Arc Flash - An Application in the Utility Industry

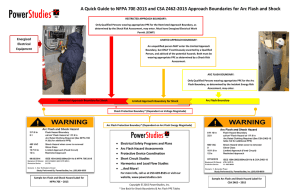

advertisement

Seattle City Light Arc Flash: Application and Case Study May 23rd – 24th Ryan Cook 1 Overview (Pre Study) • • • • • What is Arc Flash Hazard Mitigation Labeling Procedures Calculation Goals and Methods Boundary Case Study Overview (Post Study) • Worker Response – Results – PPE – Labeling • Continuing education • Future research – DC Studies What is Arc Flash • Electrical Explosion Resulting From a Low Impedance Fault • Two Types of Incidents – Bolted Faults: energy dissipated through equipment – Arcing Faults: energy dissipated through air • Causes – Conductive dust buildup – Poor maintenance – Equipment failure Insulation Factors Influencing Arc Flash Hazards • System Conditions – System voltage, loading • Size and Shape of Enclosures • Atmospheric Conditions – Temperature, humidity • Protective Devices – TCC coordination studies – Time to clear fault • Distance From Fault Why Is It Important? • NESC (2007) Article 410.A.3 States – “Effective as of January 1,2009 employer shall assess potential exposure to electric arcs for employees who work on or near energized parts or equipment.” – “Employer shall require employees to wear clothing with an effective arc rating no less than the anticipated level of arc energy.” • 2,000 People/Year Treated for Burns – 5-10 incidents/day • Easily Exceed $10 Million Per Case • 5th leading Cause of Industrial Fatalities Calculation Goals • Flash Protection Boundary • Available Incident Energy Level (cal/cm^2) At Each Piece of Equipment • Resulting PPE Requirements • To Make Information Available With Labeling Arc Flash Protection Boundaries • Flash Protection Boundary – Safe Approach limit at a distance from an exposed live part where a person could receive a second degree burn • Limited Approach Boundary – Approach limit at a distance from an exposed live part in which a shock hazard exists. Crossed only by qualified personnel • Restricted Approach Boundary – Approach limit at a distance from an exposed live part in which there is an increased risk of shock. Crossed only by qualified personnel with appropriate PPE • Prohibited Approach Boundary – Approach limit at a distance from an exposed live part in which working within is the equivalent of making contact with the live part. Crossed only by qualified personnel with appropriate PPE Personal Protection Equipment • Established by NFPA 70E (2009) • For Incident Energy Exceeding 1.2 Cal/cm2 (2nd Degree Burn) Category Energy Level Needed Cal/cm2 0 N/A 1 5 2 8 3 25 4 40 Typical PPE Examples Non-melting or untreated natural fibers FR shirt and FR pants FR shirt and FR pants and face protection FR clothing with overall and face protection Flash suit with hood Equipment Labeling • Adopted Into 2002 NEC • Required To – Warn of potential hazard and appropriate PPE needed – Be in a location providing clear visibility to workers • Required On – Switchboards and panel boards – Motor control centers Sample Label • Default Format Generated by Our Software • Very Cluttered – Labels are only mandated to specify incident energy or PPE requirement • We are Leaning Towards a Simpler Design… SCL Warning Labels • Warning Labels – Orange bar on top – States Arc Flash/Shock Hazard is present – Specifies appropriate PPE is required – Includes arc flash boundary, incident energy level, flash hazard distance, PPE category, and equipment name – For equipment rated CAT.0 – CAT.4 PPE SCL Danger Labels • Danger Labels – Red bar on top – States no safe PPE exists – Tells to de-energize before working – Includes arc flash boundary, incident energy level, flash hazard distance, and equipment name – For equipment rated higher than CAT.4 PPE Standards Used for Study • IEEE 1584-2002 – Provides empirical formulas from laboratory testing for incident energy and approach boundary calculations – Preferred in industry but does not