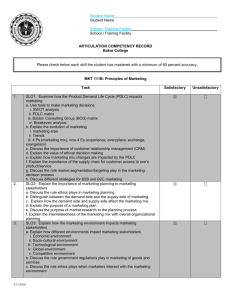

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/231184157 Improvement of Dichroic Polymer Dispersed Liquid Crystal (PDLC) Performance for Flexible Display Using Lift-off Technique Conference Paper · January 2005 CITATION READS 1 207 5 authors, including: Akio Yasuda Sony Corporation 177 PUBLICATIONS 6,462 CITATIONS SEE PROFILE All content following this page was uploaded by Akira Masutani on 29 May 2014. The user has requested enhancement of the downloaded file. Improvement of Dichroic Polymer Dispersed Liquid Crystal (PDLC) Performance for Flexible Display Using Lift-off Technique A. Masutani, T. Roberts, B. Schüller, A. Sakaigawa*, and A. Yasuda Sony Deutschland GmbH, Hedelfinger Str. 61, 70327 Stuttgart, Germany * Sony Corporation, Atsugi Tec. 4-14-1 Asahi-cho, Atsugi-shi, Kanagawa, 243-0014, Japan ABSTRACT The performance of dichroic sponge polymer dispersed liquid crystals (SPDLC) display can be improved further by incorporating a lift-off method using a substrate covered with a fluorinated-organosilane. The resulting cells achieve improved contrast, improved response time, smaller switching voltages and better uniformity, compared with the previously reported dichroic SPDLCs. The display exhibits near magazine-standard reflectivity and contrast ratio. Furthermore, the lift-off method enables rubbing-free, low temperature, roll-to-roll processing techniques. Such displays are suitable for flexible solvent-sensitive, organic thin-film transistors (TFTs). INTRODUCTION A polymer dispersed liquid crystal (PDLC) cell consists of a thin film sandwiched between transparent electrodes [1, 2]. Such films are composed of a polymer matrix within which small droplets of a liquid crystal (LC) are dispersed. PDLC films usually possess a transparent on-state and a scattering off-state. By doping PDLC with dichroic dyes, the films then exhibit an absorbing off-state (a) V and a transparent on-state [1]. Such films, known as Dichroic PDLCs (D-PDLCs), have the potential to outperform conventional reflective-type twisted nematic (TN) LC displays in some applications because they have no polarisers, leading to increased reflectivity and viewing angle [3]. Schematic diagrams of a D-PDLC in the off-state (a) and on-state (b) are shown in Fig. 1. The white rods represent the LC molecules, while the black rods represent the dichroic dyes. In the off-state, the film appears both scattering and coloured due to light absorption by the dichroic dye. In the on-state, the directors of the droplets align with the field, which makes the film transparent and colourless. One of the most common ways to prepare PDLCs is via the photo-induced phase separation (PIPS) method [3, 4]. In this method, irradiating UV light to a mixture of LC, dye and pre-polymer induces a phase separation. The result is the formation of LC and dye droplets in a polymer matrix. However, conventional D-PDLCs suffer from low contrast ratio and low on-state reflectivity, because of (1) degradation of dye/LC during fabrication, (2) dye interfering with the curing process, (3) trapping of dye/LC in the polymer matrix – thus making the dye/LC unresponsive to the electric field [5-10]. In our previous work [11, 12], we developed a simple processing method, which we dubbed the “Split” method, to overcome the aforementioned problems (Fig. 2a). The technique is as follows: firstly a pure PDLC cell with LC without dye is made – this defines the morphology of the film in the device; secondly, the substrates are split apart; (a) (b) Glass Glass Glass Glass V (b) Glass Glass Glass Glass Glass Glass Cover substrate Glass/PET Lift-off 250?msubstrate PET film Base substrate Glass/PET Fig. 1 Dichroic PDLC in the off-state (a) and on-state (b) Glass Glass Base substrate Glass/PET Base substrate Glass/PET Fig. 2 Schematic of (a) Split-SPDLC and (b) LO-SPDLC fabrications Fabrication of D-PDLC by Lift-off method For the fabrication