Fire Sentinel FSBX / FSCX Installation Instructions

advertisement

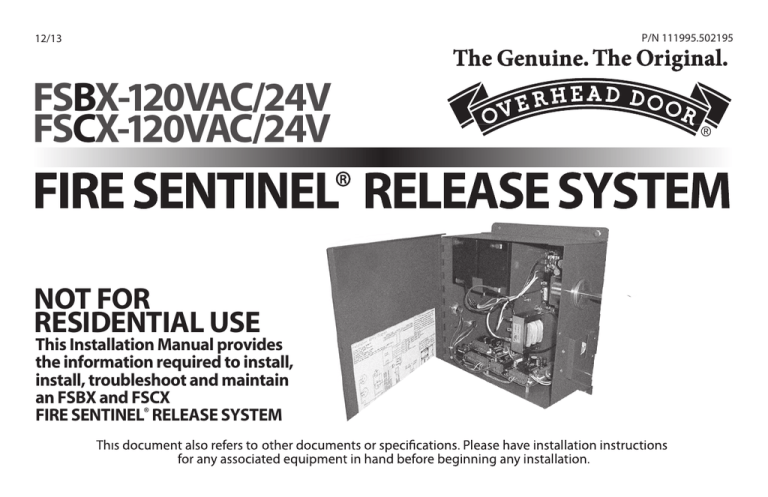

12/13 FSBX-120VAC/24V FSCX-120VAC/24V NOT FOR RESIDENTIAL USE This Installation Manual provides the information required to install, install, troubleshoot and maintain an FSBX and FSCX FIRE SENTINEL® RELEASE SYSTEM P/N 111995.502195 THIS PAGE LEFT BLANK Fire Sentinel® Release System www.overheaddoor.com 02/13 Table of Contents How to use this manual How to use this manual ....................................................................... 2 General Information ............................................................................ 4 This Installation Manual provides the information required to install, troubleshoot and maintain an FSBX and FSCX Fire Sentinel® Release System. Mechanical Installation (Mounting)................................................. 5-6 This information includes: Safety Information and Instructions................................................... 3 Electrical Connections .....................................................................7-19 High/Low Voltages .................................................................. 7 Smoke Detectors................................................................... 8-9 Supervised Annunciators...................................................... 10 Remote Test and Trouble Silence......................................... 10 Relay Outputs/Auxiliary Closed Limit .................................. 11 Control Circuit Sensing/Aux Open Limit ............................. 12 Safety Edge Connections/Wall Button Connections........... 13 Battery/Clock Backup Battery .............................................. 14 System Wiring ...................................................................15-17 Dip Switches/LEDs ................................................................. 18 Trouble Codes ........................................................................ 19 Maintenance ..................................................................................20-21 Specifications ......................................................................... 21 Testing ............................................................................................22-25 Release Device Compatibility Identifier/Replacement Parts ......... 25 Installation Notes ............................................................................... 26 Test Records ........................................................................................ 27 Warranty ............................................................................................. 28 Fire Sentinel® Release System www.overheaddoor.com • Important defining information related to safety terminology used throughout this manual, as well as safety related instructions which must be followed at all times while doing any steps/tasks/instructions detailed in this manual. • Step by step installation, set-up and testing instructions for the FSBX and FSCX units. • Important features and troubleshooting information for typical installation and normal operations that may occur. • Important warranty and returned goods policy information. DO NOT ATTEMPT TO INSTALL, REPAIR OR SERVICE THIS RELEASE DEVICE UNLESS YOU ARE A TRAINED SERVICE TECHNICIAN USING PROPER TOOLS AND INSTRUCTIONS. 12/13 2 Safety Information and Instructions WARNING Overhead Doors are large, heavy objects that move with the help of springs under high tension and electric motors. Since moving objects, springs under tension, and electric motors can cause injuries, your safety and the safety of others depend on you reading the information in this manual. If you have any questions or do not understand the information presented, call your nearest service representative. For the number of your local Overhead Door distributor, call 800-929-3667, and for Overhead Door Factory Technical Advice, call 800-275-6187. In this Manual, the words Danger, Warning, and Caution are used to stress important safety information. The word: DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. WARNING indicates an potentially hazardous situation which, if not avoided, could result in death or serious injury. CAUTION indicates a potentially hazardous situation which, if not avoided, may result in injury or property damage. The word NOTE is used to indicate important steps to be followed or important considerations. POTENTIAL HAZARD EFFECT WARNING MOVING DOOR Could result in Serious Injury or Death ELECTRICAL SHOCK Could result in Serious Injury or Death HIGH SPRING TENSION PREVENTION Do Not operate unless the doorway is in sight and free of obstructions. Keep people clear of opening while door is moving. Do Not allow children to play with the door operator. Do Not change operator control to momentary contact unless an external reversing means is installed. Do Not operate a door that jams or one that has a broken spring. WARNING Turn off electrical power before opening front cover. When replacing the cover, make sure wires are not pinched or near moving parts. Fire Sentinel® must be electrically grounded. WARNING Do Not try to remove, repair or adjust springs or anything to which door spring parts are fastened, such as, wood block, steel bracket, cable or any other structure or like item. Repairs and adjustments must be made by a trained service representative using proper tools and instructions. Could result in Serious Injury or Death Fire Sentinel® Release System www.overheaddoor.com IMPORTANT READ PRIOR TO ANY DOOR OPERATION 1. Read manual and warnings carefully. 2. Keep the door in good working condition. Periodically lubricate all moving parts of door. 3. If door has a sensing edge, check operations monthly. Make any necessary repairs to keep it functional. 4. Each month, manually operate door by disconnecting it from the operator. The Door should open and close freely. If it does not, the door must be taken out of service and a trained service representative must correct the condition causing the malfunction. 5. Keep instructions in a prominent location. 