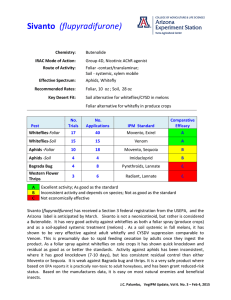

1 I. INTRODUCTION A. Importance of the Study Rice is the world’s most important food. More than half of the world’s population depends on rice for food calories and protein, especially in developing countries. By the year 2025, the world will need about 760 million tons of paddy, or 35 percent more than the rice production in 1996, in order to meet the growing demand. However, arable lands are mostly exploited, especially in Asia, where 90 percent of the world rice is produced and consumed. Rice production had steadily increased during the Green Revolution, but recently its growth has been substantially slowed down. Moreover, crop intensification during the Green Revolution has exerted tremendous pressures on natural resources and the environment. On the other hand, under the globalization of the world economy, rice producers are exposed to competition not only among themselves but also with the producers of other crops. The future increased rice production, therefore, requires improvement in productivity and efficiency. Innovative technologies such as hybrid rice, New Plant Types, and possibly transgenic rice can play an important role in raising the yield ceiling in rice production, thus increasing its productivity. Also, in many countries, the gaps between yields obtained at research stations and farmers’ fields still exist. Narrowing of these gaps could improve not only the productivity but also the efficiency of rice production (Duwayri et al., 2014) Some specialists, however, have expressed their concern about the economic gains of narrowing the yield gaps. They considered that economically there is very limited 2 scope for further increasing rice yield by closing the gaps. Other specialists believe that the yield gaps are economically exploitable for increasing rice yield. In a number of countries, regardless of the initially high yield, national yields still significantly increased during the last 30 years thanks to integrated national efforts in promoting rice development programmes. In addition, it is well known that yields are different among farmers in the same location. Good farmers usually reap more benefits from improved technologies than mediocre farmers at the same place. The challenge for policy makers, scientists and developers is how these gaps can be effectively and economically narrowed at the rice grower level. The use of foliar fertilizer is more economical and effective than the granulated form of fertilizer, which can be attributed to the presence of micronutrients such as manganese, zinc, iron and magnesium which make foliar fertilizers more advantageous than any other fertilizer containing no trace elements. Recognizing the necessity of advanced and appropriate technology to increase farm income and promote information the use of foliar fertilizers as supplement (Dordas and Cruz, 2015). B. Objectives of the Study Generally the study was conducted to evaluate the efficacy of different foliar fertilizers in rice production. Specifically, it aimed to: 1. Determine the growth and yield performance of rice as applied with Carrageenan, Humus Plus, Humic Acid and Supreme foliar fertilizers. 2. Determine the best foliar fertilizer enhance the yield of rice; and 3 3. To determine the return on investment of the different treatments. C. Time and Place of the Study The study was conducted at the Rice Production Area of Isabela State University, Echague, Isabela from September to January, 2017. D. Scope and Delimitation of the Study The study focused its scope on the evaluation of the growth and yield of rice as affected by Carrageenan, Humus Plus, Humic Acid and Supreme foliar fertilizers. The parameters gathered were plant height, number of productive and unproductive tillers per hill, number of filled and unfilled spikelets per panicle, length of panicles, grain weight per hill, grain yield per sampling area and weight of 1000 grains. E. Definition of Terms For better understanding of the study, the following terms are defined operationally: Application Rate. This is the amount of fertilizer applied per unit area of the experiment based on soil analysis. Fertilizer. It is any material either of natural and synthetic materials, including manure and nitrogen, phosphorus, and potassium compounds, applied into soil or foliage of the crop to increase its capacity to support plant growth. Foliar Feeding. It is a technique of feeding plants by applying liquid fertilizer directly to their leaves. Growth. It refers to the sum total of various physiological processes to increase the dry weight and irreversible increase in size of the plants. 4 Potential Yield. It is an estimate of the upper limit of yield increase that can be obtained from a plant. Rates of Fertilizer. It refers to the weight of a particular fertilizer applied per unit area. Recommended Rate. It is the amount of nutrients needed by the crop to attain its optimum yield. Yield. It is the economic part of the plant used for human and animal consumption and for commercial purposes. 5 II. REVIEW OF RELATED LITERATURE Benefits Derived from Micronutrient Fertilization Foliar fertilizers immediately deliver nutrients to the tissues and organs of the crop. The leaves are factories where photosynthesis produces compounds needed for growth. These are absorbed right at the site they are used acting fast. For instance, eighty percent of the phosphorus applied through conventional fertilizers may get fixed up in the soil but up to 80 percent of the foliar-added phosphorus is directly absorbed (Faizi–Asl and Valizadeh, 2005). Foliar feeding produces an almost immediate effect on the plants. The nutrients provided are already in the form that the plant needs. After absorption, all the plant has to do is utilize these nutrients (Berglund, 2002). Foliar feeding is the best way to grow plants in places where there is no enough water. This is because the plant will absorb water through its roots. Foliar nutrition results are highest when the plant is showing high growth activity, going from the vegetative to reproductive stage and when deficiencies are present or when the crop has been damaged. To achieve the best results, the foliar product should contain nitrogen, to act as an electrolyte to carry the other nutrients and phosphorous, to move the nutrients within the plant (Grotz and Guerinot, 2006). According to Kabata- Pendias and Pendias (1999) that the foliar nutrients enter the plant through the leaf stomata and hydrophilic pores in the leaf cuticle. The nutrients are only absorbed while in solution on the leaf surface. The beneficial effect of a foliar application is an increase in chlorophyll synthesis which can often result in leaves turning a darker green. The increase in photosynthetic activity will stimulate extra root growth; 6 in turn the root hairs excrete excess sugar which stimulates microbial colonies. These bacterial colonies provide auxins and other root stimulating compounds. With the increase in cellular activity gas exchange increases the uptake of water. As the roots take up more water they also bring in more of the nutrients from the soil solution. The foliar application stimulates the entire “pumping system” in the plant to increase the uptake of the base applied nutrition. Foliar spraying also stimulates nutrient uptake from the soil. The leaves