notes on spring elements

advertisement

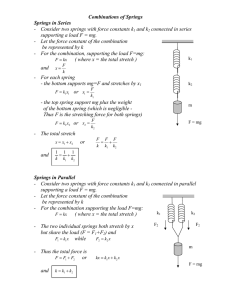

Springs ME 512 –Vibration Engineering Spring Elements • A spring is a mechanical link, which in most applications is assumed to have a negligible mass and damping. • A spring is defined as an elastic body, whose function is to distort when loaded and to recover its original shape when the load is removed. Spring Elements • The most common type of spring is the helical-coil spring used in retractable pens and pencils, staplers, and suspensions of freight trucks and other vehicles. Spring Elements • Several other types of springs can be identified in engineering applications. • Conical and Volute Springs Spring Elements • Several other types of springs can be identified in engineering applications. • Torsion Springs Spring Elements • Several other types of springs can be identified in engineering applications. • Laminated or Leaf Springs Spring Elements • In fact, any elastic or deformable body or member, can be considered as a spring. Deformation of a spring Spring Element • A spring is said to be linear if the elongation or reduction in length x is related to the applied force F as: 𝐹 = 𝑘𝑥 • Where: • F-Force • k-spring constant (force per unit length, lb/ft, N/m) • x-elongation/reduction in length Deformation of a spring Work done in deforming a spring • The work done (U) in deforming a spring is stored as strain or potential energy in the spring, and it is given by: 1 2 𝑈 = 𝑘𝑥 2 Where: 𝑈 − 𝑤𝑜𝑟𝑘 (𝑘𝐽, 𝑙𝑏 − 𝑓𝑡) 𝑙𝑏 𝑘𝑁 𝑘 − 𝑠𝑝𝑟𝑖𝑛𝑔 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡 , 𝑓𝑡 𝑚 Combination of Springs • Case 1: Springs in Parallel. 𝒌𝒆𝒒 = 𝒌𝟏 + 𝒌𝟐 + ⋯ 𝒌𝒏 Combination of Springs • Case 2: Springs in Series. 