of D-PDLC with the lift-off (LO) method, we followed mostly the previously reported recipe [11, 12]. Firstly, 78.9 wt% TL213 LC and 21.1 wt% PN393 pre-polymer were mixed together with small amount of 8µm spacers. TL213 is a nematic LC mixture from Merck, with an extraordinary refractive index (ne) of 1.77, an ordinary refractive index (no) of 1.53, ∆n (=ne-no) of 0.24 (589nm at 20ºC), and a dielectric anisotropy (∆ε) of 5.7. PN393 is a UV curable polymer from FFL Funktionsfluid GmbH, with a refractive index of 1.47. The solution was sandwiched between a base substrate and a LO substrate. The base substrate was an ITO coated glass substrate, which was weakly pre-treated with an ozone-plasma (100W for 10 min) to make the surface hydrophilic. The LO substrate was a glass substrate which has been functionalised with a fluorinated silane layer to render the surface hydrophobic. The silanisation was undertaken by immersing the LO substrate in 20µl SIH5840.0 (Heptadecafluoro1,1,2,2, -tetrahydrodecyl dimethylchlorosilane) in a vacuum desiccator at room temperature (c.a. 22°C) for 30 min. The LO substrate was allowed to dry in ambiOn-state Off-state Transmittance [%] 100 80 60 40 20 0 10µm (a) (b) Fig. 4 Optical microscope photos of (a) LO-SPDLC and (b) Split-SPDLC ent conditions in a fume hood before use. The phase separation of the TL213-PN393 solution was initiated by irradiating the cell with 2 10 mW/cm 365nm UV for 2 minutes at 23°C. Then the LO substrate was separated slowly from the PDLC film. Due to the hydrophobic surface treatments, the film only adheres to the hydrophilic base substrate. Subsequently the LC in the PDLC film was fully dissolved from of the polymer matrix by washing with methanol. The solvent was then removed by placing the cell under vacuum in an oven at 80ºC for 3 hours. The end result was an open porosity sponge consisting of a polymer matrix with air cavities (voids) on the base substrate. Then Black-4 dye (B4) doped TL203 LC was sandwiched between the base substrate and either (1) ITO coated glass cover substrate, or (2) a diffuse layer coated TFT. The different substrates were used for transmittance measurements or for reflectivity measurements respectively. The B4 dye (from Mitsubishi Chemical) consists of a mixture of six different azo and anthraquinone dyes. TL203 is a nematic LC mixture from Merck with nematic to isotropic temperature (TNI) of 77°C, with an ne of 1.73, an no of 1.53, ∆n of 0.20 (589 nm at 20°C), and a ∆ε of 11. Finally, the cell was heated to 90°C in vacuum oven for 10 min to reduce flow alignment defects in the LC. We referred to the final device as a “dichroic LO SPDLC.” Comparison of different fabrication methods for D-PDLCs PDLC test cells made with different fabrication methods were compared. The cells were denoted as “PDLC” for the cell made with the conventional Applied Voltage [V] thirdly, the first LC is replaced with a dye-doped LC; finally, the display is reassembled. We called such displays dichroic Sponge PDLC (D-SPDLC), and we demonstrated displays with favourable viewing properties, such as a reflectivity of 98% and a contrast ratio (CR) of 8 [11]. Despite this high performance, better ways of fabricating the display were desirable because the Split method was: (1) not homogeneous enough, (2) not suitable for a mass production, (3) not compatible with the additional diffuse layer developed for wide-view TFT [12], and (4) not suitable for a solvent-sensitive substrate, such as organic TFTs. This report presents an alternative approach to solve the above shortcomings, by lifting-off the PDLC film uniformly using anti-sticking lift-off substrate and then transferring the base substrate to a desired cover substrate, such as a TFT backplane (Fig. 2 b). 