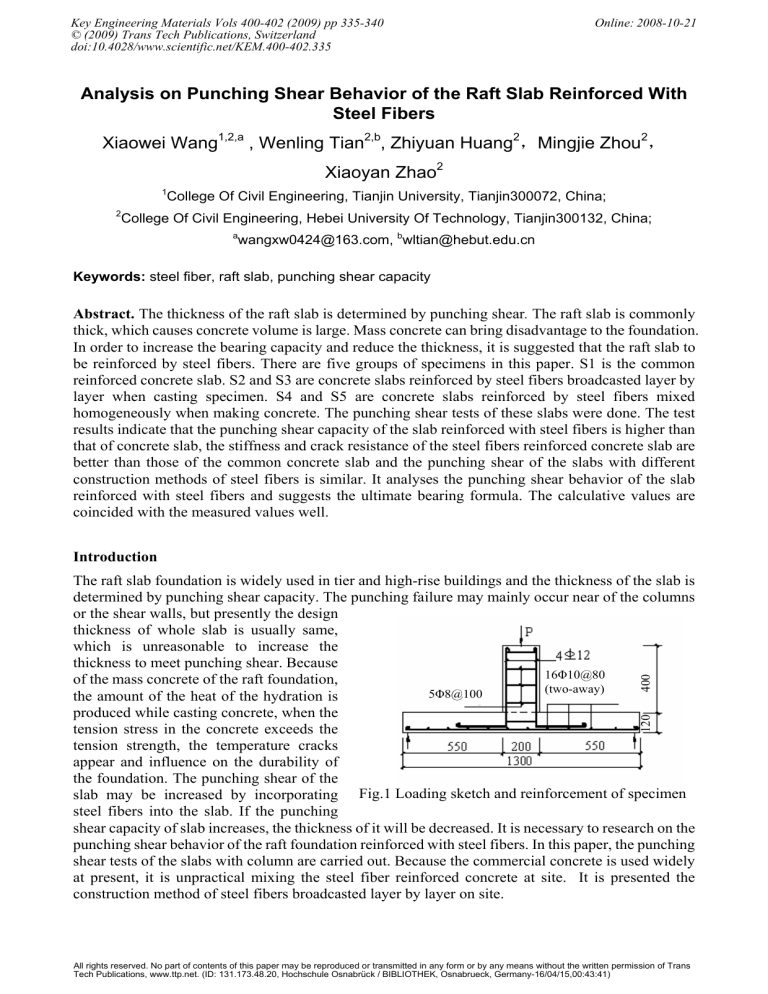

Key Engineering Materials Vols 400-402 (2009) pp 335-340 © (2009) Trans Tech Publications, Switzerland doi:10.4028/www.scientific.net/KEM.400-402.335 Online: 2008-10-21 Analysis on Punching Shear Behavior of the Raft Slab Reinforced With Steel Fibers Xiaowei Wang1,2,a , Wenling Tian2,b, Zhiyuan Huang2,Mingjie Zhou2, Xiaoyan Zhao2 1 College Of Civil Engineering, Tianjin University, Tianjin300072, China; 2 College Of Civil Engineering, Hebei University Of Technology, Tianjin300132, China; a wangxw0424@163.com, bwltian@hebut.edu.cn Keywords: steel fiber, raft slab, punching shear capacity Abstract. The thickness of the raft slab is determined by punching shear. The raft slab is commonly thick, which causes concrete volume is large. Mass concrete can bring disadvantage to the foundation. In order to increase the bearing capacity and reduce the thickness, it is suggested that the raft slab to be reinforced by steel fibers. There are five groups of specimens in this paper. S1 is the common reinforced concrete slab. S2 and S3 are concrete slabs reinforced by steel fibers broadcasted layer by layer when casting specimen. S4 and S5 are concrete slabs reinforced by steel fibers mixed homogeneously when making concrete. The punching shear tests of these slabs were done. The test results indicate that the punching shear capacity of the slab reinforced with steel fibers is higher than that of concrete slab, the stiffness and crack resistance of the steel fibers reinforced concrete slab are better than those of the common concrete slab and the punching shear of the slabs with different construction methods of steel fibers is similar. It analyses the punching shear behavior of the slab reinforced with steel fibers and suggests the ultimate bearing formula. The calculative values are coincided with the measured values well. Introduction 120 400 The raft slab foundation is widely used in tier and high-rise buildings and the thickness of the slab is determined by punching shear capacity. The punching failure may mainly occur near of the columns or the shear walls, but presently the design thickness of whole slab is usually same, which is unreasonable to increase the thickness to meet punching shear. Because 16Φ10@80 of the mass concrete of the raft foundation, (two-away) 5Φ8@100 the amount of the heat of the hydration is produced while casting concrete, when the tension stress in the concrete exceeds the tension strength, the temperature cracks appear and influence on the durability of the foundation. The punching shear of the slab may be increased by incorporating Fig.1 Loading sketch and reinforcement of specimen steel fibers into the slab. If the punching shear capacity of slab increases, the thickness of it will be decreased. It is necessary to research on the punching shear behavior of the raft foundation reinforced with steel fibers. In this paper, the punching shear tests of the slabs with column are carried out. Because the commercial concrete is used widely at present, it is unpractical mixing the steel fiber reinforced concrete at site. It is presented the construction method of steel fibers broadcasted layer by layer on site. All rights reserved. No part of contents of this paper may be reproduced or transmitted in any form or by any means without the written permission of Trans Tech Publications, www.ttp.net. (ID: 131.173.48.20, Hochschule Osnabrück / BIBLIOTHEK, Osnabrueck, Germany-16/04/15,00:43:41) 336 Advances in Concrete and Structures Experimental Design Specimen Making The specimen uses the square concrete slab with the square column, there are 5 groups of specimen in all and each group has 2 specimens. The test result of the group was the average of the two specimens. Table 1 Specimen parameters Number L[mm] L0[mm] h[mm] a[mm] fcu[N/mm2] ρf [%] S1 1300 1200 120 200 21.8 0 S2 1300 1200 120 200 24.6 1.0 S3 1300 1200 120 200 25.2 1.5 S4 1300 1200 120 200 18.8 1.0 S5 1300 1200 120 200 18.6 1.5 (L-the length of the slab side, L0-the span of the slab, h-the thick of the slab, a-the length of the column, fcu-the measured cubic strength of concrete, ρf- the volume ratio of the steel fibers.) The distributed rebar of the specimen are shown in the Fig.1. The specimen size is shown in Fig.1 and Table 1.The design strength of concrete is C20. The smooth straight line steel fibers are used. The average length of the steel fibers is 30mm, and the ratio of the length to the diameter is 45. The measured concrete strength and the volume ratio of fibers are shown in Table 1. The first group of specimen (S1) is the common concrete slab, the second and third groups (S2 and S3) are the slabs reinforced with steel fibers broadcasted layer by layer on site and the fourth and fifth groups (S4 and S5) are the slabs reinforced with steel fibers mixed when making concrete respectively. The detailed making methods of the specimen can be found in the reference [1]. Test Device The slab surface downward is supported at four sides. The axial load is applied to the column by a oil jack (shown as Fig.1). In order to measure the deflection of the slab under the load, a dial indicator is placed individually on the centre point of every side of the slab and both sides of the column. The load step is on the specimen by the oil jack, one load step is 20kN, but nearly to damage, it is changed to10kN. The deflection and the width of crack corresponding to the step load are recorded. Table 2 Test Results Number S1 S2 S3 S4 S5 ρf [%] 0 1.0 1.5 1.0 1.5 Pr [kN] 95 110 110 90 100 Pu [kN] 255 290 315 285 310 fp [mm] 6.9 7.2 7.2 7.3 7.1 fu [mm] 10.4 14.3 19.6 16.3 19.6 nu 1.14 1.24 1.12 1.22 uf(fu/fp) 1.5 2.0 2.7 2.3 2.7 (Pr-the crack load, Pu-the ultimate load, fp-the deflection corresponding to the ultimate, fu-the deflection corresponding to the 85 percent of the ultimate load, npu-the ratio of the ultimate load of S2, S3 and S4 to the ultimate load of S1.) Test Results and Analysis Test results are shown in Table 2. From the test results in Table 2, it can be seen that the crack load of the slabs reinforced with steel fibers is higher than that of the common concrete slab, the ultimate load of the slabs reinforced with steel fibers is 1.12~1.24 times of that of the common concrete slab. Analysis of Stiffness of Slabs The load-deflection curve is shown in Fig.2. From Fig.2, it can be seen that before peak load and at the same load the deflection of the slab reinforced with the steel fibers is lower than that of the concrete slab, which illustrates that the stiffness of the former is better than that of the latter. Moreover, before peak load and at the same load the deflection of S3 is lower than that of S2 before reaching peak load , this is shown that the volume ratio of steel fibers is higher the stiffness of slab is bigger. When the volume ratio of steel fibers is definite, before peak load and at the same load the Key Engineering Materials Vols. 400-402 337 deflection of S2 and S4 is similar, which P(kN) shows that the stiffness of them is similar, 350 the deflection values of S3 and S5 is also 300 shown that the stiffness of them is similar. From these, it can be seen that the stiffness 250 of slab reinforced with steel fibers 200 S1 broadcasted layer by layer is similar to the S2 150 slab reinforced by steel fibers mixed S3 S4 homogeneously when making concrete. 