DIP - Installation

advertisement

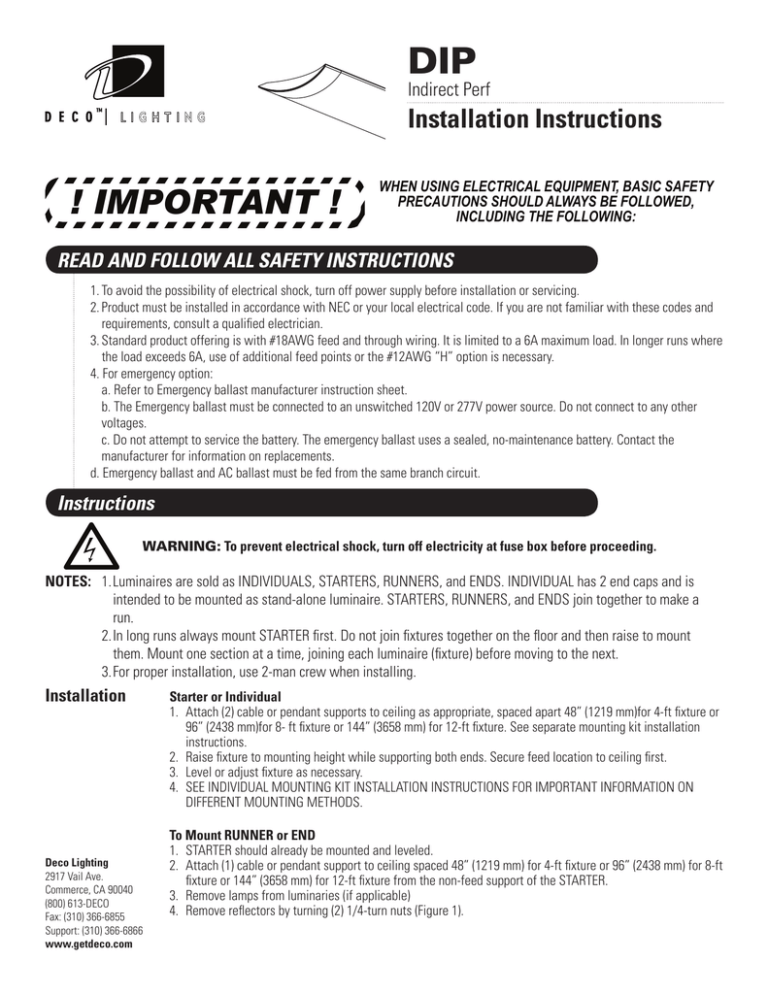

DIP Indirect Perf Installation Instructions ! IMPORTANT ! WHEN USING ELECTRICAL EQUIPMENT, BASIC SAFETY PRECAUTIONS SHOULD ALWAYS BE FOLLOWED, INCLUDING THE FOLLOWING: READ AND FOLLOW ALL SAFETY INSTRUCTIONS 1.To avoid the possibility of electrical shock, turn off power supply before installation or servicing. 2.Product must be installed in accordance with NEC or your local electrical code. If you are not familiar with these codes and requirements, consult a qualified electrician. 3.Standard product offering is with #18AWG feed and through wiring. It is limited to a 6A maximum load. In longer runs where the load exceeds 6A, use of additional feed points or the #12AWG “H” option is necessary. 4. For emergency option: a. Refer to Emergency ballast manufacturer instruction sheet. b. The Emergency ballast must be connected to an unswitched 120V or 277V power source. Do not connect to any other voltages. c. Do not attempt to service the battery. The emergency ballast uses a sealed, no-maintenance battery. Contact the manufacturer for information on replacements. d. Emergency ballast and AC ballast must be fed from the same branch circuit. Instructions WARNING: To prevent electrical shock, turn off electricity at fuse box before proceeding. NOTES: 1.Luminaires are sold as INDIVIDUALS, STARTERS, RUNNERS, and ENDS. INDIVIDUAL has 2 end caps and is intended to be mounted as stand-alone luminaire. STARTERS, RUNNERS, and ENDS join together to make a run. 2.In long runs always mount STARTER first. Do not join fixtures together on the floor and then raise to mount them. Mount one section at a time, joining each luminaire (fixture) before moving to the next. 3.For proper installation, use 2-man crew when installing. Installation Starter or Individual 1. Attach (2) cable or pendant supports to ceiling as appropriate, spaced apart 48” (1219 mm)for 4-ft fixture or 96” (2438 mm)for 8- ft fixture or 144” (3658 mm) for 12-ft fixture. See separate mounting kit installation instructions. 2. Raise fixture to mounting height while supporting both ends. Secure feed location to ceiling first. 3. Level or adjust fixture as necessary. 4. SEE INDIVIDUAL MOUNTING KIT INSTALLATION INSTRUCTIONS FOR IMPORTANT INFORMATION ON DIFFERENT MOUNTING METHODS. To Mount RUNNER or END 1. STARTER should already be mounted and leveled. Deco Lighting 2. Attach (1) cable or pendant support to ceiling spaced 48” (1219 mm) for 4-ft fixture or 96” (2438 mm) for 8-ft 2917 Vail Ave. fixture or 144” (3658 mm) for 12-ft fixture from the non-feed support of the STARTER. Commerce, CA 90040 3. Remove lamps from luminaries (if applicable) (800) 613-DECO Fax: (310) 366-6855 4. Remove reflectors by turning (2) 1/4-turn nuts (Figure 1). Support: (310) 366-6866 www.getdeco.com Instructions (cont.) INSTALLATION INSTRUCTIONS U-SERIES INDIRECT LINEAR 5. Raise fixture to mounting height while supporting both CAUTIONS ends. Make wire connections using plug-in style To avoid the possibility of electrical shock, turn off power harness. 1.While supporting end of fixture, join supplystill before installation orfar servicing. must be installed or in accordance NEC (2) or your RUNNER2.orProduct END to STARTER RUNNERwithwith 1/4-20 local electrical code. If you are not familiar with these codes hex bolts (provided) (Figure 2). and requirements, consult a qualified electrician. 3. end Standard product offering with #18AWG feed and through 6. Secure far of RUNNER or isEND to ceiling mounting It is limited to a 6A maximum load. In longer runs hardware. wiring. where the load exceeds 6A, use of additional feed points or 7. Level fixturetheas#12AWG necessary. “H” option is necessary. 