12/13 3 General Information The Overhead Door Fire Sentinel® Release Systems (FSBX and FSCX) are intended for use on rolling, single-slide and center parting level and inclined track doors. All models are normally energized Fail-Safe Sentinels incorporating an internal battery pack and proprietary control circuitry. All comply with UL864 9th Edition, December 31, 2008 requirements and ULC S527-99. The Devices respond to emergency conditions generated by manual or automatic initiating devices and shall be installed in accordance with NFPA and UL 864 9th Edition Standards effective 12.31.08 and ULC S527-99. The available FSBX and FSCX features* include exclusive, annual test standard compliance technology, coded test plate diagnostics, selectable time delays, minimum 24 hour battery support for release and smoke detectors, external control system diagnostics, form-C relay outputs, supervised annunciator and limit switch outputs and troubleshooting capabilities. The system incorporates an Annual Internal Clock/Calendar which generates a Test Trouble Signal if the system has not been tested within 365 days per National Fire Code requirements. Motorized and manual installations are addressed by model to accommodate specifications required by AHJ/AHJD (Authority Having Jurisdiction). * Check model label on unit to be installed to verify applicable features and options. CAUTION : REVIEW ALL INSTALLATION INSTRUCTIONS, PROCEDURES, CAUTIONS AND WARNINGS CONTAINED WITHIN THIS MANUAL PRIOR TO INSTALLING AND/OR SERVICING THIS PRODUCT. AS WITH ALL RELEASING DEVICE SYSTEMS, MAXIMUM FIRE PROTECTION IS PROVIDED WHEN INSTALLED IN ACCORDANCE WITH FACTORY SPECIFICATIONS AND USED WITH FUSE LINK SYSTEMS. CAUTION: PROPER OPERATION CAN ONLY BE PROVIDED ONCE PROPERLY INSTALLED AND INPUT POWER HAS BEEN APPLIED. CAUTION: TEST SYSTEM REGULARLY TO ENSURE PROPER OPERATION! (TESTING SHOULD BE DONE AT LEAST MONTHLY.) For Technical Support, please call 1-800-275-6187 Fire Sentinel® Release System www.overheaddoor.com 02/13 4 Mechanical Installation FIGURE 1 Mounting Procedure: NO LESS THAN 12” WARNING : TO REDUCE THE RISK OF SERIOUS INJURY OR DEATH AND PREVENT DAMAGE TO THE UNIT, ALL INPUT CONNECTIONS MUST BE MADE WITH POWER SOURCES DISCONNECTED. DO NOT INSTALL THIS UNIT WITHOUT REVIEWING AND UNDERSTANDING ALL WARNINGS AND INSTRUCTIONS CONTAINED HEREIN, AND IN THE DOOR MANUFACTURERS INSTRUCTIONS AND MANUALS. WARNING : TO PREVENT SERIOUS INJURY OR DEATH - DO NOT INSTALL THIS UNIT ON A MOTORIZED DOOR WITHOUT A REVERSING ELECTRIC SAFETY EDGE. CAUTION : THESE INSTALLATION PROCEDURES MUST BE FOLLOWED TO ENSURE PERFORMANCE OF THE FSBX OR FSCX TO APPROPRIATE STANDARDS AND CODES. NO LESS THAN 12” Typical installation configuration may not accurately depict door manufacturer’s recommendations. See door manufacturer’s recommendations for use of this product with the door being installed. All hardware must be supplied by the door manufacturer or installer. Use only hardware approved and recognized by the appropriate testing or listing agencies in conjunction with the installation of this product. Only properly trained technicians, using proper tools and instructions, are to perform installation and testing as described herein. 1) The Release Device may be mounted on a vertical surface or optionally on a horizontal surface as illustrated in Figure 1. continued on next page Fire Sentinel® Release System www.overheaddoor.com 12/13 5 Mounting Procedure (continued): 2) The Release Device Enclosure must be mounted with minimum #10 size fastening screws or bolts for securing to structures other than masonry. • Masonry applications shall use 1/4" or greater anchors or studs as required to ensure proper mounting strength. Release device and associated hardware (sash chain [provided and preferred] or 1/16" cable, eyebolts, fuse links and turnbuckles) shall be installed as per door manufacturer recommendations. FIGURE 2 Supervised Electromagnet Armature inserted into retainer*. *Supports sash chain/cable until power is supplied 3) Complete hardware installation by connecting fuse links, sash chain, S-hooks and turnbuckles per door manufacturer specifications. Place Armature in Supervisory Retaining Bracket (Figure 2) and attach cable or sash chain to the armature. Remove sash chain slack by adjusting turnbuckle. Do Not exceed 40 lbs maximum pull rating on device. The retaining bracket is meant to hold the armature and cable/sash until input power is supplied. The armature will be removed from the retainer and aligned with the supervised electromagnet when input power is supplied. S-hook & sash chain/cable to door Supervised Retaining Bracket Supervised Electromagnet Armature removed from retainer and affixed to electromagnet when input power is supplied. Fire Sentinel® Release System www.overheaddoor.com 02/13 6 Electrical Connections High Voltage/Low Voltage: Installation of all wiring and connections, including Class 1 and Class 2 circuits, must be performed in accordance with, but not limited to, the latest NFPA, UL and N.E.C. standards and codes. In addition, all installations subject to Canadian standards shall be performed in accordance with the Canadian Electrical Code, Part1, with respect to wiring material type, wiring gauge related to power capacity requirements, circuit length and wiring methods. This unit is designed so that it may be used on automated motorized doors which incorporate appropriate safety features (see options below). Current UL Recognized Monitored Reversing Devices 1) MillerEdge ME/MT series edge sensors 2) Overhead Door Photocells Kit P/N OPAKPE.S 3) Safe-T-Beams®: Model OSTB-BX P/N 37221R (OHD) Figure 3 1) BEFORE BEGINNING, turn off and disconnect power supply sources for the Control Panel as well as motor where applicable. 2) Verify voltage rating of Control Panel to power source being used. Model voltage is indicated on the side of the unit. 3) Connect power source inputs to TBX (chassis mount) screws 1 and 3. • Screw 2 of any model shall be utilized for earth ground where applicable. 4) For 120 VAC, connect L1/HOT to terminal 1. Connect L2/NEUT to terminal 3. Connect GROUND to terminal 2. 5) For 24 VDC, connect +24V to terminal 1, COMMON to termminal 3 and GROUND to terminal 2. • DO NOT connect battery at this time! Power Voltage 112087.0001 TBX Low Voltage 1-(L1) or (AC) or (DC-) 2-(Earth GND) 3-(L2) or (AC) or (DC+) FIGURE 3 WARNING : FAILURE TO DISCONNECT POWER SOURCES COULD RESULT IN ELECTRICAL SHOCK, SEVERE INJURY OR DEATH. Fire Sentinel® Release System www.overheaddoor.com 12/13 7 Electrical Connections Smoke Detectors: WARNING : TO REDUCE THE RISK OF SERIOUS INJURY OR DEATH AND PREVENT DAMAGE TO THE UNIT, ALL FIELD CONNECTIONS MUST BE MADE WITH POWER DISCONNECTED TO ALL COMPONENTS. 