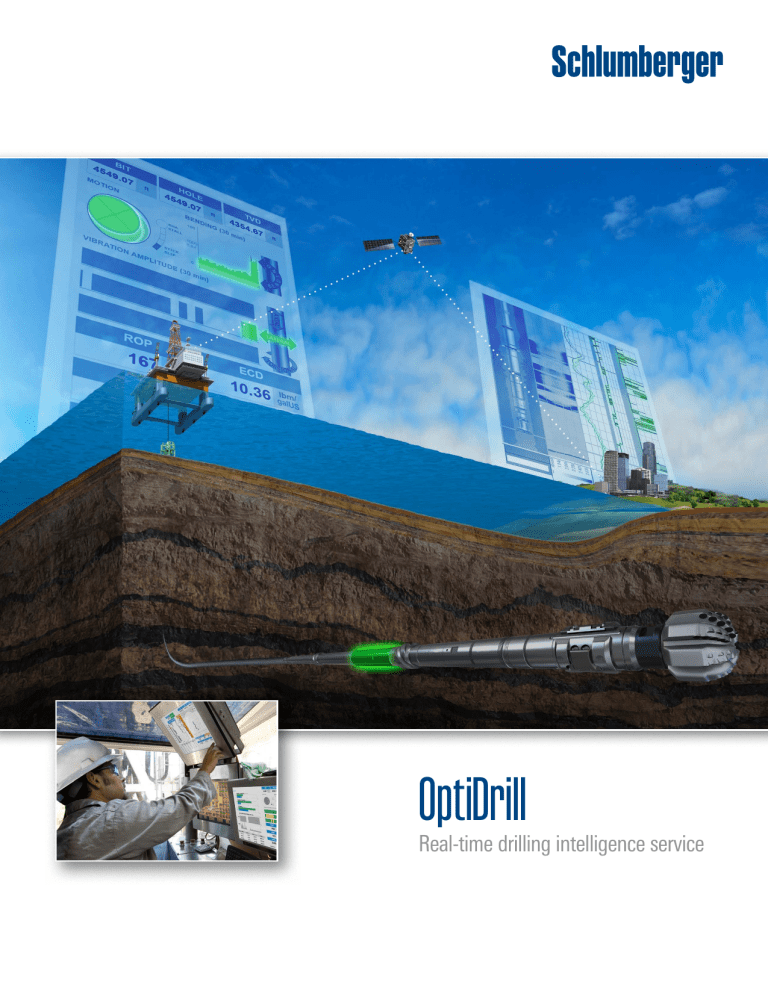

OptiDrill Real-time drilling intelligence service OptiDrill Real-time drilling intelligence service Manage downhole conditions and BHA dynamics with the OptiDrill* real-time drilling intelligence service. Integrated downhole and surface data provide actionable information on a rigsite display to mitigate risk and increase efficiency. These data are simultaneously interpreted by remote experts, who collaborate with the drilling team to improve performance. Applications Benefits ■■ Risk mitigation ■■ ■■ Drilling performance improvement ■■ ■■ Wellbore quality enhancement Reduce BHA failures Identify and mitigate poor hole cleaning and sticking pipe tendencies Features ■■ Downhole sub with 19 drilling mechanics and dynamics sensors ■■ Real-time drilling answers, including ●● downhole detection of whirl, bit bounce, and stick/slip motions and severity ■■ Improve ROP by maximizing drilling efficiency ●● estimation of weight on reamer ■■ Extend bit runs by preserving cutting structures ●● continuous calculation of borehole friction factors ■■ Manage borehole tortuosity to aid casing running ●● estimation of wellbore curvature from bending moment ■■ Optimize BHA design and bit selection ●● plugged-nozzle and drillstring washout quick event detection ■■ Evaluate drilling technology performance ■■ Rigsite dashboard with integrated data display ■■ Validate and calibrate drilling models ■■ While-drilling monitoring, analysis, and recommendations from remote experts ■■ Continuous recording of low- and high-frequency data for postrun analysis Quantify risk and manage downhole conditions The OptiDrill service helps you mitigate risk and improve drilling performance through early detection of ROP limiters and drilling hazards. Real-time motion detection and weight-on-reamer information allow the rigsite team to proactively manage parameters. The OptiDrill service provides the driller with immediate guidance on how to mitigate severe downhole dynamics. Early intervention typically lessens the severity of an event, protecting the BHA and extending the length of the bit run. Mitigating shock and vibration to maximize drilling efficiency The OptiDrill service detects whirl, bit bounce, and stick/slip motions and their severity. In the example below, a large-hole BHA is crossing a formation boundary and experiencing severe backward whirl. This motion is detected downhole by the OptiDrill service’s sub and displayed in real time with a recommended mitigation on the rigsite display. A MOTION BENDING (30 min) 100 G DIN BHA STALL STICK SLIP EN 1,000 ft.lbf B 0 VIBRATION AMPLITUDE (30 min) AXIAL Severe Backward Whirl Advice: Stop and restart with lower surface RPM BIT HOLE TVD 4,549.07 ft. 4,549.07 ft. 4,354.67 ft. B WEIGHT TRANSFER (1,000 lbf) MOTION Surface BENDING (30 min) Downhole 10 BHA STALL 20 1,000 ft.lbf Surface STICK SLIP Downhole 0 6 9.5 10 ECD/MWin (lbm/gal) 12 EN DIN 0 TORQUE TRANSFER (1,000 ft.lbf) D LATERAL 100 G C B 0 VIBRATION AMPLITUDE (30 min) AXIAL ECD MWTI 10.5 LATERAL KEY TIME-BASED TRENDS (60 min) 10.5 TO ECD (lbm/gal) E ROP 10 10,000 167 DMSE (psi) ft/h RPM 0 03:00 03:15 03:30 10.36 c/min 1,098 Incl (deg) Azim (deg) TVD (ft) PRESSURE FLOW X,153.16 27.91 281.71 X,009.72 X,277.91 28.95 284.67 X,119.42 