4. For EM option: 8. After completing entire run, replace reflectors using 1/4a. Refer to Emergency ballast manufacturer instruction sheet. turn nuts. Insure reflectorballast is centered in the tohousing. b. The Emergency must be connected an unswitched or 277V power source. Do not connect to any other 9. Install lamps.120V voltages. c. Do not attempt to service the battery. The emergency ballast uses a sealed, no-maintenance battery. Contact the manufacturer for information on replacements. d. Emergency ballast and AC ballast must be fed from the same branch circuit. Document Drawing/Page CI297X01R4 JAD Date DCR # 08/05/08 08-390 FIGURE 1 1/4-Turn Nuts (2 Per Reflector) FIGURE 2 Mounting Hardware (Shown with Pendant Adapter) Plug-In Wire Document Dimming Ballast Options INSTALLATION INSTRUCTIONS Connectors Drawing/Page FOR OPTIMUM PERFORMANCE AND LAMP LIFE ADHERE U-SERIES INDIRECT LINEAR TO THE FOLLOWING: 1/4-20 Hex Bolts (2 Qty.) 1. Use only NOTES: GE or Osram Sylvania T5 fluorescent lamps as EMERGENCY BATTERY OPTION (EM) 1. Luminaires are sold as INDIVIDUALS, STARTERS, RUNNERS, marked on the luminaire. Connect in NOTE: Refer to the emergency ballast manufacturer instruction and ENDS. INDIVIDUAL has 2 end caps and is intended to be each ballas sheet (included) for information regarding installation, testing, and stand-alone STARTERS, 2. Burn in newmounted lampsas100 hoursluminaire. at full light levelRUNNERS, before NOTE: The maintenance. ENDS join together to make a run. dimming.2. and of a multi-w In long runs always mount STARTER first. Do not join fixtures NOTE: Standard (non-EM) luminaire feed and wire harness has 3 wires: NOTE: Stan 3. For optimumtogether lamponlife, theand luminaire should be started the floor then raise to mount them. Mount oneat Black (Hot 120V-277V), White (Common), and Green (Ground). EM (Hot 120Vsection at a time, joining each luminaire (fixture) before full light output and then dimmed to the desired luminaire has 4-wire feed and harness. ColorsTapped are as follows: ing luminai moving to the next. Black – HOT SWITCHED 120V or 277V 1/4-20 Holes are as follo the light 3.level. Starting a luminaire thewhen dimmed mode Red – HOT UNSWITCHED 120V or 277V For proper installation, use 2-manin crew installing. Black – HO will reduce lamp life. COMMON entire run, replace reflectors using 1/4-turn nuts. Red – HO 8.White After– completing FIXTURE INSTALLATION – GROUND White – CO Insure reflector is centered in the housing. 4. Use only compatible dimming controllers as specified by theGreen ballast manufacturer. or INDIVIDUAL Mounting Instructions Green – GR 9.NOTE: Install lamps. When joining together aappropriate run of luminaires(120V that do not all contain 5. DimmingSTARTER luminaires use discreet voltage ballasts. Connect these luminaires to or 277V) 1. Attach (2) cable or pendant supports to ceiling as appropriate, the -EM option, the non-EM fixtures must have 4-wire feed and/or wire spaced apartmarkings 48" (1219 mm)for 4-ft fixture or 96" (2438 mm)for 8Wiring D power supply. See on the luminaire. harness. DIMMING This is accomplished by OPTIONS ordering the(P, -R option. BALLAST L, OR C) ft fixture or 144" (3658 mm) for 12-ft fixture. See separate 1.are Mount INDIVIDUAL luminaire or entire run. See preceding Dimming luminaire has 4-wire feed and harness. Colors as follows: FOR FIXTURE OPTIMUMINSTALLATION PERFORMANCE AND LAMP LIFE ADHERE TO THE KIT mounting kit installation instructions. Comm instructions and separate MOUNTING FOLLOWING: Raise fixture to 120V mounting while supporting both ends. Black – HOT2. SWITCHED orheight 277V INSTALLATION instructions. Do not replace reflectors or install 1. Use only GE or Osram Sylvania T5 fluorescent lamps as marked Secure feed location to ceiling first. lamps at this time. Red – DIMMED HOT 2-WIRE 3. Level or adjust fixture as necessary. 