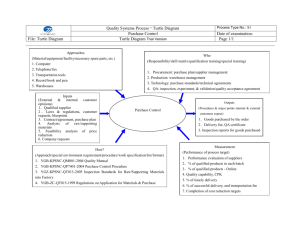

Table of contents Abstract Chapter 1: Introduction 1.1) Industry Overview 1.2) Company Overview 1.3) SWOT Analysis 1 2 2 4 6 Chapter 2: Manufacturing and Quality Assurance Processes 2.1 Supplier Quality Assurance (SQA) 2.1.1 Processes involved 2.1.2 Manufacturing Capabilities of the company 2.1.3 The commodities received 2.1.3 Inspection facilities 2.1.5 Functions of quality assurance department 7 7 7 7 8 8 2.2 Quality System Procedure 2.2.1 Receiving Inspection report 2.2.2 Responsibilities of SQA personnel 9 9 9 2.3 Audit 2.3.1 Types of audit 2.3.2 Process of audit 2.3.3 Types of records 10 10 11 2.4 Supplier Periodic Assessment form for existing supplier 2.4.1 Types of approval 2.4.2 Elements of supplier assessment form 2.4.3 New suppliers’ criteria 12 12 12 12 2.5 Agreement of Inspection (AOI) 2.5.1Introduction 2.5.2 Components of an approved AOI 2.5.3 Inspection parameters 15 15 15 16 2.6 Sampling plan for receiving inspection 2.6.1 Introduction 2.6.2 Some important definitions 2.6.3Characteristics based sampling 2.6.4 General 2.6.5 Storing, preserving and disposal of samples 2.6.6 Inspection plan preparation 2.6.6.a Process of creation of IP 16 16 16 17 17 17 17 17 2.7 Supplier corrective action report handling 2.7.1 Types of rejection 2.7.2 Elements of SCAR 2.7.3 SCAR closure 2.7.4 NC movement 18 18 19 19 2.8 Advance Product Quality Planning (APQP) 2.8.1 Phases of APQP 20 20 2.9 Failure Mode Effect Analysis (FMEA) and Process Plan FMEA 2.9.1 Elements of FMEA 2.9.2 Process Plan FMEA 2.9.2.a Functions of PPFMEA 2.9.3 Development of PFMEA 2.9.4 Special Process instruction 2.9.5 Electrical and mechanical test plan 2.9.6 Relentless Root Cause Analysis (RRCA) 2.9.7 Quality Control Tools (QCT) 21 21 21 21 22 22 22 23 24 2.10 Sample development review and risk assessment 2.10.1 Checkpoints at the first review 2.10.2 Risk Assessment 2.10.3 Supplier selection and assessment 2.10.4 Machine development 2.10.5 Process engineering 25 25 25 25 26 26 2.11 First Article Inspection (FAI) 2.11.1 Types of FAI 2.11.2 Periodic qualification test summary 2.11.3 Technology transfer to the operation team 2.11.4 Team feasibility commitment 2.11.5 Component sourcing and development 2.11.6 Customer specific review 2.11.7 Inspection for new suppliers 27 27 27 27 28 28 28 29 2.12 Final Article Inspection 2.12.1 Introduction 2.12.2 In-process quality inspection 2.12.3 8-D analysis 29 29 30 30 Chapter 3: Observation and Analysis Results Recommendations Conclusion Learning outcomes References