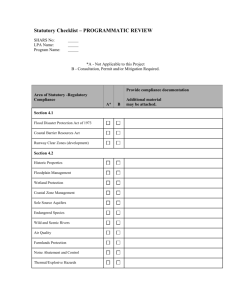

Background • • • Mandated by DaimlerChrysler for all tier 1 suppliers Strongly recommended by General Motors and Ford The Timken Company has been utilizing Layered Process Audits since 2004 Definition LPA’s Like Preflight Checklist. • • • An ongoing system of process checks that verify proper methods, settings, tools, gages, operator craftsmanship, error proofing devices, and other important inputs are in place in order to achieve optimal results. Redundant process checks to make sure everything is right. Ensure multiple eyes looking at the process to ensure the key work steps are being performed properly. Is Everything Ready for Take-off Requirements for LPA’s • LPA’s shall be conducted for high risk elements at a minimum of once per shift. • Checklist of high risk items can be established using reference items such as, customer complaints, warranty issues, PFMEA, etc. • • Audit items should be unambiguous and specific. LPA results should be recorded and posted and reaction plans for non-conformances found during audit shall be documented. Requirements for LPA’s • • • Non-conformances should be corrected immediately. Audit results shall be summarized and reviewed by plant leadership (nonconformance database) Successive levels of plant leadership shall perform the exact same audit as the first level auditors and insure that first level audits are being done. • • • LPA items can be added and taken away. An audit item should not be deleted, unless the risk is eliminated and verified. LPA items should be limited to those items critical to the process or the plant’s objectives. Avoid putting too many items on the audit. Continuously improve the audit process (living document). 20% Scrap Reduction Goal Requirements for LPA’s • • • • • Multiple layers verifying critical processes are ready to go. (Rib Angle) Gives management a reason to be on the floor. Makes management presence on floor commonplace. Ensures problem solving solutions (corrective actions) stay in place. Identifies problems upstream, before issue reaches customer. Generates continuous improvement opportunities. 20% Scrap Reduction Goal Benefits of LPA’s Roadblocks to LPA’s • • • Culture shift in some cases to have associates do audits each shift and have management looking over their shoulder. Too many items on LPA, makes it impossible task Can become rubber stamp process. Managers get busy and don’t follow through on audit, undermining audit importance. 20% Scrap Reduction Goal • • • Nothing done with the data Verification of LPA item not clear to everyone (different interpretation of OK) 20% Scrap Reduction Goal Roadblocks to LPA’s