2. on At the the luminaire. feed location(s), make wire connections. BRANCH in new lamps 100switched hours at (Hot) full light level before dimming. 4. SEE INDIVIDUAL MOUNTING KIT INSTALLATION INSTRUCTIONS FOR 2. Burn White – COMMON CIRCUIT a. Connect incoming to black leadwire. 3. For lamp life, unswitched the luminaire should be leadwire. started at full light IMPORTANT INFORMATION ON DIFFERENT MOUNTING METHODS. b. optimum Connect incoming (Hot) to red Green – GROUND Hot output and then dimmed to the desired the light level. Starting a To Mount RUNNER or END: 1. STARTER should already be mounted and leveled. 2. Attach (1) cable or pendant support to ceiling spaced 48" (1219 mm) for 4-ft fixture or 96" (2438 mm) for 8-ft fixture or 144" (3658 mm) for 12-ft fixture from the non-feed support of the STARTER. 3. Remove lamps from luminaries (if applicable) 4. Remove reflectors by turning (2) 1/4-turn nuts (Figure 1). 5. Raise fixture to mounting height while supporting both ends. Make wire connections using plug-in style harness. While still supporting far end of fixture, join RUNNER or END to STARTER or RUNNER with (2) 1/4-20 hex bolts (provided) (Figure 2). 6. Secure far end of RUNNER or END to ceiling mounting hardware. 7. Level fixture as necessary. NOTE: Both the switched and unswitched lead must be fed from luminaire the dimmed mode reduce lamp life. a 120V or the sameinbranch circuit and bewill connected to either 4. Use only compatible dimming controllers by the 277V power source (as appropriate – seeas EMspecified fixture voltage ballast suffix).manufacturer. Do not connect to any other voltages. 5. Dimming luminaires usecommon discreet(Neutral) voltage ballasts. c. Connect incoming to white Connect leadwire.these luminaires to incoming appropriate (120Vtoorgreen 277V) power supply. See d. Connect ground leadwire. luminaire. 3. markings For each on EMthe fixture, remove ballast channel wire access cover Emergency Battery Option NOTE: Refer to the emergency ballast manufacturer instruction sheet (included) for information regarding installation, testing, and maintenance. NOTE: Standard (non-EM) luminaire feed and wire harness has 3(Figure wires: Black (Hot 120V-277V), 3), by loosening knurled nut. LUTRON HI-LUME AND ECO-10 DIMMING White (Common), and Green (Ground). EM luminaire has 4-wire and Colors are asandfollows: 4. feed Join the twoharness. ends of the battery connector remove the EM Lutron Dimming luminaire has 4-wire feed and harness. Colors are as Tag. Black – HOT SWITCHED 120V or 277V follows: 5. Replace ballast channel wire access cover and tighten knurled nut. Black – HOT SWITCHED 120V or 277V Red – HOT UNSWITCHED 120V or 277V 6. Replace reflectors using 1/4-turn nuts. Red – DIMMED HOT 7. Install lamps. White – COMMON White – COMMON 8. Supply A.C. power to the INDIVIDUAL luminaire or entire run. Green – GROUND Green – GROUND 1. Mount INDIVIDUAL luminaire or entire run. See preceding FIGURE 3 FIXTURE INSTALLATION instructions and separate Ballast Channel Wire LED Test Access Cover Light/Switch MOUNTING KIT INSTALLATION instructions. Do not replace reflectors or install lamps at this time. 2. At the feed location(s), make wire connections. a. Connect incoming switched (Hot) to black leadwire. b. Connect incoming unswitched (Hot) to red leadwire. NOTE: Both the switched and unswitched lead must EM Tag be fed from the same branch circuit and be connected to either a 120V or 277V power source (as appropriate see EM fixture voltage suffix). Do not connect to any Knurled Nut other voltages. c. Connect incoming common (Neutral) to white leadwire. d. Connect incoming ground to green leadwire. 