Battery Switch Schematic

advertisement

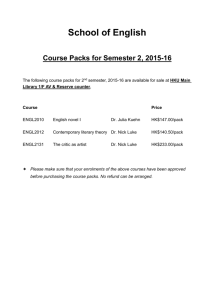

Robust, High Energy Rechargeable Power Source J.L. Radtke Four Dewalt DC9360 nanophosphate battery packs were combined in a series-parallel configuration for a robust, high energy power source. Originally intended for the prototype Neodymics Cyclemotor electric bicycle kit, this power source may be used in other applications. Output power was at least 1.4 kW, at 70 volts. Energy capacity was about 300 WHr. Recharge time was one hour, and claimed cycle life exceeds 2000. System was successfully tested over 50 cycles. Battery packs were not modified, and functionality of the internal battery maintenance system (BMS) was retained. Battery packs were charged using the original Dewalt chargers. This allowed use of the latest battery technology (nanophosphate cells from A123 Systems) without designing and building a BMS and charging system. Each battery pack was supported during discharge in its own connector. Each connector was cut from the base of a Dewalt flashlight. A resistor network was built into each connector, to set the output (speed) control of each pack. This network and the battery pack pinout are described in figure 1. Figure 2 is a schematic of the series-parallel discharge circuit. Pushing SW2 turns on packs B1 and B3, which energizes the optically coupled MOSFET relays U1 and U2. When energized, these relays enable all packs simultaneously. D1 provides indication of on/off status. Packs are turned off when SW1 is pushed. D2 is a dual schottky diode, with low forward voltage drop. These diodes form an “ORing” network to prevent a weaker pair of series connected packs from draining a stronger pair. D3 and D4 provide a similar function for the switching circuit. D5 is a reverse bias protection diode. Inductor L1 prevents the capacitive load of the motor controller from actuating the BMS protection circuitry (shutting a pack down) when the system is turned on. J. L. Radtke is an engineer with NeodymicsTM in Madison, WI USA (e-mail: jr at neodymics.com). R2 7.7 K 1 Speed Control (Unswitched Negative Terminal) 2 Negative Output (Enabled by BMS) R3 8.5 K R4 1K 3 NC 4 NC 5 Speed Control 6 Speed Control 7 Speed Control 8 NC 9 Enable 10 Positive Output Figure 1. DeWalt DC9360, 36 Volt Nanophosphate Pack Bottom view, showing external resistor network added to each connector SW1 R1 6 K, 1 W “OFF” F1 25 A D1 “ON” D2 40IRCPQ100 2 D3 1N4148 3 8 D4 1N4148 1 7 6 L1 300 uH 5 SW2 “ON” 1 + + Enable Enable 2 3 B1 DeWalt DC 9360 U1 NEC PS7141C-2A B2 DeWalt DC 9360 - 4 1 8 7 6 5 2 2 3 4 U2 NEC PS7141C-2A + Enable Enable B3 DeWalt DC 9360 - 1,3 + B4 DeWalt DC 9360 - Figure 2. Schematic of the series-parallel discharge circuit. Warning: this circuit produces dangerous voltages! D5 40IR CPQ100 Load (72 Volts)