C4XL10-D240-PR

6.92 [176]

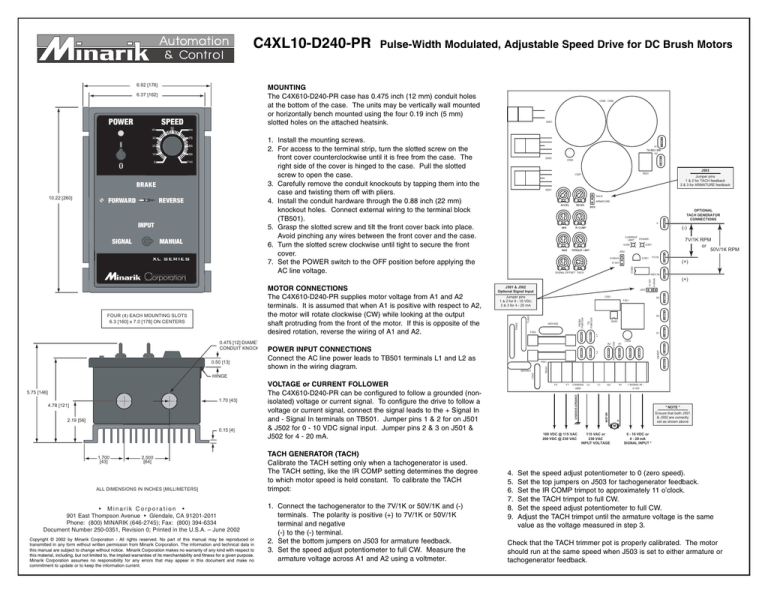

MOUNTING

The C4X610-D240-PR case has 0.475 inch (12 mm) conduit holes

at the bottom of the case. The units may be vertically wall mounted

or horizontally bench mounted using the four 0.19 inch (5 mm)

slotted holes on the attached heatsink.

6.37 [162]

SPEED

MANUAL

XL SERIES

Corporation

MOTOR CONNECTIONS

The C4X610-D240-PR supplies motor voltage from A1 and A2

terminals. It is assumed that when A1 is positive with respect to A2,

the motor will rotate clockwise (CW) while looking at the output

shaft protruding from the front of the motor. If this is opposite of the

desired rotation, reverse the wiring of A1 and A2.

FOUR (4) EACH MOUNTING SLOTS

6.3 [160] x 7.0 [178] ON CENTERS

0.475 [12] DIAMET

CONDUIT KNOCK

0.50 [13]

TACH

ARMATURE

IL502

2.19 [56]

0.15 [4]

1.700

[43]

2.500

[64]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

• Minarik Corporation •

901 East Thompson Avenue • Glendale, CA 91201-2011

Phone: (800) MINARIK (646-2745); Fax: (800) 394-6334

Document Number 250-0351, Revision 0; Printed in the U.S.A. – June 2002

Copyright © 2002 by Minarik Corporation - All rights reserved. No part of this manual may be reproduced or

transmitted in any form without written permission from Minarik Corporation. The information and technical data in

this manual are subject to change without notice. Minarik Corporation makes no warranty of any kind with respect to

this material, including, but not limited to, the implied warranties of its merchantability and fitness for a given purpose.

Minarik Corporation assumes no responsibility for any errors that may appear in this document and make no

commitment to update or to keep the information current.

(+)

0-10V

SIGNAL OFFSET TACH

J501 & J502

Optional Signal Input

100V/1K

(+)

