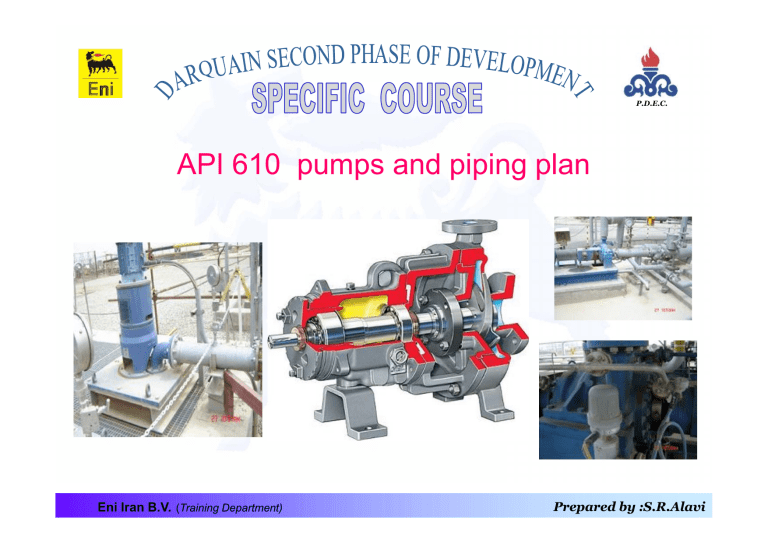

P.D.E.C. API 610 pumps and piping plan Eni Iran B.V. (Training Department) Prepared by :S.R.Alavi OVERVIEW API 610 PUMP DEFINATION BASIC DESIGN ITEMS CLASSIFICATION LUBRICATION API PLAN ROTOR,WEAR RINGS,… MECHANICAL SEAL & STUFFING BOX Eni Iran B.V. (Training Department) SECOND STAGE PUMPS FLOW SERVE ,NIEVE,… ١ API 610 scope Eni Iran B.V. (Training Department) ٢ Pumps are covered by this standards as follows •Overhang •Between bearing •Vertically suspended Eni Iran B.V. (Training Department) ٣ Not Complied API 610 For Non flammable ,Non-hazardous services not exceeding any of the limits below Users or purchaser can consider the pumps that do not comply with API 610: Eni Iran B.V. (Training Department) ٤ Eni Iran B.V. (Training Department) ٥ Eni Iran B.V. (Training Department) ٦ API 610 (OH2), Overhung Impeller, Centerline Mounted Eni Iran B.V. (Training Department) ٧ API 610 (OH2), Overhung Impeller, Centerline Mounted Applications: Boiler Circulation, Gas Industry Service , General Purpose, High Temperature Service Petrochemical Processing, Petroleum Distribution, Water Eni Iran B.V. (Training Department) ٨ API 610 (OH2), Overhung Impeller, Centerline Mounted Low Flow, High Head Design for smooth and stable operation outside the preferred operating region specified by API 610. Replaceable Volute Inserts to handle changing operating conditions. High efficiency patented design radial blade impeller Eni Iran B.V. (Training Department) ٩ API 610 (OH2), Overhung Impeller, Centerline Mounted Features: Choice of bearings Standard - single row, deep groove, radial bearing and duplex, single row 40° angular contact thrust bearings. Special bearing arrangements for high suction pressures Bearing lubrication and cooling options Oil mist and oil purge for continuous bearing lubrication Fan cooling for high operating or high ambient temperatures Finned cooling insert for efficient water cooling Optional inducer for reduced NPSHR Eni Iran B.V. (Training Department) ١٠ API 610 (OH2), Overhung Impeller, Centerline Mounted Operating parameters Flows to 30 m3/h (130 gpm) Heads to 215 m (700 ft) Pressures to 80 bar (1160 psi) Temperatures from -160°C (-250°F) to 450°C (840°F) Eni Iran B.V. (Training Department) ١١ API 610 (OH3), Vertical in-line Applications: Boiler Circulation, Gas Industry Service , General Purpose, High Temperature Service, Petrochemical Processing, Petroleum Distribution, Water Industries: Catalytic Cracking, Crude Handling and Treatment, Delayed Coking, Distillation, Gas-to-Liquids, Gas Treatment, Hydrocraking, Hydrotreating,LNG, Logistics and Tank Farm, NGL, SAGD, Utilities, Water Handling and Treatment Eni Iran B.V. (Training Department) ١٢ API 610 (OH3), Vertical in-line •Space Saving Design engineered for safe, reliable performance in cryogenic, high temperature and high working pressure services •Replaceable Volute Inserts to handle changing operating conditions. •Patented Radial Blade Impeller provides a continuously rising performance curve with low flow stability. Eni Iran B.V. (Training Department) ١٣ API 610 (OH3), Vertical in-line API 682 Seal Chamber accommodates a wide variety of seal configurations, including dual pressurized and un-pressurized cartridge types for the most severe services Dynamically Balanced Impeller limits vibration and ensures smooth operation over wide flow range. Eni Iran B.V. (Training Department) ١٤ API 610 (OH3), Vertical in-line Features: Bearing lubrication options Oil cascade Oil mist Grease lube Optional Inpro top bearing isolator Optional inducer for low NPSH requirements Other configurations HWM-2 (OH3, low flow, high head, 2stage) Operating parameters Flows to 30 m3/h (130 gpm) Heads to 220 m (725 ft) Pressures to 50 bar (750 psi) Temperatures from -185°C (-300°F) to 400°C (750°F) Eni Iran B.V. (Training Department) ١٥ API 610 (OH4) Overhung, Vertical In-Line Pump Applications: Booster, Fuel, Hydrocarbon Booster, High Temperature Service, Petroleum Production and Refining, Pipeline Booster, Petrochemical Processing, Petroleum Distribution, Tank Farm Transfer Industries: Automotive and Aircraft, Bleach Chemicals, Boiler Feed, Chemical and Liquor, Crude Handling and Treatment, Gas-to-Liquids, Gas Treatment, LNG, Logistics and Tank Farm, NGL, OEM, Scale Recycle, Utilities, Water Handling and Treatment Standards: API610 Eni Iran B.V. (Training Department) ١٦ API 610 (OH4) Overhung, Vertical In-Line Pump API 682 Seal Chamber accommodates a wide variety of seal configurations for the most demanding services. A full complement of API 610 seal flush plans is available. Double Suction Enclosed Impeller minimizes both NPSHA and thrust loading on the motor bearings, ensuring Reliable operation across a wide variety of head-flow demands. Double Volute case design provides radial balance. Motor Ratings to 895 kW (1200 hp) available for high flow pipeline booster and tank farm transfer services. Eni Iran B.V. (Training Department) ١٧ API 610 (OH4) Overhung, Vertical In-Line Pump Features: •Standard case wear rings •Optional impeller wear rings •Metal-to-metal case to cover sealing with confined gasket •Rigid spacer type coupling •Impeller nut design, threaded to tighten with rotation Eni Iran B.V. (Training Department) ١٨ API 610 (OH5), Overhung, Vertical In-Line Pump Applications: Acid Transfer, Flammable Liquids, Fuel, Gas Production, Gas Industry Service , General Purpose, Hydrocarbon Booster, Light Oils, Gasoline, Petrochemical Processing, Petroleum Distribution, Water Industries: Catalytic Cracking, Crude Handling and Treatment, Delayed Coking, Distillation, Gas-to-Liquids, Gas Treatment, Hydrocraking, Hydrotreating, LNG, Logistics and Tank Farm, NGL, SAGD, Utilities, Water Handling and Treatment Standards: API610 Eni Iran B.V. (Training Department) ١٩ API 610 (OH5), Overhung, Vertical In-Line Pump •Hydraulics Are Custom Tuned for the actual duty point by project-specific design of multi-channel diffuser. •Diffuser Technology provides low vibration, wide flow range, virtually zero radial loads, and very low shaft deflection at any flow rate. Eni Iran B.V. (Training Department) ٢٠ API 610 (OH5), Overhung, Vertical In-Line Pump API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and un-pressurized cartridge types for the most severe services. Dynamically Balanced Impeller limits vibration and assures smooth operation over wide flow range. Eni Iran B.V. (Training Department) ٢١ API 610 (OH5), Overhung, Vertical In-Line Pump Features: Positively locked, anti-rotation impeller nut with threads unexposed to pumped fluid BS 4082R compliant Other configurations PVML-MAG (magnetic drive design) Operating parameters Flows to 500 m3/h (2200 gpm) Heads to 275 m (900 ft) Pressures to 40 bar (600 psi) Temperatures to 250°C (480°F Eni Iran B.V. (Training Department) ٢٢ API 610 (OH6), Integral gear driven Eni Iran B.V. (Training Department) ٢٣ API 610 (OH6), Integral gear driven The kind of pump have incorporated point emission and volute hydraulics with a more robust gearbox. This results in lower minimum flows, thereby extending the operating range of the pump. High speed shaft with integral gear and balanced idler shaft with sleeved bearings to insure a low vibration unit and extended seal life. Eni Iran B.V. (Training Department) ٢٤ Eni Iran B.V. (Training Department) ٢٥ API 610 (OH6), Integral gear driven Eni Iran B.V. (Training Department) ٢٦ Eni Iran B.V. (Training Department) ٢٧ API 610 (BB1) Between Bearing Axially Split Single Stage Applications: Booster, Coolant Injection, Component Cooling, Crude Oil Loading, Crude Oil Transfer, Fire Protection, Feedwater Booster, Gas Scrubbing, General Purpose, Hydrocarbon Processing, Liquified Gas Industry Service, Oil Transportation, Process Charge, Pipeline, Pipeline Booster, Power Recovery, Sea Water, Water