9 8 7 6 5 4 3 2 1 0 V10 V90 PDLC PDLC Split SPDLC Split DSPDLC LO SPDLC LO DSPDLC Fig. 3 On- and off-state transmittance Split SPDLC Split DSPDLC LO SPDLC LO DSPDLC Fig. 5 Applied voltage required for 10% (V10) and 90% (V90) of the On-state transmittance Rise Time at V90 600 500 400 300 200 LO-SPDLC refilled with 4% B4 doped TL203 Conventional TN TFT 100 White-state Reflectivity [%] Responce Time [ms] Decay Time at V90 80 60 40 20 0 100 0 0 PDLC Split SPDLC Split DSPDLC LO SPDLC LO DSPDLC Fig. 6 Rise time when V90 is applied, and decay time when V90 is removed PIPS method, “Split SPDLC” for the cell made with the Split method, and “LO SPDLC” for the cell made with the LO method. For comparison, Split and LO SPDLCs doped with 3wt% B4 dye were also made, these are denoted as “Split D-SPDLC” and “LO D-SPDLC” respectively. Fig. 3 shows how the On- and Off-state transmittance (Ton & Toff) differs between the cells. Ton stays almost constant between 82 and 83% for conventional PDLCs, Split and LO SPDLCs with no B4 dopant. Because of the absorption by the dye, both D-SPDLCs have approximately 5% lower Ton than the non-doped materials. Toff of the Split SPDLCs is approximately 8% higher than the conventional PDLC, which means that the Split SPDLC is not as scattering as the conventional PDLC. This is partly due to inhomogeneities within the SPDLC film. In contrast, the LO method produced more homogeneous films; which thus led to more efficiently scattering films, as can be seen by the reduction in Toff. Furthermore directly, the microscope photographs (Fig. 4) show that the LO SPDLC has more uniform droplet morphology than compared to the Split SPDLC. Fig. 5 shows the applied voltages required for 10% (V10) and 90% (V90) of the transmittance when Ton is taken as 100%. The V90 of both SPDLCs is noticeably increased compared to the conventional PDLC. This is probably due to the increased polymer-LC interaction caused by the use of different LCs and the removal/refilling process. Interestingly, LO SPDLC has c.a. 1V reduction in V90 compared to the Split SPDLC. The same trend could also be seen with the doped SPDLCs. The cause for the reduction in the switching voltage is expected, and is likely to be because of the improved droplet uniformity and slightly thinner cell gap because the LO film is more homogeneous. As we have previously reported [11], the reduction in V90 by 1~1.3V when B4 dyes are added to SPDLCs can be observed. The cause of this is yet to be fully understood. The variations in rise and decay times (ton & toff) when V90 is applied are shown in Fig. 6. Rise time 20 40 60 Angle of Incident Light [degrees] 80 Fig. 7 Reflectivity of D-SPDLCs compared with TN TFT at their white-states is the time taken from when the voltage is applied, to when the cell transmittance reaches 90% of |Ton - Toff|. Decay time is the time taken from when the applied voltage is turned off, to when the cell transmittance reaches 10% of |Ton - Toff|. Again, the same trends as previously reported [11] were observed; specifically that compared with PDLCs, both SPDLCs successfully showed reductions in both ton and toff. The response times for SPDLCs prepared by the Split and LO methods are comparable. However, when the SPDLCs are doped with 3wt% B4, the LO D-SPDLC ton did not show as much increase as the Split D-SPDLC. The reason for this improvement with the LO method has still to be fully explained, we expect it to be because of the improved droplet uniformity and film thickness. Characterisation of Reflective D-PDLC Display Prepared by Lift-off method As well as transmissive display cells, dichroic LO SPDLCs were also fabricated on a reflective TFT substrate. An additional diffuse layer coated on the substrate suppressed the metallic glare and improved the viewing angle dependency of the TFT’s existing diffuse reflector. Fabricating D-SPDLC on such diffuse layer was not directly possible with the Split method because the diffuse layer on the substrate was often removed or damaged during the splitting process. The reflectivity of the LO D-SPDLC cell was measured and compared with a commercially available reflective-type TN TFT