1) When installing smoke detectors with this unit, refer to NFPA 72 and NFPA 80 and any other applicable codes or regulations for instructions concerning proper placement and detection coverage. See Electrical Connections pages 8, 9, 11 and 12 for information. • End of line devices and supervisory resistors shall be installed for electrical supervision of smoke detectors and annunciators. NOTE: 1. DO NOT interface this unit to 4-wire smoke detectors that do not incorporate electrical supervision! 2. Field and System Wiring shall consist of 22-18 AWG wiring. Use only 350 VAC, 125VDC, 2 Amp, 2 AG Fast Acting fuses. All circuits are not power limited. All End -of-Line devices must be installed adjacent to the last initiating device. FIGURE 4B FIGURE 4A P/N 608964.0005 (SLR835BH-2) 2W-B & 2WT-B 112228.0001 112228.0001 112228.0001 (5) + OUT (4) – OUT (3) – IN (2) + IN (1) (5) + OUT (4) – OUT (3) – IN (2) + IN (1) Typical wiring: See compatibility list on page 25 and instructions provided with detector for additional information. Field wiring shall consist of 22-18 AWG wire. Do not mix and match 2-wire smoke detectors from different manufacturers. Normally Open 2-wire Initiating Devices: 1) Connect wiring from N/O smoke loop to TB-1, screws 1 and 2. 2) End-of-line supervisory resistor shall be connected at the end-of-line detector as shown in Figure 4A or 4B base wiring. Two Class B Style A detectors maximum @ 0.060 Amp/14VDC-28.6VDC maximum. (continued next page) Fire Sentinel® Release System www.overheaddoor.com 02/13 8 Electrical Connections Smoke Detectors (continued) Normally Open 4-wire Initiating Devices: 1) Connect wiring from N/O smoke loop to TB-1, screws 1 and 2, making sure end of line supervisory resistor (112228.0001) is installed as indicated. 2) Auxiliary power (+28.6VDC) for smoke detectors may be obtained from TB1 positions 3 and 4. Observe proper polarity — TB1-3 (+), TB1-4 (-). 3) (2) detector maximum @ 0.075 Amp/28.6VDC maximum. 4) Electrical power supervision in the form of an end-of-line device (EOLR-1) shall be provided on all smoke detectors. See information and specifications from detector manufacturer, Figures 5 and 6 base wiring. FIGURE 5 EOLR-1 COM 2 N/O (-) 112228.0001 (-) (5) COM (4) N.O. (3) - IN/OUT (2) + OUT (1) + IN (+) (-) Alarm Relay Module Installation 1 (+) (+) 112228.0001 NOTE: TB1 initiating device loops are supervised and cannot be directly series or parallel connected between release devices or shared with other alarm equipment. Incorrect wiring from unit to unit may cause damage to FIRE . SENTINEL®. ALARM RELAY MODULE FIGURE 6 4W-B & 4WT-B (5) COM (4) N.O. (3) - IN/OUT (2) + OUT (1) + IN (-) FIRE ALARM PANEL (+) SUPERVISORY RESISTOR * 112228.0001 * A supervisory resistor must be installed at the Relay Module. Fire Sentinel® Release System www.overheaddoor.com 12/13 9 Electrical Connections ANNUNCIATOR 112228.0001 DC - FIGURE 7 • (+24VDC output), connect annunciator (optional) observing polarity to TB1-10 (+) and TB1-11(-). • Install resistor as illustrated. Figure 7. • DO NOT connect a speaker to this output. REMOTE TEST PLATE Remote Test and Trouble Plate: Fire Sentinel® Release System www.overheaddoor.com Common (BLK) 02/13 (RED) FIGURE 8 The Remote Test and Trouble Plate provides convenient test and trouble silencing capabilities. The Trouble Silence function allows a user to temporarily silence the Trouble Sounder with a keyed function. The plate includes an LED Trouble Indicator, which illuminates indicating that trouble still exists. If the trouble condition is not corrected after 24 hours the trouble sounder will commence again and a manual intervention for reset is required. • Connect wiring from remote test plate to TB1 positions 15, 16, 17 and 18. • Observe wiring sequence as indicated in Figure 8. • Trouble Code table located on page 19. Remote Trouble DC + Reset (GRN) WARNING : TO REDUCE THE RISK OF SERIOUS INJURY OR DEATH AND PREVENT DAMAGE TO THE UNIT, ALL FIELD CONNECTIONS MUST BE MADE WITH POWER DISCONNECTED TO ALL COMPONENTS. Test (WHT) Supervised Annunciators: 10 Electrical Connections FIGURE 9 10 Relay Outputs: Two separate SPDT dry contact relay outputs (resistive) are provided for switching or signaling of supplementary devices. A non-delayed output(relay toggles on alarmbeginning of time delay) is provided on TB1-12 (C), 13 (N/C), and 14 (N/O) and a Trouble Relay output for supplementary trouble annunciating devices is provided on TB1-19 (C), 20 (N/C), and 21 (N/O). The Trouble Relay toggles indicating a fault in any of the supervised connections including initiating devices, signalling devices and supervised option modules. See figure 9. 11 12 13 14 15 16 17 18 19 20 21 System Trouble Relay Alarm Relay (On circuit board.) (On circuit board.) NOTE: Relay contacts 2A @ 28 VDC resistive, common mode Auxiliary Open Limit FIGURE 10 Refer to Operator manufacturer’s wiring instructions for proper Auxiliary Closed Limit AOM EOLR-1 112228.0001 112228.0001 Remote Test Reset Station 112228.0001 AOM Auxiliary Closed Limit: 112228.0001 112228.0001 112228.0001 Reset Remote Trouble Test Common Annunciator + AUX Close Limit Switch FSBX is not intended for use with external automation. Wiring connections are to be made within 20 feet (6.1 m) and are to be enclosed in conduit. AUX Common AUX Open Limit Switch Annunciator Annunciator – Required for FSCX – optional for FSBX Connect a normally open dry contact (Contacts close when door is at down limit) to position TB-1, 8 and 9. See figure 10. Smoke Power TB1-3 (+) and TB1-4 (–) Alarm Relay Fire Sentinel® Release System www.overheaddoor.com 12/13 System Trouble Relay 11 Electrical Connections FIGURE 11 WARNING: TO REDUCE THE RISK OF SERIOUS INJURY OR DEATH AND PREVENT DAMAGE TO THE UNIT, Monitored Safety Edge Control Sense (+) BLUE Control Sense Out (–) YELLOW ALL FIELD CONNECTIONS MUST BE MADE WITH POWER DISCONNECTED TO ALL COMPONENTS. ELECTRIC OPERATOR Control Circuit Sensing: FSCX ONLY This option is used to detect the presence of control voltage on motor driven doors for automated fire alarm closure. When control circuit voltage is not present (24V-30V AC or DC) the FSCX will sound a trouble, indicating the loss of door operator control voltage. In alarm, if control voltage is not present FSCX will mechanically release the door after the factory set 10 second delay (or longer optional delay). Connect control circuit voltage to position 30 (–) and 31(+). Monitored Operator Safety Edge Common Monitored Operator Safety Edge In Close Open AOM Auxiliary Open Limit 112228 0001 112228.0001 Stop Auxiliary Closed Limit 3-Button Common Open EOLR-1 Remote Test Reset Station 112228 0001 Close Stop 112228.0001 3-Button Common Station 112228.0001 112228 000 Reset Remote Trouble Test Common Annunciator – Annunciator + • Connect a normally open dry contact (Contacts close when door is at up limit) to positions TB-1, 7 and 8. AUX Close Limit Switch Auxiliary Open Limit: FSCX ONLY AUX Common AUX Open Limit Switch Annunciator Smoke Power TB1-3 (+) and TB1-4 (–) Alarm Relay (On circuit board.) Fire Sentinel® Release System www.overheaddoor.com 02/13 System Trouble Relay (On circuit board.) 