𝟏 𝟏 𝟏 𝟏 = + +⋯ 𝒌 𝒌 𝒌 𝒌 Equivalent Spring Constants (𝑘𝑒𝑞 ) • Rod under axial load 𝑘𝑒𝑞 𝐸𝐴 = 𝐿 Where: 𝐸 − 𝑚𝑜𝑑𝑢𝑙𝑢𝑠 𝑜𝑓 𝑒𝑙𝑎𝑠𝑡𝑖𝑐𝑖𝑡𝑦 𝐴 − 𝑐𝑟𝑜𝑠𝑠 𝑠𝑒𝑐𝑡𝑖𝑜𝑛𝑎𝑙 𝑎𝑟𝑒𝑎 𝐿 − 𝐿𝑒𝑛𝑔𝑡ℎ 𝑜𝑓 𝑡ℎ𝑒 𝑅𝑜𝑑 L Equivalent Spring Constants (𝑘𝑒𝑞 ) • Tapered Rod under Axial Load 𝑘𝑒𝑞 𝜋𝐸𝐷𝑑 = 4𝐿 Where: 𝐸 − 𝑚𝑜𝑑𝑢𝑙𝑢𝑠 𝑜𝑓 𝑒𝑙𝑎𝑠𝑡𝑖𝑐𝑖𝑡𝑦 𝐷, 𝑑 − 𝑒𝑛𝑑 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟𝑠 𝐿 − 𝐿𝑒𝑛𝑔𝑡ℎ 𝑜𝑓 𝑡ℎ𝑒 𝑅𝑜𝑑 Equivalent Spring Constants (𝑘𝑒𝑞 ) • Helical Spring Under Axial Load 𝑘𝑒𝑞 𝐺𝑑4 = 8𝑛𝐷3 Where: 𝐺 − 𝑠ℎ𝑒𝑎𝑟 𝑚𝑜𝑑𝑢𝑙𝑢𝑠 𝐷 − 𝑚𝑒𝑎𝑛 𝑐𝑜𝑖𝑙 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 𝑛 − 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑎𝑐𝑡𝑖𝑣𝑒 𝑐𝑜𝑖𝑙𝑠 𝑑 − 𝑤𝑖𝑟𝑒 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 Helical Spring • Deflection of Round-wire Helical Springs: 𝑇𝐿 𝜃= 𝐽𝐺 𝐹𝐷𝑚 𝑇= ; 2 𝐿 = 𝜋𝐷𝑚 𝑁𝑐 ; 4 𝜋𝐷𝑤 𝐽= 32 3𝑁 3𝑁 𝜃𝐷𝑚 8𝐹𝐷𝑚 8𝐹𝐶 𝑐 𝑐 𝛿= = = 4 2 𝐺𝐷𝑤 𝐺𝐷𝑤 Helical Springs: • End Connections for Compression Helical Springs: Helical Springs Table AT 16 – pg 589 Equivalent Spring Constants (𝑘𝑒𝑞 ) • Fixed-Fixed Beam with load at the middle 192𝐸𝐼 𝑘𝑒𝑞 = 𝐿3 • Cantilever beam with end load 3𝐸𝐼 𝑘𝑒𝑞 = 3 𝐿 • Simply supported beam with load at the middle 48𝐸𝐼 𝑘𝑒𝑞 = 3 𝐿 Where: 𝐸 − 𝑚𝑜𝑑𝑢𝑙𝑢𝑠 𝑜𝑓 𝑒𝑙𝑎𝑠𝑡𝑖𝑐𝑖𝑡𝑦 𝐼 − 𝑎𝑟𝑒𝑎 𝑚𝑜𝑚𝑒𝑛𝑡 𝑜𝑓 𝑖𝑛𝑒𝑟𝑡𝑖𝑎 𝐿 − 𝑙𝑒𝑛𝑔𝑡ℎ 𝑜𝑓 𝑡ℎ𝑒 𝑏𝑒𝑎𝑚 Table AT 1 – Properties of Sections @ pg 563 T-Beam: Determine Area Moment of Inertia (I) • Determine the location of NA (Neutral Axis) based on the bottom of the I beam: 𝐴1 𝑦1 + 𝐴2 𝑦2 𝑦= 𝐴1 + 𝐴2 • Determine the Moment of Inertia: 𝐼= 𝐼𝑖 + 𝐴𝑖 𝑦𝑖 − 𝑦 𝑏𝑖 ℎ𝑖3 𝐼𝑖 = 12 2 Equivalent Spring Constants (𝑘𝑒𝑞 ) • Hollow shaft under torsion 𝑘𝑒𝑞 𝜋𝐺 = (𝐷4 − 𝑑4 ) 32𝐿 Where: 𝐺 − 𝑠ℎ𝑒𝑎𝑟 𝑚𝑜𝑑𝑢𝑙𝑢𝑠 𝐷 − 𝑜𝑢𝑡𝑒𝑟/𝑜𝑢𝑡𝑠𝑖𝑑𝑒 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 𝑑 − 𝑖𝑛𝑛𝑒𝑟/𝑖𝑛𝑠𝑖𝑑𝑒 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 𝐿 − 𝑙𝑒𝑛𝑔𝑡ℎ 𝑜𝑓 𝑠ℎ𝑎𝑓𝑡 Example 1: • The figure below shows the suspension system of a freight truck with a parallel-spring arrangement. Find the equivalent spring constant of the suspension if each of the three helical springs is made of steel with a shear modulus 𝑮 = 𝟖𝟎𝒙𝟏𝟎𝟗 𝑵/𝒎𝟐 and has five effective turns, mean coil diameter 𝑫 = 𝟐𝟎 𝒄𝒎, and wire diameter 𝒅 = 𝟐 𝒄𝒎.