after spraying will generate more carbohydrates that it will transport down to the root and release as exudates. This will stimulate the microbial life in the soil and the microbes will thrive around the root mass making more nutrients available to the plant. Therefore it is a very good idea to use liquid fertilizers to supplement nutrient programs to give your crops the optimum amount of nutrients it needs to get fast and efficient goodness into the plant so it can work harder to produce top quality food. Micronutrient spraying is a new method for crop feeding, which micronutrients in form of liquid are used into leaves (Nasiri et al., 2010). Foliar application of microelements is more beneficial than soil application. Since application rates are lesser as compared to soil application, same application could be obtained easily and crop reacts to nutrient application immediately (Zayed et al., 2011). Foliar spraying of microelements is very helpful when the roots cannot provide necessary nutrients (Kinaci and Gulmezoglu, 2007; Babaeian et al., 2011). Moreover, soil pollution would be a major problem by micronutrients soil application. As people are concerned about the environment and plant leaves uptake nutrients better than soil application, foliar spraying was created (Bozorgi et al., 2011). Crop roots are unable to absorb some important nutrients such as zinc, because of soil properties, such as high pH, lime or heavy texture, 7 and in this situation, foliar spraying is better as compared to soil application (Kinaci and Gulmezoglu, 2007). Narimani et al. (2010) reported that microelements foliar application improve the effectiveness of macronutrients. It has been found that microelements foliar application is in the same level and even more influential as compared to soil application. It was suggested that micronutrients could be applied successfully to compensate shortage of those elements (Arif et al., 2006). These authors found that based on soil properties, foliar spraying could be effective 6 to 20 times as compared to soil application. Resistance to different stresses was increased by foliar application of micronutrients (Ghasemian et al., 2010). Since in field situation, soil features and environmental factors which affect nutrients absorption are extremely changeable, foliar application could be an advantage for crop growth (Seifi Nadergholi et al., 2011). Effectiveness of foliar spraying is higher and the cost of foliar application is lower as compared to soil application. Microelements are defined substances that are crucial for crop growth; however, they are used in lower amounts as compared to macronutrients, such as N, P and K. They have a major role in cell division and development of meristematic tissues, photosynthesis, respiration and acceleration of plant maturity (Zeidan et al., 2010). One of the most important roles of micronutrients is keeping balanced crop physiology. Furthermore, these elements play vital roles in CO2 flowing out, improvement in vitamin A and immune system activities (Narimani et al., 2010). Zinc plays a special role in synthesizing proteins, RNA and DNA (Kobraee et al., 2011). Zinc and iron take over different roles in crop, such as formation, partitioning and utilization of photosynthesis assimilates (Sawan et al., 2008). The major role of zinc element in crops is not clear Nasri et al. (2011). These authors found that although zinc is an important element which should be provided for crop growth, but it 8 could be poisonous in large amount. As a matter of fact, the importance of zinc foliar application is due to being given to crop immediately (Alloway, 2003). Gul et al. (2011) claimed that profitability of micronutrients was obtained in combination with macro elements, such as nitrogen and potassium. Ghasemian et al., (2010) declared that zinc element is essential in chlorophyll production and pollen function. Mechanisms of Uptake of Foliar Applied Nutrients Green leaves are organs whose important functions are photosynthesis. Nutrient will pass through these various layers, whereas at other times it may pass through the spaces between these layers, which are typical for inorganic ions and ions absorbed by leaves stomata’s (Eichert et al., 1998; Eichert and Burkhardt, 2001). When the stomatas are open, foliar absorption is often easier (Burkhardt et al., 1999). Remobilization of mineral nutrients is important during ontogenesis of a plant (Papadakis et al., 2007). Description of the Foliar Fertilizers Used in the Study Humus Plus. It contains nutrients (minerals such as, nitrates, phosphates, potassium, copper, zinc dissolved in water) that plants need to be healthy. A soil conditioner and a plant growth stimulant it contain 16.10 Potassium Humates, 76.10-80% Humic Acid, water soluble powder 99% it is a humate from Leonardite that partially decomposed humus, or soil organic matter. It is a natural decomposed dead plants and animals for thousands of years. Foliar Supreme. It is a foliar nutrient containing phosphorus, potassium and micronized elemental sulfur. 9 Carrageenan. Carrageenans or carrageenins are a family of linear sulphated polysaccharides that are extracted from red edible seaweeds. They are widely used in the food industry, for their gelling, thickening, and stabilizing properties a substance extracted from red and purple seaweeds, consisting of a mixture of polysaccharides. It is used as a thickening or emulsifying agent in food products. Humic Acids. A principal component of humic substances, which are the major organic constituents of soil (humus), peat and coal. It is also a major organic constituent of many upland streams, dystrophic lakes, and ocean water. It is produced by biodegradation of dead organic matter. Guaranteed Analysis of Different Foliar Treatments Carrageenan Guaranteed Analysis of Different Foliar Treatments N% P2O5 % K2O % Ca ppm 2.02 4 6 120 Mg ppm 9 Fe ppm 48 Zn ppm 35 Mn ppm 5 Cu ppm 0.40 Amino acids + Fulvic acid + Humic acid > 1.88% Aluminium (AI) + Boron(B) + Cobalt(Co) < 300 ppm Sulphur (S) + Iron (Fe) + Sodium (Na) > 1% Iodine (I) + Manganese(Mn): 500 – 800 ppm Cytokinins + Alginic Acid + Mannitol + Gibberellins> 0.5 % Humus Plus Humic Acid 80% Phosphorus 0.82% Fulvic Acid 5.0% Potassium 5.4% pH- 10-11 10 Organic carbon 37.6% Nitrogen 1.1% Organic Matter 84.0% Calcium 5.0% Boron 10% Humic Acid Potassium 0.90% N, P, K and Ca Humic Acid 4.5% Supreme Foliar Analysis wt/wt* wt/vol Phosphate P2O5 16.00% 24.00% Potassium K2O 10.00% 15.00% Sulphur S 30.00% 45.00% pH (10% Solution) 4.5-5.5 11 III. MATERIALS AND METHODS A. Securing of Seeds The seeds of rice (NSIC 222) were secured at the Seed Production Office of the Isabela State University, Echague, Isabela. B. Location of the Experimental Area The experiment area was conducted at the Rice Production Area of the Isabela State University, Echague, Isabela. C. Collection of Soil Samples and Analysis Soil samples were randomly collected in the proposed experimental area. It was collected at plow level using shovel. The collected samples were spread in a newspaper and thoroughly air dried, pulverized, inert and other debris were removed. One kilogram composite soil was packed and submitted to the Regional Soils Laboratory, Cagayan Valley Research Center, City of Ilagan for analysis. The result of the analysis was the basis for fertilizer