2,481 1,268 X,403.45 30.09 287.62 X,228.67 Sensor MD (ft) lbm/gal DIFF PRESSURE 119 03:45 RSIONAL ECD psi psi gal/min A Animation of downhole motions requiring immediate attention to preserve the life of the BHA D Quantification of weight and torque transfer to enable early identification of abnormal downhole conditions B Progression of vibration type and amplitude to help modify drilling parameters and minimize energy lost to vibrations E C Guidance to aid mitigation Calculation of equivalent circulation density (ECD) and downhole mechanical specific energy (DMSE) to understand hole cleaning and drilling efficiency trends TO RSIONAL Managing drilling parameters to extend the life of the reamer In reaming-while-drilling applications, the OptiDrill service continuously estimates weight on reamer by combining downhole measurements from below the reamer with surface measurements. In the example below, the BHA is passing through formations with significant strength contrasts. The driller is using the estimated weight on reamer and a visualization of the reamer location to proactively manage surface weight to keep the weight on reamer within an acceptable range. ROP Weight On Reamer Gamma Ray X,810 X,860 A B 22:45 X,880 X,900 22:50 X,920 RTSTAT 22:55 X,910 X,960 ROP BIT ON BOTTOM 3089 X,038.98 Weight On Reamer Gamma Ray 23:00 X,810 ft HOLE TVD X,038.98 ft X,586.42 ft 0 GTF -30 30 TF 168 X,980 X,860 -60 22:45 X,000 X,880 X,900 X,020 60 23:05 22:50 -90 X,920 0 ft/h 200 X,910 0 200 23:10 gAPI 0 22:55 90 20 1,000 lb -120 X,960 120 23:00 X,980 -150 X,000 X,020 0 A 200 0 200 23:10 0 20 MD (ft) Incl (deg) Azim (deg) TVD BR TR (ft)(deg/100ft) MWD X,527.99 34.68 299.01 X,108.19 -0.11 0.26 0.18 MWD X,655.55 34.67 298.56 X,273.10 -0.01 -0.36 0.20 MWD X,782.69 35.44 296.12 X,377.18 0.61 -1.92 1.26 MWD X,907.44 35.22 295.09 X,478.96 -0.18 -0.82 0.51 MWD X,992.46 35.29 295.15 RSS X,030.52 35.65 298.15 Visualization of the location of the reamer in the formation to help determine cause of change in weight on reamer 150 180 23:05 B DLS AXIAL VIB LATERAL VIB TORSION VIB LOW LOW LOW Surface Weight 14 1,000 lbf ECD 11.01 Bit Weight 3 1,000 lbf ROP lbm/ gal 111 Weight on Reamer 11 1,000 lbf RPM ft/h 82 c/min Estimation of weight on reamer to increase the life of the reamer through proactive management of surface weight on bit and rpm Wellbore Quality Depth, m Scale BHA and Caliper Borehole Image EcoScope*† Caliper EcoScope Density Image Drilling Performance Improvement Borehole Curvature PowerDrive Orbit* Inclination Pressure Drilling Efficiency Drilling Mechanics and Downhole Forces Pressures Bending Curvature Risk Mitigation Equivalent Mud Weight ROP Weight Torque and Rotational Speed Bending Moment Mechanical Specific Energy 0 m/h 20 Dynamic Bending Delta Mechanical Specific Energy Borehole Friction Factor Quick Event Detection Algorithms Drilling Dynamics, Vibration Amplitudes, and Motions rms Axial Vibration Severity Bit-Bounce Severity rms Lateral Vibration Severity Whirl Type Whirl Severity rms Torsional Vibration Severity Stick /Slip Severity Borehole Friction Factor Quick Event Detection Low Risk Low Risk Low Risk Normal Drilling Normal Drilling Low Risk Low Risk Rotating Friction Factor Medium Risk Medium Risk Medium Risk Forward Whirl Medium Risk