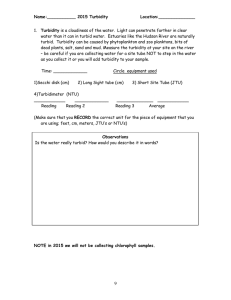

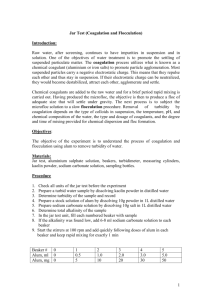

1.0 Introduction and Objective 1.1 Introduction Jar test is a small-scale test used for treatment of chemicals in water or waste water treatment. It is used to treat excessive of turbidity and algal growth in water. It is also done by varying the amount of treatment chemicals or also known as catalyst and other parameters such as pH and mixing rate of the treatment. It stimulates the process of coagulation and flocculation in real water treatment. The real purpose of this jar test is to help determining the optimum amount of certain conditions to run a full-scale water treatment process. Coagulation is a process where the destabilization of the given colloidal suspension or solution is taking place. (Bratby, n.d.) The process is achieved through the use of appropriate treatment chemicals, in which could be, aluminum or iron salts, which serves the process as the coagulant agents. Flocculation, on the other hand, is referred to the induction of destabilized particles in order to come together to make contact and hereby form large agglomerates which can be separated easier by the pull of gravitational settings. (Coagulation and Flocculation Process Fundamentals, n.d.) This process usually happens after coagulation, the water with the charged colloids is then linked into the flocculation process tank. Turbidity is a measure of the degree to which the water loses its transparency due to the presence of suspended particulates. (“Turbidity,” n.d.) As the total suspended solids in the water increases, the murkier the sample will be which in the end resulted to high turbidity. Thus, this turbidity is the main parameter to be analyse to determine purity of treated water. In this experiment, three sets of test run are done to determine the optimum dosage of coagulant, optimum dosage of flocculant and optimum pH level. From this data, the proper coagulant and flocculant dosage needed in full-scale process could determine. 1.2 Objectives To perform jar testing on the sample water To determine the optimum coagulant dosage, flocculant dosage and pH value for heavy metals removal in sample water To determine the turbidity reduction of sample water after applying optimum operating condition 2.0 Procedure 1) 1 litre of synthetic wastewater was filled up into 6 beakers. 2) The pH and turbidity of the synthetic wastewater was checked and recorded. 3) 5 of the 6 beakers was injected with alum in an increasing order, means that every beaker has more alum than the one before it, starting with 0.5 mL until 2.5 mL. 4) Then, the 5 beakers that was injected with alum, was injected again with polymer solution with the same amount into each beaker, which is 1.0 mL polymer. 5) The sixth beaker was not injected with alum and polymer as the beaker is used for comparison in the end of the experiment. 6) The pH was remained consistent for every beaker. 7) All the beakers was set into the jar test machine accordingly, and the machine was switched on while the stirrer was set to 200 rpm for the duration of 1 minute. 8) After that, the stirrer was slowed down to 20 rpm for 4 minutes. 9) Next, the stirrer was stopped and the floc was let to settle down for 10 minutes. 10) Finally, all of the beakers was checked and recorded for their turbidity and pH. 11) Step 1 to 10 was repeated with the optimum alum dosage injected (the lowest turbidity result) and constant pH for every beaker, except that the polymer solution injected was in an increasing order, starting from 0.5 mL until 2.5 mL. 12) Step 1 to 10 was repeated again, with the optimum alum and polymer solution dosage injected (the lowest turbidity result) for every beaker, except that the pH was manipulated in an increasing order, starting from 5.45 until 9.17, by injecting 1% of NaOH and 1% of H2SO4 solutions into the beakers. 