12 Electrical Connections Safety Edge Connection: FSCX ONLY— Figure 11 FIGURE 11 (repeated) MONITORED EDGE INTERFACE MODULE • Connect safety edge across the operator’s “safety edge” sense terminal and the FSCX “Safety Edge” TB-1, no. 26 and 27. WALL BUTTON CONNECTION FSCX ONLY • Connect operator’s “open” terminal to FSCX “open” TB-1, no. 24. • Connect operator’s “close” terminal to FSCX “close” TB-1, no. 25. • Connect operator’s “common” terminal to FSCX “operator common” TB-1, no. 22. • Connect operator’s “stop” terminal to the “stop” terminal on the 3-button control. • Connect operator’s “open” terminal to the “open” terminal on the 3-button control. • Connect operator’s “close” terminal to the “close” terminal on the 3-button control. • Connect 3 button common to TB-1, no. 23. 112228 000 112228.0001 MONITORED SAFETY EDGE Control Sense (+) ELECTRIC OPERATOR BLUE Control Sense (–) YELLOW Monitored Operator Safety Edge Common Monitored Operator Safety Edge In AOM Auxiliary Open Limit Auxiliary Closed Limit Close Open 3-button Common EOLR-1 Operator Common Remote Test Reset Station 112228 0001 112228.0001 Open 112228.0001 112228 0001 Close Stop Reset Remote Trouble Test Common Annunciator – 3-Button Common Station Annunciator + AUX Close Limit Switch AUX Common AUX Open Limit Switch Annunciator Smoke Power TB1-3 (+) and TB1-4 (–) Alarm Relay (On circuit board.) Fire Sentinel® Release System www.overheaddoor.com 02/13 System Trouble Relay (On circuit board.) 13 Electrical Connections SYSTEM BACKUP BATTERIES Battery: Must be connected at this time, 1) Install System Backup Batteries. • Connect + lead of left battery to – lead of right battery using jumper wire provided. • Connect black wire to black terminal on left battery. • Connect red wire to red terminal on right battery. Red wire to Red terminal 2) Connect the non-rechargeable batteries* (112087.0001) to the FSBX or FSCX observing Figure 12 for proper mounting and connection. NOTE: The transformer is used only in 120VAC models and is not provided on 24VDC models. Power Voltage Replaceable fuses 2A @ 350VAC,125VDC, 2AG Fast Acting Black wire to Black terminal 112087.0001 TBX Low Voltage 1-(L1) or (AC) or (DC-) 2-(Earth GND) 3-(L2) or (AC) or (DC+) * Batteries must be replaced with P/N 112087.0001. Standard AA batteries will not work and may cause damage to the unit and will void the factory warranty. FIGURE 12 Fire Sentinel® Release System www.overheaddoor.com 02/13 14 Electrical Connections FIGURE 13 Replaceable fuses 2A @ 350VAC,125VDC, 2AG Fast Acting PARTS KIT FUSE 2JQ2-R REMOTE TEST PLATE 8.0001 RESISTOR TROUBLE NORMAL TEST A C -1 A C -2 11222 RESET BAT- BAT+ Fire Sentinel® Release System www.overheaddoor.com 12/13 15 Electrical Connections All information on this page applies to both Figure 13A and 14. WARNING : TO REDUCE THE RISK OF SERIOUS INJURY OR FIGURE 13A * Fire Sentinel® Release System TERM-4 TERM-3 TERM-2 TERM-1 www.overheaddoor.com F I R E (+) 120VAC 112228.0001 (-) 112228.0001 Remote Test Reset Station * ADA SOUNDER/STROBE * WHT GRN BLK (+) (-) RED GRN WHT BLK (+) (-) * 1 2 3 4 5 6 7 8 FOUR-WIRE INITIATING DEVICE ALARM RELAY 1 OR— 3 — SYSTEM TROUBLE RELAY TERM-10 TWO-WIRE INITIATING DEVICE FIRE SENTINEL® MODEL FSBX120VAC TERM-11 TERM-2 TERM-1 TERM-14 TERM-13 TERM-12 (+) TERM-7 TERM-8 TERM-9 (-) 112228.0001 ON SYSTEM WIRING NOTES: 1. Supervised, 35 Ohm maximum line impedance. 11228.0001 end of line resistor required for supervision. 2. Not supervised, 75 Ohm maximum line impedance. 3. 4 Class B Style A detectors maximum 112228.0001 end of line resistor required for supervision. 4. 2 Class B Style W notification appliances maximum @ 0.16 Amp/28.6VDC maximum Supervised 20 Ohm maximum line impedance. Place 112228.0001 at positions 10 and 11 if appliances are not used. 5. Form C dry contacts, relay contacts 2A @ 28.6VDC resistive, common mode. 6. End of line relay (EOLR-1) shall be installed with 4-wire detectors. Do Not loop wire under terminals for connections. 7. Smoke power TB1-3 (+) and TB1-4 (–). Supervised, see items 2, 6 above. 8. (2) Class B Style A detectors maximum @ 0.075 Amp/28.6VDC maximum Supervised, see item 1 above. 9. All wiring connections are to be made within 20 feet (6.1 m), enclosed in conduit and in the same room. GROUND FAULT: 20 kOhms maximum from one conductor to earth ground. 10. Replace batteries every 2 years. (+) (-) ORANGE TERM-21 TERM-20 TERM-19 Field and System Wiring shall consist of 22-18 AWG wiring. Use only 350 VAC, 125VDC, 2 Amp, 2 AG Fast Acting fuses. All circuits are not power limited. * DOWN LIMIT PROXIMITY SWITCH WHITE TERM-18 TERM-17 TERM-16 TERM-15 DEATH AND PREVENT DAMAGE TO THE UNIT, ALL INPUT CONNECTIONS MUST BE MADE WITH THE UNIT POWERED DOWN. ALL AUXILIARY LIMIT SWITCHES MUST BE DRY CONTACTS. * OPTIONAL EQUIPMENT NOT INCLUDED WITH THE RELEASE DEVICE. 12/13 16 Electrical Connections All information on this page applies to Figures 13A and 14. TERMINAL LEGEND AND HOOKUPS: 1. Smoke Alarm Return 2. Smoke Alarm Power 3. Smoke Alarm Power 4. Power Return (System Ground) FOUR-WIRE INITIATING DEVICE (+) (–) RMX® / RSX® / RHX® / CDX™ OPERATOR (+) 112228.0001 (+) (–) L3 L2 L1 AUX OUTPUT BOARD RED GREEN WHITE BLACK TERM-18 TERM-17 TERM-16 TERM-15 ADA SOUNDER/STROBE * F I R E TERM-21 TERM-20 TERM-19 112228.0001 (–) * (N) L1 TERM-10 WHITE GREEN BLACK 3 TERM-22 TERM-23 FIRE SENTINEL® TERM-24 MODEL TERM-25 FSCX120V TERM-14 TERM-13 TERM-12 TERM-11 (+) System Trouble Relay TERM-7 TERM-8 TERM-9 Alarm Relay TERM-27 TERM-26 12345678 SPLICE OPEN CLOSE STOP BLUE 1 YELLOW YELLOW SPLICE *OPTIONAL EQUIPMENT NOT INC LUDED WITH THE RELEASE DEV IC E. FSBX. Fire Sentinel® Release System NO SAFETY NO SAFETY EXT INTLK EXT INTLK SPLICE (–) TERM-30 (+) TERM-31 120VAC www.overheaddoor.com 115V 208V 230V NEUTRAL L NE 2 LINE(HOT) GND L NE 1 SINGLE PHASE * PURPLE YELLOW ORANGE RED OPEN CLOSE GND 1-BTN ODC STB ODC STB BROWN TAN BLUE GND THREE PHASE GND L2 N L1 L1 DN1** GREEN PURPLE PINK BLACK * LINE 3 LINE 2 LINE 1 GND UP1 GREY WHITE ORANGE ON Remote Test Reset Station TERM-2 TERM-1 RELAY BOARD TERMINALS FROM LEFT: 22. 