Medium Risk Medium Risk Plugged- Drillstring Nozzle Washout Quick Quick Event Event Detection Detection High Risk High Risk High Risk Backward Whirl High Risk High Risk High Risk Severe Risk Severe Risk Severe Risk Chaotic Whirl Severe Risk Severe Risk Severe Risk X,925 X,950 X,975 Absent 1.846 2.041 2.236 2.431 2.626 X,000 84 degree 88 Tool Bending Curvature 0 g/cm3 6 º/30 m Wellbore Bending Curvature 0 Flow Rate ECD 1,000 galUS/min Surface WOB Surface Torque 13 lbm/galUS 16 0 lbf 20,000 0 ft.lbf 25,000 Standpipe Pressure Equivalent Static Density Avg Downhole WOB Avg Downhole Torque 0 psi 4,000 13 lbm/galUS 16 Downhole Differential Pressure Max. Static Density 0 6 º/30 m 13 lbm/galUS 16 0 psi 4,000 Data from the OptiDrill service is transmitted to surface for use by the rigsite team and for interpretation by remote experts. The experts collaborate with the drilling team to reduce risk, improve drilling performance, and manage borehole quality. 0 ft.lbf 25,000 0 lbf 20,000 0 ft.lbf 10,000 Max. Downhole WOB Max. Downhole Torque 0 lbf 20,000 0 ft.lbf 10,000 13 lbm/galUS 16 Mud Weight In Downhole Mechanical Specific Energy 0 Max. Bending Moment 0 ft.lbf 25,000 Min. Static Density Receive while-drilling support from interpretation experts Avg Bending Moment 6,000,000 psi Surface Mechanical Specific Energy 0 Surface rpm 0 0 7 0 7 0 7 0 3 –1 3 0 7 0 0.5 0 1 Probability 0 100 Pickup Friction Factor 0 0 0.5 Slack-Off Friction Factor 0.5 7 6,000,000 psi 0 c/min 200 13 lbm/galUS 16 Wellbore quality monitoring Drilling performance improvement Risk mitigation To aid casing running, the service detects microdogleg and spiraling using bending moment data. Real-time wellbore quality data logs enable evaluation of the stability of the borehole over time. In addition to the rigsite visualization of drilling efficiency information and immediate guidance for mitigating BHA dynamics, remote interpretations are shared with the rigsite team to help identify optimal surface parameters. Automated quick event detection algorithms monitor for indications of plugged bit nozzles and drillstring washout. Using surface and downhole measurements, the OptiDrill service continuously calculates torque and drag to provide borehole friction factors for early identification of sticking pipe tendencies. Improve future performance with postrun insight Bending moment, up–down The OptiDrill service records low- and high-frequency data, which are available for postrun analysis to evaluate drilling system performance. This information provides valuable input for the planning of future wells. Key applications of this recordedmode information include ■■ ■■ ■■ ■■ validating and calibrating drilling models increasing knowledge of formation drillability otic Cha l 3 whir 2 optimizing BHA design and bit selection Be nd evaluating the performance of drilling technology. ing mo ar irl d wh me nt, Forw lef t–r igh t , min Time 1 0 A BHA with a reamer entered forward whirl motions and then chaotic whirl motions, which were detected and mitigated in real time. Postrun analysis revealed that the whirling motions occurred when the reamer entered an unstable formation. This information will be used while drilling future wells planned in this formation. 