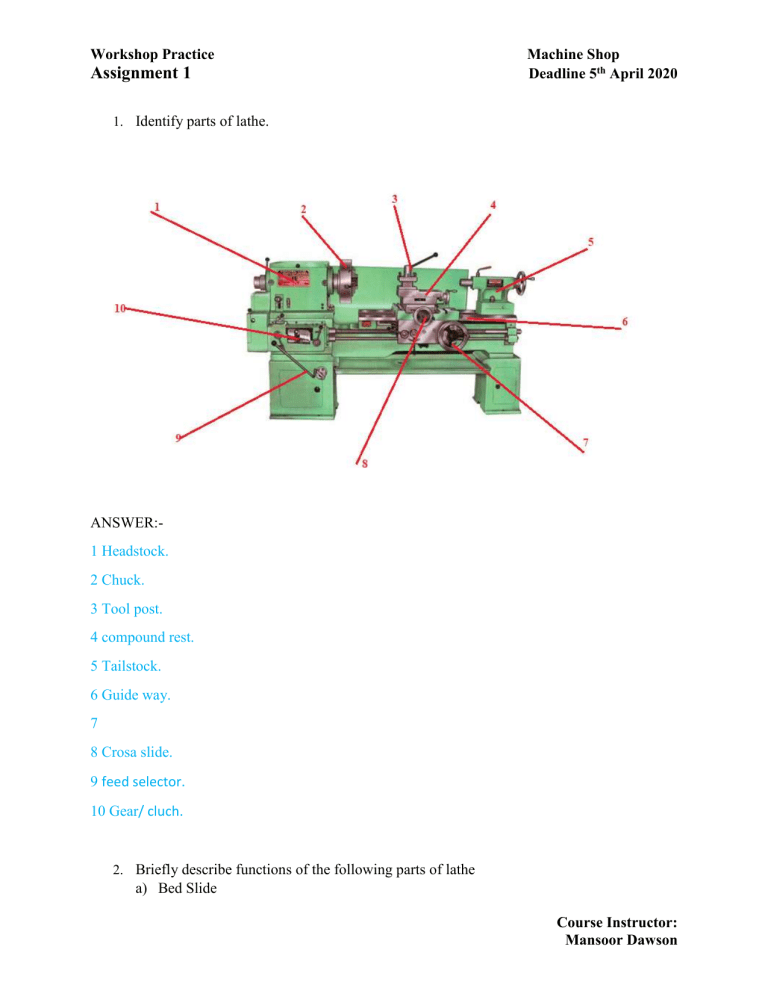

Workshop Practice Assignment 1 Machine Shop Deadline 5th April 2020 1. Identify parts of lathe. ANSWER:1 Headstock. 2 Chuck. 3 Tool post. 4 compound rest. 5 Tailstock. 6 Guide way. 7 8 Crosa slide. 9 feed selector. 10 Gear/ cluch. 2. Briefly describe functions of the following parts of lathe a) Bed Slide Course Instructor: Mansoor Dawson Workshop Practice Assignment 1 Machine Shop Deadline 5th April 2020 b) Cross Slide c) Tail Stock:- Tail stock is located on the right hand side of the lathe machine . It is adjustable ( you can remove it from the bed of the lathe machine). Tail stock is used to hold the revolving center through which we center our tool and ut is used in the process of drilling. It moves backwards and forwards on the bed. d) Chuck:- chuck is the part of lathe machine which is used to hold the work piece. It is most popular work holding device which is used in any lathe machine. It has different shape and size.Following are the different types of chucks used in lathe machine: Four jaws independent chuck. Three jaws universal chuck. Combination chuck. Magnetic Chuck. Collet chuck. Air or hydraulic operated chuck. Drill Chuck. e) Head Stock:- Head stock is a box which is located on the left hand side of the lathe machine. It is used to operate the spendle and all the gear mechanism which is used to operate the spendle is located on the head stock and the on and off button also located on it. f) Carriage:- The carriage is used for the support, guide and feed the tool against the job when the machining is done. It is used to hold , controls and cutting tool. It gives rigid support to the tool during operation.It transfer power from feed rod to cutting tool through apron mechanism for longitudinal cross-feeding. It simplifies the theard cutting operation with the help of lead screw and half nut mechanism. It is consist of 1 Saddel 2 Compound rest. 3 cross slide. 4 Tool post. 5 Apron. 3. Briefly describe the following operations performed on Lathe a) Facing:- Facing is a process of finishing the ends of the work piece by removing the metal from it ends. It is used to make the ends of work piece flat and smooth and to make the piece of required lenght. b) Turning:- Turning is the process in which we reduce the diameter of the work piece according to the given dimesion. In this process the tool move linearly while the work piece rotates. c) Taper Turning:- Taper Turing is a process in which the diameter of the work pice is reduces uniformly from one end to another at certain angle. Taper turning can be either internal or external. Course Instructor: Mansoor Dawson Workshop Practice Assignment 1 Machine Shop Deadline 5th April 2020 d) Drilling :- The tailstock of a lathe can be used for drilling, with the aid of a drill chuck attachment. The drill chuck has a morse taper shaft which can be push into the shaft of the tailstock, locking it in position.The usual starting point for drilling with a centre lathe is to use a countersink bit. This is used to drill slightly into the material and creates a starting point for other drills that are going to be used e) Boring:- Boring is a process in which we increase the inner diameter of the work piece. In this process the work piece rotates while the cutting tool moves parallel to the axis of rotation. f) Reaming:- reaming is a cutting process that involves the use of a rotary cutting tool to create smooth interior walls in an existing hole in a workpiece. The rotary cutting tool used in reaming is known as a reamer. We move reamer in clock wise direction if we move it in anti-clock wise the edges of work piece gets damage. g) Threading h) Knurling:- It is an operation of obtaining a diamond shape on the workpiece for the gripping purpose. This is done to provide a better gripping surface when operated by hands. It is done using a knurling tool. The tool consists of a set of hardened steel roller, and it is held rigidly on the toolpost.It is done at the lowest speed available on a lathe. 4. Compare between drilling, boring and reaming operations. Answer:- All this process one thing common that this process are used to makes hole in work piece by using lathe machine. Drilling is the operation to produce a cylinderical hole in a work piece where the boring is a process in which a hole is already present and we in large it by using cutting tool. Reaming is the operation of finishing and sizing a hole which is already drilled or bored the tool which is used is called reamer. Course Instructor: Mansoor Dawson