3-button Common 23. Stop 24. Open 25. Close 26. Analog Operator Safety Edge 27. Analog Operator Safety Edge Common 28. Digital Operator Safety Edge 29. Digital Operator Safety Edge 30. Control Sense Out 31. Control Sense In (–) 112228.0001 Annunciator Output (+) Annunciator Return (–) Alarm Relay Common (dry contact) Alarm Relay Normally Closed (dry contact) Alarm Relay Normally Open (dry contact) Remote Common (System Ground) Remote Test (must be dry switch contact) Remote Reset (must be dry switch contact) Remote Trouble Indicator (red LED anode) Trouble Relay Common (dry contact) Trouble Relay Normally Closed (dry contact) Trouble Relay Normally Open (dry contact) (–) OR— TERM-4 TERM-3 TERM-2 TERM-1 15. 16. 17. 18. 19. 20. 21. (+) * TWO-WIRE INITIATING DEVICE — 5. N/A 6. N/A 7. Auxiliary Open Limit Switch (must be dry switch contact) 8. Limit Switch Common 9. Auxiliary Close Limit Switch (must be dry switch contact) 10. 11. 12. 13. 14. * FIGURE 14 (+) External Radio (–) STOP MONITORED EDGE INTERFACE MODULE * SENSING EDGE * **DOWN LIMIT—USE PROXIMITY SWITCH 12/13 17 Electrical Connections Dip Switches: Refer to Figure 15. 8. LED Indications when lit: NOTE: Relay Board LEDs are not shown. JP3 LED 9 LED 11 JP19 LED LED 19 2 LED 10 JP21 1 1 RESET JP23 7. LED 23 JP16 6. FIGURE 15 S5 6 5. Delay Alarm Time (OFF: 10s, ON: 20s.) Delay Alarm Time Extended (OFF: as set by 1, ON: 60s.) Safety Timer (OFF: 2 minutes, ON: 4 minutes.) Annunciator Down Limit (if set ON: notification appliances will shut off when automated door reaches down limit in tests only.) Auto Open on Reset (if set ON: automated doors will open when the alarm is reset in tests only.) Relay Board Present (OFF: Board not present ON: Board present [use to enable/disable relay board functions.]) Stop on Obstruction (ON: in alarm, automated doors will stop at the obstruction on the third closing cycle.) (See Test Procedures, page 24) Alarm on Power Loss (ON: loss of external power will trigger an alarm sequence.) JP25 1. 2. 3. 4. LED 20 S6 LED LED 22 21 Three LEDs in the upper left corner of the board are: Green: AC Present - LED 9 Yellow: Battery OK - LED 10 Yellow: Trouble - LED 11 Next to the JP16 header connector: Yellow: Magnet open/not present - LED 2 Green: Magnet on- LED19 Upper Right: Green: 5V Power on - LED 23 LEDs along the Terminal Block—left to right: Yellow: Smoke detector loop open - LED 22 Red: Smoke detector alarm or short - LED 21 Green: Open Limit - LED 6 Green: Down Limit - LED 4 Yellow: Alarm annunciator loop open - LED 7 Red: Alarm annunciator loop short - LED 8 TEST Fire Sentinel® Release System www.overheaddoor.com S4 ON 1 2 3 4 5 6 7 8 1 ON LED LED 6 4 JP8 JP9 2 3 1 2 3 4 4 5 6 7 8 9 LED 7 JP4 LED 8 JP6 10 11 12 13 14 JP26 JP10 JP2 15 16 17 18 19 20 21 5 6 7 8 02/13 18 Electrical Connections (Trouble Code Chart) The Trouble LED on the Main Board will flash out these codes in sequence. Each trouble present is counted out in sequence separated by a distinct pause. After all uncleared troubles have been counted out, the sequence repeats. TROUBLE LED (YELLOW) TROUBLE CODE (1) FLASH MAGNET FAULT Check electromagnet cable and terminal JP3 (3) FLASHES GROUND FAULT Check all low voltage field wiring especially insulation (5) FLASHES BATTERY NOT CHARGING Check SLA battery cables (6) FLASHES CHARGER VOLTAGE FAIL Check AC voltage and wiring (7) FLASHES BATTERY LOW (8) FLASHES EXTERNAL POWER LOSS (9) FLASHES RETAINER SWITCH (10) FLASHES ANNUNCIATOR CIRCUIT OPEN Check annunciator (Horn/Strobe) wiring; Verify EOL resistor is installed (11) FLASHES ANNUNCIATOR CIRCUIT SHORT Check annunciator (Horn/Strobe) wiring (12) FLASHES ALARM LOOP OPEN (15) FLASHES TEST REQUIRED (16) FLASHES REAL-TIME CLOCK ERROR (17) FLASHES STUCK RESET (18) FLASHES CONTROL SENSING VOLTAGE NOT PRESENT (22) FLASHES NON-RECHARGEABLE BATTERY RUN TIME EXCEEDED (29) FLASHES SAFETY EDGE FAULT Fire Sentinel® Release System REQUIRED ACTION Check AC voltage and wiring; Check fuse F3; replace with known good battery Check AC voltage and wiring; Check fuse F2 Remove armature from bracket and place on magnet Check smoke alarm wiring and smoke alarm EOL (resistor/relay termination) Perform drop or close test Replace non-rechargeable battery and perform drop or close test Check reset button and keyswitch; Check keyswitch wiring Check terminals 30, 31 and pigtail - Check operator has power Replace non-rechargeable battery Check safety edge and safety edge wiring www.overheaddoor.com 12/13 19 Maintenance WARNING : TO PREVENT POSSIBLE SERIOUS INJURY OR DEATH DURING MAINTENANCE: • PLACE DOOR IN FULLY CLOSED POSITION • DISCONNECT ANY AND ALL POWER FROM SYSTEM AND SYSTEM COMPONENTS INCLUDING MOTORS WHERE APPLICABLE System batteries must be changed a minimum of every two years or upon generation of system battery trouble. Included is a pair of sealed lead acid rechargeable batteries utilized for system battery backup, as well as a pair of on-board lithium battery used for the System Annual Test Clock. All batteries should be replaced simultaneously by a properly trained technician using proper tools and instructions. For proper replacement parts, see list on page 25. Batteries should be disposed of in accordance with Federal, State and Local Regulations. System fuses are all 2A @ 350V, 125VDC, 2AG Fast Acting. Reference pages 14, 15 (Figures 12 and 13). Fire Sentinel® Release System www.overheaddoor.com 02/13 20 Electrical and Mechanical Specifications MODEL FSBX MODEL FSCX ELECTRICAL ELECTRICAL OPERATING VOLTAGES: CURRENT REQUIREMENTS: 24 VDC.....................................................SUPERVISORY (non-alarm) .385 A/Alarm .610 A maximum. 120 VAC................................................. 0.430 A maximum. INPUT POWER SUPERVISED: NOTE: 1. Initial power up inrush current shall not exceed 3 times rated current on any model. OPERATING VOLTAGES: CURRENT REQUIREMENTS: 24 VDC.....................................................SUPERVISORY (non-alarm) .385 A/Alarm .610 A maximum. 120 VAC ............................................... 