technical specification for foam protection system

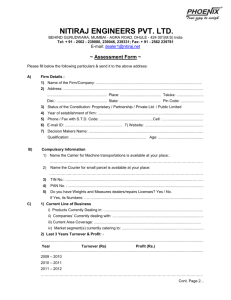

advertisement