3.0 Result Table 3.1: Set 1 readings for Optimum Coagulant Dosage Jar Coagulant dosage (ml) Flocculants dosage (ml) Initial pH Final pH Initial turbidity (NTU) Final turbidity (NTU) 1 2 3 4 5 6 (Control) 0.5 1.0 1.5 2.0 2.5 0.0 1.0 1.0 1.0 1.0 1.0 0.0 7.74 7.20 7.74 6.83 7.74 6.66 7.74 6.49 7.74 6.19 7.74 7.74 293.00 293.00 293.00 293.00 293.00 293.00 77.00 47.70 33.20 21.60 5.32 249.00 Table 3.2: Set 2 readings for Optimum Flocculants Dosage Jar Coagulant dosage (ml) Flocculants dosage (ml) Initial pH Final pH Initial turbidity (NTU) Final turbidity (NTU) 1 2 3 4 5 6 (Control) 2.5 2.5 2.5 2.5 2.5 0.0 0.5 1.0 1.5 2.0 2.5 0.0 7.74 6.41 7.74 6.31 7.74 6.13 7.74 6.01 7.74 5.94 7.74 6.71 293.00 293.00 293.00 293.00 293.00 293.00 6.77 3.67 3.55 4.18 3.35 281.00 Table 3.3: Set 3 readings for Optimum pH value Jar Coagulant dosage (ml) Flocculants dosage (ml) Initial pH Final pH Initial turbidity (NTU) Final turbidity (NTU) 1 2 3 4 5 6 (Control) 2.5 2.5 2.5 2.5 2.5 0.0 2.5 2.5 2.5 2.5 2.5 0.0 5.45 4.10 6.68 5.10 7.38 5.48 8.57 5.80 9.17 6.00 7.74 7.30 293 293 293 293 293 293.00 3.88 5.69 9.89 21.3 11.1 293.00 Table 3.4: Optimum Experiment Condition Coagulant Dosage (ml) Flocculants Dosage (ml) pH Value Initial Turbidity (NTU) Final Turbidity reduction (%) 4.0 2.50 2.50 5.45 293.00 3.88 98.68 % Discussion The main objective of this experiment is to determine the optimum operating conditions; the coagulant dosage, flocculant dosage and pH value, for heavy metals removal in sample water through jar test. Therefore, the percentage of turbidity reduction with optimum operating conditions can be calculated. In this experiment, four sets of jar test are conducted in order to determine the optimum coagulant dosage, flocculant dosage and pH value for heavy metals removal in sample water. The last set of jar test is to determine percentage of turbidity reduction under optimum operating conditions which are determined from the previous sets of jar test. The first and second set of jar testing varies the coagulant dosage and flocculant dosage being added to each beaker respectively. Meanwhile, the third set of jar test varies the pH of each beaker by either adding 1% H2SO4 solution to increase the acidity or 1% NaOH solution to increase the alkalinity. The fourth set of jar test is injected with the amount of optimum chemical dosage and optimum pH. However, none of the chemicals is added in Jar 6 as it sets as control in this experiment. Moreover, for each set, the initial turbidity reading is taken for each jar; Jar 1, 2, 3, 4, 5 and 6. After adding the chemicals with the assigned dosage, and applying rapid and slow mixing, the final turbidity is measured by using turbidity meter. The jar with lowest turbidity reading means that the jar has been injected with optimum dose of coagulant or flocculant, and has been set to the optimum pH. Table 3.1, 3.2 and 3.3 displays that the raw water turbidity for every jar in each set is 293.00 NTU. From Table 3.1, the turbidity reduced to 249.00, 77.00, 47.70, 33.20, 21.60 and 5.32 NTU corresponding to 0, 0.5, 1.0, 1.5, 2.0 and 2.5 mL of 1% alum doses respectively. The lowest turbidity measured is 5.32 NTU, from Jar 5 with 2.5 mL of 1% alum added. Meanwhile, from Table 3.2, the turbidity reduced to 281.00, 6.77, 3.67, 3.55, 4.18 and 3.35 NTU corresponding to 0, 0.5, 1.0, 1.5, 2.0 and 2.5 mL of 1% polymer doses respectively. The lowest turbidity reading recorded in Table 3.2 is 3.35 NTU which is also from Jar 5 with 5 mL of 1% polymer dosage. Apart from that, Table 3.3 shows that turbidity reduced to 3.88, 5.69, 9.89, 21.3, 11.1, 293.00 NTU corresponding to pH of 5.45, 6.68, 7.38, 8.57, 9.17 and 7.74 respectively. The lowest turbidity measured is 3.88 NTU which is the pH of 5.45. In overall, it is found that 2.5 mL is optimum dose for coagulant and flocculant along with pH 5.45 as the optimum pH. This shows that a higher dose is not necessarily to get higher treatment efficiency. Therefore, optimum operating condition is determined since low or over dosage may reduce the efficiency of turbidity reduction. Besides that, Klimiuk et al. (1999) states that coagulation performance increases as it goes toward more acidic. This is due to hydroxocomplexes of a positive