0.430 A maximum. INPUT POWER SUPERVISED: NOTE: 1. Initial power up inrush current shall not exceed 3 times rated current on any model. DOOR POSITION INPUTS: MAXIMUM LOOP RESISTANCE: 35 Ohms. MAXIMUM CURRENT: Not to exceed .002 A maximum. MAXIMUM VOLTAGE: 5VDC. FORM C OUTPUT (MAXIMUM CONTACT RATING): 2 A @ 28VDC resistive, common mode. SMOKE DETECTOR POWER: 18.6–28.8VDC @ .021 A STANDBY, .075 A ALARM. (See pages 8 & 9.) FUSES: ALL FUSES: 2A @ 350V, 125VDC, 2AG, Fast Acting Type (See figure 12 & 13). NOTIFICATION APPLIANCES: 28.8VDC @ .160 A ALARM (See figures 7). BATTERY BACKUP: 12VDC, 5AH, QTY=2, 24hr. supervised circuit. GROUND FAULT: 20 kOhms maximum from one conductor to earth ground. REMOTE TEST/RESET STATION: SPDT, 1A @ 125VAC. Position 1-test, Position 2-normal, Position 3-trouble/alarm reset. Indicators—Red LED - trouble indication (see Trouble Codes pg. 19) On the reset of a trouble, the sounder will turn off, but the LED will remain lighted until the troubles are fixed and a reset is performed. The sounder will reactivate within 24 hours if the trouble is not cleared. CONTROL SENSE-ALL MODELS: Input voltage: 24VAC / DC typical Input Current—Not to exceed .005 A. DOOR POSITION INPUTS: MAXIMUM LOOP RESISTANCE: 35 Ohms. MAXIMUM CURRENT: Not to exceed .002 A maximum. MAXIMUM VOLTAGE: 5VDC. FORM C OUTPUT (MAXIMUM CONTACT RATING): 2 A @ 28VDC resistive, common mode. SMOKE DETECTOR POWER: 18.6–28.8VDC @ .021 A STANDBY, .075 A ALARM. (See pages 8 & 9.) FUSES: ALL FUSES: 2A @ 350V, 125VDC, 2AG, Fast Acting Type (See figure 12 & 13). NOTIFICATION APPLIANCES: 28.8VDC @ .160 A ALARM (See figures 7). BATTERY BACKUP: 12VDC, 5AH, QTY=2, 24hr. supervised circuit. GROUND FAULT: 20 kOhms maximum from one conductor to earth ground. REMOTE TEST/RESET STATION: SPDT, 1A @ 125VAC. Position 1-test, Position 2-normal, Position 3-trouble/alarm reset. Indicators—Red LED - trouble indication (see Trouble Codes pg. 19) On the reset of a trouble, the sounder will turn off, but the LED will remain lighted until the troubles are fixed and a reset is performed. The sounder will reactivate within 24 hours if the trouble is not cleared. MECHANICAL MECHANICAL LOAD RATING: SUPPORT AND RELEASE–40lb. maximum. PHYSICAL DIMENSIONS: 10.250" x 9.750" x 4.750" (H x W x D) I.D. WEIGHT: 19 lbs. w/batteries. LOAD RATING: SUPPORT AND RELEASE: 40lbs. maximum. PHYSICAL DIMENSIONS: 10.250" x 9.750" x 4.750" (H x W x D) I.D. WEIGHT: 20 lbs. with batteries. Fire Sentinel® Release System www.overheaddoor.com 12/13 21 Test Procedures Mechanical Door Drop Test for Models BX and CX: WARNING : TO PREVENT POSSIBLE SERIOUS INJURY OR DEATH: • WHILE PERFORMING THE MECHANICAL OR ELECTRICAL DOOR DROP TEST, KEEP YOURSELF AND ANY OTHERS CLEAR OF THE DOOR AND ANY MOVING PARTS. • CLEAR ANY OBJECTS OR PEOPLE FROM DOOR PATH. • PROHIBIT TRAFFIC THROUGH THE DOOR OPENING WHILE TESTING. NOTE: TESTING MUST BE PERFORMED AND WITNESSED FOR NORMAL OPERATION AFTER INSTALLATION. A “Test Required” trouble will occur until a complete test cycle is performed. This is a normal condition and part of the Internal Annual Test Clock/Calendar. The annual test is a National Fire Code requirement. More frequent tests may be required by the local Authority Having Jurisdiction (AHJ). Refer to test procedures contained herein, as well as other testing programs recommended by door manufacturer. The following tests as described using the Remote Test Plate (RTP) may alternatively be performed by the chassis mounted push button test and reset switches. It is recommended that test and reset functions be performed utilizing the RTP provided with the unit. Test steps 1-5 verify a mechanical release to a non-motorized door or a motorized door with external power normal. Test steps 6-10 verify a mechanical release under battery power with external power loss. 1) Turn ON power to the FSBX or FSCX and turn OFF power to the motor operator (if applicable). • A "Test Required" trouble and "Retainer Switch" trouble will be generated at power up. This is normal. Fire Sentinel® Release System www.overheaddoor.com • Turn RTP to RESET, then NORMAL, to silence the troubles. • Remove the Armature from the Retaining Bracket (Figure 2, page 6) and align it with the Supervised Electromagnet. WARNING: CLEAR THE DOOR OPENING BEFORE BEGINNING STEP 2. 2) Turn RTP to the TEST position. The annunciator will sound indicating a door closure is about to occur and after a 10 second factory set alarm verification delay (or longer optional delay) the device will mechanically release the door. 3) Turn RTP to RESET position and then back to the NORMAL position. This test verifies a mechanical release for a non-motorized door or in absence of power to the motor for externally automated doors. 4) Mechanically reset the door and reattach Armature to the Supervised Magnet. • Make sure the door is fully raised. 5) DO NOT restore power to the motor. WARNING: CLEAR THE DOOR OPENING BEFORE BEGINNING STEP 6. 6) Turn OFF power to the FSBX or FSCX. 7) The power LED (red) will turn off and "External Power Loss" and "Battery Not Charging" troubles will be generated in approximately 10 seconds. This is a normal condition. • Turn the RTP to the TEST position. The annunciator will sound indicating a door closure is about to occur and after a 10 second factory set alarm verification delay (or longer optional delay) the device will mechanically release the door. 8) Turn the RTP to the RESET position and then back to NORMAL. This test verifies a mechanical release in absence of power to the FSBX or FSCX and motor (if applicable). 9) Mechanically reset the door and reattach the armature to the release magnet. 10) Restore power to the Release System and Motor operator and raise the door to the fully open position. • Turn the RTP to RESET and back to NORMAL to clear trouble indicator on the RTP. 02/13 22 Test Procedures Automatic Door Closure Tests (Motorized Doors/FSCX only): WARNING : TO PREVENT POSSIBLE SERIOUS INJURY OR DEATH: • WHILE PERFORMING THE MECHANICAL OR ELECTRICAL DOOR DROP TEST, KEEP YOURSELF AND ANY OTHERS CLEAR OF THE DOOR AND ANY MOVING PARTS. • CLEAR ANY OBJECTS OR PEOPLE FROM DOOR PATH. • PROHIBIT TRAFFIC THROUGH THE DOOR OPENING WHILE TESTING. WARNING : THIS EQUIPMENT IS DESIGNED TO BE USED IN CONJUNCTION WITH AN OPERATOR INCORPORATING A MONITORED REVERSING FEATURE SAFETY EDGE. DO NOT EXECUTE THIS TEST WITHOUT A SAFETY EDGE INSTALLED! 