Role of Nuclear Pharmacist in Clinical Translation of Positron Em

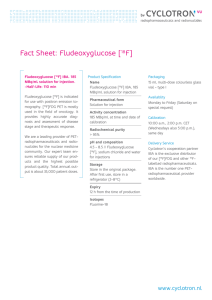

advertisement