100 S5 Analysis of Ductility of Slabs 50 From Fig.2 it can be seen that after the peak f(mm) 0 load the load-deflection curves of S2, S3, S4 0 5 10 15 20 25 and S5 decline slower than that of S1. The Fig.2 Load-deflection curve of slabs ratio uf of fu to fp is named the ductility factor. From Table 2, the ductility factor of the common concrete slab is 1.5, but to the steel fibers concrete slabs, it is above 2.0. The results of ductility factor express that the ductility of the slab reinforced with steel fibers is better than that of the concrete slab, moreover the volume ratio of steel fibers is higher the ductility is better. When the volume ratio of steel fibers is definite, the ductility of S2 is similar to S4 and the ductility of S3 is also similar to S5. It shows that the construction methods of steel fibers have no significant influence on the ductility of slab. Table 3 Width of crack (mm) P[kN] 100 120 140 160 180 200 0.04 0.1 0.14 0.19 0.21 0.54 S2 0.08 0.11 0.13 0.18 S3 0.05 0.07 0.11 0.07 0.09 0.04 0.09 Number S1 S4 S5 80 0.02 220 240 0.25 0.4 0.57 0.15 0.2 0.26 0.38 0.14 0.19 0.27 0.39 0.59 0.13 0.16 0.19 0.24 0.4 Analysis of Crack of Slabs The test results in Table 2 show that the cracks of the slabs reinforced with steel fibers occur later than that of the concrete slab, and steel fibers prevent the crack occurrence and increase the crack load. The results of the crack width corresponding to the load step are shown in Table 3. It can be concluded that at the same load the crack width of the slab reinforced with steel fibers is thinner than that of the concrete slab, moreover the S2 S1 higher the volume ratio of the steel fibers is, the thinner the crack width is. For example, when the load is 160kN, the crack width of S1 is 0.19mm, but the crack width of S2 is only 0.13mm; when the load is 200kN, the crack width of the above two slabs is respectively 0.54mm and 0.25mm. This is shown that the cracks of the Fig.3 Crack of slab slab reinforced with steel fibers develop slowly, moreover the cracks of it is relatively thin and dense. Because when the crack occurs the steel fibers crossing the crack bear certain tensile force and prevent the development of the crack. When the load continues to increase, the tensile stress of the concrete between the cracks increases 338 Advances in Concrete and Structures h0 h x caused by the increasing of the steel fibers bearing tensile force, when the tensile stress exceeds the tensile strength of concrete, new crack occurs. So the cracks of the slabs reinforced with steel fibers are widely thin and dense (as Fig.3). Contrast the results of S2 to S4 and S3 to S5 in the Table 3, it can be seen that when the volume ratio of steel fibers is definite, the similarity of the crack width of the two types of slabs shows that the ductility of them is similar. Analysis of Punching Shear Capacity of Slabs The failure process of the slab reinforced with steel fibers is similar to that of the concrete slab. The punching shear crack of the bottom of the slab occurs at the instant of the failure, but before the load reaches the peak the strain in concrete near to the crack is IV tensile zone minor, so the initial position of the punching shear crack is III compressive zone not at the bottom of the slab. II tensile zone To the same as the root of the column, the crack does not occur till to the ultimate load, the possibility of the initial I compressive zone crack occurs on the surface of the slab is little. So the Fig.4 Shear compressive and shear tensile zones of failure section position of the shear crack occurring is the middle of the slab. Shengyuan Cao and Xiaolin Guo in China proved that the failure shear inclined-section is divided into four shear tensile and shear compressive alternately zones (as Fig.4). I and IV are little and can be neglected. So the failure shear inclined-section is generally divided into two zones of II and III [2].The failure of the reinforced concrete slab under the concentrated load is the result from the common action of the flexural failure and punching shear failure. P Under the load, the flexural