The lowest contact is an “auxiliary” contact which has a current rating much lower than that of the large motor power contacts, but is actuated by the same armature as the power contacts. The auxiliary contact is often used in a relay logic circuit, or for some other part of the motor control scheme, typically switching 120 Volt AC power instead of the motor voltage. One contactor may have several auxiliary contacts, either normally-open or normally-closed if required. The three “opposed-question-mark” shaped devices in series with each phase going to the motor are called overload heaters. Each “heater” element is a low-resistance strip of metal intended to heat up as the motor draws current. If the temperature of any of these heater elements reaches a critical point (equivalent to a moderate overloading of the motor), a normally-closed switch contact (not shown in the diagram) will spring open. This normally-closed contact is usually connected in series with the relay coil, so that when it opens the relay will automatically de-energize, thereby shutting off power to the motor. Overload heaters are intended to provide overcurrent protection for large electric motors, unlike circuit breakers and fuses which serve the primary purpose of providing overcurrent protection for power conductors. 7 Jogging Control Circuits Sometimes called “inching,” jogging is the term given to the momentary energization of a motor only so long as an operator is pressing a button. A jog circuit is a circuit that allows an operator to either start the motor or “jog” the motor and are commonly used for motors controlling conveyor belts to allow for precise positioning of materials. Any motor starter that is used to jog a motor will be subjected to repetitive inrush currents, which can cause overheating of the power contacts. If a motor is expected to be jogged more than five times in a minute, the motor starter should be increased in size and horsepower rating for this more severe operating condition. To achieve a jog function, there are several common circuit designs, each with their own advantages and disadvantages. A common feature that all jog circuits have is that they have some method of disabling the holding contact used in the three-wire circuit. This is usually accomplished by putting some component in series with the holding contact, such as a switch or momentary pushbutton. i) Jog Circuit with Selector Switch The most basic of the jog circuits, this is essentially a three-wire circuit with an SPST (singlepole, single-throw) switch connected in series with the holding contact. In the closed position, the SPST switch offers no opposition to the flow of current and the circuit behaves the same as a standard three-wire circuit. The normally open push button is acting as a “start” or “run” button. If the SPST switch is opened, then it has introduced an open in series with the 2-3 holding contacts, effectively removing them from the circuit. Without the holding contact, the motor starter will only be energized as long as an operator is pressing the normally open pushbutton, which acts as a “jog” button in this position. 8 The main advantage of this circuit is the ease of installation and the cheapness of equipment. The main disadvantage is that you must change the position of your selector switch to change the function of your button. ii) Dangerous Jog Circuit This uses a four-contact momentary pushbutton as the “Jog” button. This button has one set of normally closed contacts which are wired in series with the 2-3 holding contact, and one set of normally open contacts which are in series with only the stop button and the motor starter. In normal operation, the stop and start buttons provide their standard functions in a three-wire circuit, as the 2-3 holding contact is in series with the normally closed contacts of the jog button. If the jog button is pressed, the normally closed contacts will open and the normally open contacts will close, providing a path for current to energize the motor starter. When the motor starter is energized, all contacts associated with it will change their state, including the 2-3 holding contact, but because the jog button is being depressed the holding contact cannot maintain power to the starter. Once the jog button is released the motor comes to a stop. This circuit is sometimes referred to as the “dangerous jog circuit” for reasons which may appear obvious now. If the jog button’s normally closed contacts are able to return to their normal condition before the motor starter’s armature has had a chance to drop out, then the coil will remain energized and the motor will continue to run. This is dangerous because if an operator pushes a jog button, expecting the motor to stop when they release the button, and the motor continues to run, it could introduce a hazard to a person caught off guard. In short, we never want machines to surprise people. This circuit has the advantage of being simple to install and has separate buttons dedicated to starting and jogging the motor. The main disadvantage is the hazard introduced by the quick return of the jog button to its normal state. 9 iii) Jog Circuit with Control Relay A more sophisticated jogging circuit uses a control relay as shown in the figure below. Control relays behave just like motor starters but lack overload protection and power contacts. Control relays are loads that must be connected in parallel with the motor starter to ensure they get their rated voltage. In any schematic diagram, the current must find its way from Line 1 to Line 2 and energize only one load along the way. Switches offer either infinite resistance when they are open or zero resistance when they are closed, so some device must limit the current to prevent short circuits. Notice that the current that passes through the control relay does not pass through the motor starter. This means that they will both get their rated value of voltage and pull in their armatures. As a rule, we NEVER connect loads in series. Under normal conditions, if the start button is pressed, current will be able to complete the circuit and energize the control relay. Once the relay is energized, the two normally open contacts associated with it will change their state and close. This will provide a path for current to energize the motor starter, closing the 2-3 holding contacts and running the motor. The circuit will continue to operate as a standard three-wire circuit providing low-voltage protection (LVP) until either the stop button is pressed, or an overload occurs. If the jog button is pressed while the motor is running, there will be no change to the circuit. If, however, the jog button is pressed while the motor is not running, it will provide a path for current to energize the motor starter. The current will not be able to energize the control relay, and so once the jog button is released, the starter drops out and the motor comes to a stop. The advantage of this circuit lies in its safety and reliability. Having two separate buttons for “run” and “jog” functions increases ease of control for the operator. The disadvantage is the additional cost and installation time associated with the control relay and additional current drawn in the control circuit due to the second coil. 10 Electrical Interlocks Electrical interlocking is accomplished by installing the normally closed contact of one direction’s coil in series with the opposite direction’s coil, and vice versa. This ensures that when the forward coil is energized, pushing the reverse pushbutton will not energize the reverse coil. The same situation is in effect when the reverse coil is energized. In both situations the stop button will need to be pressed to de-energize the running coil and return all its auxiliary contacts back to their original state. Then the opposite direction coil can be engaged. Pushbutton Interlocks Pushbutton interlocking requires the use of four-contact momentary push buttons with each pushbutton having a set of normally open and normally closed contacts. To achieve pushbutton interlocking, simply wire the normally closed contacts of one pushbutton in series with the normally open contacts of the other pushbutton, and the holding contacts will be connected in parallel with the appropriate button’s normally open contacts. This circuit still requires the installation of electrical interlocks. Pushbutton interlocking doesn’t require the motor coils to be disengaged before reversing direction because the normally closed forward contacts are in series with the normally open reverse contacts, and vice-versa. Pushing one button simultaneously disengages one coil while starting the other. This sudden reversal (plugging) can be hard on the motor, but if quick reversal of the motor is required, this circuit can be a solution. Mechanical Interlocks Forward / reverse starters must never close their power contacts simultaneously. The best way to provide this is through electrical interlocks, which prevent the one coil from being energized if the other is engaged. A failure in electrical interlocking can cause both coils to be energized at the same time. 11 If both become energized, some form of mechanical interlock is required to prevent both armatures from pulling in. Represented on schematic diagrams as a dotted line between the two coils, a mechanical interlock is a physical barrier that is pushed into the path of one coil’s armature by the movement of the adjacent coil. This means that even if both coils are energized, only one armature will be able to pull in fully. The coil that is prevented from pulling in will make a terrible chattering sound as it tries to complete the magnetic circuit. Mechanical interlocks should be relied on as a last resort for protection. 12