recommendation. D. Land Preparation, Laying-out and Experimental Design The area was cleared from grasses and stubbles to facilitate land preparation. It was plowed initially by tractor and left idle for two weeks giving time for the weeds to decay. An animal-drawn plow was used for the final plowing, harrowing and leveling. The 287 square meter experimental area was divided in three equal blocks with a dimension of 4 meters x 20.5 meters with one meter distance between blocks. Each block 12 was further subdivided into six equal plots of 3 meters x 4 meters with 50 centimeters distance between plots. The experimental treatments were randomly allocated following the procedure for Randomized Complete Block Design (RCBD). E. Seedling Production A seedbed was leveled and raised at 4-5 centimeters height. The seeds were placed in a container for soaking. The seeds was soaked in water and incubate for 12 hours. Washed and changed the water every three hours. Incubated the seeds for 36 hours and washed with clean water for every three hours and the moisture was maintain by watering with sprinkle and until the seeds germinated. The pre-germinated seeds was sown on the seedbed. The seedlings were irrigated at 2-3 centimeters after 7 days to maintain its growth. One hundred grams of urea was dissolved in four gallons of water and sprayed to the seedlings at 15 days after sowing to produce vigorous seedlings. The occurrence of insect pests and diseases was strictly monitored for immediate control. F. Experimental Treatments The different treatments used in the study were the following: T1 – Control T2 – 60-20-0 kg NPK ha-1 (based soil analysis) T3 – Carrageenan Foliar Fertilizer T4 – Humus plus Foliar Fertilizer T5 – Humic Acid Foliar Fertilizer T6 – Supreme Foliar Fertilizer 13 G. Spraying of Molluscicide and Herbicide Molluscicide was sprayed before transplanting to control the golden apple snails (kuhol) living in the experimental area while the weeds were controlled by spraying herbicide (Butachlor) three days after transplanting following the recommendation of the manufacturer. H. Application of Fertilizer The rate of fertilizer 60-20-0 kg NPK was applied in the study. Basal application 2.0 bags per hectare 16-20-0, 0.5 bag per hectare 21-0-0 and 10 bags per hectare organic fertilizer was applied. In first topdressing, 2.0 bags per hectare 21-0-0 was done by applying at 7-10 days after transplanting. Second topdressing, 1.0 bag per hectare 46-0-0 was done by applying at 20-25 days after transplanting. Third topdressing, 0.7 bag per hectare 46-0-0 was applied in 35-40 days after transplanting and 1.0 bag per hectare 0-060 was applied during booting stage. The application of inorganic fertilizer were supplemented with foliar fertilizers and were applied at 30, 45 and 60 after transplanting at 1 liter per hectare every schedule of spraying. I. Pulling of Seedlings and Transplanting At 23 days after sowing the seeds, pulling of seedlings was done carefully to avoid root damage. This was done a day before transplanting. Two seedlings per hill were transplanted at a distance of 20 x 20 centimeters. Missing hills were replanted upon observation of mortality to have a complete plant population per plot. 14 J. Care and Management of the Crop Water Management. Water was maintained at a depth of 3-5 centimeters at the early stage of crop growth up to ripening period of the panicles. All plots were drained two weeks before harvesting. Weed Control. Weeds was controlled by applying Butachlor granules at the rate of one kg per hectare three days after transplanting. Hand weeding was done to complement herbicide application. Insect Pest and Disease Control. Maximum protection against insect pest and diseases was done. K. Harvesting, Threshing, Cleaning and Drying The harvesting was done when 80% of the grains in the panicles turned yellow in color. Sample plants were harvested within the sampling area which were located at the middle portion of each plot. Harvesting of samples per treatment was done one by one to avoid intermixing of samples. Samples were tied one by one and tags were placed per treatment. The paddy was threshed after measuring the number of tillers, length of panicles and counting the number of spikelets. Cleaning was done by winnowing to remove the unfilled grains, leaves and straw that mixed in the newly threshed samples. Sun drying of grain samples was done immediately in undisturbed pavement and repeated sun drying was done until 14 percent moisture content was attained. 15 L. Data Gathered 1. Plant Height. Ten sample stakes were placed in each sample plant for every plot was measured from the base of the culm to the tip of the highest leaf and to the tip of the panicle at maturity. 2. Number of Productive and Unproductive Tillers per Hill. The number of productive and unproductive tillers were separately counted and recorded. The tiller bearing with filled spikelets were considered productive tillers. The tillers without panicle or panicles with empty spikelets were considered unproductive tillers. 3. Length of Panicles. Ten panicles were randomly taken from the productive tillers per treatment. The length was measured from the base up to the tip of the panicle using foot rule. 4. Number of Filled and Unfilled Spikelets per Panicle. The sample panicles were also used in counting the number of filled spikelets per panicle. The filled spikelet was carefully detached and counted. On the other hand, the unfilled spikelets were also counted and recorded just the same. The total number of each variable was divided by ten to obtain the number of filled and unfilled spikelets per panicle. 5. Weight of 1000 Filled Grains. After weighing the grain yield, 1,000 grains were randomly taken from the variety and weighed using the digital weighing balance. 6. Dry Grain Yield per Hill. The grain of the ten sample hills was weighed after drying using the digital weighing balance. 7. Grain Yield per Sampling Area. The dried grain yield obtained in a six (6) square meters sampling area from each plot was weighed using the digital weighing balance. 16 8. Yield per Hectare. The seed weight per six (6) square meters sampling area was the basis for the computation of yield per hectare using the formula: Weight/Sampling Area (kg) Yield per Hectare = 10000 m2 2 Sampling Area (m ) M. Statistical Analysis All the data gathered were collated, tabulated and analyzed following the Analysis of Variance for the Randomized Complete Block Design. Treatment means were compared using the Duncan’s Multiple Range Test (DMRT) if the result is significant. N. Cost and Return Analysis The return on investment was computed using the simple economic analysis. The cost of production was based on the prevailing price of farm inputs and labor on community. The gross income was determined based on the prevailing price of rice per kilo in the market. The net income is equal to the gross income minus the cost of production and the return of investment was computed by dividing the net income with the cost of production multiplied by 100. 17 IV. OBSERVATION AND DISCUSSION OF RESULTS A. Observation 1. Stand and Vigor of the Crop. The plants in the different treatments had good stand even in the midst of typhoon Lawin. However, it was observed that plants treated with inorganic fertilizer plus Carrageenan Foliar fertilizer had more healthy leaves as manifested with the dark green color of the leaves and sturdy over the plants in the other treatments. 