Industries: Boiling Water Reactors Safety, Crude Handling and Treatment, Crude Pipeline, Logistics and Tank Farm, Products Pipeline, Pressurized Water Reactors - Safety, Utilities Eni Iran B.V. (Training Department) ٢٨ API 610 (BB1) Between Bearing Axially Split Single Stage Double Suction Impeller and Double Volute Casing inherently result in optimum axial and radial thrust balance over the full operating range. Hydraulically Balanced double suction impeller reduces NPSH requirements and ensures smooth, efficient operation over a wide range of conditions. Eni Iran B.V. (Training Department) ٢٩ API 610 (BB1) Between Bearing Axially Split Single Stage Eni Iran B.V. (Training Department) ٣٠ API 610 (BB1) Between Bearing Axially Split Single Stage Seal Chambers to API 682 dimensional criteria allow for installation of cartridge design single, dual un-pressurized and dual pressurized mechanical seals to meet safety and environmental requirements. Eni Iran B.V. (Training Department) ٣١ API 610 (BB1), Between Bearing, Axially Split, Two Stage Pump Applications: •Fire Protection, •Gas Scrubbing •Water Supply, •Water Treatment, •Hydrocarbon Processing, • Pipeline, • Water Industries: Logistics and Tank Farm, Utilities, Water Handling and Treatment Eni Iran B.V. (Training Department) ٣٢ API 610 (BB1), Between Bearing, Axially Split, Two Stage Pump Double Suction First-stage Impeller reduces NPSHr and often eliminates the need for booster units Eni Iran B.V. (Training Department) ٣٣ API 610 (BB1), Between Bearing, Axially Split, Two Stage Pump Double Volute Construction for both stages minimizes hydraulic loads in any service condition down to minimum flow. Mechanical seal API 682 Seal Chambers operate at suction pressure and allow for installation of cartridge design single, dual un-pressurized and dual pressurized mechanical seals to meet safety and environmental requirements Eni Iran B.V. (Training Department) ٣٤ API 610 (BB1), Between Bearing, Axially Split, Two Stage Pump Features: Choice of bearings Ball radial and thrust Sleeve radial and ball thrust Sleeve radial and tilting pad thrust Tilting pad radial and tilting pad thrust Choice of materials Carbon steel 12% chrome Austenitic and duplex stainless steels Monel Eni Iran B.V. (Training Department) ٣٥ API 610 (BB1), Between Bearing, Axially Split, Two Stage Pump Operating parameters Flows to 2950 m3/h (13 000 gpm) Heads to 685 m (2250 ft) Pressures to 64 bar (910 psi) Temperatures to 200°C (400°F) Speeds to 2000 rpm Eni Iran B.V. (Training Department) ٣٦ Radially Split 2 stages BB2 Heavy-duty Casing with 180° staggered volutes Suction and Discharge Nozzles available in top-top, in-line side, or same side configurations. Eni Iran B.V. (Training Department) ٣٧ Radially Split 2 stages BB2 Applications: Boiler Feed water, Gas Scrubbing, Heater Charge, High Temperature Service, Hydrocarbon Processing, Liquefied Gas Industry Service, Petroleum Production and Refining, Petrochemical Processing, Petroleum Distribution, Utility Pump Design, consisting of either a single or double suction first stage impeller, incorporates a heavy-duty casing with 180° staggered volutes. Eni Iran B.V. (Training Department) ٣٨ Radially Split 2 stages BB2 Mechanical seal Seal Chambers to API 682 Dimensional criteria allow for installation of cartridge design single, dual un pressurized and dual pressurized mechanical seals to meet safety and environmental requirements. Features: Choice of bearings Ball radial and thrust Sleeve radial and ball thrust Sleeve radial and tilting pad thrust Tilting pad radial and tilting pad thrust Choice of materials Carbon steel 12% chrome Austenitic and duplex stainless steels Monel Eni Iran B.V. (Training Department) ٣٩ Radially Split 2 stages BB2 Operating parameters Flows to 1000 m3/h (4400 gpm) Heads to 650 m (2100 ft) Pressures to 80 bar (1160 psi) Temperatures to 450°C (850°F) Eni Iran B.V. (Training Department) ٤٠