Section – V : Technical Specification B) ELECTRICAL

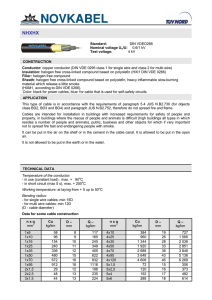

advertisement