Journal of The Electrochemical Society, 160 (3) F309-F311 (2013)

F309

0013-4651/2013/160(3)/F309/3/$31.00 © The Electrochemical Society

Scaling with Ohm’s Law; Wired vs. Wireless

Photoelectrochemical Cells

John Newman∗,z

Research Triangle Solar Fuels Institute, Research Triangle Park, North Carolina 27709, USA

Ohm’s law is used to evaluate the scalability of wired and wireless photoelectrochemical cells. Simple but comparable geometries

show clearly that the wired device is far superior to wireless devices.

© 2013 The Electrochemical Society. [DOI: 10.1149/2.020304jes] All rights reserved.

Manuscript submitted December 11, 2012; revised manuscript received January 16, 2013. Published January 25, 2013.

Photoelectrochemical cells (PECs) have been under investigation

for many years, perhaps as long as photovoltaic arrays. While the

latter have decreased in capital cost by a factor of 59 and their life

has been extended from 2 to 25 years during the period from 1974

to 2008,1 PECs are still hampered by a short life, and their cost is

not proved through significant production. Nevertheless, PECs offer

the possibility and promise of producing directly hydrogen and other

fuels or fuel precursors.

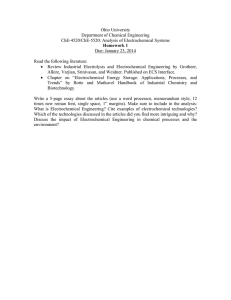

One stated advantage of PECs is that they could be wireless, or

at least self-contained, so that sunlight and water produce hydrogen

and oxygen, the former being more storable than electricity. It has

been fashionable to speak of a wireless device as desirable or even

essential.2–4 Figure 1a depicts a wireless device with a compact unit,

perhaps a triple-junction photovoltaic cell, providing a direct connection between the anode and the cathode, while the ionic conductor

takes a much longer path. In the wired device (Figure 1b), an electronic

conductor completes the circuit between the anode and the cathode

by a relatively long path, but with the ionic path being as short as

possible. The device has been drawn to facilitate comparison.

Since the design of practical electrochemical cells has traditionally

emphasized the placement of the electrodes only a short distance apart,

it is appropriate to explore or reiterate the issues involved in ohmic

drop in the ionically and electronically conducting parts of the circuit.

The ionic conductor may have a conductivity of 0.2 S/cm, perhaps

as high as 0.8 S/cm, like sulfuric acid in a lead-acid battery. Copper,

an electronic conductor, has a conductivity of 6 × 105 S/cm, and

even lead is 4.6 × 104 S/cm. Indium tin oxide has a conductivity

of about 324 S/cm. Thus, to keep ohmic losses small, the designer

generally seeks the shortest, most direct ionic pathway between the

two electrodes.

To build a large-scale device, consideration of the ohmic drop

should be important. Recent papers have addressed the design. Spurgeon and Lewis5 measured series losses in cells with thin polymer

electrolytes that did not contain liquid water because they electrolyzed

water from the vapor phase. This is one way to avoid series resistance

problems in a PEC, but under the definitions used here, this cell is

wired, just like a fuel cell. Another way to reduce series resistance

is to perforate cells of the type described by Reece et al.2 and Licht

et al.3 with a grid of holes, which can be filled with liquid or polymer

electrolyte. 30 years earlier, Orazem and Newman6,7 described three

device architectures for optimizing the performance of PECs and utilized perforated electrodes in two out of three of them. Hernandez et

al.8 have measured series resistance and overpotentials due to concentration variations in solution. Haussener et al.9 studied modeling, simulation, and design criteria for photoelectrochemical water-splitting

systems. They found that “small electrode dimensions (mm to cm

range) and large electrolyte heights were required to produce small

overall resistive losses in the system.”

Spurgeon et al.10 proposed a system with small bipolar electrodes

sticking through an ion exchange membrane. The smallness of this

system avoids ohmic problems. However, this design is not proved

∗

z

Electrochemical Society Honorary Member.

E-mail: newman@newman.cchem.berkeley.edu

out in terms of the economics of generating and collecting hydrogen

on the scale of a primary energy supplier.

Analysis

An electrochemical cell generally contains ionically conducting

and electronically conducting elements which, together with any external elements, should form a complete circuit. One can construct a

triple-junction photovoltaic device that provides enough electric potential to split water into hydrogen and oxygen. 1.229 V is needed,11

plus more potential to overcome various losses, such as ohmic drop

and kinetic and concentration overpotentials. The hydrogen should

preferably be used to produce a liquid fuel, such as methanol, gasoline, or diesel fuel.12

Let the normal current density on the electrodes be in , and let us

take this to be uniform. The current flowing parallel to the electrodes

is the integral of the normal current and works out to be

ix =

in x

,

h

[1]

where x is the distance along the electrodes from the upper end and

h is the distance available for the current flow in this direction. This

distance is in the electrolyte in Figure 1a and in the electronically

conducting current collector in Figure 1b.