3. For each EM fixture, remove ballast channel wire access cover (Figure 3), by loosening knurled nut. Circu MULTI-WIRE BRANCH CIRCUIT Standard • 2-lamp • 3-lamp • 1-lamp • 2-lamp • 3-lamp • 1-lamp • 2-lamp • 3-lamp DUAL SWITCHING OPTION EMERGENCY BATTERY OPTION (EM) Instructions (cont.) NOTE: Refer to the emergency ballast manufacturer instruction sheet (included) for information regarding installation, testing, and maintenance. NOTE: Standard (non-EM) luminaire feed and wire harness has 3 wires: Connect incoming power according to the wiring diagram. This allows each ballast to be switched on and off separately. NOTE: The incoming hot lines must be on the same phase or be part of a multi-wire branch circuit. NOTE: Standard luminaire feed and wire harness has 3 wires: Black (Hot 120V-277V), White (Common), and Green (Ground). Dual switching luminaire has 4-wire feed and harness. Colors are as follows: Black – HOT (Ballast 1) Red – HOT (Ballast 2) White – COMMON Green – GROUND 120V-277V), (Common), and Greenand (Ground). EM the EM Tag. 4. Join theBlack two(Hot ends of theWhite battery connector remove luminaire has 4-wire feed and harness. Colors are as follows: 5. ReplaceBlack ballast access – HOTchannel SWITCHEDwire 120V or 277V cover and tighten knurled nut. – HOT UNSWITCHED 120V or 277V 6. ReplaceRed reflectors using 1/4-turn nuts. White – COMMON 7. Install lamps. Green – GROUND 8. Supply A.C. power to the INDIVIDUAL luminaire or entire run. NOTE: When joining together a run of luminaires that do not all contain harness. This is accomplished by ordering the -R option. Dual Switching Option 1. Mount INDIVIDUAL luminaire or entire run. See preceding Connect incoming power according to the diagram.KIT FIXTURE INSTALLATION instructions and wiring separate MOUNTING INSTALLATION instructions. Do not replace reflectors or install This allows each ballast to be switched on and off lamps at this time. separately. 2. At the feed location(s), make wire connections. a. Connecthot incoming to black NOTE: The incoming linesswitched must(Hot) be on theleadwire. same phase b. Connect incoming unswitched (Hot) to red leadwire. or be part of aNOTE: multi-wire branchandcircuit. Both the switched unswitched lead must be fed from the same branch circuit andand be connected to either a 120V NOTE: Standard luminaire feed wire harness has or3 277V power source (as appropriate – see EM fixture voltage wires: Black (Hot 120V-277V), White (Common), and Green suffix). Do not connect to any other voltages. Connect incoming common has (Neutral) to whitefeed leadwire. (Ground). Dualc.switching luminaire 4-wire and d. Connect incoming ground to green leadwire. harness. Colors follows: 3. Forare each as EM fixture, remove ballast channel wire access cover (Figure 3), 1) by loosening knurled nut. Black – HOT (Ballast 4. Join the two ends of the battery connector and remove the EM Red – HOT (Ballast 2) Tag. 5. Replace ballast channel wire access cover and tighten knurled nut. White – COMMON 6. Replace reflectors using 1/4-turn nuts. Green – GROUND 7. Install lamps. the -EM option, the non-EM fixtures must have 4-wire feed and/or wire Wiring Diagrams (D-Option) Common 2-WIRE BRANCH CIRCUIT Black Ballast 1 Ballast 2 Switch Hot Red Switch Fuse Circuit Breaker Switch Hot Phase 1 MULTI-WIRE BRANCH CIRCUIT Black Ballast 1 Fuse Circuit Breaker Common White Ballast 2 Hot Phase 2 8. Supply A.C. power to the INDIVIDUAL luminaire or entire run. Standard Lamp Configurations (Dual