cracks Vcc occur at some points near to the Vc column bottom surface of the slab, when the principal tensile stress of neutral axis Va some points exceeds the tensile Fr strength of concrete the shear cracks occur. The upper part of the slab is in Vr the state of the shear compressive Fig.5 Failure section and forces and the lower part of it is in the state of the tensile shear (as Fig.5). The shear cracks develop gradually upward and downward with the increase of the load. The shear compressive zone of concrete bears large part of the shear of the crack and the steel (rebars) bears the little part of it (called as the dowel action of tensile reinforcement bars). The shear compressive zone of the concrete is in the triaxial compression state, when the strain of the concrete reaches the ultimate compressive strain in the state of compressive-shear combined stress the punching shear failure is induced. The punching shear failure of the common concrete slab is brittle, but that of the slab reinforced with steel fibers is relatively ductile because the steel fibers make the tensile and shear strength of concrete increase, restrict the development of the shear crack and prolong the failure process. From the analysis above, under the concentrated load the punching shear failure section and the forces are shown in the Fig.5. The minute tensile force of the concrete below the neutral axis may be neglected [3].The punching shear strength of concrete slab is related to the concrete strength, the size of the inclined-section of the punching shear cone, the ratio of longitudinal reinforcement and so on. From the Fig.5, it is obtained the equation as follows: Key Engineering Materials Vols. 400-402 F= Vc +Vr +Va 339 (1) In the formula P-the ultimate bearing capacity of the punching failure of the concrete slab; Vc-the shear capacity of the shear-compressive zoneof concrete; Vr-the shear capacity of the dowel action of tensile reinforcement bars; Va-the force of the aggregate interlock capacity of concrete. Va, Vc and Vr is related with each other, at the same load step they can not reach the maximum ttogether generally. The theory analysis shows that at the ultimate failure state the force of the aggregate interlock capacity of concrete decreases greatly because of the large expansion of the crack. Compared to Vc and Vr,Va can be neglected completely. The determination of the shear bearing of the shear compressive area of concrete is complex. It is related with concrete strength, the height of the shear-compressive zone, the angle of the punching failure, the ratio of the tensile reinforcement and so on. The formula of Vc is seen in the reference [3]: Vc = 4(xcotθ+ a ) x⋅ cotθ⋅ f c (2) In the formula a-the side length of the square column; x-the height of the compressive zone concret; θ-the angle of the punching failure surface, the value of it is 45° generaally. The calculation of the dowel action of tensile reinforcement bars is very complex. It is related with the ratio of tensile reinforcement, the diameter of the bar and so on. The reference [3] gives the empirical equation of the shear bearing of the dowel action of tensile reinforcement bars: Vr = b . l n . f t (3) In the formula b-the width of the slab which is in the same plane with the bar; ln-the critical length, l n = 15.85 f cu−1 / 3 d 2 / 3 (fcu-the cubic compressive strength, d- the diameter of the bar); ft-the axial tensile strenth. The main function of fibers is to prevent the development of the microcracks inter of the concrete and block the occurance and development of the macrocracks. The steel fibers make the tensile and shear stength of concrete increase obviously, equalling to the hoops of punching shear resistance the steel fibers that crossing the cracks can directly bear part of the tensile force and make the