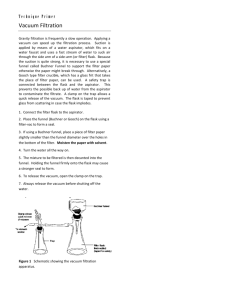

Synthesis of Lidocaine Hydrogen Sulphate Session 1 Step 1 – Formation of 2-chloro-2,6-dimethylacetanlide Prepare a solution of 0.75g of sodium acetate in 15 mL of distilled water, using a 25 ml conical flask. In a fume hood, using a clean, dry 50 mL conical flask, mix, in this order, 0.5g of 2,6dimethylaniline, 3.6 mL of glacial acetic acid, and 0.37 mL of chloroacetyl chloride. Warm on a steam bath for 4 minutes, swirling occasionally. Remove from the steam bath, and add the sodium acetate solution. A milky white solid will form. Cool the mixture in an ice bath for a few minutes, and filter off the product using a vacuum Buchner flask and funnel. Rinse the product with small amounts of water, until the vinegary smell of acetic acid has gone. Leave the vacuum on for a further 15 minutes to help dry the product. Transfer product to a large piece of filter paper to air dry. Weigh the product, calculate the molar percentage yield, and determine the melting point (literature value 145-146oC). Step 2 – Synthesis of 2-diethylamino-2,6-dimethylacetanilide (Lidocaine) In a 25 mL round bottomed flask, in a fume hood, place 0.4g of obtained 2-chloro-2,6dimethylacetanilide, 6 mL of toluene, and a stirring bar. Add 1.7 mL of diethylamine. Attach a reflux condenser, and reflux vigorously, for 90 minutes. Allow the mixture to cool and leave until the next laboratory session. Session 2 Dissolve any formed solid under reflux. Cool, and filter out any solid through a funnel plugged with cotton wool, transfering the liquid toluene into a 100 mL separatory funnel. Wash with water three times, by adding 5 mL of water, swirling, allowing to separate, and discarding lower water layer. Repeat twice. Then extract toluene layer with dilute 2M HCl, by adding 5mL of 2M HCl, swirling, allowing to separate, and keeping the lower aqueous layer. Add another 5 mL of 2M HCl, swirl, separate and combine lower layer with previous one. Repeat once more. To acid extracts, add approx. 5mL of 30% KOH to make solution strongly alkaline (universal pH indicator paper turns dark blue). Yellowish white crystals of Lidocaine should appear. Cool in ice for 10 minutes, and filter off solid using a vacuum Buchner flask and funnel. Wash with small volumes of water. Allow to dry, transfer solid to large filter paper to air dry. Weigh solid, and calculate molar percentage yield. Determine melting point (literature value 68-69oC). Step 3 – Formation of Lidocaine hydrogen sulphate Using a small conical flask, dissolve the Lidocaine in diethyl ether (about 5 mL usually), and add, dropwise, around 1 mL of the 2.2M sulphuric acid in ethanol. Mix the solutions thoroughly and scratch the inside surface of the conical flask to induce crystalisation. You may find it necessary to add some more diethyl ether to start crystalisation. A thick milky solid should form. Dilute with an equal volume of acetone and filter through a small Buchner flask and funnel, or Hirsch funnel. Wash through with more acetone and transfer solid to a filter paper to air dry. You can use an infra red lamp to dry also. Record the weight of solid, calculate the molar percentage yield (from Lidocaine), and determine the melting point (literature value 210-212oC). Adapted from Laboratory of Organic Chemistry, Natural Products and Pharmaceuticals, edited Jan Milecki, UAM, Poznan, 2013.