Switching Option) FIGURE 3 • 2-lamp 4ft: Ballast 1 – Outside lamp (1) Channel Wire LED Test Ballast 2Light/Switch – Outside lampBallast (1) Access Cover • 3-lamp 4ft: Ballast 1 – Outside lamps (2) Ballast 2 – Inside lamp (1) • 1-lamp 8ft: Ballast 1 – Start side lamp (1) Ballast 2 – End side lamp (1) • 2-lamp 8ft: Ballast 1 – Outside lamps (2) Ballast 2 – Outside lamps (2) EM Tag • 3-lamp 8ft: Ballast 1 – Outside lamps (4) Ballast 2 – Inside lamps (2) • 1-lamp 12ft: Ballast 1 – Start side lamp (2) Knurled Nut Ballast 2 – End side lamp (1) • 2-lamp 12ft: Ballast 1 – Outside lamps (3) Ballast 2 – Outside lamps (3) • 3-lamp 12ft: Ballast 1 – Outside lamps (6) Ballast 2 – Inside lamps (3) White Red Switch Fuse Circuit Breaker Standard Lamp Configurations (D-Option) INSTALLATION INSTRUCTIONS • 2-lamp 4ft: • • • • • Ballast 1 – Outside lamp (1) U-SERIES INDIRECT LINEAR Ballast 2 – Outside lamp (1) KIT 3-lamp 4ft: Ballast 1 –CABLE Outside MOUNTING lamps (2) Ballast 2 – Inside lamp (1) 1-lamp 8ft: Ballast 1 – Start side lamp (1) CAUTIONS Ballast 2 – End side lamp (1) 1. 8ft: To avoid theINSTALLATION possibility electrical INSTRUCTIONS 2-lamp Ballast 1 – Outsideoflamps (2) shock, turn off power supplyBallast before2installation or servicing. – Outside lamps (2) LINEAR U-SERIES INDIRECT 2. 8ft: Product must1be installedlamps in accordance with NEC or your 3-lamp Ballast –CABLE Outside (4) MOUNTING KIT local electrical you are Ballast 2 –code. InsideIf lamps (2)not familiar with these codes and requirements, consult a qualified 1-lamp 12ft: Ballast 1 – Start side lamp (2) electrician. CAUTIONS Ballast 2 – End side lamp (1) • 2-lamp Ballast 1 – Outside (3) shock, turn off power 1. 12ft: To avoid the possibility oflamps electrical FEED LOCATION INSTALLATION – Outside lamps (3) supplyBallast before2installation or servicing. Below Ceiling Junction Box — T-Bar Mount • 3-lamp Ballast – Outside (6) 2. 12ft: Product must1be installedlamps in accordance with NEC or your 1. Break T-Bar Clip into 2 sides. Ballast 2 –code. InsideIf lamps (3)not familiar with these codes local electrical you are 2. Insert square-neck bolt into Side 1 of T-Bar Clip. and requirements, consult a qualified electrician. 3. Place Side 1 of the T-Bar Clip around T-bar. Snap Side 2 into place, securing the clip and bolt to the T-bar (Figure 1). Mounting Below Ceiling Junction Box — T-Bar Mount 1. Break T-Bar Clip into 2 sides. 2. Insert square-neck bolt into Side 1 of T-Bar Clip. 3. Place Side 1 of the T-Bar Clip around T-bar. Snap Side 2 into place, securing the clip and bolt to the T-bar (Figure 1). 4. Secure T-Bar Clip to the building structure above with customer supplied wire or other appropriate means. 5. Secure Cover Plate to T-Bar Clip with 1/4-20 keps nut. For drop ceiling tile use plastic spacer to offset Cover Plate. When installing Cover Plate, take care to orient ground wire down and conduit knockouts facing up 90° from T-bar (Figure 2). 6. Remove one of the knockouts on the Cover Plate. 7. Cut clearance hole in the ceiling tile to match the hole in the Cover Plate. Make certain that the hole is large enough to clear the power supply connector (customer supplied). FIGURE 1 FEED LOCATION INSTALLATION Below Ceiling Junction Box — T-Bar Mount T-Bar T-Bar Clip T-Bar Clip 1. Break T-Bar Clip into 2 sides. (Side (Side 2) 1) 2. Insert square-neck bolt into Side 1 of T-Bar Clip. 3. Place Side 1 of the T-Bar Clip around T-bar. Snap Side 2 into place, securing the clip and bolt to the T-bar (Figure 1). Document Drawing/P 6. R Document Drawing/P 7. C P s 8. In 9. B B 6. 