The ohmic drop along the electrodes is a second integral, this time

of Ohm’s law:

=

in x 2

.

κh 2

[2]

The main contribution comes from the flow of current over the distance

L. Thus, the potential variation along one side of Figure 1 is in L2 /2κh;

the variation along both sides is in L2 /κh. The current density across

the bottom, from Equation 1 with x = L and h replaced by h2 , is

in L/h2 , and the corresponding ohmic potential drop is in LL2 /κh2 . The

total potential variation in the electrolyte thus is

in L L

L2

=

+

,

[3]

κ

h

h2

where κ is the conductivity of the medium and L2 and h2 apply to

the current path around the end at the bottom. This is the potential

variation in the electrolyte (or the metal in the case of Figure 1b) from

the top of the left side to the top of the right side.

Equation 3 shows how cell size can scale with conductivity. Often

the electrochemistry or the desired process dictates the magnitude

of the current density and the magnitude of the tolerable potential

variation along an electrode. Equation 3 then shows that lengths can

be proportional to the square root of the conductivity of the critical

material, which may be the electrolyte or the current collector.

As an example, take in = 10 mA/cm2 , h = h2 = 0.1 cm, and L2

= 0.5 cm. For Figure 1a, take κ = 0.2 S/cm and L = 10 cm. The

formula yields of 52.5 V. This is clearly intolerable. Therefore

we reduce L by a factor of 100 to L = 0.1 cm. Then = 30 mV.

This is still significant compared to an overall cell potential of about

1.8 V, but we accept it as tolerable.

F310

Journal of The Electrochemical Society, 160 (3) F309-F311 (2013)

6.

Use of earth-abundant materials. There should be a trade-off here;

how much more are we willing to pay for a catalyst that works

vs. a low-efficiency, earth-abundant catalyst?

Summary and Additional Remarks

Figure 1. Side views of wireless (a) and wired (b) photoelectrochemical cell

designs. (Photovoltaic (PV) arrays are in the plane of the page.) The (ionic)

current path in the wireless design occurs in the solution, and the water splitting

reactions can occur at the surfaces of the PV, assuming a transparent anode

catalyst layer (e.g., cobalt oxide). The (electronic) current path of the wired

design is through a wire (e.g., copper), which is connected between the photoactive PV side and the positive electrode. A porous separator or membrane

can be used to separate the evolved gases. Current densities in the normal and

tangential directions are represented by in and ix , respectively. Figure is not

drawn to scale.

Now apply the formula to Figure 1b, with κ = 6 × 105 S/cm,

corresponding to Cu, and L = 10 cm. then equals 17.5 μV.

This is so low that we decide to reduce h and h2 to 0.01 cm or 100

μm. then works out to be 0.175 mV, still smaller than that for

Figure 1a, even though the current path is 100 times longer and one

tenth as wide. The wired system is superior to the wireless system,

and there is leeway to redesign the left side of Figure 1b to permit

illumination to reach the photovoltaic device.

In practice, the wired version needs to use a grid pattern (and

perhaps a conductive transparent material like indium tin oxide) designed to compromise between conduction and transmittance of solar

illumination.6

Other Design Criteria

In the systems considered here, the focus is on direct production

of liquid fuels from sunlight, CO2 , and H2 O without the need for

organics like alcohols and sugars to depolarize the positive electrode.

Some other factors, besides ohmic drop, to consider in the design are

1.

2.

3.

4.

5.

Device size. Because of the diffuse nature of solar radiation, the

land area needed to produce electricity is about 34,000 km2 /TW,

depending on the device efficiency, latitude, and cloud cover. To

cover this area, the device size should be as large as practical,

as developed in the main topic of this article. Nanodevices are

really not desirable, although nanostructured components such as

porous electrodes may be.

Separate products. For safety reasons, the hydrogen and oxygen must emerge in different ports, and they should not require

additional separation. The piping requirements again speak for

devices as large as practical.

Life. Putting semiconductor materials, catalysts, and chromophores in direct contact with electrolytic solutions compromises life and needs to be considered in the selection of materials

and the details of device design. Limited life is a problem with

PECs.

Cost. Ultimately one wants to produce energy, in the form of

electricity, hydrogen, or liquid fuels, which can compete in the

market place. Capital cost, life, and efficiency enter directly into

product cost.12

Storage. A basic problem with electricity and hydrogen is storing

them in amounts and for durations related to the source and the

application. The cost of storing liquid fuels is much less than for

electricity and hydrogen.12

This simple example analyzed above carries the clear message that

electronic conductivities are so much higher than ionic conductivities

that designers through the years were correct to focus on the electrolytic solution and make the ionic current path as short as possible.

It embodies a scaling law that, for comparable ohmic losses in the

ionic and electronic parts of the circuit, the ratio of lengths for electronic parts to ionic parts can generally be proportional to the ratio

of the square root of the electronic conductivity to that of the ionic

conductivity.

