173

advertisement

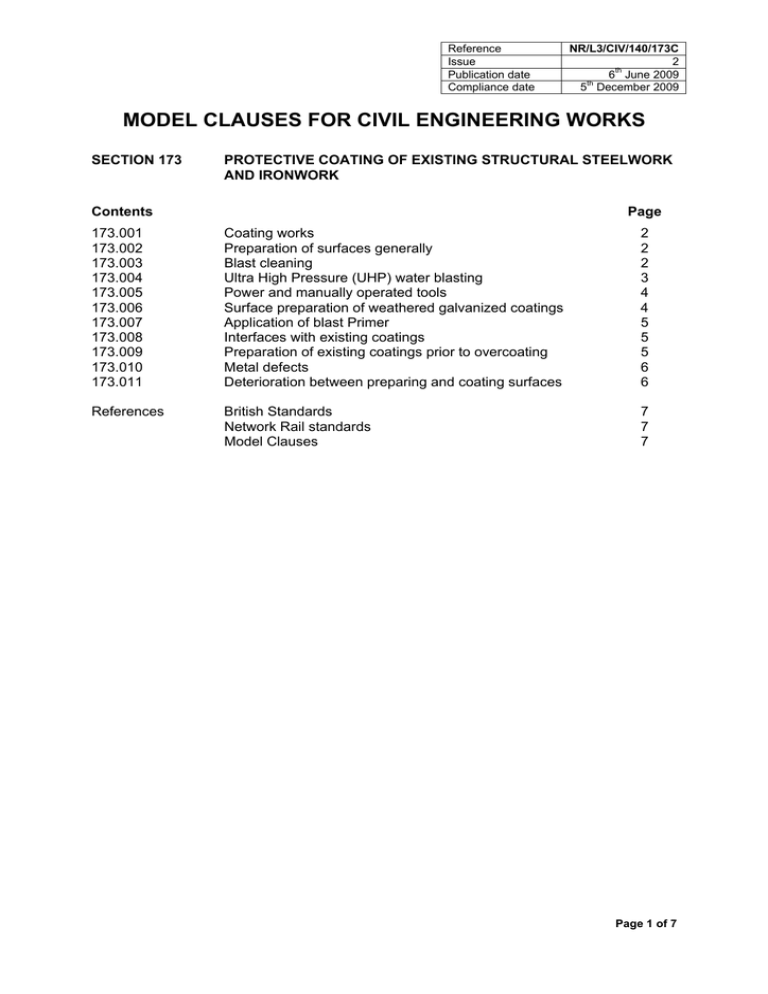

Reference Issue Publication date Compliance date NR/L3/CIV/140/173C 2 6th June 2009 5th December 2009 MODEL CLAUSES FOR CIVIL ENGINEERING WORKS SECTION 173 PROTECTIVE COATING OF EXISTING STRUCTURAL STEELWORK AND IRONWORK Contents Page 173.001 173.002 173.003 173.004 173.005 173.006 173.007 173.008 173.009 173.010 173.011 Coating works Preparation of surfaces generally Blast cleaning Ultra High Pressure (UHP) water blasting Power and manually operated tools Surface preparation of weathered galvanized coatings Application of blast Primer Interfaces with existing coatings Preparation of existing coatings prior to overcoating Metal defects Deterioration between preparing and coating surfaces 2 2 2 3 4 4 5 5 5 6 6 References British Standards Network Rail standards Model Clauses 7 7 7 Page 1 of 7 Reference Issue Publication date Compliance date SECTION 173 Coating works NR/L3/CIV/140/173C 2 6th June 2009 5th December 2009 PROTECTIVE COATING OF EXISTING STRUCTURAL STEELWORK AND IRONWORK 173.001 The protective coating system(s), coatings, sealants etc., shall be in accordance with Appendix 173/1. Areas to receive partial protective coating systems shall be as specified on the Contract Drawings. Preparation of surfaces generally 173.002 The preparation of the surfaces of existing structural steelwork and ironwork shall be in accordance with Appendix 173/1 and with the relevant Clauses of this Section of Model Clauses. Blast cleaning 173.003 Prior to blast cleaning, heavy corrosion products shall be removed and thick deposits of oil, grease and other contaminants shall be scraped off from the areas to be coated. The surfaces shall then be washed down with fresh water and, where required, an emulsifyable degreaser to remove dirt and surface contamination using a water pressure of about 2000 to 4000 psi (140 to 280 bars). The minimum surface standard shall be either; i) Sa2½ to BS EN ISO 8501-1, or ii) where a thermally sprayed metal coating is to be applied, Sa3 to BS EN ISO 8501-1. Unless otherwise agreed with the Employer’s Representative, containment shall be provided to on-site works so that spent grit, other debris and any overspray from the coating works does not contaminate the ground, adjacent buildings or water, or affect personnel or vehicles outside the work boundary. Unless otherwise agreed with the Employer’s Representative, non-metallic grit abrasives shall be used unless local blast cleaning by vacuum-blasting is employed. Except where flash blasting cleaning is used and unless otherwise agreed with the Employer’s Representative, only grit abrasives complying with the requirements of BS EN ISO 8504-2 shall be used. The abrasive shall be capable of providing a sharp, angular blast profile of 70 to 100 microns amplitude (that is, a mean peak to valley height (Rtm) of 70 to 100 microns). Flash blast cleaning shall be undertaken using a fine expendable abrasive, such as furnace slag or mineral abrasives, and a pressure no greater than 2.7 bars (40 psi) to give a surface profile of 20 to 30 microns. Page 2 of 7 Reference Issue Publication date Compliance date NR/L3/CIV/140/173C 2 6th June 2009 5th December 2009 Following blast cleaning, residual dust and debris shall be removed from blast cleaned areas using a soft dusting brush, or a vacuum cleaner, or clean dry compressed air or a combination of these. The level of residual dust shall be assessed in accordance with BS EN ISO 8502-3, residual dust levels shall not be worse than Class 1. Arrangements for leaving in place any tightly adhering scale that is exposed following the blast cleaning of existing coatings, shall be agreed with the Employer’s Representative. Ultra High Pressure (UHP) water blasting 173.004 The Employer’s Representative shall agree the quality of the fresh water to be used for UHP water blasting. All deteriorated existing coatings and corrosion products shall be removed by the use of UHP water blasting at pressures of between 36,000 and 40,000 psi (about 2,700 bars) and with a water flow of between 12 and 20 litres per minute. This shall be by use of a hand held safety lance with a rotary head, or UHP blasting equipment fitted with a vacuum shroud. Hand held safety lances shall be used on complicated structures which have little flat surface area. Care shall be taken not to damage sound coatings on surfaces adjacent to the area being treated by UHP water blasting. The Employer’s Representative shall determine if the level of light flash rusting is acceptable and tightly adherent (that is, not easily removed by wiping with a cloth). The level of flash rusting will be compared with the pictorial reference in BS EN ISO 85014 and agreement reached following