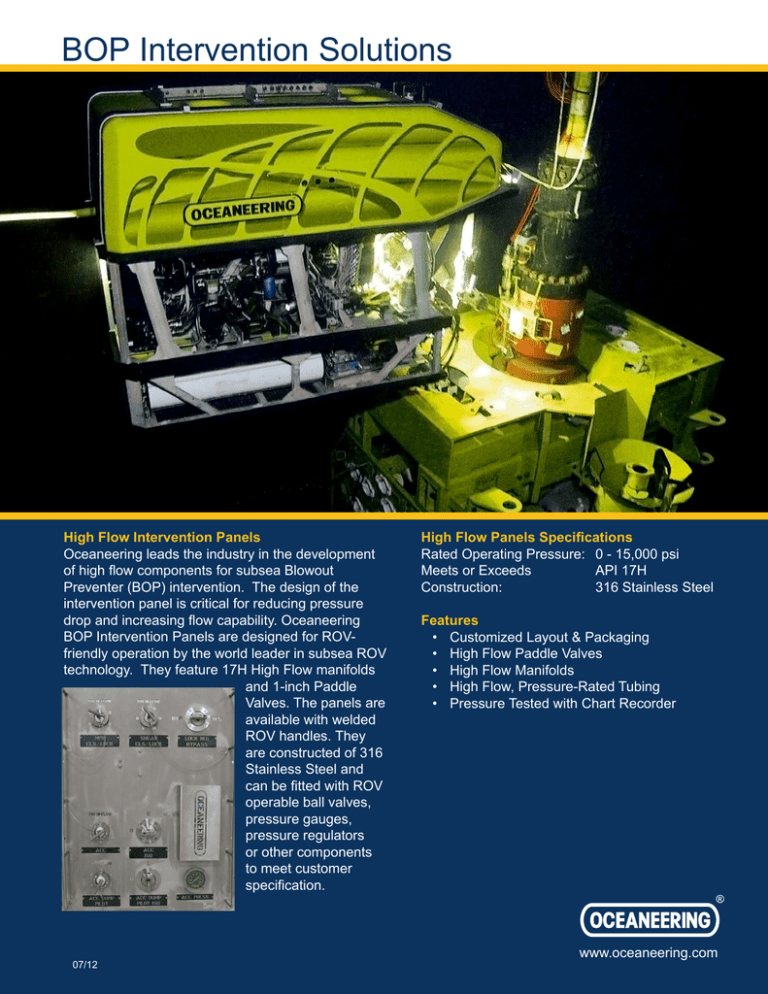

BOP Intervention Solutions

advertisement

BOP Intervention Solutions High Flow Intervention Panels Oceaneering leads the industry in the development of high flow components for subsea Blowout Preventer (BOP) intervention. The design of the intervention panel is critical for reducing pressure drop and increasing flow capability. Oceaneering BOP Intervention Panels are designed for ROVfriendly operation by the world leader in subsea ROV technology. They feature 17H High Flow manifolds and 1-inch Paddle Valves. The panels are available with welded ROV handles. They are constructed of 316 Stainless Steel and can be fitted with ROV operable ball valves, pressure gauges, pressure regulators or other components to meet customer specification. 07/12 High Flow Panels Specifications Rated Operating Pressure: 0 - 15,000 psi Meets or Exceeds API 17H Construction: 316 Stainless Steel Features • Customized Layout & Packaging • High Flow Paddle Valves • High Flow Manifolds • High Flow, Pressure-Rated Tubing • Pressure Tested with Chart Recorder www.oceaneering.com BOP Intervention Skids & Topside Test Units The Oceaneering Gen II BOP Intervention Skid provides a dedicated fluid supply for BOP function testing. The Gen II Skid comprises a compact modular design, to maintain ROV maneuverability. It is adaptable to any work-class ROV and uses a bladder style fluid storage tank and a 50 HP duplex pump for function testing and accumulator charging. A subsea intelligent display, in-line pressure gauges, flow meters and other instrumentation allow constant monitoring of output pressure and flow. The lightweight frame and compact footprint Intervention Skids Specifications Capacity Range: Input Flow Range: Input Pressure Range: Output Flow Range: Output Pressure Range: Weight in Air: Weight in Water: 64 - 135 gal 0 – 30 gpm 0 – 3,000 psi 0 – 10 gpm 0 – 5,000 psi 1,600 lb 100 lb Features • Modular Design for Quick Maintenance • Fully Instrumented for Performance Monitoring • Compact, Lightweight Design • Periodic OEM Recertification Availability enable adding ROV tooling without removing the skid. Semi-annual factory recertification keeps the skid in operable and ready-to-use condition. The modular design facilitates preventive maintenance and repairs. Custom engineered cage-mounted systems are also available. Skids are offered with a companion Topside Test Unit to provide identical control and performance to that of the ROV skid, but for topside testing. The Topside Test Unit is powered by an available Hydraulic Power Unit and is equipped with adjustable inlet flow and pressure control valves, plus an outlet pressure relief valve. 2 Auxiliary Accumulator System The Oceaneering Auxiliary High Pressure Accumulator System, or Six Shooter, solves the challenge of meeting 45 second minimum closing times at the maximum allowable surface pressure for ROV intervention systems. As requirements for Secondary BOP Stack control become increasingly stringent, operators now have a proven method for ROV intervention that meets current regulatory rules for matching the primary stack control requirements. The Oceaneering Six Shooter provides a modular, independent source of subsea accumulated volume that can be accessed quickly