2. Occurrence of Insect Pests. Golden apple snail (Pomacea canaliculata) was observed during the establishment of the crop but the application of molluscicide was done to control its occurrence. Weeds were also observed in the experimental area such as the purple nutsedge (Cyperus rotundus) and jungle rice (Echinochloa colona) weeds but they were controlled by hand weeding. Rice bug (Leptocorisa oratorius) was also observed at milking stage. This was controlled by the application of insecticides following the manufacturer’s recommendation. 3. Number of Days to Maximum Tillering. The fertilized and the unfertilized plants had their maximum tillering at 32 days after transplanting. 4. Number of Days to Panicle Initiation. The plants had 50% panicle initiation at 54 days after transplanting. 5. Number of Days to Physiological Maturity. The plants in all treatments attained their physiological maturity at 88 days after transplanting as indicated on the 80% of the grains per panicle turning into yellow color. 18 6. Climatic Data during the Conduct of the Study. The climatic data during the conduct of the study was taken at the nearest weather station from the experimental area which is located at the Philippine Atmospheric, Geophysical and Astronomical Services Administration - Agro meteorological Station, Isabela State University, Echague, Isabela (Figure 1). The minimum temperature ranged from 21.31° C to 23.63° C while maximum temperature 25.55° C to 33.16° C. The relative humidity ranged from 88.71 percent to 98.50 percent in the morning while it ranged from 72.71 percent to 94.75 percent in the afternoon. Soil moisture was always available as manifested by the amount of rainfall Temperature (°C), Relative Humidity (%) & Rainfall (mm) during the study which ranged from 2.53 mm to 17.09 mm. Max. Temp. (°C) Min. Temp. (°C) R.H.(%) 2:00 PM Rainfall (mm) R.H. (%) 8:00 AM 120 100 80 60 40 20 0 1 2 3 4 5 6 7 8 9 W E E K S A F T E R TRANSPLANTING Figure 1. Climatic Data during the Conduct of the Study. 10 19 B. Discussion of Results 1. Plant Height at 30, 60 Days after Transplanting and Maturity. The height of plants at 30, 60 days after transplanting and maturity as influenced by different foliar fertilizer are shown in Table 1. No Significant result was obtained in the height of plants at 30 days after transplanting with means ranging from 65.08 to 71.19 centimeters. On the other hand, the application of foliar fertilizers significantly influenced the height of plants at 60 days after transplanting. Tallest plants were obtained in plants treated with Carrageenan Foliar Fertilizer (T3), Humus Plus Foliar Fertilizer (T4), Humic Acid Foliar Fertilizer (T5), Supreme Foliar Fertilizer (T6) and 60-20-0 kg NPK ha-1 (based on soil analysis) (T2) with mean values of 108.25, 107.91, 107.73, 107. 29 and 106.68 centimeters, respectively. Shortest plants were found in the Control (T1) with 94.90 centimeters. The height of plants at maturity was affected by the application of different foliar fertilizers. The plants fertilized with Carrageenan Foliar Fertilizer (T3), Humus Plus Foliar Fertilizer (T4), Humic Acid Foliar Fertilizer (T5) and Supreme Foliar Fertilizer (T6) and 60-20-0 kg NPK ha-1 (based on soil analysis) (T2) produced the tallest plants at maturity days after transplanting with mean values of 121.60, 119.31, 118.64, 118.48 and 118.47 centimeters, respectively. The plants in the Control plot (T1) obtained the shortest plants with a mean of 102.57 centimeters. The result of the study was attributed to the supplementation of foliar fertilizers. Foliar feeding of nutrient promotes root absorption of the same nutrient or other nutrients through improving root growth and nutrients movement from terminal leaves to depth roots. Leaf feeding enhances overall nutrient level in the plant and sugar production during times of stress and it also increases 20 biochemical activities in the leaf by increasing chlorophyll a, b and carotenoids, which presumably favor the photosynthesis. Foliar applications of micro-nutrients increased the primary metabolites like photosynthetic pigments. Previous studies showed that when Carrageenan is degraded or reduced to tiny sizes through irradiation technology, it can promote growth in rice plants and make it resistant to certain pests (Ranada, 2015). Table 1. Plant Height (cm) of NSIC Rc 222 Variety at 30, 60 Days after Transplanting and Maturity as Influenced by Supplementation of Different Foliar Fertilizers. TREATMENTS T1 – Control Plant Height (cm) 30 DAT 60 DAT Maturity 65.08 94.90b 102.57b T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 67.58 106.68a 118.47a T3 – Carrageenan Foliar Fertilizer 69.78 108.25a 121.60a T4 – Humus Plus Foliar Fertilizer 68.33 107.91a 119.31a T5 – Humic Acid Foliar Fertilizer 71.19 107.73a 118.64a T6 – Supreme Foliar Fertilizer 70.43 107.29a 118.48a ANOVA RESULT ns ** ** C.V. (%) 3.19 0.98 0.72 Note: Means with common letter/s are not significantly different with each other using DMRT. 2. Number of Productive and Unproductive Tillers per Hill. The Table 2 shows the number of productive and unproductive tillers per hill as influenced by different foliar fertilizer. Significant differences were noted in the number of productive tillers, wherein plants applied with Carrageenan Foliar Fertilizer (T3) obtained most number of productive tillers with a mean of 22.17. Comparable result was noticed in plants treated with Humus plus Foliar Fertilizer (T4), Humic Acid Foliar Fertilizer (T5) 21 and Supreme Foliar Fertilizer (T6) which had mean values of 18.13, 18.10 and 17.90, respectively. It was followed by the plants treated with 60-20-0 kg NPK ha-1 (based soil analysis) (T2) with a mean value of 13.93. The control plots (T1) revealed the least number of productive tillers with 13.33. The increase in number of productive tillers was observed in the application of Carrageenan conformed to the findings of Carlos (2015). Since in field situation, soil features and environmental factors which affect nutrients absorption and supplementation of foliar application could be an advantage for crop growth and development (Seifi Nadergholi et al., 2011). The number of unproductive tillers showed significant variations among the treated plants over the Control (T1) with a mean value of 1.43. Treated plants with 60-20-0 kg NPK ha-1 (based soil analysis) (T2), Supreme Foliar Fertilizer (T6), Humic Acid (T5), Humus Plus Foliar Fertilizer (T4) and Carrageenan Foliar Fertilizer (T3) obtained the least number of unproductive tillers which had comparable mean values of 0.73, 0.63, 0.43 and 0.37, respectively. 