consultation with the Contractor. Unless otherwise agreed with the Employer’s representative, flash rusting shall be removed by dry flash blasting. Unless otherwise agreed with the Employer’s representative, where no blast profile is present following UHP water blasting, the surfaces to be coated shall be blast cleaned. During and following UHP operations, residual water shall be removed from all areas; water that does not drain naturally shall be physically removed by suction, mopping or similar means. Water discharged into the foul water sewer or surface water drainage shall be of a quality acceptable to the Environment Agency or local Water Authority as appropriate. This might involve filtering out solids and possibly holding filtered water in tanks until the results of water quality testing are available and consent obtained for discharging the water. When UHP is the only preparation method used, the edges of sound coating adjacent to the prepared steel area shall be thoroughly abraded for a minimum width of 50 mm and the edges feathered or tapered to provide a smooth transition from the new coating to the existing sound coating. Page 3 of 7 Reference Issue Publication date Compliance date Power and manually operated tools NR/L3/CIV/140/173C 2 6th June 2009 5th December 2009 173.005 Unless otherwise instructed in Appendix 173/1 or approved by the Employer’s Representative, the use of power tools and hand cleaning to prepare a surface ready for coating shall be restricted to the repair of local areas and small defects. Where power and manually operated tools are used, the areas of exposed bare steel shall be prepared to a minimum surface standard of St3 to BS EN ISO 8501-1 with ‘bright’ steel the required finish. ‘Bright’ steel can be defined as ‘surfaces free from defects with an overall bright appearance’. Following preparation by power and manually operated tools, all residual dust shall be removed using a soft dusting brush just prior to the application the coating system. Following this the surface shall be washed down with fresh water and then allowed to dry completely: particular consideration shall be given to the location of potential corrosion traps, crevices and recesses. The initial Primer coat shall be applied within 4 hours of the completion of the surface preparation. Surface preparation of weathered galvanized coatings 173.006 Galvanized surfaces that are contaminated with any type of salt shall be washed with fresh water by water jetting at 140 bars (2000 psi): following this the surface shall be allowed to dry thoroughly prior to any further preparation and coating works. The preferred method of surface preparation is light abrasion by flash blast-cleaning. Flash blast cleaning, which may also be referred to as sweep blast-cleaning, is a technique used to roughen a surface without damaging it unduly or removing the zinc coating. Chilled iron grit shall not be used. Previously coated galvanized surfaces shall be prepared by lightly abrading soundly adhering paint with a medium grade non-metallic scouring pad. Loosely adherent paint shall be removed by scraping back to a bare zinc surface and preparing such areas as above. Galvanized surfaces which have weathered for more than 12 months and exhibit a dull grey surface shall have all surface contamination deposits removed by white spirit and the surface lightly scuffed with a medium grade non-metallic scouring pad. The light scuffing shall be applied to produce a freshly cleaned surface but not be so excessive as to remove the protective dull grey film of weathered zinc. The final preparation shall involve the washing down of the surface with fresh water and then allowing it to dry completely: particular consideration shall be given to the location of potential corrosion traps, crevices and recesses. Page 4 of 7 Reference Issue Publication date Compliance date Application of blast Primer NR/L3/CIV/140/173C 2 6th June 2009 5th December 2009 173.007 Before applying the blast Primer, residual dust and debris shall be removed from the blast-cleaned areas using a soft dusting brush, or a vacuum cleaner, or clean dry compressed air, or a combination of these. The level of residual dust shall be assessed in accordance with BS EN ISO 8502-3, and residual dust levels shall not be worse than Class 1. Unless otherwise agreed with the Employer’s Representative, the initial coat of blast Primer shall be applied to blast-cleaned steel before the prepared surface shows any deterioration and in all cases within 4 hours of the completion of the blast cleaning. Where flash blast cleaning is undertaken, the initial coat shall be applied within 1 hour of the completion of the blast cleaning. The Primer shall be applied by an airless