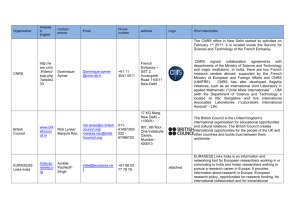

Industrial Chemistry Laboratory Cologne Making Martinez, Chelsea M. Prof. Medarlo De Jesus Professor 26 February 2016 Industrial Chemistry Laboratory 2 Abstract This experiment primarily aims to give knowledge on the preparation of cologne. Various materials were used and each has its own role in the overall product. Varying the amounts of both alcohol and essential oil corresponds to change in the quality of the product. Temperature also plays a vital role in the evaluation of the final product. There are three types of components that can be used to make hand blended perfumes, essential oils, fragrance oils and aroma chemicals. Manufactured perfumes use "aroma chemicals" which are the broken down constituents of fragrance oils and synthesized constituents of natural essential oils. In this experiment, a cologne rather than a perfume was made. Its quality was examined by evaluating its fragrance, persistence and effect on skin and fabrics. Basically, fragrances have three basic constituents – vehicle, fixatives and odorous substances. The most common solvent or vehicle, used for holding and blending fragrances, is highly refined ethyl alcohol. It can contain substantial amount of water depending on the solubility of the oil employed. The odour of the vehicle must be removed to avoid odour interference with the fragrant product. Meanwhile, fixatives are substances that have lower volatility compared to odorous oils. It can retard and even up the rate of evaporation of various odorous constituents. These odorous constituents give the significant scent to the fragrance, and are generally categorized as essential oils, isolates and synthetic or semi-synthetic chemicals. Introduction The first source of aroma chemicals is from isolates of essential oils -- the second source is chemically modified isolates from essential oils. -- The third source of aroma chemicals is from the petrochemical industry. Essential oils are the volatile essences extracted from various parts of living plants. They are said to be the "life force" of the plant. Of the thousands of plants in the world, only 200 produce essential oils that are used in the art of perfumery. Essential oils are very intense and must be diluted when using to make perfumes. Some essential oils are readily soluble in oil, some are only soluble in alcohol. Because essential oils are highly concentrated they cannot be used directly on the skin. Fragrances are products that make a major contribution to the cosmetic industry, as well as to the production of soaps and detergents. These products are industrially useful in masking, neutralizing, and altering the odor of various products. It can provide additional crating aroma for normally odorless products. Egyptians were responsible for the origin of perfume. They utilized scents in everything from religious ceremonies to burial preparations and even daily wear. Industrial Chemistry Laboratory The rich elites of Egyptian society, male and female alike, would adorn themselves with aromas like lily to denote their status. The Persians took over the use of perfume as a sign of political status, but it wasn't until the Greeks and Romans became acquainted with it that it began to be viewed as a form of art and produced en masse and in consistent quality. Archaeologists recently uncovered a perfume factory from 2,000 BC, located in Cyprus, which seemed to have specialized in the production of scents like coriander, laurel, myrtle, lavender, and rosemary. Perfume slowly spread throughout the globe, and for a while, scents were reserved mainly for use in religious ceremonies. However, in 1190, perfume began to be produced commercially in Paris, and from there, it blossomed into a massive industry once more. There are primarily three fragrance constituents that contribute to the quality of the cologne: vehicle, fixative and odorous substances. The table below shows each constituent’s function. Table 1. Three Fragrance constituents Constituent Function1 Vehicle Projects the scent it carries which are inert to the solute and is not irritating to skin Fixatives Retard or even up the rate of oil evaporation Odorous substances Gives scent and identity to the fragrance product Austin, G.T., 1984, Shreve’s Chemical Process Industries. 