ANNE ARUNDEL COUNTY, MARYLAND Annapolis, Maryland

advertisement

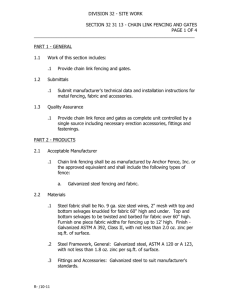

ANNE ARUNDEL COUNTY, MARYLAND Annapolis, Maryland ADDENDUM NO. 3 April 23, 2012 IFB NO. 12-009 SERVER ROOM, DESIGN AND CONSTRUCTION TO ALL BIDDERS: Please see the following for the above-mentioned IFB resulting from questions from potential bidders. 1. Q: Regarding Addendum #2, Q & A #8, what is the anticipated date of award the Bidder should use in creating their proposed time line? A: In creating the time line, do not use specific dates, rather use # of days or weeks to complete that portion of the work. 2. Q: Clause 3.3.2 of the Technical Specifications, calls out that there shall be no progress payments for this IFB. As the Generator Set is a long lead item will the contractor be allowed to submit a progress payment for this item? A: No. There shall be no progress payments on this project. 3. Q: Regarding clause 3.5.6.2, of the Technical Specifications, is the requirement a total of two (2) - 4” conduits or two (2) - 4” conduits per manhole? A: The requirement is one (1) 4” conduit per manhole. 4. Q: What is the required depth below grade for the base of the manholes? A: The minimum depth below grade for the base of the manholes shall be thirty (30) inches. 5. Q: Is the Contractor required to provide stub-outs for the manholes for future incoming fiber optic lines? If so provide the size(s) and quantity per manhole and the length(s). A: The Successful Bidder shall provide a stub out for one (1) 2” conduit per manhole. 6. Q: What are the proposed walls and ceiling finishes? A: The proposed walls and ceilings shall be painted a neutral color in accordance with the "Design Manual and Standard Specifications and Details for Construction" latest edition, found at: http://www.aacounty.org/DPW/Engineering/DesignManual.cfm 7. Q: What is the proposed floor finish? A: This question is answered in Clause #6 in Addendum #1. 8. Q: As stated in clause 3.1.12 of the Technical Specifications, the Successful Bidder shall be responsible for installing an additional emergency egress door. Please designate and show the location for the new emergency egress door in a plan view. Please provide sizes and specifications for the door(s) and hardware. A: The diagram below shows the location of the additional egress door. The new egress door shall be the same size and similar specifications as the existing door to the server room. The new door location will require the relocation of an electrical outlet. 9. Re: Addendum #2, Clause 9 clarification: The fence around the generator shall be chain link, six feet (6') in height, and shall conform to the requirements of the Board of Education Anne Arundel County Chain Link Fences and Gates specification 02821 (attached). 10. Add Clause 3.5.5.1.5 as follows: Relocating the existing thermostat and power switch for an overhead heater. 11. Modify Clause 3.5.5.1.4 as follows: remove the words "Removing or" from this clause. 12. All other Terms and Conditions remain the same. NOTE: THIS ADDENDUM AND ACKNOWLEDGMENT MUST ACCOMPANY THE BID RESPONSE TO MAKE IT VALID. Return to: Purchasing Agent Anne Arundel County Heritage Office Complex 2660 Riva Road, 3rd Floor, Annapolis, MD 21401 Sir/Madam: This will acknowledge receipt of Addendum No. 3 to IFB NO. 12-009 SERVER ROOM, DESIGN AND CONSTRUCTION Date: _________ FIRM NAME: _________________________________ SIGNATURE: _________________________________ TITLE: _______________________________________ Signature shall conform to requirements of the IFB. SECTION 02821 CHAIN LINK FENCES AND GATES PART 1 1.01 GENERAL RELATED DOCUMENTS A. Conditions of the Contract (General, supplementary, and other Conditions), Drawings, Specifications, and addenda, apply to this section. 1.02 SECTION INCLUDES A. Bonded vinyl coated chain link fence as shown on plans 1.03 RELATED SECTIONS A. Section 02320 Fill excavation grading. B. Section 03000 Cast in place concrete. 1.04 REFERENCES A. ASTM F 567 1.05 SUBMITTALS A. General: Follow the procedures specified in the “General Provisions”. 