10. R T 7. C b 11. P L sC 8. In 9. B FIGU B 10. T b 11. L C FIGU FIGURE 1 T-Bar Clip (Side 1) T-Bar T-Bar Clip (Side 2) 1/4-20 x 1" Square Neck Bolt 4. Secure T-Bar Clip to the building structure above with customer supplied wire or other appropriate means. 5. Secure Cover Plate to T-Bar Clip with 1/4-20 keps nut. For drop ceiling tile1/4-20 usexplastic spacer to offset Cover Plate. When installing 1" Square Neck Bolt Cover Plate, take care to orient ground wire down and conduit knockouts facing up 90° from T-bar (Figure 2). 12. T 13. T 14. S 4. Secure FIGURE 2 T-Bar Clip to the building structure above with customer T-Bar Clip supplied wire or other appropriate means. 5. Secure Cover Plate to T-Bar Clip with 1/4-20 keps nut. For drop ceiling tile use plastic spacer to offset Cover Plate. When installing Cover Plate, take care to orient ground wire down and conduit knockouts facing up 90° from T-bar (Figure 2).Spacer Drop Ceiling 12. T 13. T 14. S (If Necessary) FIGURE 2 T-Bar Clip Cover Plate – Remove One Knockout 1/4-20 Keps Nut Drop Ceiling Spacer (If Necessary) 2. Product must be installed in accordance with NEC or your local electrical code. If you are not familiar with these codes and requirements, consult a qualified electrician. Mounting (cont.) FEED LOCATION INSTALLATION Below Ceiling Junction Box — T-Bar Mount 1. Break T-Bar Clip into 2 sides. 2. Insert square-neck bolt into Side 1 of T-Bar Clip. 3. Place Side 1 of the T-Bar Clip around T-bar. Snap Side 2 into place, securing the clip and bolt to the T-bar (Figure 1). 8. Install ceiling tile. 9. Bring electrical power using customer supplied flexible conduit, FIGURE BX, or1 Romex and secure to the Cover Plate. 10.Thread 1/4-20 hex nut onto square neck bolt about half way up the bolt. 11.Loosen Canopy Collar and slide down cable. Slide Canopy over Coupler (Figure 3). 12.Tighten Coupler onto square neck bolt against 1/4-20 hex nut. 13.Trim Cable and Cord to desired mounting height plus 8 in. 14.Strip cord back tobuilding revealstructure 6 in of leadwire. 4. sheathing Secure T-Bar Clip to the above with customer supplied wire or otherheight appropriate means. 15.Raise fixture to mounting and secure to cable. 5. Secure Cover Plate to T-Bar Clip with 1/4-20 keps nut. For drop See a. forsingle cable and b. Plate. for adjustable ceilingadjustable tile use plastic spacer to offset Cover When installing Cover Plate, take care to orient ground wire down and conduit Y-cable. knockouts facing up 90° from T-bar (Figure 2). a. For single adjustable cable, loosen knurled Safety Nut. 2 on Glider and feed Cable into Glider Depress FIGURE plunger (Figure 4). b. For adjustable Y-cable, Place Molded-T Toggles into keyslots on housing. Plug keyholes with Push Rivets. Loosen Safety Cap. Depress plunger on Y-Glider and feed Fixture Cable into Y-Glider. Level fixture by tightening Thumb Screw and securing Y-cable in position (Figure 5). 16.Adjust fixture to desired mounting height. 17.Tighten Safety Nut or Safety Cap. 18.Feed cord through side hole in Canopy. 19.Make wire connections. 20.Slide Canopy up Cable and Cord. 21.Secure Cord with Cord Bushing (provided). 22.Secure Canopy with Collar. T-Bar Clip (Side 1) T-Bar supply connector (customer supplied). 8. Install ceiling tile. 9. Bring electrical power using customer supplied flexible conduit, BX, or Romex and secure to the Cover Plate. 