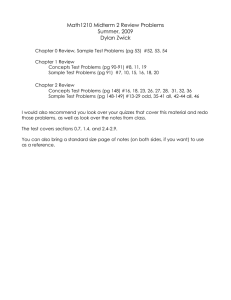

Testing Machines and Systems for the

advertisement