1. Product data in the form of manufacturer’s technical data, specifications, and installation instructions for fence and gate posts, fabric, gates, and accessories. 2. Shop drawings showing layout for fence and gates posts, fabric, gates and accessories. 1.06 QUALITY ASSURANCE A. Single-Source Responsibility: Obtain chain link fences and gates as complete units, including necessary erection accessories, fittings, and fastenings from a single source or manufacturer. PART 2 2.01 PRODUCT MANUFACTURERS A. Manufacturers: Subject to compliance with requirements, provide products by one of the following: 1. Aluminum Steel Fencing and Fabric Board of Education Anne Arundel County (school) (revised) 12-009Addendum3.doc- 4 a. American Chain Link Fence Company b. Anchor Fence, Inc. c. BWF Fence System. d. Page Aluminized Steel Corp. 2.02 FABRIC A. Steel Fabric: Comply with Chain Link Fence Manufactures Institute (CLFMI) Product Manual. Furnish one-piece fabric widths for fencing up to 12 feet high. Wire size includes zinc or aluminum coating. 1. Size: 2-inch mesh, 9-gage (0.148-inch diameter) wire. 2. Aluminized Steel Finish: Fabric conforming to ASTM A 491 with not less than 0.40 oz. aluminum per sq. ft. of uncoated surface on 6 and 9 gage wire and not less than 0.35 oz. aluminum per sq. ft. of uncoated surface on 11 gage wire, in accordance with ASTM A 817. 2.03 FRAMING A. Strength requirements for posts and rails conforming to ASTM F 669. B. Pipe shall be straight, true to section, material, and sizes specified, and shall conform to the following weights per foot. Outside NPS in Diameter Type (OD) in I Steel inches 1 1.315 1.68 1-1/4 1.660 2.27 1-1/2 1.900 2.72 2 2.375 3.65 2-1/2 2.875 5.79 3 3.500 7.58 Board of Education Anne Arundel County (school) (revised) 12-009Addendum3.doc- 5 C. Steel Framework, General: Posts, rails, braces, and gate frames. 1. Type I Pipe: Hot-dipped galvanized steel pipe conforming to ASTM F 1083, plain ends, standard weight (schedule 40) with not less than 1.8 oz. zinc per sq. ft. of surface area coated. D. End, corner, and pull posts for following fabric heights: 1. Up to 6 feet: 2.375 inch OD Type I. E. Line or intermediate posts for following fabric heights: 1. Up to 6 feet: 2.375 inch OD Type I. F. Gate Posts: Furnish posts for supporting single gate leaf, or one leaf of a double gate installation, for nominal gate widths as follows: G. Center Rail: Manufacturer’s longest lengths, with expansion-type couplings, approximately 6 inches long, for each joint. Provide means for attaching top rail securely to each gate corner, pull, and end post. 1.66-inch OD Type I. H. Bottom and Top Wire: Provide manufacturer’s standard galvanized steel wire continuous form post to post. 2.04 FITTING AND ACCESSORIES A. Material: Comply with ASTM F 626. Mill – finished aluminum or galvanized iron or steel, to suit manufacturer’s standards. 1. Zinc Coating: Unless specified otherwise, galvanize steel fence fitting and accessories in accordance with ASTM A 153, with zinc weights per Table 1. B. Tie Wires: 9-gauge (0.148-inch diameter) galvanized steel with a minimum of 0.80 oz. Per sq. ft. of zinc coating of surface area in accordance with ASTM A 641. C. Post Brace Assembly: Manufacture’s standard adjustable brace at end and gate posts and at both sides of corner and pull posts, with horizontal brace located at midheight of fabric. Use same material as top rail for brace, and truss to line post with 3/8-inch diameter rod and Board of Education Anne Arundel County (school) (revised) 12-009Addendum3.doc- 6 adjustable tightener. Provide manufacturers standard galvanized steel or cast iron or cast aluminum cap for each end. D. Post and Line Caps: Provide weather-tight closure cap for each post. Provide line post caps with loop to receive tension wire or top rail. E. Tension or Stretcher Bars: Hot-dip galvanized steel with minimum length 2 inches less than full height of fabric, minimum cross-section of 3/16 inch by 3/4 inch and minimum 1.2 oz. Zinc coating per sq. ft. of surface area. Provide one bar for each gate and end post, and two for each corner and pull post, except where fabric is integrally woven into post. F. Tension and Brace Bands: Minimum 3/4 – inch – wide hot-dip galvanized steel with minimum 1.2 oz. zinc coating per sq. ft. or surface area. 1. Tension and Brace Bands: Minimum 12 gage (0.105 inch) thick. 