surface charged are formed. The negative hydrocomplexes will be formed more as the hydroxyl ion concentration is high which it will provide great electrokinetic attraction (Klimiuk et al., 1999). Finally, as display from Table 3.4, the turbidity reduced to 3.38 NTU under optimum coagulant and flocculant dosage, and optimum pH value. Table 3.4 also highlights the percentage of turbidity reduction under stated optimum operating condition is 98.68 %. However, from Table 3.3, the lowest turbidity after reduction is 3.35 NTU which is lower than 3.38 NTU under optimum operating condition. This is not align with the expectation as the final turbidity under optimum operating condition is supposedly to reduce some more. Hence, there is few error that may has occur while conducting the experiment. The possible source of error may be the inaccuracy of pH readings during the last set of jar test especially to Jar 1. This is because too much 1% NaOH solution has been added until it reached pH 12, which later requires addition of 1% H2SO4 solution to set the pH below 6. Comparing to other jars, Jar 1 has slightly more chemicals being added which may become of the factors that disturb the sedimentation process. Hence, the final turbidity measured is slightly higher than what it is expected. 5.0 Conclusion and Recommendation In conclusion, the optimal alum dosage needed to be injected into the synthetic wastewater was 2.5 mL, while the lowest turbidity achieved after it settles down was 5.32 NTU. Other than that, the favourable polymer solution dosage needed to be injected into the synthetic wastewater was 2.5 mL and the lowest turbidity achieved by the wastewater was 3.35 NTU. Plus, the most suitable pH condition needed for the wastewater to achieve the lowest turbidity was 5.45 and the turbidity value was 3.88 NTU. Finally, the percentage of turbidity reduction under stated optimum operating condition was 98.68%. For recommendation, in order to minimize the chance of errors occurring, a really small syringe or a dropper must be used when injecting 1% NaOH and 1% H2SO4 into the wastewater. This is because the pH of the wastewater can be easily changed by providing even a small amount of the NaOH and H2SO4. Therefore, carefully injecting these solutions is a way to control the changes of pH value. 6.0 References Bratby, J. (n.d.). COAGULATION and FLOCCULATION With an emphasis on water and wastewater treatment. Retrieved from https://www.ircwash.org/sites/default/files/25380CO-1277.pdf Coagulation and Flocculation Process Fundamentals. (n.d.). Retrieved from https://www.mrwa.com/WaterWorksMnl/Chapter 12 Coagulation.pdf Klimiuk, E., Filipkowska, U., & Korzeniowska, A. (1999). Effects of pH and coagulant dosage on effectiveness of coagulation of reactive dyes from model wastewater by polyaluminium chloride (PAC). Polish Journal of Environmental Studies, 8, 73-80 Turbidity. (n.d.). Retrieved March 14, 2019, from https://www.lenntech.com/turbidity.htm 7.0 Appendix A. Sample of calculation i. Calculating turbidity reduction in percentage (%): Initial tubidity − Final turbidity × 100% Initial turbidity = 293 − 3.88 × 100% = 𝟗𝟖. 𝟔𝟖% 293 B. Laboratory Exercise 1) Why jar test must be done according to the condition of the real plant? Because real plants or industrial activities are the main contributor to effluent discharge into the river. Therefore, jar test needs to be done according to the condition to these effluents discharged. By using the obtained optimal coagulant dosage, flocculant dosage and pH, the best turbidity can be achieved whenever treating the wastewater, according to their conditions. 2) Name few of the coagulants. Organic Coagulants Inorganic Coagulants PolyAmines Aluminum Sulfate (Alum) PolyDADMACs Aluminium Chloride Melamine Polyaluminum Chloride (PAC) Formaldehydes Aluminum Chlorohydrate (ACH) Tannins Ferric Sulfate 3) What is DOE (Department of Environment) Standard A and Standard B of Iron according to Environmental Act of Malaysia (1974)? Iron (Fe) Standard A Standard B 1.0 mg/L 5.0 mg/L C. Jotter note