The history of electrochemical engineering has included much

work on the consequences of ohmic drop in electrolytic solutions,

with emphasis on current and potential distributions in complex geometries and including also the effects of surface and concentration

overpotentials.13

For large aspect ratios L/h in Figure 1b, the effects of resistance

in the electrodes and other electronic conductors become significant

and have been treated in addition to those in the electrolytic solution. Tobias and Wijsman treated this electrode effect.14 It must be

accounted for in the design of cathodic-protection systems that extend over appreciable distances.13,15 Lanzi and Landau16 treated some

special cases. Such potential drop in electrodes limits how big one

can make the grids or current collectors of lead-acid (and other) batteries, and these grids are designed to get the most power with a given

amount of material.17–19 Trost et al. give a glimpse of some of this

work.20

These wired and wireless devices have been drawn with the same

geometry in order to facilitate comparison. Figure 1b has a short ionic

path, denoted H+ , but in Figure 1a the protons must flow around the

end of the center section. In Figure 1a, the electrons take the short

path, whereas in the wired Figure 1b the electrons have to go around.

References

1. Alan C. O’Connor, Ross J. Loomis, and Fern M. Braun, Retrospective Benefit-Cost

Evaluation of DOE Investment in Photovoltaic Energy Systems, RTI International,

3040 Cornwallis Road, Research Triangle Park, NC 27709, August, 2010.

2. Steven Y. Reece, Jonathan A. Hamel, Kimberly Sung, Thomas D. Jarvi,

Arthur J. Esswein, Joep J. H. Pijpers, and Daniel G. Nocera, Science, 334, 645 (2011).

3. S. Licht, B. Wang, S. Mukerji, T. Soga, M. Umeno, and H. Tributsch, Journal of

Physical Chemistry, B, 104, 8920 (2000).

4. Michael G. Walter, Emily L. Warren, James R. McKone, Shannon W. Boettcher,

Qixi Mi, Elizabeth A. Santori, and Nathan S. Lewis, Chemical Reviews, 110, 6446

(2010).

5. Joshua M. Spurgeon and Nathan S. Lewis, Energy & Environmental Science, 4, 2993

(2011).

6. Mark E. Orazem and John Newman, Journal of the Electrochemical Society, 131,

2582 (1984).

7. Mark E. Orazem and John Newman, Journal of the Electrochemical Society, 131,

2857 (1984).

8. Emil A. Hernandez-Pagan, Nella M. Vargas-Barbosa, TsingHai Wang, Yixin Zhao,

Eugene S. Smotkin, and Thomas E. Mallouk, Energy & Environmental Science, 5,

7582 (2012).

9. Sophia Haussener, Chengxiang Xiang, Joshua M. Spurgeon, Shane Ardo,

Nathan S. Lewis, and Adam Z. Weber, Energy & Environmental Science, 5, 9922

(2012).

10. Joshua M. Spurgeon, Michael G. Walter, Junfeng Zhou, Paul A. Kohl, and

Nathan S. Lewis, Energy & Environmental Science, 4, 1772 (2011).

11. Gilbert Newton Lewis and Merle Randall, Thermodynamics and the Free Energy of

Chemical Substances. New York: McGraw-Hill Book Company, Inc., 1923.

12. John Newman, Paul G. Hoertz, Christopher A. Bonino, and James A. Trainham,

Journal of the Electrochemical Society, 159, A1722 (2012).

13. John Newman and Karen E. Thomas-Alyea, Electrochemical Systems (Hoboken,

New Jersey: Wiley-Interscience, 2004).

14. Charles W. Tobias and Robert Wijsman, Journal of the Electrochemical Society, 100,

459 (1953).

15. John Newman, Journal of the Electrochemical Society, 138, 3554 (1991).

16. Oscar Lanzi and Uziel Landau, Journal of the Electrochemical Society, 137, 1139

(1990).

17. John Newman and William Tiedemann, Journal of the Electrochemical Society, 140,

1961 (1993).

Journal of The Electrochemical Society, 160 (3) F309-F311 (2013)

18. William Tiedemann, Frank DeSua, and John Newman, “Potential Distribution in the

Lead-Acid Battery Grid.” D. H. Collins, ed. Power Sources 6, pp. 15–23. London:

Academic Press, 1977.

19. William H. Tiedemann and John Newman, “Current and Potential Distribution in

Lead-Acid Battery Plates.” Sidney Gross, ed. Proceedings of the Symposium on

F311

Battery Design and Optimization, pp. 39–49. Princeton: The Electrochemical Society,

Inc., 1979.

20. Gary G. Trost, Victoria Edwards, and John Newman, “Electrochemical Reaction

Engineering.” James J. Carberry and Arvind Varma, eds. Chemical Reaction and

Reactor Engineering, pp. 923–972. New York: Marcel Dekker, Inc., 1987.