10. Thread 1/4-20 hex nut onto square neck bolt about half way up the bolt. 11. Loosen Canopy Collar and slide down cable. Slide Canopy over Coupler (Figure 3). FIGURE 3 T-Bar Clip (Side 2) 1/4-20 x 1" Square Neck Bolt INSTALLATION INSTRUCTIONS U-SERIES INDIRECT LINEAR 1/4 -20 Hex Nut CABLE MOUNTING KIT Ground Document Drawing/Page Coupler 15. Raise fixtureWire to mounting height and secure to cable. See a. for INSTALLATION INSTRUCTIONS single adjustable cable and b. for adjustable Y-cable. Canopy a. For single adjustable loosen knurled Safety Nut. Depress U-SERIEScable, INDIRECT LINEAR plunger on Glider and feed Cable into KIT Glider (Figure 4). CABLE MOUNTING Document Drawing/Page Collar 15. Raise4 fixture to mounting height and secure to cable. See a. for FIGURE single adjustable Cable cable and b. for adjustable SafetyY-cable. Nut Cord Glider Safety Nut. Depress a. For singlePower adjustable cable, loosen knurled plunger on Glider feedneck Cable into Glider1/4-20 (Figurehex 4).nut. 12. Tighten Coupler onto and square bolt against 13. Trim Cable and Cord to desired mounting height plus 8 in. FIGURE 14. Strip4cord sheathing back to reveal 6 in of leadwire. Cable Safety Nut Power Cord Glider T-Bar Clip Drop Ceiling Spacer (If Necessary) Cover Plate – Remove One Knockout 1/4-20 Keps Nut b. For adjustable Y-cable, Place Molded-T Toggles into keyslots on housing. Plug keyholes with Push Rivets. Loosen Safety Cap. Depress plunger on Y-Glider and feed Fixture Cable into Y-Glider. Level fixture by tightening Thumb Screw and securing Y-cable in position (Figure 5). b. For adjustable Y-cable, Place Molded-T Toggles into keyslots FIGUREon 5 housing. Plug keyholes with Push Rivets. Loosen Safety Safetyfeed Cap Fixture Cable into Fixture Cable on Y-Glider and Cap. Depress plunger Y-Cable Power Cord Y-Glider. Level fixture by tighteningY-Glider Thumb Screw and securing Y-cable in position (Figure 5). Thumb Screw Keyslot FIGURE 5 Fixture Cable Safety Cap Power Cord Y-Glider Y-Cable Thumb Screw T-Bar Mou 1. Insert sq 2. Place Sid securing 3. Secure T T-Bar Mou supplied 1. Install Insert sq 4. ce 2. Loosen Place Sid 5. C securing Coupler. 3. Tighten Secure TC 6. supplied 7. Trim Cab 4. Raise Install Fix ce 8. 5. Secure Loosen CC 9. Coupler.fix 10. Adjust 6. Tighten S C 11. 7. Slide Trim Cab 12. Can 8. Secure Raise Fix 13. C 9. Secure C Fixed Ceilfix 10. Adjust 1. 11. Secure Tighten CS 2. cu 12. Using Slide Can AdapterC 13. Secure 3. Raise fix Fixed Ceil Mounting 1. Secure C 2. Using6 cu FIGURE Adapter 3. Raise fix Mounting Keyslot Push Rivets (2 Qty.) 16. Adjust fixture to desired mounting height. 17. Tighten Safety Nut or Safety Cap. 18. Feed cord through side hole in Canopy. Push Rivets 19. Make wire connections. (2 Qty.) 20. Slide Canopy up Cable and Cord. 16. Secure Adjust fixture to desired mounting height. 21. Cord with Cord Bushing (provided). 17. Secure Tighten Canopy Safety Nut Safety Cap. 22. withorCollar. 18. Feed cord through side hole in Canopy. Below Junction Box — Rigid Ceiling Mount 19. MakeCeiling wire connections. 1. one of conduit knockouts from the Cover Plate. 20. Remove Slide Canopy upthe Cable and Cord. 2. through the (provided). ceiling and attach to the Cover 21. Bring Securepower Cord supply with Cord Bushing 22. Plate. Secure Canopy with Collar. 3. Securely mount Crossbar and Cover Plate to the ceiling using Below Ceiling Junction Box — Rigid Ceiling Mount customer supplied bolts or screws. 1. Follow Removeabove one of the conduit knockouts from the Cover Plate. 4. steps for BELOW CEILING JUNCTION BOX — T-BAR 2. MOUNT Bring power supply through the ceiling and attach to the Cover numbers 10-22. Plate. Standard Box Mount 3. SecurelyJunction mount Crossbar and Cover Plate to the ceiling using 1. Raise fixture to mounting Screw Crossbar to recessed customer supplied bolts orheight. screws. box using supplied bolts or screws. 4. junction Follow above steps customer for BELOW CEILING JUNCTION BOX — T-BAR 2. Follow steps10-22. for BELOW CEILING JUNCTION BOX — T-BAR MOUNTabove numbers MOUNT numbers 10-22. Below Ceiling Junction Box — Rigid Ceiling Mount 1. Remove one of the conduit knockouts from the Cover Plate. 