failure zone detach difficultly. So the punching shear bearing of the shear compressive zone of concrete is greatly improved, it increaes with the increase of the characteristic content parameter λ( f λf=ρflf/df), moreover it is linear essentially with λf [4]. The angle of punching shear failure of slab reinforced with steel fibers decreased little and is about 30~45°, in order to ensure unified calculation it takes 45°. Revising the results it is obtained the formula of the ultimate bearing capacity Pf of the punching failure of the slab with steel fibers reinforced as follows: Pf = 4(1 + 0.45 λ f )(xcotθ + a ) x⋅ cotθ⋅ f c + bl n f t (4) The calculated ultimate bearing capacity results of slabs are shown in Table 3. The results show that the calculated and measured results are in good agreement. Analysis of the Construction Method of Steel Fibers Broadcasted Layer by Layer on Site Based on the above analysis of the test results, it is concluded that both the construction method of steel fibers broadcasted layer by layer on site and that of the steel fibers mixed homogeneously when 340 Advances in Concrete and Structures making concrete have no great difference on the punching shear behavior. But to the former, the fibers Table 3 The calculated ultimate bearing capacity of the slabs Number λf Pu [kN] Pf [kN] Pf/Pu S1 S2 S3 S4 S5 0 0.450 0.675 0.450 0.675 255 290 315 285 310 254 285 324 270 306 1.00 1.05 1.01 0.96 0.98 are in the randomly distributed state between the two-dimension and three-dimension. To ensure the structure to be safer, it may be considered steel fibers in the randomly distributed state of three-dimension while analyzing force. The construction method of steel fibers broadcasted layer by layer on site is simple and convenient, it is adapted to the using of commercial concrete and the structure partially reinforced with steel fibers. The joint of the column of the raft slab is reinforced by steel fibers, the total fibers is divided into several equal share, while pouring about 20cm thick of concrete one layer of steel fibers is broadcasted till pour is over, at last the concrete is vibrated fully. Summary From the above analysis of the punching shear capacity of slab, it is concluded that the ultimate bearing capacity and stiffness of the raft slab can be improved if it is reinforced with steel fibers; the development of the cacks is prevented and the width of it is decreased.That is to say under the condition that the ultimate bearing capacity of the punching failure remains constant the thickness of the raft slab may be decreased. The punching shear behavior of the slab made by steel fibers broadcasted layer by layer on site is similar to the slab made by steel fibers mixed homogeneously when making concrete. It analyses the punching shear capacity of the slab reinforecd with steel fibers and suggests the formula of the ultimate punching shear bearing, the calculated and measured results are in good agreement. References [1] Zhi Yuan Huang: Experimental and Applied Study on Raft Foundation Reinforced by Steel Fibers, master thesis of HeBei University of Technology (2004),p.10 [2]Theodorakopoulos, D.D. and Swamy, R.N.: Ultimate punching shear strength analysis of slab-column connections, Journal of Cement and Concrete Composites 6(2002), p.509 [3]Sheng Yuan Cao, Xiao Lin Guo: The punching shear mechanism and strength of reinforced concrete, The basic theory and application of concrete structure and the second symposium(1990) [4]Guo Fan Zhao, Shao Min Peng and Cheng Xiang Huang: The steel fiber reinforced concrete structure, China Building Industry Press (1999), p.21 Advances in Concrete and Structures 10.4028/www.scientific.net/KEM.400-402 Analysis on Punching Shear Behavior of the Raft Slab Reinforced with Steel Fibers 10.4028/www.scientific.net/KEM.400-402.335