250 Downhole rpm Surface rpm Rotational speed, rpm 200 150 100 50 0 18:26 18:27 18:28 18:29 18:30 18:31 18:32 18:33 18:34 18:35 Time A postrun visualization of surface and downhole rpm was used to evaluate the effectiveness of a surface control system to minimize stick/slip. The chart was created using high-resolution (50-Hz) data recorded by the OptiDrill service. 18:36 Specifications Mechanical OptiDrill 675 OptiDrill 900 Nominal OD, in [cm] Nominal ID, in [cm] Max. OD (wearband), in [cm] Length, ft [m] Weight in air, lbm [kg] Top thread connection Bottom thread connection Connection makeup torque, ft.lbf [N.m] Connection yield torque, ft.lbf [N.m] Mechanical Operations 6.89 [17.50] 4.80 [12.19] 7.78 [19.76] 9.84 [2.99] 903 [410] 5½ FH box NC50 (41/2 IF) box 24,000 [32,539] 44,000 [59,655] 9.18 [23.31] 5.74 [14.57] 10.40 [26.41] 11.54 [3.51] 2,151 [976] 75/8 H90 box 75/8 Reg box 65,000 [88,128] 114,000 [154,563] Max. temperature, degF [degC] Max. shock (cycles), gn 302 [150] 250 302 [150] 250 Operating flow range, galUS/min Max. operating pressure, psi [MPa] Max. differential pressure, psi [MPa] Pressure drop coefficient (C)† Max. dogleg severity, °/100 ft Rotating Sliding Max. overpull (tension), lbf Max. weight on bit, lbf Max. operating torque, ft.lbf [N.m] Mud properties Max. lost circulation material Max. sand content, % 0 to 800 30,000 [206] 5,000 [34] 142,000 0 to 1,600 30,000 [206] 5,000 [34] 1,420,000 8 16 550,000 120,000,000/L2‡ 24,000 [32,539] 6 12 930,000 550,000,000/L2‡ 65,000 [88,128] No limit 1 No limit 1 † Pressure drop, psi = [(mud weight, lbm/galUS) × (flow, galUS/min)2] /C. L = the distance (ft) from the bottom of the stabilizer blades immediately above the OptiDrill service sub to the top of the stabilizer blades immediately below the OptiDrill service sub. ‡ Data Acquisition and Processing Sample rate Digital signal processor Processing time Real-time telemetry Downhole memory Low frequency High frequency Power supply 19 channels at 10,000 Hz 180 Mflops 2-s window Fully compatible with Orion II* data compression platform and the IntelliServ® Network™ 200 MB (250 h at 0.5 Hz [configurable]) 1,500 MB (140 h at 50 Hz [fixed]) Low-power tool bus (LTB) and battery (75 h) Power-saving mode Trip-in time Battery-saver time Specifications OptiDrill 675 Service Measurement Sensor Real-Time Range Weight on bit† Strain gauge Torque† Strain gauge Bending moment† Strain gauge Vibration Axial (x) Lateral (y and z) Rotational speed Accelerometer Annular and internal pressure Annular and internal temperature Continuous inclination † Weight Magnetometer and gyroscope Strain gauge PT1000 Accelerometer Real-Time Resolution ±75,000 lbf [±333,616 N] ±24,000 ft.lbf [32,540 N.m] 61,000 ft.lbf [82,705 N.m] RecordedMode Range ±93,000 lbf [±413,684 N] ±30,000 ft.lbf [40,675 N.m] 76,000 ft.lbf [103,042 N.m] 0 to 31.75 gn 0 to 63.50 gn –500 to 1,000 rpm 30,000 psi 0 to 31.75 gn 0 to 63.50 gn –500 to 1,000 rpm 30,000 psi –50 to 204 degC 0° to 180° Real-Time Processing RecordedMode Processing 2-s moving window 2-s moving window 2-s moving window Bandwidth ±3,000 lbf [±13,344 N] ±1,000 ft.lbf [±1,355 N.m] ±3,000 ft.lbf [±4,067 N.m] 10-s moving window 10-s moving window 10-s moving window 0.125 gn 0.25 gn 1 rpm 0.007 gn 0.007 gn <1 rpm 30-s rms 30-s rms 2-s window 0.2 to 150 Hz 0.2 to 