replace NFPA 70E – Voltages between 208 V – 15 kV, three phase, operating in 50 – 60 Hz range • NESC Article 410 – Provides arc flash hazard data for higher voltage studies • NFPA – 70E-2004 (applies to industry) Personal Protective Equipment (PPE) requirements Establishes Arc Flash protection boundaries Available Software • SKM Power Tools – Widely utilized in industry – Employs IEEE 1584 calculation methods – Used in Boundary station service arc flash study • ARCPRO – Industry standard for high voltage arc flash studies – Relies on NESC arc hazard data for incident energy calculation – Used in Boundary switchyard arc flash study Calculation Methods: Step 1 • Collect Field Data – Transformer Impedances, ratings, grounding methods – Conductors Type, size, length – Fuse and breaker ratings – Equipment type MCC, switchgear Calculation Methods: Step 2 • Model the Electrical System and Identify All Possible System Operating Modes – Perform short circuit studies – Perform protective coordination studies With this information we can calculate incident energy levels and the flash protection boundary at each fault location… Boundary Case Study: Station Service • Scope of Arc Hazard Analysis per IEEE 1584 Includes the Following: – Service areas fed from > 75kVA transformer – 3 phase panels rated > 208V – System voltages < 13.8kV Boundary Station Service Operation Scenarios • Normal Operation – Two 13.8kV feeders • Scenario 1: Reduced Operation – One 13.8kV feeder • Scenario 2: Backup Power – 2a : Only 750kW generator running – 2b : Only 250kW generator running Station Service Normal Operation One Line Diagram Station Service Results • Worst Case – Normal operation • Highest incidents of equipment >CAT.3 PPE • Problem Areas: – Switchgear WA, WB, and NA – Panels L27, L8, NE, and VH – Paint booth Boundary Case Study: Switchyard • No Specific Formulas Govern Systems >13.8kV • NESC Arc Flash Calculation Data Used for This Study Switchyard One Line Diagram Switchyard Results I Using arc flash calculation data from NESC and fault current calculations from ASPEN, ARCPRO is used to calculate incident energy LOCATION HIGHEST AVAILABLE INCIDENT ENERGY LEVEL (CAL/CM2 ) FIELD PPE RECOMMENDATION BOUNDARY 1.4 1 ROSS/DIABLO 4.7 2 CEDAR FALLS 1.9 1 TOLT 1.5 1 GORGE 2.6 1 Switchyard Results II • Incident Energy Threat Much Lower than Station Service Due To: – Faster breaker opening times – Greater working distance from fault – Equipment generally not worked live Recommendations • Dangerous! – De-energize when working near or around equipment • Category 4 – If working live, adjust instantaneous settings to pickup lower fault magnitude. De-energize recommended • Category 3 – Adjust protective device settings to decrease interrupting time In Retrospect: Overall Study • Labor Intensive – SKM modeling limitations • System Configurations • Protective relay settings – Scope of data collection • Some Questionable Results Due to: – Miscoordination of protective devices • Long breaker opening times – Missing data In Retrospect: Labeling • Industrial Label Maker by Brady® – Global mark 2 – Around $4000 – Expensive replacement tape • Locations – Front/rear access of switchgear – Independent breaker cubicles – Under panel label In Retrospect: PPE Rollout Provided by Work Rite® • Daily wear – Electrical constructors • • • • Cat 2: 5 shirts, 5 pants, coveralls, rain coat, and jacket Cat 3 and 4 available upon request Alternative catalog selection Laundering stipend • Intermediate wear – Engineers/ Other powerhouse staff • Cat 2: 2 shirts, 2 pants, coveralls, and jacket Ongoing Work • System changes – CIP Projects – Increased generation • Education – Availability of Results • Powerhouse binders – DPP/SOP Documentation – General guidelines • New employee training Future • DC study – High potential risk – Research being conducted by NFPA • Establishing safety guidelines • PPE recommendations – Not conducted at SCL • Other utilities? 33