22 Table 2. Number of Productive and Unproductive Tillers of NSIC Rc 222 Variety per Hill as Influenced by Supplementation of Different Foliar Fertilizers. Productive Tillers 11.23d Unproductive Tillers 1.43a T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 13.93c 0.77b T3 – Carrageenan Foliar Fertilizer 22.17a 0.37b T4 – Humus Plus Foliar Fertilizer 18.13b 0.43b T5 – Humic Acid Foliar Fertilizer 18.10b 0.63b T6 – Supreme Foliar Fertilizer 17.90b 0.73b TREATMENTS T1 – Control ANOVA RESULT ** ** C.V. (%) 3.38 16.19 Note: Means with common letter/s are not significantly different with each other using DMRT. 3. Length of Panicles. Analysis of variance showed significant result of the length of panicles as influenced by different foliar fertilizers presented in Table 3. Longest panicles were observed in plants applied with Carrageenan Foliar Fertilizer (T3) with a mean value of 27.06 centimeters. It was followed by treated plants Humus Plus Foliar Fertilizer (T4), Humic Acid Foliar Fertilizer (T5), Supreme Foliar Fertilizer (T6) and 6020-0 kg NPK ha-1 (based soil analysis) (T2) which had mean values of 24.31, 24.21, 24.06 and 23.00 centimeters, respectively. Shorter panicle was observed in the untreated plots (T1) with a mean value of 20.90 centimeters. The length of panicles varied significantly due to the application of the combination of inorganic and supplemtation of foliar fertilizer. Increasing panicle length is in harmony with increasing concentrations of micro elements from foliar fertilizer as cited by Malakouti and Kavousi (2004). Panicle length 23 was also significantly higher by applying Carrageenan compared with those in the untreated plants. Carrageenan produced longer rice panicle is associated with producing more rice grains (Carlos, 2015). Table 3. Length (cm) of Panicles of NSIC Rc 222 Variety as Influenced by Supplementation of Different Foliar Fertilizers. TREATMENTS Length (cm) of Panicle T1 – Control 21.01c T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 23.00b T3 – Carrageenan Foliar Fertilizer 27.06a T4 – Humus Plus Foliar Fertilizer 24.31b T5 – Humic Acid Foliar Fertilizer 24.21b T6 – Supreme Foliar Fertilizer 24.06b ANOVA RESULT ** C.V. (%) 3.03 Note: Means with common letter/s are not significantly different with each other using DMRT. 4. Number of Filled and Unfilled Spikelets. The number of filled and unfilled spikelets per panicle as affected by different foliar fertilizers are presented in Table 4. Significant variation was obtained in the number of filled spikelets, whereby the application of Carrageenan Foliar Fertilizer (T3) produced the most number of filled spikelets with a mean value of 216.20. It was followed by plants treated with Humus Plus Foliar Fertilizer (T4), Humic Acid Foliar Fertilizer (T5), Supreme Foliar Fertilizer (T6) and 60-20-0 kg NPK ha-1 (based on soil analysis) (T2) with mean values of 167.50, 156.90, 155.13 and 144.10, respectively. The unfertilized plants (T1) obtained the least 24 number of filled spikelets with 101.04. The result means that the foliar fertilizers composed of micromineral fertilizer which significantly increase the number of grains per panicle. Malakouti (2005) stated that the application of foliar fertilizer at early reproductive stage of the plants enhanced grain development (Malakouti and Kavousi, 2004). The number of unfilled spikelets showed significant variation among treatments treated with Supreme Foliar Fertilizer (T6), 60-20-0 kg NPK ha-1 (based on soil analysis) (T2), Humic Acid Foliar Fertilizer (T5), Humus Plus Foliar Fertilizer (T4) and Control (T1) produced the most number of unfilled spikelets with means of 56.20, 55.10, 53.97, 46.97 and 41.20, respectively. The least number of unfilled spikelets were obtained by treated plants with Carrageenan the Foliar Fertilizer with a mean value of 35.80. Table 4. Number of Filled and Unfilled Spikelets of NSIC Rc 222 Variety as Influenced by Supplementation to Different Foliar Fertilizers. T1 – Control Filled Spikelets 101.04c Unfilled Spikelets 41.20a T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 144.10b 55.10a T3 – Carrageenan Foliar Fertilizer 216.20a 35.80b T4 – Humus Plus Foliar Fertilizer 167.50b 46.97a T5 – Humic Acid Foliar Fertilizer 156.90b 53.97a T6 – Supreme Foliar Fertilizer 155.13b 56.20a TREATMENTS ANOVA RESULT ** * C.V. (%) 7.18 15.65 Note: Means with common letter/s are not significantly different with each other using DMRT. 25 5. Weight of 1000 Seeds. The weight of 1000 seeds as affected by different foliar fertilizers is presented in Table 5. It was noticed that foliar fertilizers did not significantly influence the weight of 1000 seeds with means ranging from 29.25 to 34.45 grams. Table 5. Weight (g) of 1000 Seeds of NSIC Rc 222 Variety as Influenced by Supplementation of Different Foliar Fertilizers. TREATMENTS T1 – Control Weight (g) of 1000 Seeds 29.25 T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 30.90 T3 – Carrageenan Foliar Fertilizer 34.45 T4 – Humus Plus Foliar Fertilizer 32.00 T5 – Humic Acid Foliar Fertilizer 31.73 T6 – Supreme Foliar Fertilizer 30.90 ANOVA RESULT ns C.V. (%) 5.20 Note: Means with common letter/s are not significantly different with each other using DMRT. 6. Weight of Grains per Hill and Grain Yield per Sampling Area. The weight of grains per hill and sampling area as affected by the different foliar fertilizers are shown in Table 6. Results revealed the application of foliar fertilizers had significant effect on the grain yield per hill wherein the grain weight progressively increased with the application of Carrageenan Foliar Fertilizer (T3) with a mean value of 61.00 grams while the by plants treated with Humus Plus Foliar Fertilizer (T4), Humic Acid Foliar Fertilizer 26 (T5) and Supreme Foliar Fertilizer (T6) and 60-20-0 kg NPK ha-1 (based on soil analysis) (T2) had comparable grain weights with mean values of 47.60, 47.03, 46.37 and 45.47 grams, respectively. Lightest grains was produced in the control plots (T1) with 21.90 grams. The result implies that foliar fertilizers led to a significant increase in rice grain weight. Faranak Fareghi Naeini et al. (2014) reported similar results and they further stated that application of foliar fertilizer in heading stage may increase the dry matter and leaf area duration that may to increase in the 1000-grain weight. The result of the study also conformed with the findings of Ranada (2015) that adding small amount of Carrageenan leading to higher grain weight. Likewise, significant result was noted on the grain yield per sampling area wherein plants fertilized with Carrageenan Foliar Fertilizer (T3) produced heaviest grains with a mean value of 7.23 kilograms. This was followed by treated plants with Humic Acid Foliar Fertilizer (T5), Humus Plus Foliar Fertilizer (T4) and Supreme Foliar Fertilizer (T6) and 60-20-0 kg NPK ha-1 (based on soil analysis) (T2) had mean values of 5.40, 5.35 and 5.02 and 4.45 kilograms, respectively. The unfertilized plots (T1) revealed the least weight of grains with 1.56 kilograms. 27 Table 6. Weight of Grains per Hill (g) and Grain Yield per 6 m2 Sampling Area (kg) of NSIC Rc 222 Variety as Influenced by Supplementation of Different Foliar Fertilizers. TREATMENTS T1 – Control Weight of Grains Per Sampling Per Hill (g) Area (kg) 21.90c 1.56c T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 45.47b 4.45b T3 – Carrageenan Foliar Fertilizer 61.00a 7.23a T4 – Humus Plus Foliar Fertilizer 47.60b 5.35b T5 – Humic Acid Foliar Fertilizer 47.03b 5.40b T6 – Supreme Foliar Fertilizer 46.37b 5.02b ANOVA RESULT ** ** C.V. (%) 6.74 5.95 Note: Means with common letter/s are not significantly different with each other using DMRT. 7. Projected Grain Yield per Hectare. The projected grain yield per hectare of NSIC Rc 222 Variety as affected by different foliar fertilizers are presented in Table 7. The grain yield of the different treatments is organized in a descending order: T3 had 12050.00 kilograms (12.05 tons), T5 had 9005.56 kilograms (9.01 tons), T4 had 8911.11 kilograms (89.11 tons), T6 had 8366.67 kilograms (8.37 tons), T2 had 7416.67 kilograms (7.42 tons) and T1 with 2600.00 kilograms (2.6 tons). 