150 Hz 4 Hz <1 psi ±0.25-gn rms 30-s rms ±0.25-gn rms 30-s rms ±5 rpm 30-s moving window ±30 psi 1-s avg 1 psi 2-s window 200 Hz –50 to 204 degC 1 degC 0.04 degC ±1 degC 1-s avg 2-s window 10 Hz 0° to 180° 0.1° ±0.4° 30-s avg 30-s window 10 Hz Accuracy Real-Time Processing Bandwidth ±4,000 lbf [±17,792 N] ±2,000 ft.lbf [±2,712 N.m] ±6,000 ft.lbf [±8,135 N.m] 10-s moving window 10-s moving window 10-s moving window RecordedMode Processing 2-s moving window 2-s moving window 2-s moving window 30-s rms 30-s rms 2-s window 0.2 to 150 Hz 0.2 to 150 Hz 4 Hz 2-s window 200 Hz 10 Hz 0.1° 200 Hz 200 Hz 200 Hz on bit, torque, and bending moment are compensated downhole for temperature, differential pressure, and hydrostatic pressure. OptiDrill 900 Service Measurement Sensor Real-Time Range Weight on bit† Strain gauge Torque† Strain gauge Bending moment† Strain gauge Vibration Axial (x) Lateral (y and z) Rotational speed Accelerometer Annular and internal pressure Annular and internal temperature Continuous inclination †Weight Accuracy 300 lbf [1,334 N] 100 ft.lbf [135 N.m] 120 ft.lbf [163 N.m] RecordedMode Resolution 50 lbf [222 N] 7 ft.lbf [9 N.m] 5 ft.lbf [7 N.m] Magnetometer and gyroscope Strain gauge PT1000 Accelerometer Real-Time Resolution ±125,000 lbf [±556,027 N] ±81,000 ft.lbf [109,821 N.m] 132,000 ft.lbf [178,968 N.m] RecordedMode Range ±156,000 lbf [±693,922 N] ±101,000 ft.lbf [136,938 N.m] 165,000 ft.lbf [223,710 N.m] 500 lbf [2,224 N] 320 ft.lbf [434 N.m] 260 ft.lbf [353 N.m] RecordedMode Resolution 80 lbf [355 N] 17 ft.lbf [23 N.m] 11 ft.lbf [15 N.m] 0 to 31.75 gn 0 to 63.50 gn –500 to 1,000 rpm 30,000 psi 0 to 31.75 gn 0 to 63.50 gn –500 to 1,000 rpm 30,000 psi 0.125 gn 0.25 gn 1 rpm 0.007 gn 0.007 gn <1 rpm 1 psi <1 psi ±0.25-gn rms 30-s rms ±0.25-gn rms 30-s rms ±5 rpm 30-s moving window ±30 psi 1-s avg –50 to 204 degC 0° to 180° –50 to 204 degC 1 degC 0.04 degC ±1 degC 1-s avg 2-s window 0° to 180° 0.1° ±0.4° 30-s avg 30-s window 10 Hz 0.1° on bit, torque, and bending moment are compensated downhole for temperature, differential pressure, and hydrostatic pressure. 200 Hz 200 Hz 200 Hz Find out more about the OptiDrill service at slb.com/OptiDrill Animation Watch an animation that shows how the OptiDrill service provides actionable information to mitigate drilling risk and increase efficiency. Case Study Total eliminates a planned bit run with OptiDrill service in a 17½-in section in the North Sea. Tech Report OptiDrill service improves BHA reliability to help an operator drill to section TD in one run in deepwater Gulf of Mexico. slb.com/OptiDrill *Mark of Schlumberger Other company, product, and service names are the properties of their respective owners. †Japan Oil, Gas and Metals National Corporation (JOGMEC), formerly Japan National Oil Corporation (JNOC), and Schlumberger collaborated on a research project to develop LWD technology that reduces the need for traditional chemical sources. Designed around the pulsed neutron generator (PNG), EcoScope service uses technology that resulted from this collaboration. The PNG and the comprehensive suite of measurements in a single collar are key components of the EcoScope service that deliver game-changing LWD technology. Copyright © 2015 Schlumberger. All rights reserved. 14-DR-0183