2.05 GATES A. Fabrication: Fabrication perimeter frames of gates from metal and finish to match fence framework. Assemble gate frames by welding. Provide horizontal and vertical members to ensure proper gate operation and attachment of fabric, hardware, and accessories. Space frame members maximum of 8 feet apart unless otherwise indicated. 1. Provide same fabric as for fence unless otherwise indicated. Install fabric with tension bars and bands at vertical edges and at top and bottom edges. 2. Install diagonal cross-bracing consisting of 3/8-inch diameter adjustable-length truss rods on gates to ensure frame rigidity without sag or twist. B. Swing Gates: Comply with ASTM F 900. 1. Steel: a. Up to 6 feet High and 8 feet Wide: Fabricate perimeter frames of minimum 1.660inch OD Type I. 2. Gate Hardware: Provide hardware and accessories for each gate, galvanized per ASTM A 153, and in accordance with the following: Board of Education Anne Arundel County (school) (revised) 12-009Addendum3.doc- 7 a. Hinges: Size and material to suit gate size, non-lift-off type, offset to permit 180-deg gate opening. Provide 1-1/2 pair of hinges for each leaf over 6-foot nominal height. b. Latch: Heavy duty, forked type or plunger-bar type to permit operation from either side of gate, with padlock eye as integral part of latch. c. Keeper: Provide Keeper for vehicle gates, which automatically engages gate leaf and holds it in open position until manually released. PART 3 3.01 EXECUTION INSTALLATION A. General: Install fence in compliance with ASTM F 567. 1. Apply fabric to outside of framework. B. Setting Posts: Center and align posts in sleeve. Space maximum 10 feet o.c., unless otherwise indicated. 1. Protect portion of posts above ground from concrete splatter. Place sealer between posts and sleeves, vibrate or tamp for consolidation. Check each post for vertical and top alignment, and hold in position during placement and finishing operation. C. Top and Bottom Wire: run wire continuously through line posts, bending to radius for curved runs and at other posts terminating into rail end attached to posts of post caps fabricated to receive wire. D. Center Rails: Provide center rails for fabric height 11 feet and over. Install in one piece between posts and flush with post on fabric side, using rail ends and special offset fittings where necessary. E. Brace Assemblies: Install braces so posts are plumb when diagonal rod is under proper tension. F. Fabric: Leave approximately 2 inches between finish grade and bottom selvage unless otherwise indicated. Pull fabric taut and tie to posts, rails, and tension wires. Install fabric on security side on fence, and anchor to framework so that fabric remains in tension after pulling force is released. Board of Education Anne Arundel County (school) (revised) 12-009Addendum3.doc- 8 G. Tension or Stretcher Bars: Thread through or clamp to fabric 4 inches o.c., an secure to end, corner, pull, and gate posts with tension bands spaced not over 15 inches o.c. H. Tie Wires: Use U-shaped wire of proper length to secure fabric firmly to posts and rails with ends twisted at least 2 full turns. Bend ends of wire to minimize hazard to persons or clothing. I. Fasteners: Install nuts for tension bands and hardware bolts on side of fence opposite fabric side. Peen ends of bolts or score threads to prevent removal of nuts. J. Gates: Install gates plumb, level, and secure for full opening without interference. Install ground-set items in concrete for anchorage. Adjust hardware for smooth operation and lubricate where necessary. END OF SECTION Board of Education Anne Arundel County (school) (revised) 12-009Addendum3.doc- 9