and easily for emergency BOP intervention. Any ROV of opportunity connects the Six Shooter to the BOP Stack via Hydraulic Flying Leads and industry standard 17H High Flow hot stabs. ROV operable paddle valves on the control panels allow convenient and direct control. The Six Shooter can supply high flow (100 gpm) control fluid at selectable pressures of 5,000 psi and 3,000 psi, or 3,000 psi and 1,500 psi with its dual pressure regulators. The primary Six Shooter module consists of six piston style accumulators. Each 100 gallon accumulator is rated for up to 7,500 psi charge pressure. A secondary Six Shooter module can be easily incorporated into the system if more volume is required. Subsea installation from a service vessel or rig uses a mudmat with a central guide pin, provided as standard installation equipment. A guide funnel assembly secured to the Six Shooter is lowered onto the mudmat guide pin. The Oceaneering Six Shooter is purpose built to meet today’s requirements for BOP Intervention and secondary control. It is designed for long-term subsea deployment. With periodic recertification through Oceaneering the Six Shooter remains ready for emergency use at any time. Assembled and tested to the industry’s highest quality standards in Houston, the Oceaneering Six Shooter is the proven solution for fast, reliable BOP intervention. Six Shooter Systems Specifications Rated Output Pressure: Rated Charge Pressure: Rated Output Flow: Weight in Air: Weight in Water: 5,000 psi 7,500 psi 100 gpm 60,000 lb 45,000 lb Features • Capable of Ram Closure in 45 seconds • Selectable, Pressure-Regulated Output • Subsea Rechargeable Volume • Reliable Cycle Tested Components • Modularity for Optional Increased Volume • Flexible Subsea Installation Options • Proven, Simple Deployment Scenarios • Periodic OEM Recertification Availability 3 United States Huntsville, Alabama San Diego, California Groton, Connecticut Orlando, Florida Panama City, Florida Pearl Harbor, Hawaii Bayou Vista, Louisiana Houma, Louisiana Lafayette, Louisiana Morgan City, Louisiana New Orleans, Louisiana Hanover, Maryland Portsmouth, New Hampshire Middletown, Rhode Island Clear Lake, Texas Corpus Christi, Texas Friendswood, Texas Houston, Texas Chesapeake, Virginia Silverdale, Washington International Cabinda, Angola Lobito, Angola Luanda, Angola Baku, Azerbaijan Perth, Western Australia Macaé, Brazil Niteroi - RJ, Brazil St. John’s, Newfoundland, Canada Halifax, Nova Scotia, Canada Cairo, Egypt Gloucester, England Immingham, England London, England Stockton, England Thurrock, England Whitley Bridge, England Malabo, Equatorial Guinea Mumbai, India Kuala Lumpur, Malaysia Miri, Sarawak, Malaysia Mexico D.F., Mexico Cd. del Carmen, Mexico Eket, Nigeria Ikeja, Lagos, Nigeria Port Harcourt, Nigeria Warri, Nigeria Nodeland, Norway Stavanger, Norway Johannesburg, Republic of South Africa Aberdeen, Scotland Rosyth, Scotland Jurong, Singapore Zug, Switzerland Abu Dhabi, U.A.E. Dubai, U.A.E. Swansea, Wales Denotes Corporate Office Oceaneering International, Inc. | Deepwater Technical Solutions (DTS) | 11915 FM 529 | Houston, TX 77041 phone: 832.467.7600 | email: toolpool@oceaneering.com | www.oceaneering.com OCEANEERING® is a registered trademark of Oceaneering International, Inc.