J501

Jumper pins

1 & 2 for 0 - 10 VDC

2 & 3 for 4 - 20 mA

C501

T501

S3

S2

MOV502

F502

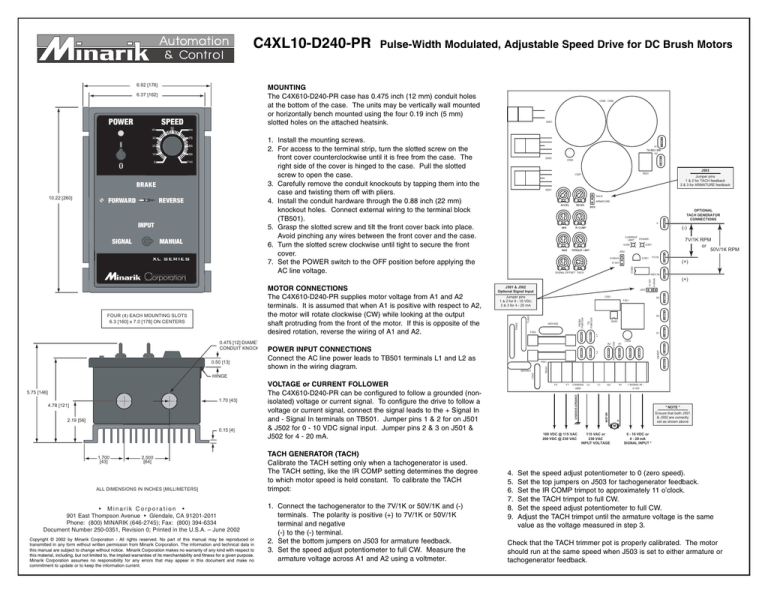

POWER INPUT CONNECTIONS

Connect the AC line power leads to TB501 terminals L1 and L2 as

shown in the wiring diagram.

Q503

S1

A1

C502

F501

MOV501

VOLTAGE or CURRENT FOLLOWER

The C4X610-D240-PR can be configured to follow a grounded (nonisolated) voltage or current signal. To configure the drive to follow a

voltage or current signal, connect the signal leads to the + Signal In

and - Signal In terminals on TB501. Jumper pins 1 & 2 for on J501

& J502 for 0 - 10 VDC signal input. Jumper pins 2 & 3 on J501 &

J502 for 4 - 20 mA.

1. Connect the tachogenerator to the 7V/1K or 50V/1K and (-)

terminals. The polarity is positive (+) to 7V/1K or 50V/1K

terminal and negative

(-) to the (-) terminal.

2. Set the bottom jumpers on J503 for armature feedback.

3. Set the speed adjust potentiometer to full CW. Measure the

armature voltage across A1 and A2 using a voltmeter.

7V/1K

IC501

4-20mA

A2

TACH GENERATOR (TACH)

Calibrate the TACH setting only when a tachogenerator is used.

The TACH setting, like the IR COMP setting determines the degree

to which motor speed is held constant. To calibrate the TACH

trimpot:

7V/1K RPM

or

50V/1K RPM

IL501

J502

F2

F1

CHASSIS

GND

CHASSIS GROUND

1.70 [43]

4.78 [121]

(-)

CURRENT

POWER

LIMIT

HINGE

5.75 [146]

OPTIONAL

TACH GENERATOR

CONNECTIONS

-

0-10V

SIGNAL

Q501

4-20mA

INPUT

Jumper pins

1 & 2 for TACH feedback

2 & 3 for ARMATURE feedback

INHIBIT

REVERSE

IC502

FORWARD

J503

R501

C507

FROM REV SW

BRAKE

10.22 [260]

A2

C505

L2

L1

A2

A1

+ SIGNAL IN 0-10V

* NOTE *

MOTOR

100

A1

Q502

TO

PWR SW

90

L1

10

1. Install the mounting screws.

2. For access to the terminal strip, turn the slotted screw on the

front cover counterclockwise until it is free from the case. The

right side of the cover is hinged to the case. Pull the slotted

screw to open the case.

3. Carefully remove the conduit knockouts by tapping them into the

case and twisting them off with pliers.

4. Install the conduit hardware through the 0.88 inch (22 mm)

knockout holes. Connect external wiring to the terminal block

(TB501).

5. Grasp the slotted screw and tilt the front cover back into place.

Avoid pinching any wires between the front cover and the case.

6. Turn the slotted screw clockwise until tight to secure the front

cover.

7. Set the POWER switch to the OFF position before applying the

AC line voltage.

L2

80

FROM

PWR SW

70

20

TB501

30

0

D501

60

TH501

50

C503

40

C504 C506

TH502

POWER

Pulse-Width Modulated, Adjustable Speed Drive for DC Brush Motors

Ensure that both J501

& J502 are correctly

set as shown above

+

M

100 VDC @ 115 VAC

200 VDC @ 230 VAC

4.

5.

6.

7.

8.

9.

115 VAC or

230 VAC

INPUT VOLTAGE

0 - 10 VDC or

4 - 20 mA

SIGNAL INPUT *

Set the speed adjust potentiometer to 0 (zero speed).

Set the top jumpers on J503 for tachogenerator feedback.

Set the IR COMP trimpot to approximately 11 o’clock.

Set the TACH trimpot to full CW.

Set the speed adjust potentiometer to full CW.

Adjust the TACH trimpot until the armature voltage is the same

value as the voltage measured in step 3.

Check that the TACH trimmer pot is properly calibrated. The motor

should run at the same speed when J503 is set to either armature or

tachogenerator feedback.