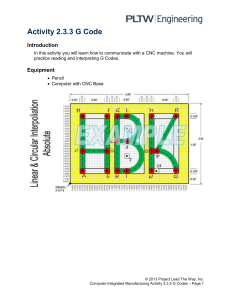

Activity 2.3.3 G Code Introduction In this activity you will learn how to communicate with a CNC machine. You will practice reading and interpreting G Codes. Equipment Pencil Computer with CNC Base © 2013 Project Lead The Way, Inc. Computer Integrated Manufacturing Activity 2.3.3 G Codes – Page 1 Use the grid below to draw a set of straight lines and arcs to create capital alphabetical characters for your initials (first, middle, and last), marking all endpoints and centerpoints on the grid intersections. Design must contain a minimum of 3 arcs. We will use a 1/8 in. end mill to produce the initials. Note: The grid consists of 1/16 in. spaces. Remember to consider tool cutter compensation so that each letter will end after milling with a dimension of 1.50 x 0.75 in. Label each of the significant points in your design with an alphabetical letter. Chart each of the significant coordinates in the table below using absolute coordinates. Note: Remember to record arc center points as well as end points. © 2013 Project Lead The Way, Inc. Computer Integrated Manufacturing Activity 2.3.3 G Codes – Page 2 Coordinates for Straight and Curved Letter Initials Using Linear and Circular Interpolation Absolute Coordinates Point A B C D E F G H I J K L M N O P Q R S T U V W X Y Z AA BB CC DD EE FF GG HH II JJ KK LL MM NN OO X Absolute Coordinates Y Point PP QQ RR SS TT UU VV WW XX YY ZZ AAA BBB CCC DDD EEE FFF GGG HHH X Y © 2013 Project Lead The Way, Inc. Computer Integrated Manufacturing Activity 2.3.3 G Codes – Page 3 NC Code – Straight & Curved Letter Initials – Linear & Circular Interpolation Absolute Coordinates Write G&M code that would allow a 1/8 in end mill tool to create the design using absolute coordinates. Bloc k G X Y Z I J Safe Position Cut Increment Spindle Speed Feed Rate Plunge Feed Rate Tool 6 R F M 0.1 Above Material 0.0625 3000 RPM 18 IPM 9 IPM 1/8 End Mill T S ; Comments % O00001 N00 G17 G20 G28 G40 G49 G80 G90 (Safe start) N10 N20 M06 G43 H06 N30 N40 M03 G54 G00 N50 N60 N70 (Tool Change – Tool 6 -1/8 End Mill) T06 X Y (Spindle On CW – Speed 3000 RPM) (Rapid to Above Point A) Z0.1 G01 S3000 Z -0.0625 (Rapid to 0.1 Above Part) F9. (Plunge 1/16 @ 9 in./min) F18. (Cut to point B) © 2013 Project Lead The Way, Inc. Computer Integrated Manufacturing Activity 2.3.3 G Codes – Page 4 Block G G01 X Y Z Z.1 I J R F M F9. T S ; Comments (Retract from part) G28 (Go to machine zero) M30 (Rewind program) % © 2013 Project Lead The Way, Inc. Computer Integrated Manufacturing Activity 2.3.3 G Codes – Page 5