1) Make sure the DIP switch at position 6 (relay board PRESENT) is set in the ON position on the Main Circuit Board. • Make sure the door is open and there are no obstructions in its path. WARNING: KEEP THE DOOR OPENING CLEAR OF ALL PERSONNEL. THIS TEST SHOULD BE PERFORMED USING THE TEST AND RESET FUNCTIONS OF THE REMOTE TEST STATION. (It may be performed using the test and reset switches of the device enclosure.) 2) Turn key switch to TEST and leave it there The annunciator will turn on indicating that a door closure is about to occur. After the factory set 10 second delay (or longer optional delay), the device will turn on the motor initiating a closure. 3) Allow the door to fully close. 4) Reset the FSCX by turning the key switch to the RESET position, then back to NORMAL. back to NORMAL. 5) Open the door. THREE CYCLE OBSTRUCTION TEST with release on obstruction 1) Make sure the DIP switch at position 6 (relay board PRESENT) is set in the ON position on the Main Circuit Board. • Place a chair or other suitable obstruction in the normal path of the door. Fire Sentinel® Release System www.overheaddoor.com WARNING: KEEP THE DOOR OPENING CLEAR OF ALL PERSONNEL. THIS TEST SHOULD BE PERFORMED USING THE TEST AND RESET FUNCTIONS OF THE REMOTE TEST STATION. (It may be performed using the test and reset switches of the device enclosure.) 2) Turn the key switch to TEST and leave it there. The annunciator will turn on indicating that a door closure is about to occur. After the factory set 10 second delay (or longer optional delay), the device will turn on the motor initiating a closure. Upon contact with the obstruction, the safety edge will reverse the motor and raise the door to the fully open position. The FSCX will make three attempts to close the door with the motor, after which the FSCX will release the door through the drop release mechanism. STAND CLEAR OF ANY PATH THE OBSTRUCTION MIGHT TAKE AFTER BEING STRUCK BY THE DROPPED DOOR. The door will drop onto the obstruction and will fully close once the obstruction is removed. The annunciator will continue to sound until the alarm condition is cleared. 3) Reset the FSCX by turning the key switch to the RESET position and then back to NORMAL. 4) Reset the door sash chain and armature. *N-O REV INPUT will not allow “STOP ON OBSTRUCTION.” THREE CYCLE OBSTRUCTION TEST WITH STOP ON OBSTRUCTION 1) Make sure the DIP switches at position 6 (relay board PRESENT) and position 7 (stop on obstruction) are set in the ON position on the Main Circuit Board. • Place a chair or other suitable obstruction in the normal path of the door. WARNING: KEEP THE DOOR OPENING CLEAR OF ALL PERSONNEL. THIS TEST SHOULD BE PERFORMED USING THE TEST AND RESET FUNCTIONS OF THE REMOTE TEST STATION. (It may be performed using the test and reset switches of the device enclosure.) 2) Turn the key switch to TEST and leave it there The annunciator will turn on indicating that a door closure is about to occur. After the factory set 10 second delay (or longer optional delay), the device will turn on the motor initiating a closure. CONTINUED NEXT PAGE 02/13 23 Test Procedures Automatic Door Closure Tests (Motorized Doors/FSCX only) (continued): Upon contact with the obstruction, the safety edge will reverse the motor and raise the door to the fully open position. The FSCX will make three attempts to close through the motor. On the third up limit the FSCX will close the door and stop at the obstruction. WARNING : TO PREVENT POSSIBLE SERIOUS INJURY OR DEATH: • WHILE PERFORMING THE MECHANICAL OR ELECTRICAL DOOR DROP TEST, KEEP YOURSELF AND ANY OTHERS CLEAR OF THE DOOR AND ANY MOVING PARTS. • CLEAR ANY OBJECTS OR PEOPLE FROM DOOR PATH. • PROHIBIT TRAFFIC THROUGH THE DOOR OPENING WHILE TESTING. THREE CYCLE OBSTRUCTION TEST WITH STOP ON OBSTRUCTION CONTINUED If the obstruction is removed, the FSCX will wait 10 seconds and then close the door. Should the door contact a second obstruction, the FSCX will fully open the door, then attempt to close the door again. If the obstruction is still there, the FSCX will open the door to the up limit and mechanically release the door. STAND CLEAR OF ANY PATH THE OBSTRUCTION MIGHT TAKE AFTER BEING CONTACTED BY THE DROPPED DOOR. The annunciator will continue to sound until the alarm condition is cleared. 3) Reset the FSCX by turning the key switch to the RESET position and then back to NORMAL. 4) Reset door sash chain and armature. 5) Open the door. AUTO OPEN ON RESET TEST 1) Make sure the DIP switches at position 5 (auto open on reset, test only) and position 6 (relay board PRESENT) are set in the ON position on the Main Circuit Board. Fire Sentinel® Release System www.overheaddoor.com WARNING: KEEP THE DOOR OPENING CLEAR OF ALL PERSONNEL. THIS TEST SHOULD BE PERFORMED USING THE TEST AND RESET FUNCTIONS OF THE REMOTE TEST STATION. (It may be performed using the test and reset switches of the device enclosure.) 2) Turn the key switch to TEST and leave it there. • Make sure there are no obstructions in the path of the door. 3) Allow the door to fully close. 4) Reset the FSCX by turning the key switch to the RESET position and back to NORMAL. • After the reset is complete the door will automatically start to open to the up limit. NOTIFICATION OFF ON CLOSE LIMIT TEST 1) Make sure the DIP switches at position 4 (notification off on down limit, test only) and position 6 (relay board PRESENT) are set to the ON position on the Main Circuit Board. WARNING: KEEP THE DOOR OPENING CLEAR OF ALL PERSONNEL. THIS TEST SHOULD BE PERFORMED USING THE TEST AND RESET FUNCTIONS OF THE REMOTE TEST STATION. (It may be performed using the test and reset switches of the Device Enclosure.) 2) Make sure the operator is not in the down limit • If in the down limit, press the open button on the 3-button station to open the door. 3) Turn the key switch to TEST and leave it there. • Make sure there are no obstructions in the path of the door. 4) Allow the door to fully close. • When the door reaches the down limit, the notification appliances will shut off. If the open button on the 3-button station is pressed and the door leaves the down limit, the notification appliances will turn back on. 5) Reset the FSCX by turning the key switch to RESET and then back to NORMAL. NOTE: If Dip Switch 5 is not set to ON—the door will automatically re-open. 02/13 24 Test Procedures Automatic Door Closure Tests (Motorized Doors/FSCX only) (continued): WARNING : TO PREVENT POSSIBLE SERIOUS INJURY OR DEATH: • WHILE PERFORMING A MECHANICAL OR ELECTRICAL DOOR DROP TEST, STAY CLEAR OF THE DOOR AND ANY MOVING PARTS. • CLEAR ANY OBJECTS OR PEOPLE FROM DOOR PATH. • PROHIBIT TRAFFIC THROUGH THE DOOR OPENING WHILE TESTING. ALARM ON POWER LOSS TEST 1) Make sure the DIP switch at position 8 (alarm on power loss) is set in the ON position on the Main Circuit Board. 