display. The detector was set at 0º (surface normal) while the incident parallel white light was moved from 15º to 70º. The normalization value of 100% reflectance was taken using a Diffusing White Standard (Labsphere SRS 99-020). When the incident light was at 30º, the Dichroic LO SPDLC achieved a reflectivity of 66% in its on-state and 4.8% in the off-state (Fig. 7). At this angle the contrast ratio, defined as (Reflectivity at white-state)/(Reflectivity at black-state), for the Dichroic LO SPDLC panel was 13.8. This value is close to that of magazine (Fig. 8). Contrast Ratio 30 25 20 15 10 5 0 Poster TN-LCD D-SPDLC Magazine Newspaper 0 10 20 30 40 50 60 70 80 90 100 Reflectivity [%] Fig. 8 Position map of papers and D-SPDLC Conclusion By creating a new type of D-PDLC film and the development of a novel lift-off method, we have obtained a high reflectivity, high contrast, polariser-free display. Compared with existing This new method enables: (1) homogeneous display, (2) processes which are compatible with existing conventional TFT fabrication process, (3) improved compatibilities with novel diffusing layers [12] on TFTs, and (4) the use of solvent-sensitive TFTs, such as the materials used in flexible/organic TFTs. We have also found that the Dichroic LO SPDLC has improved shorter rise times and smaller switching voltages than compared to the Dichroic Split SPDLC. We have demonstrated the application of the Dichroic LO SPDLC to a reflective TFT substrate. The contrast ratio achieved was 14 and the reflectivity was 66%. Furthermore, this method allows a study of dye absorption enhancement by scattering because the PDLC’s morphology and electro-optical properties can be precisely tuned during the first step of the fabrication process. Such methods and materials are expected to thus have the potential to achieve a bright, high contrast, fast-switching and flexible paper-like display. Acknowledgements We would like to express our sincere gratitude to Professor David Bloor, Dr. Nigel Clark and Dr. Lars-Olof Pålsson from the University of Durham (UK) for fruitful discussions throughout the development of these materials and processes. [1] [2] [3] [4] REFERENCES J.L. Fergason, 1983, 4616903, US Patent. J.L. West, "Phase-separation of liquid-crystals in thermoplastics". Abstracts of Papers of the American Chemical Society, 1987. 194: p.82. P.S. Drzaic, "Polymer dispersed nematic liquid-crystal for large area displays and light valves", J. App. Phys., 1986. 60 (6): p.2142-2148. J.W. Doane, N.A. Vaz, B.G. Wu, and S. Zumer, "Field controlled light-scattering from nematic microdroplets", App. Phys. Lett., 1986. View publication stats 48 (4): p.269-271. G.M. Zharkova, S.A. Streltsov, and V.M. Khachaturyan, "Guest-host effect in polymer-dispersed nematic liquid-crystals", J. Struct. Chem., 1993. 34 (6): p.930-933. [6] P.S. Drzaic, Liquid crystal dispersions. Series on liquid crystals, ed. H.L. Ong. Vol. 1. 1995, Singapore: World Scientific Publishing. [7] J.J. Wu, C.M. Wang, and S.H. Chen, "Effects of dichroic dye in UV-cured polymer dispersed liquid crystal films", Jpn. J. App. Phys. Pt. 1 Reg. Pap., 1996. 35 (5A): p.2681-2685. [8] P.S. Drzaic, "Recent progress in dichroic polymer-dispersed liquid crystal materials", Pure App. Chem., 1996. 68 (7): p.1435-1440. [9] P.S. Drzaic, R.C. Wiley, and J. McCoy, Proc. SPIE, 1989. 1080: p.41. [10] L. Bouteiller and P. LeBarny, "Polymer-dispersed liquid crystals: Preparation, operation and application", Liq. Cryst., 1996. 21 (2): p.157-174. [11] A. Masutani, A. Roberts, B. Schüller, A. Sakaigawa and A. Yasuda, "Improved Performance of a Novel Polariser-Free Dye Doped Polymer Dispersed Liquid Crystal for Reflective Display", Journal of the SID, Vol. 12/3 [12] A. Masutani, M. Dürr, A. Roberts, B. Schüller, A. Sakaigawa and A. Yasuda, "A Method of Controlling the Diffusing Reflector Properties for Reflective Displays", AD/IMID '04 Conference Proceedings (2004.8, Daegu, Korea) [5]