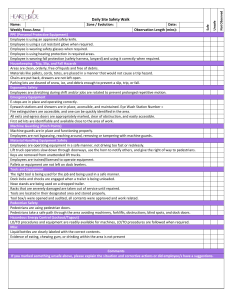

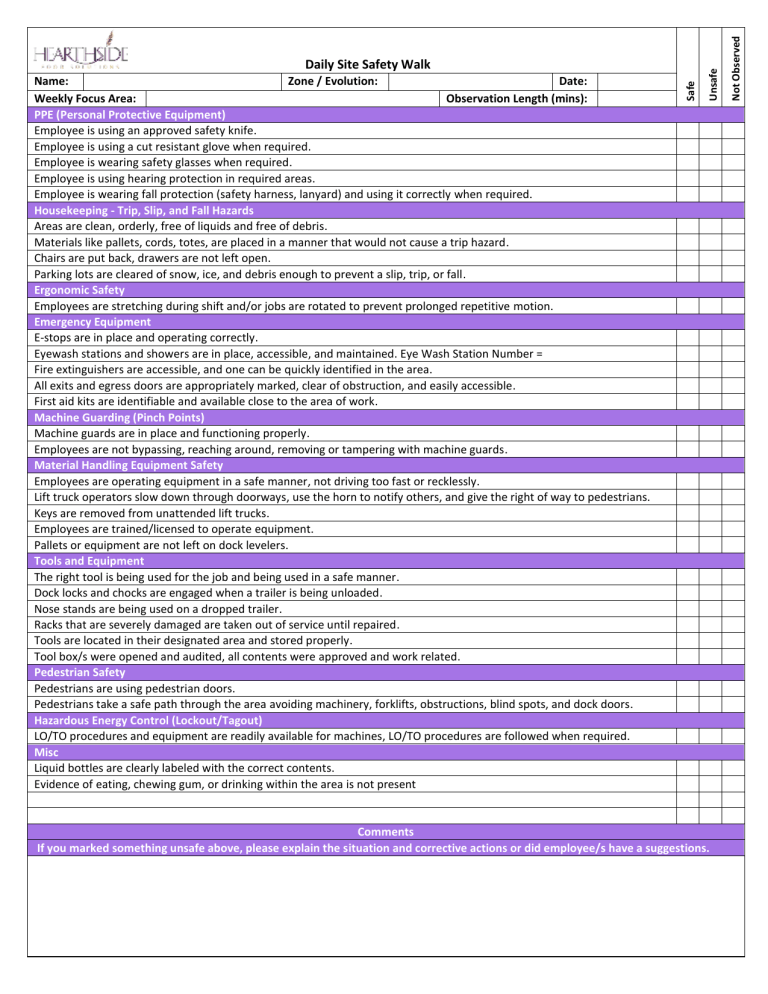

Comments If you marked something unsafe above, please explain the situation and corrective actions or did employee/s have a suggestions. Not Observed Unsafe Name: Zone / Evolution: Date: Weekly Focus Area: Observation Length (mins): PPE (Personal Protective Equipment) Employee is using an approved safety knife. Employee is using a cut resistant glove when required. Employee is wearing safety glasses when required. Employee is using hearing protection in required areas. Employee is wearing fall protection (safety harness, lanyard) and using it correctly when required. Housekeeping - Trip, Slip, and Fall Hazards Areas are clean, orderly, free of liquids and free of debris. Materials like pallets, cords, totes, are placed in a manner that would not cause a trip hazard. Chairs are put back, drawers are not left open. Parking lots are cleared of snow, ice, and debris enough to prevent a slip, trip, or fall. Ergonomic Safety Employees are stretching during shift and/or jobs are rotated to prevent prolonged repetitive motion. Emergency Equipment E-stops are in place and operating correctly. Eyewash stations and showers are in place, accessible, and maintained. Eye Wash Station Number = Fire extinguishers are accessible, and one can be quickly identified in the area. All exits and egress doors are appropriately marked, clear of obstruction, and easily accessible. First aid kits are identifiable and available close to the area of work. Machine Guarding (Pinch Points) Machine guards are in place and functioning properly. Employees are not bypassing, reaching around, removing or tampering with machine guards. Material Handling Equipment Safety Employees are operating equipment in a safe manner, not driving too fast or recklessly. Lift truck operators slow down through doorways, use the horn to notify others, and give the right of way to pedestrians. Keys are removed from unattended lift trucks. Employees are trained/licensed to operate equipment. Pallets or equipment are not left on dock levelers. Tools and Equipment The right tool is being used for the job and being used in a safe manner. Dock locks and chocks are engaged when a trailer is being unloaded. Nose stands are being used on a dropped trailer. Racks that are severely damaged are taken out of service until repaired. Tools are located in their designated area and stored properly. Tool box/s were opened and audited, all contents were approved and work related. Pedestrian Safety Pedestrians are using pedestrian doors. Pedestrians take a safe path through the area avoiding machinery, forklifts, obstructions, blind spots, and dock doors. Hazardous Energy Control (Lockout/Tagout) LO/TO procedures and equipment are readily available for machines, LO/TO procedures are followed when required. Misc Liquid bottles are clearly labeled with the correct contents. Evidence of eating, chewing gum, or drinking within the area is not present Safe Daily Site Safety Walk