2. Bring power supply through the ceiling and attach to the Cover Plate. 3. Securely mount Crossbar and Cover Plate to the ceiling using customer supplied bolts or screws. 4. Follow above steps for BELOW CEILING JUNCTION BOX — T-BAR MOUNT numbers 10-22. Standard Junction Box Mount 1. Raise fixture to mounting height. Screw Crossbar to recessed junction box using customer supplied bolts or screws. 2. Follow above steps for BELOW CEILING JUNCTION BOX — T-BAR MOUNT numbers 10-22. NON-FEED LOCATION INSTALLATION T-Bar Mount 1. Insert square-neck bolt into Side 1 of T-Bar Clip. Standard Junction Box Mount 2. Place Side 1 of the T-Bar Clip around T-bar. Snap Side 2 into1. place, securing theheight. clip Screw and bolt to tothe T-bar Raise fixture to mounting Crossbar recessed junction box using customer supplied bolts or screws. (Figure 1). 2. Follow above steps for BELOW CEILING JUNCTION BOX — T-BAR 3. Secure T-Bar Clip to the building structure above with customer supplied MOUNT numbers wire 10-22. or other appropriate means. 4. Install ceiling tile. If necessary, notch tile to fit over T-bar clip. 5. Loosen Canopy Collar and slide down cable. Slide Canopy over Coupler. 6. Tighten Coupler onto square neck bolt. 7. Trim Cable to desired mounting height plus 8 in. 8. Raise Fixture to mounting height. 9. Secure Cable Assembly to fixture. See Figures 4 and 5. 10.Adjust fixture to desired mounting height. 11.Tighten Safety Nut or Safety Cap. FIGURE 6 b. For adjustable Y-cable, Place Molded-T Toggles into keyslots on housing. Plug keyholes with Push Rivets. Loosen Safety Cap. Depress plunger on Y-Glider and feed Fixture Cable into Y-Glider. Level fixture by tightening Thumb Screw and securing Y-cable in position (Figure 5). Mounting (cont.) FIGUREup 5 Cable. 12.Slide Canopy 13.Secure Canopy with Collar. Fixture Cable Safety Cap Power Cord Y-Glider Y-Cable Thumb Screw Fixed Ceiling Mount 1. Secure Cable Assembly to fixture. See Figures 4 and 5. 2. Using customer supplied bolt or screw, screw Ceiling Mounting Adapter into ceiling (Figure 6). 3. Raise fixture to mounting height. Tighten Coupler into Ceiling Mounting Adapter. 16. Adjust fixture to desired mounting height. 8. 9. 10. 11. 12. 13. Raise Fixture to mounting height. Secure Cable Assembly to fixture. See Figures 4 and 5. Adjust fixture to desired mounting height. Tighten Safety Nut or Safety Cap. Slide Canopy up Cable. Secure Canopy with Collar. Fixed Ceiling Mount 1. Secure Cable Assembly to fixture. See Figures 4 and 5. 2. Using customer supplied bolt or screw, screw Ceiling Mounting Adapter into ceiling (Figure 6). 3. Raise fixture to mounting height. Tighten Coupler into Ceiling Mounting Adapter. Keyslot FIGURE 6 Screw – #10 or #8 (Customer Supplied) Push Rivets (2 Qty.) 17. 18. 19. 20. 21. 22. Tighten Safety Nut or Safety Cap. Feed cord through side hole in Canopy. Make wire connections. Slide Canopy up Cable and Cord. Secure Cord with Cord Bushing (provided). Secure Canopy with Collar. Below Ceiling Junction Box — Rigid Ceiling Mount 1. Remove one of the conduit knockouts from the Cover Plate. 2. Bring power supply through the ceiling and attach to the Cover Plate. 3. Securely mount Crossbar and Cover Plate to the ceiling using customer supplied bolts or screws. 4. Follow above steps for BELOW CEILING JUNCTION BOX — T-BAR MOUNT numbers 10-22. Standard Junction Box Mount 1. Raise fixture to mounting height. Screw Crossbar to recessed junction box using customer supplied bolts or screws. 2. Follow above steps for BELOW CEILING JUNCTION BOX — T-BAR MOUNT numbers 10-22. Ceiling Mounting Adapter Section View