5th edition. McGraw-Hill: USA 1 3 Experimental Section Material Used: graduated cylinders, 100mL beakers, 250 mL beakers, stirring rods, dropper Reagents Used: 95% ethanol, essential oil(enchanted and eternity) Cologne Making: Three formulations were followed. cologne %w Alcohol %w Essential oil %w Water C-1 60.0 3.0 37.00 C-2 40.0 3.0 57.00 C-3 60.0 5.0 35.00 Cologne Formulation The required amounts of alcohol, enssential oils and water were weighed. The essential oil was dissolved in alcohol and then water was added to this mixture. The resulting solution was stirred thoroughly. This cologne was divided into two and were transferred into separate bottles which were then tightly covered. Evaluation: One bottle was stored in a refrigerator and the other was stored at room temperature overnight. The fragrance and persistence were evaluated for each. Effects on skin were also determined by applying the cologne directly on skin and allowing it to stay for Industrial Chemistry Laboratory 4 a certain period of time. Same was done for the fabric. Discussion of Results Table 2. Colognes stored at refrigerator Formulation Fragrance Persistence C-1 C-2 C-3 The smell of alcohol is stronger than the oil at first but the longer it stays, the more pleasing the smell The smell of alcohol overpowers the scent of oil but eventually the smell of the oil fades The cologne smells just fine. The combination becomes great and exact. Effect on Fabric 3 hrs Effect on Skin Sticky feeling 2 hrs Slippery Reference. Fast absorbance 4 hrs Slippery with some volatile feeling Fastest absorbance Absorbed by the fabric faster than C-2 Table 3. Colognes stored at room temperature ( several hours after the laboratory experiment) Formulation C-1 C-2 C-3 Fragrance The smell of alcohol is stronger than the oil at first but the longer the time it takes to stay, the more pleasing the smell The smell of alcohol overpowers the scent of oil but eventually the smell of the oil fades The cologne smells just fine. The combination becomes great and exact. Persistence 15 mins Effect on Skin Non-irritating. Feels smooth 2 mins Sticky feeling 3 hours Sticky feeling and the cologne is a little bit viscous compared to the other two Effect on Fabric The cologne spread easily on the fabric. Becomes pale yellow at indefinite reason Fabric absorbed the cologne faster relative to C-1 It takes time before the fabric absorbed the cologne. It is quite ironic, because it has the higher % (w) alcohol and essential oil. Industrial Chemistry Laboratory Tables 2 and 3 shows the data gathered after storing the colognes at different temperatures. Both conditions revealed same fragrances for the colognes. Also it was noticed that C-2 had the least time of persistence for both cold and room temperature. It is because this cologne formulation has the least amount of alcohol and greatest amount of water among the three formulations. It can be inferred that increasing the amount of water in the formulation reduces the persistence of the cologne. When it comes to viscosity, C-3 appeared to be most viscous since it has the greatest amount of essential oil added relative to the other substances. 5 Figure 1. Final products Figure 1 shows the obtained cologne after storing them at different temperatures. Additional Observations For C-1 on the above table, the persistence is almost the same for both cases. It was determined for both skin and fabric while for the rest of the formulations have a longer persistence when applied on fabric than when applied on skin. After letting the C-2 settle at room temperature overnight, its cloudiness reduced as it was cooled down to room temperature. The C-3 formulation is apparent and transparent compared to C-1 and C-2 formulations. The persistence of the colognes were greater when they underwent exposure to freezing temperature overnight and cooled down compared to when exposed to room temperature. Conclusion and Recommendations In this experiment, cologne was successfully prepared at different concentration using different cologne formulations consisting of the main constituents of fragrance namely, the vehicle, odorous substance and water. Industrial Chemistry Laboratory It can be inferred that cologne has least amount of odorous substance, as for its concentration in the mixture ranges about 2-3% wt/wt. Higher concentration of essential oil essentially leads to stronger cologne fragrance. On the other hand, vehicle (commonly ethyl alcohol) can mask or interfere with the fragrance, leading to less concentrated smell, although it can improve persistence as proven by the evaluation made. Water, also reduces the strength of fragrance because it acts as the diluter, producing cheaper but lowers the quality of the cologne. Regarding the temperature at which colognes are stored, those stored at colder temperature were proved to last longer than those stored at room temperature. By the virtue of temperature dependence of vapor pressure, essential oils can readily vaporize at higher temperature than at lower temperature at 6 the same pressure). pressure (atmospheric For further enhancement of the product, more research on the right proportions of the reagents is recommended, something that will improve the persistence and scent of the cologne. References Forteneau, A. (2004). Chemistry perfumes your daily life. Journal of Chemical Education. 56(7):327-40. Grant, N. Perfumes and the art of perfumery. Journal of Chemical Education. March 10, 1972, p. C3 (N). Shiner, L. (2015). Art scents: perume, design and olfactory. Oxford Journal. 34(1):234-31