28 Table 7. Projected Grain Yield per Hectare of NSIC Rc 222 Variety as Influenced by Supplementation of Different Foliar Fertilizers. TREATMENTS T1 – Control T2 – 60-20-0 kg NPK ha-1 (based soil analysis) Computed Grain Yield kilograms tons 2600.00 2.60 7416.67 7.42 T3 – Carrageenan Foliar Fertilizer 12050.00 12.05 T4 – Humus Plus Foliar Fertilizer 8911.11 8.91 T5 – Humic Acid Foliar Fertilizer 9005.56 9.01 sT6 – Supreme Foliar Fertilizer 8366.67 8.37 8. Cost and Return Analysis. The cost and return analysis per hectare of NSICRc 222 variety as influenced by different foliar fertilizers are presented in Table 8. The return on investment of selling dried grains is organized in a descending order: T3 had 299.34 percent, T5 had 221.29 percent, T4 had 217.84 percent, T2 had 208.50 percent, T6 had 204.34 percent and T1 had 84.33 percent. 29 Table 8. Cost and Return Analysis of One Hectare NSIC Rc 222 Variety Production as Influenced by Different Foliar Fertilizers. COST OF PRODUCTION 28210.00 GROSS INCOME 52000 NET INCOME 23790 ROI (%) 84.33 T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 48081.67 148333 100252 208.50 T3 – Carrageenan Foliar Fertilizer 60350.00 241000 180650 299.34 T4 – Humus Plus Foliar Fertilizer 56072.78 178222 122149 217.84 T5 – Humic Acid Foliar Fertilizer 56058.90 180111 124052 221.29 T6 – Supreme Foliar Fertilizer 54981.67 167333 112352 204.34 TREATMENTS T1 – Control 30 V. SUMMARY, CONCLUSION AND RECOMMENDATION A. Summary The study was conducted to evaluate the efficacy of different foliar fertilizers in rice production. Specifically, it was conducted to determine the growth and yield performance of rice as applied with Carrageenan Foliar Fertilizer, Humus Plus Foliar Fertilizer, Humic Acid Foliar Fertilizer and Supreme Foliar Fertilizers, determine the best foliar fertilizer enhance the yield of rice and to determine the return on investment of the different treatments. The study was conducted at the rice production area of the Isabela State University, Echague, Isabela from October to January 2017. The different treatments used were T1– Control, T2 – 60-20-0 kg NPK ha-1 (based on soil analysis), T3 – Carrageenan Foliar Fertilizer, T4 – Humus Plus Foliar Fertilizer, T5 – Humic Acid Foliar Fertilizer and T6 – Supreme Foliar Fertilizer. The experiment was laid out in Randomized Complete Block Design with three replications. The results of the study are summarized as follows: 1. No significant differences was noted in height of plants at 30 days after transplanting. 2. Taller plants at 60 days after transplanting and at maturity were obtained in plants treated with Carrageenan Foliar Fertilizer. 3. Most number of productive tillers was noted in plants fertilized with Carrageenan Foliar Fertilizer but the untreated plants had the most number of unproductive tillers. 4. Longest panicles and most number of filled spikelets per panicle were observed in plants applied with Carrageenan Foliar Fertilizer. 31 5. The plants applied with Supreme Foliar Fertilizer, 60-20-0 kg NPK ha-1 (T2), Humic Acid Foliar Fertilizer, Humus Plus Foliar Fertilizer and without fertilizer attained the most number of unfilled spikelets. 6. The different treatments including the control had comparable weight of 1000 seeds. 7. Heaviest grain per hill as well as the grain yield per sampling area were produced in the application of Carrageenan Foliar Fertilizer. 8. The supplementation of foliar fertilizer using Carrageenan garnered the highest return on investment with 299.34 percent. B. Conclusion The application of Carrageenan Foliar Fertilizer on NSIC Rc 222 significantly obtained the highest grain yield per unit area. C. Recommendation Based from the results of the study, the application of 9 liters per hectare supplementation of Carrageenan foliar fertilizer is recommended because it increased yield by 3.63 percent. Further study is recommended during the dry season to obtain more conclusive results. 32 LITERATURE CITED Alloway B. J. 2003. Zinc in Soil and Crop Nutrition. International Zinc Association, p. 114. Arif M, M. A. Chohan, S. Ali, R. Gul and S. Khan. 2006. Response of wheat to foliar application of nutrients. J. Agric. Biol. Sci., 1(4). Babaeian M, A. Tavassoli, A. Ghanbari, Y. Esmaeilian and M. Fahimifard. 2011. Effects of Foliar Micronutrient Application on Osmotic Adjustments, Grain Yield and Yield Components in Sunflower (Alstar cultivar) under water stress at three stages. Afr. J. Agric. Res., 6(5): 1204-1208. Berglund, D. R. 2002. Soybean Production Field Guide for North Dakota and Northwestern Minnesota. Published in cooperative and with support from the North Dakota Soybean Council. Bozorgi H. A, E. Azarpour and M. Moradi. 2011. The Effect of Bio, Mineral Nitrogen Fertilization and Foliar Zinc Spraying on Yield and Yield Components of Faba Bean. World Appl. Sci. J., 13(6): 1409-1414. Burkhardt, J., S. Dreitz, H. E. Goldbach, and T. Eichert. 1999. Stomatal uptake as an important factor for foliar fertilization. In: Technology and Application of Foliar Fertilizers: Proceedings of the Second International Workshop on Foliar Fertilization, ed. Soil and Fertilizer Society of Thailand, pp. 63–72. Bangkok: Soil and Fertilizer Society of Thailand. Carlos, M. A. 2015. Carrageenan from Seaweeds: A Breakthrough that Boosts Rice Productivity. DOST-PCAARRD S&T Media Service. Dordas, R. D. Jr. and R. A. Cruz. 2015. Effect of Different Liquid Fertilizers on Yield and Economic Analysis of Glutinous Corn (Zea mays Linn.) 2(2): 558-562. Duwayri, M., D. T. Tran, and V. N. Nguyen. 2014. Reflections on Yield Gaps in Rice Production: How to Narrow the Gaps. FAO, Rome, Italy Eichert, T., and J. Burkhardt. 2001. Quantification of stomatal uptake of ionic solutes using a new model system. Journal of Experimental Botany 52: 771–781. Eichert, T., E. H. Goldbach, and J. Burkhardt. 1998. Evidence for the Uptake of Large Anions through Stomatal Pores. Botanica Acta 111: 461–466. Faizi–Asl V and G. Valizadeh. 2005. Study of the Effect of the Simultaneous Use of Phosphorous and Zinc on the Absorption of the Micronutrients and Phosphorous 33 and on the Remaining Zinc in the Soil Under Dryland Cultivation of the Wheat Cultivar Sardari. The Seedlings and Seed Journal, 21(2): 241– 267. Faranak Fareghi naeini, Hamid Dehghanzadeh and Gholamreza Moafpourian. 2014. Effects of Foliar Application of Micro Fertilizers on Grain Yield and Yield Components of The Rice Sazandegi, Cultivar (Oriza sativa L.). Agric. sci. dev., Vol (3), No (5), May, 2014. pp. 191-193. Ghasemian V., A. Ghalavand, A. SorooshZadeh and A. Pirzad. 2010. The Effect of Iron, Zinc and Manganese on Quality and Quantity of Soybean Seed. Journal of Phytology 2(11): 73-79. Grotz N., and M. L. Guerinot 2006. Molecular Aspects of Cu, Fe and Zn Homestasis in Plants. Biochim. BiophysActa. 1763(7): 595-608. Kabata- Pendias A and Pendias H, 1999. Biogeochemistry of Trace Elements. PWN, WarSaw, Poland. Kinaci E. and N. Gulmezoglu. 2007. Grain Yield and Yield Components of Triticale upon Application of Different Foliar Fertilizers. Interciencia, 32(9): 624-628. Kobraee S, K. Shamsi and B. Rasekhi. 