2) UNPLUG the unit from the AC power source OR DISCONNECT the DC power input to the unit. • After the factory set 10 second time delay (or longer optional delay) the device will close the door. 3) Re-apply AC or DC power to the unit. 4) Reset the FSCX by turning the key switch to RESET and back to NORMAL. After completing all tests, verify the door is in normal operating condition (open or closed) and that all power required for normal operation has been restored to the unit and operator. This equipment is designed to operate with its power source applied. SET DIP SWITCHES AS DESIRED. Fire Sentinel® Release System www.overheaddoor.com Release Device Compatibility Identifier Photoelectric Smoke Detectors System Sensor Model No ............Description 2W-B ..............................................2-wire smoke detector, compatibility identifier A 2WT-B............................................2-wire smoke detector w/135°F thermal sensor, compatibility identifier A 4W-B ..............................................4-wire smoke detector 4WT-B............................................4-wire smoke detector w/135°F thermal sensor Hochiki Model No ...........................Description SLR835BH-2................................2-wire smoke detector w/135°F thermal sensor, compatibility identifier HD-6 Heat Detectors System Sensor Model No ............Description 5603 ...............................................135°F fixed temperature 5604 ...............................................194°F fixed temperature Hochiki Model No ...........................Description DFE-135 ..................................... 135˚F fixed temperature Notification Devices System Sensor Model No ............Description SR ...............................................Strobe. Set for 15 cd per System Sensor Instructions HR ...............................................Horn. Set for non-temporal horn per System Sensor Instructions P2R ...............................................Horn/Strobe. Set for 15 cd and non-temporal horn per System Sensor instructions End of Line Devices System Sensor Model No ..........Description EOLR-1 ..........................................End of line relay Replacement Parts Overhead Door Part No................Qty ......................................Description . 111658.0001.S ...........................1 ..........................................Sytem backup battery (12 Volt) 112087.0001.S ...........................1 ...........................................System non-rechargeable battery (NRB2.4-7.2) 112325.0001.S ...................... as req'd ..............................End of line relay w/Plate 112249.0001.S .........................as req'd ..............................End of line resistor w/Plate 111995.XXXXXX .....................as req'd ..............................Installation Manual 112012.0001.S ...........................1 ..........................................Armature Assembly 112007.0001.S ...........................1 ...........................................Remote Test Plate 112226.0001.S...........................10 pack..............................Fuse 2A 112228.0001.S ...........................10 pack..............................Supervisory Resistor 12/13 25 Installation Notes Fire Sentinel® Release System www.overheaddoor.com 02/13 26 Test Records DATE SERIAL # INSTALLER/TESTER NAME WITNESS NAME PASS FAIL Make copies of this page as needed for additional testing. Keep records of all tests in a permanent file. Fire Sentinel® Release System www.overheaddoor.com 02/13 27 Overhead Door Corporation Fire Sentinel® Release System Claims under this warranty must be made promptly after discovery, within the applicable warranty period, and in writing to the authorized distributor or installer whose name and address appeared below. (Proof of purchase and identification as the original purchaser may be required.) The purchaser must allow Seller reasonable opportunity to inspect any Product claimed to be defective prior to removal or any alteration of its condition. Limited Warranty The Distributor of Overhead Door Corporation products whose name appears below (”Seller”) warrants to the original purchaser of the Fire Sentinel® Release System specified below (”Product”), subject to all terms and conditions hereof, that the Product and all components thereof will be free from defects in material and workmanship under normal use and service for the following period, measured from the date of the installation: • One (1) year its option,the Product or any part thereof which is determined by Seller to be defective during the applicable warranty period. Any labor charges are excluded and will be the responsibility of the purchaser. This warranty is made to the original purchaser of the Product only, and is not transferable or assignable. This warranty applies only to the Product which is installed in commercial or industrial building applications. This warranty does not apply to any unauthorized alteration or repair of the Product, or to any Product or component which has been damaged or deteriorated due to misuse, neglect, accident or failure to provide necessary maintenance, normal wear and tear, or acts of God or other causes beyond the resonable control of Seller and does not cover batteries, or repairs and maintenance to the operator or door components. MODEL #: SERIAL #: ORIGINAL PURCHASER: INSTALLATION ADDRESS: DOOR NUMBER (MULTIPLE DOOR INSTALLATIONS): DOOR TYPE: SELLER: SELLER’S ADDRESS: DATE OF INSTALLATION: SIGNATURE OF SELLER: THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY OTHER WARRANTIES, EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL SELLER BE RESPONSIBLE FOR, OR LIABLE TO ANYONE FOR, SPECIAL, INDIRECT, COLLATERAL, PUNITIVE, INCIDENTAL OR CONSEQUENTIAL DAMAGES, even if Seller has been advised of the possibility of such damages. Such excluded damages include, 28 THIS PAGE LEFT BLANK Fire Sentinel® Release System www.overheaddoor.com THIS PAGE LEFT BLANK Fire Sentinel® Release System www.overheaddoor.com 1 Door Drive Mt. Hope, Ohio 44660 800-275-6187 www.overheaddoor.com