spray process to give a complete obscuring coat at the specified dry film thickness. The blast Primer shall be protected from moisture and atmospheric contamination until the application of the next coat of the protective coating system has been completed. Interfaces with 173.008 Where corroded areas have been cleaned to bare metal or where coatings of substantial thickness has been removed from existing coatings within an area of sound coating the edges of the surrounding coating shall be feathered back and thoroughly abraded for a minimum of 50 mm back from any repair area and edges shall be feathered or tapered into the repair area to ensure a smooth transition from the repair to sound coating. Where 90% of a panel or other clearly defined area has been cleaned down to bare metal, the coatings in the remaining 10% of the area shall be removed. A smooth transition shall be provided at the junction at overlaps, interfaces and areas between new and retained existing coatings. Preparation of sound coatings prior to overcoating 173.009 Soundly adhering coatings to be overcoated shall be prepared, following the removal of any deposits of oil, grease and other contaminants, by lightly abrading with a medium grade nonmetallic scouring pad and warm water, followed by a cold water rinse and allowed to dry thoroughly. Page 5 of 7 Reference Issue Publication date Compliance date Metal defects NR/L3/CIV/140/173C 2 6th June 2009 5th December 2009 173.010 Any weld spatter, rough weld caps, sharp edges, laminations or other metal defects exposed after preparation shall be removed. The requirements of BS EN ISO 8501-3 shall be complied with when applicable. Coatings around corrosion sores shall be removed from the area surrounding each sore to exhibit at least 25 mm of ‘bright steel’. Except for narrow breaks in the paint film, where corrosion sores are separated by less than 150 mm the intervening coatings shall be removed. Pitting shall be opened out unless this is likely to reduce the thickness of the steelwork to below an acceptable minimum. In such cases, the Employer’s Representative shall be consulted to agree the acceptable minimum thickness. Adherent mill scale shall be removed using, where necessary, dry abrasive blast cleaning or pneumatic tools. Evidence of significant corrosion shall be reported to the Employer’s Representative immediately. Evidence of significant corrosion shall be reported immediately to the Employer’s Representative. Following the removal of metal defects, the treated areas shall be blast cleaned. Deterioration between preparing and coating surfaces 173.011 The surface conditions of the steelwork shall not deteriorate between the preparation of the surface and the application of the coatings. When prepared or partly coated steelwork is stored uncovered at a location classified as coastal or marine for longer than one month, or if subject to sea mist or spray, the entire surface area of the steelwork shall be rinsed with clean warm water and allowed to completely dry prior to any further coating. Page 6 of 7 Reference Issue Publication date Compliance date NR/L3/CIV/140/173C 2 6th June 2009 5th December 2009 REFERENCES This is a list of publications referred to within this Section of the Model Clauses. Amendments and additions to these are provided in Appendix 173/2. British Standards Title BS EN ISO 8501-1 Preparation of steel substrates before application of paints and related products. Visual assessment of surface cleanliness. Rust grades and preparation grades of uncoated steel substrates and of steel substrates after overall removal of previous coatings. Preparation of steel substrates before application of paints and related products. Visual assessment of surface cleanliness. Preparation grades of welds, edges and other areas with surface imperfections. Preparation of steel substrates before application of paints and related products. Visual assessment of surface cleanliness. Initial surface conditions, preparation grades and flash rust grades in connection with high-pressure water jetting. Preparation of steel substrates before application of paints and related products. Tests for the assessment of surface cleanliness. Assessment of dust on steel surfaces prepared for painting (pressure-sensitive cleaned steel tape method). Preparation of steel substrates before application of paints and related products. Surface preparation methods. Part 2: Abrasion blast-cleaning. BS EN ISO 8501-3 BS EN ISO 8501-4 BS EN ISO 8502-3 BS EN ISO 8504-2 Network Rail standards Title NR/L3/CIV/040 Specification for the use of protective coating systems Model Clauses Title 176 Protective coating systems Issue date 2007 2007 2006 2000 2000 Issue date 03/09 Issue date 06/09 Page 7 of 7