2011. Effect of Micronutrients Application on Yield and Yield Components of Soybean. Annals Biol. Res., 2(2): 476-482. Malakouti, M. G. 2005. Sustainable Agriculture and Increase Yield by Optimizing Fertilizer Use in Iran. Sana Pub. 496 Pp. Malakouti M. G. and M. Kavousi. 2004. Balanced Nutrition of Rice. Depart. Of Agric. Ministry of Agriculture, I. R. Of IRAN Middleton, L. J., and J. Sanderson. 1965. The Uptake of Inorganic Ions by Plant Leaves. Journal of Experimental Botany 16: 197–215. Narimani H, M. M. Rahimi, A. Ahmadikhah and B. Vaezi. 2010. Study on the Effects of Foliar Spray of Micronutrient on Yield and Yield Components of Durum Wheat. Arch. Appl. Sci. Res., 2(6): 168-176. Nasiri Y, S. Zehtab-Salmasi, S. Nasrullahzadeh, N. Najafi and K. Ghassemi-Golezani. 2010. Effects of Foliar Application of Micronutrients (Fe and Zn) on Flower Yield and Essential Oil of Chamomile (Matricaria chamomilla L.). J. Med. Plants Res., 4(17): 1733-1737. Nasri M, M. Khalatbari and H. Aliabadi Farahani. 2011. Zn-foliar Application Influence on Quality and Quantity Features in Phaseolous vulgaris under Different Levels of N and K Fertilizers. Adv.Environ. Biol., (Adv. Environ. Biol) 5(5): 839-846. 34 Papadakis, I. E., T. E. Sotiropoulos, and I. N. Therios. 2007. Mobility of iron and manganese within two citrus genotypes after foliar applications of iron sulfate and manganese. Journal of Plant Nutrition 30: 1385– 1396. Ranada, P. 2015. Seaweed Additive Can Boost Rice Yield by 65% – Gov’t Scientists. Sawan ZM, M. H. Mahmoud and A. H. El-Guibali. 2008. Influence of Potassium Fertilization and Foliar Application of Zinc and Phosphorus on Growth, Yield Components, Yield and Fiber Properties of Egyptian Cotton (Gossypium barbadense L.). J. Plant Ecol., 1(4): 259-270. Seifi Nadergholi M, M. Yarnia and K. F. Rahimzade. 2011. Effect of Zinc and Manganese and Their Application Method on Yield and Yield Components of Common Bean (Phaseolus vulgaris L.CV. Khomein). Middle-East J Sci Res. 8(5): 859-865. Zayed B.A., A.K.M. Salem and H.M. El Sharkawy. 2011. Effect of Different Micronutrient Treatments on Rice (Oryza sativa L.) Growth and Yield Under Saline Soil Conditions. World J. Agric. Sci., 7(2): 179-184 Zeidan M. S., M.F. Mohamed and H.A. Hamouda. 2010. Effect of Foliar Fertilization of Fe, Mn and Zn on Wheat Yield and Quality in Low Sandy Soils Fertility. World J. Agric. Sci., 6(6): 696-699. 35 EXPERIMENTAL LAYOUT RANDOMIZED COMPLETE BLOCK DESIGN T3 T5 T6 T6 T2 T1 T4 T3 T2 T5 T4 T3 T1 T6 T4 T2 T1 T5 4m LEGEND: 14 m Treatments: T1 – Control T2 – 60-20-0 kg NPK ha-1 based soil analysis T3 – Carrageenan Foliar Fertilizer T4 – Humus plus Foliar Fertilizer T5 – Humic Acid Foliar Fertilizer T6 – Supreme Foliar Fertilizer Total Area - - - - - - - - - - - - - - - - - - - - - Block Size - - - - - - - - - - - - - - - - - - - - - Plot Size - - - - - - - - - - - - - - - - - - - - - Alleyways between Blocks - - - - - - - - - - Alleyways between Plots - - - - - - - - - - - - 287 square meters 4 m x 20.5 m 3mx4m 1m 0.5 m 20.5 m 3m 36 Appendix Table 1. Plant Height (cm) 30 Days after Transplanting. R E P L I C A T I O N I II III 64.10 64.66 66.47 TREATMENT T1 – Control TOTAL MEAN 195.23 65.08 T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 68.71 66.65 67.39 202.75 67.58 T3 – Carrageenan Foliar Fertilizer 71.80 68.48 69.05 209.33 69.78 T4 – Humus Plus Foliar Fertilizer 68.52 66.68 69.78 204.98 68.33 T5 – Humic Acid Foliar Fertilizer 67.94 74.92 70.72 213.58 71.19 T6 – Supreme Foliar Fertilizer 67.81 71.42 72.06 211.29 70.43 TOTAL 408.88 412.81 415.47 1237.16 MEAN 68.15 68.80 69.25 68.73 ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 74.63 14.93 ERROR 10 47.94 4.79 TOTAL 17 126.24 C.V. = 3.19% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 3.66 1.83 0.38ns 4.10 7.56 3.11ns ns – not significant 3.33 5.64 37 Appendix Table 2. Plant Height (cm) at 60 Days after Transplanting. R E P L I C A T I O N I II III 95.83 93.27 95.60 TREATMENT T1 – Control TOTAL MEAN* 284.70 94.90b T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 105.90 106.18 107.97 320.05 106.68a T3 – Carrageenan Foliar Fertilizer 108.83 108.69 107.24 324.76 108.25a T4 – Humus Plus Foliar Fertilizer 108.37 106.45 108.92 323.74 107.91a T5 – Humic Acid Foliar Fertilizer 108.29 106.99 107.91 323.19 107.73a T6 – Supreme Foliar Fertilizer 106.91 108.05 106.92 321.88 107.29a TOTAL 634.13 629.63 634.56 1898.32 MEAN 105.69 104.94 105.76 105.46 * Means with common letter/s are not significantly different with each other using DMRT. ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 406.04 81.21 ERROR 10 10.71 1.07 TOTAL 17 419.24 C.V. = 0.98% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 2.49 1.24 1.16ns 4.10 7.56 75.79** 3.33 ns – not significant ** – significant at 1% level 5.64 38 Appendix Table 3. Plant Height (cm) at Maturity. R E P L I C A T I O N TOTAL MEAN* I II III 103.38 102.56 101.77 307.71 102.57b TREATMENT T1 – Control T2 – 60-20-0 kg NPK ha-1 (based 118.79 soil analysis) 117.42 119.21 355.42 118.47a T3 – Carrageenan Foliar Fertilizer 122.96 120.75 121.10 364.81 121.60a T4 – Humus Plus Foliar Fertilizer 119.75 118.66 119.52 357.93 119.31a T5 – Humic Acid Foliar Fertilizer 118.49 117.57 119.86 355.92 118.64a T6 – Supreme Foliar Fertilizer 117.81 118.74 118.90 355.45 118.48a TOTAL 701.18 695.70 700.36 2097.24 MEAN 116.86 115.95 116.73 116.51 * Means with common letter/s are not significantly different with each other using DMRT. ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 721.17 ERROR 10 6.97 TOTAL 17 731.05 C.V. = 0.72% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 2.91 1.46 2.09ns 4.10 7.56 144.23 207.01** 3.33 0.70 ns – not significant ** – significant at 1% level 5.64 39 Appendix Table 4. Number of Productive Tillers. R E P L I C A T I O N I II III 11.30 11.40 11.00 TREATMENT T1 – Control TOTAL MEAN* 33.70 11.23d T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 14.80 13.50 13.50 41.80 13.93c T3 – Carrageenan Foliar Fertilizer 22.20 22.00 22.30 66.50 22.17a T4 – Humus Plus Foliar Fertilizer 17.30 18.00 19.10 54.40 18.13b T5 – Humic Acid Foliar Fertilizer 17.50 18.30 18.50 54.30 18.10b T6 – Supreme Foliar Fertilizer 17.80 17.80 18.10 53.70 17.90b TOTAL 100.90 101.00 102.50 304.40 MEAN 16.82 16.83 17.08 16.91 * Means with common letter/s are not significantly different with each other using DMRT. ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 217.83 43.57 ERROR 10 3.26 0.33 TOTAL 17 221.36 C.V. = 3.38% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 0.27 0.13 0.41ns 4.10 7.56 133.68** 3.33 ns – not significant ** – significant at 1% level 5.64 40 Appendix Table 5. Number of Unproductive Tillers. R E P L I C A T I O N TOTAL MEAN* I II III 1.40 1.40 1.50 4.30 1.43a TREATMENT T1 – Control T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 0.90 0.70 0.70 2.30 0.77b T3 – Carrageenan Foliar Fertilizer 0.40 0.50 0.20 1.10 0.37b T4 – Humus Plus Foliar Fertilizer 0.60 0.50 0.20 1.30 0.43b T5 – Humic Acid Foliar Fertilizer 0.60 0.80 0.50 1.90 0.63b T6 – Supreme Foliar Fertilizer 0.80 0.70 0.70 2.20 0.73b TOTAL 4.70 4.60 3.80 13.10 MEAN 0.78 0.77 0.63 0.73 * Means with common letter/s are not significantly different with each other using DMRT. ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 2.18 0.44 ERROR 10 0.14 0.01 TOTAL 17 2.40 C.V. = 16.19% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 0.08 0.04 2.92ns 4.10 7.56 31.34** 3.33 ns – not significant ** – significant at 1% level 5.64 41 Appendix Table 6. Length (cm) of Panicles. R E P L I C A T I O N I II III 20.80 20.89 21.33 TREATMENT T1 – Control TOTAL MEAN* 63.02 21.01c T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 22.67 23.53 22.79 68.99 23.00b T3 – Carrageenan Foliar Fertilizer 28.28 26.27 26.63 81.18 27.06a T4 – Humus Plus Foliar Fertilizer 25.25 23.79 23.89 72.93 24.31b T5 – Humic Acid Foliar Fertilizer 24.20 23.47 24.95 72.62 24.21b T6 – Supreme Foliar Fertilizer 25.24 23.08 23.87 72.19 24.06b TOTAL 146.44 141.03 143.46 430.93 MEAN 24.41 23.51 23.91 23.94 * Means with common letter/s are not significantly different with each other using DMRT. ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 58.36 11.67 ERROR 10 5.26 0.53 TOTAL 17 66.06 C.V. = 3.03% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 2.45 1.22 2.33ns 4.10 7.56 22.19** 3.33 ns – not significant ** – significant at 1% level 5.64 42 Appendix Table 7. Number of Filled Spikelets. R E P L I C A T I O N I II III 92.00 104.53 106.60 TREATMENT T1 – Control TOTAL MEAN* 303.13 101.04c T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 146.50 136.80 149.00 432.30 144.10b T3 – Carrageenan Foliar Fertilizer 201.40 207.20 240.00 648.60 216.20a T4 – Humus Plus Foliar Fertilizer 149.10 176.40 177.00 502.50 167.50b T5 – Humic Acid Foliar Fertilizer 157.20 149.80 163.70 470.70 156.90b T6 – Supreme Foliar Fertilizer 142.30 139.80 183.30 465.40 155.13b TOTAL 888.50 914.53 1019.60 2822.63 MEAN 148.08 152.42 169.93 156.81 * Means with common letter/s are not significantly different with each other using DMRT. ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 20747.20 4149.44 ERROR 10 1266.48 126.65 TOTAL 17 23619.48 C.V. = 7.18% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 1605.80 802.90 6.34ns 4.10 7.56 32.76** ns – not significant ** – significant at 1% level 3.33 5.64 43 Appendix Table 8. Number of Unfilled Spikelets. R E P L I C A T I O N I II III 44.20 39.60 39.80 TREATMENT T1 – Control TOTAL MEAN* 123.60 41.20a T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 53.70 59.00 52.60 165.30 55.10a T3 – Carrageenan Foliar Fertilizer 43.90 30.60 32.90 107.40 35.80b T4 – Humus Plus Foliar Fertilizer 53.20 50.50 37.20 140.90 46.97a T5 – Humic Acid Foliar Fertilizer 62.10 47.80 52.00 161.90 53.97a T6 – Supreme Foliar Fertilizer 71.40 38.10 59.10 168.60 56.20a TOTAL 328.50 265.60 273.60 867.70 MEAN 54.75 44.27 45.60 48.21 * Means with common letter/s are not significantly different with each other using DMRT. ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 1047.44 209.49 ERROR 10 569.03 56.90 TOTAL 17 2007.27 C.V. = 15.65% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 390.80 195.40 3.43ns 4.10 7.56 3.68** 3.33 ns – not significant ** – significant at 5% level 5.64 44 Appendix Table 9. Weight (g) of 1000 Seeds. R E P L I C A T I O N I II III 29.90 29.40 28.45 TREATMENT T1 – Control TOTAL MEAN* 87.75 29.25 T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 32.10 32.60 28.00 92.70 30.90 T3 – Carrageenan Foliar Fertilizer 32.35 34.00 37.00 103.35 34.45 T4 – Humus Plus Foliar Fertilizer 32.00 32.20 31.80 96.00 32.00 T5 – Humic Acid Foliar Fertilizer 31.10 31.40 32.70 95.20 31.73 T6 – Supreme Foliar Fertilizer 31.20 30.30 31.20 92.70 30.90 TOTAL 188.65 189.90 189.15 567.70 MEAN 31.44 31.65 31.53 31.54 ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE SUM F – VALUES MEAN OF OF SQUARE Computed Tabular FREEDOM SQUARES 0.05 0.01 ns REPLICATION 2 0.13 0.07 0.02 4.10 7.56 TREATMENT 5 44.34 8.87 ERROR 10 26.87 2.69 TOTAL 17 71.35 C.V. = 5.20% 3.30ns 3.33 ns – not significant 5.64 45 Appendix Table 10. Weight of Seeds per Hill. R E P L I C A T I O N TOTAL MEAN* I II III 22.00 22.10 21.60 65.70 21.90c TREATMENT T1 – Control T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 44.70 46.90 44.81 136.41 45.47b T3 – Carrageenan Foliar Fertilizer 59.70 60.40 62.90 183.00 61.00a T4 – Humus Plus Foliar Fertilizer 47.70 46.90 48.20 142.80 47.60b T5 – Humic Acid Foliar Fertilizer 42.80 54.30 44.00 141.10 47.03b T6 – Supreme Foliar Fertilizer 42.80 52.00 44.30 139.10 46.37b TOTAL 271.70 294.60 277.81 844.11 MEAN 43.28 47.10 44.30 44.90 * Means with common letter/s are not significantly different with each other using DMRT. ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 2407.58 481.52 ERROR 10 91.52 9.15 TOTAL 17 2545.97 C.V. = 6.74% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 46.87 23.43 2.56ns 4.10 7.56 52.61** ns – not significant ** – significant at 1% level 3.33 5.64 46 Appendix Table 11. Weight of Seeds per Sampling Area. R E P L I C A T I O N I II III 1.62 1.51 1.55 TREATMENT T1 – Control TOTAL MEAN* 4.68 1.56c T2 – 60-20-0 kg NPK ha-1 (based soil analysis) 4.60 4.20 4.55 13.35 4.45b T3 – Carrageenan Foliar Fertilizer 7.24 7.25 7.20 21.69 7.23a T4 – Humus Plus Foliar Fertilizer 5.30 5.34 5.40 16.04 5.35b T5 – Humic Acid Foliar Fertilizer 4.90 5.25 6.06 16.21 5.40b T6 – Supreme Foliar Fertilizer 4.85 5.31 4.90 15.06 5.02b 28.51 28.86 29.66 87.03 4.75 4.81 4.94 TOTAL MEAN 4.84 * Means with common letter/s are not significantly different with each other using DMRT. ANALYSIS OF VARIANCE SOURCE OF VARIATION DEGREE OF FREEDOM REPLICATION 2 TREATMENT 5 51.69 10.34 ERROR 10 0.83 0.08 TOTAL 17 52.63 C.V. = 5.95% SUM F – VALUES MEAN OF SQUARE Computed Tabular SQUARES 0.05 0.01 0.12 0.06 0.70ns 4.10 7.56 124.95** 3.33 ns – not significant ** – significant at 1% level 5.64 47 Appendix Table 12. Projected Grain Yield per Hectare. TREATMENTS T1 – Control Computed Yield kilograms tons 1.56 2600.00 T2 – 60-20-0 kg NPK ha-1 (based soil analysis) T3 – Carrageenan Foliar Fertilizer 4.45 7416.67 7.23 12050.00 T4 – Humus Plus Foliar Fertilizer 5.35 8911.11 T5 – Humic Acid Foliar Fertilizer 5.40 9005.56 T6 – Supreme Foliar Fertilizer 5.02 8366.67 48 Republic of the Philippines ISABELA STATE UNIVERSITY Echague, Isabela MEMORANDUM TO: DR. RUFINO B. CALPATURA College of Agriculture Isabela State University Echague, Isabela Please serve as the Adviser to Ms. DIVINA G. MENDOZA’s thesis entitled “ENHANCING THE GROWTH AND YIELD PERFORMANCE OF RICE (Oryza sativa L.) THROUGH DIFFERENT FOLIAR FERTILIZERS”. Your comments, suggestions and recommendations will be made part of the thesis study. (SGD) ARTEMIO A. MARTIN JR., Ph.D. Department Chairman 49 Republic of the Philippines ISABELA STATE UNIVERSITY Echague, Isabela MEMORANDUM TO: ENGR. VICTORIANO V. CASCO College of Agriculture Isabela State University Echague, Isabela Please serve as Member of the Advisory Committee to Ms. DIVINA G. MENDOZA’s thesis entitled “ENHANCING THE GROWTH AND YIELD PERFORMANCE OF RICE (Oryza sativa L.) THROUGH DIFFERENT FOLIAR FERTILIZERS”. Your comments, suggestions and recommendations will be made part of the thesis study. (SGD) ARTEMIO A. MARTIN JR., Ph.D. Department Chairman 50 Republic of the Philippines ISABELA STATE UNIVERSITY Echague, Isabela MEMORANDUM TO: DR. NATIVIDAD C. CALPATURA College of Agriculture Isabela State University Echague, Isabela Please serve as Member of the Advisory to Ms. DIVINA G. MENDOZA’s thesis entitled “ENHANCING THE GROWTH AND YIELD PERFORMANCE OF RICE (Oryza sativa L.) THROUGH DIFFERENT FOLIAR FERTILIZERS” Your comments, suggestions and recommendations will be made part of the thesis study. (SGD) ARTEMIO A. MARTIN JR., Ph.D. Department Chairman