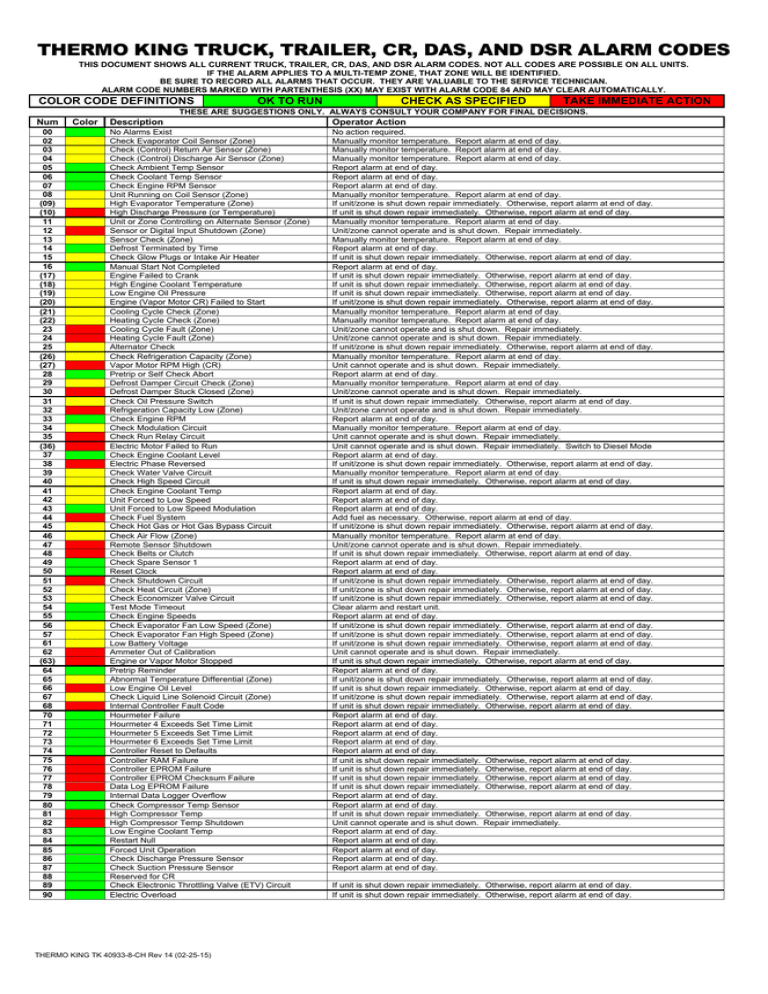

thermo king truck, trailer, cr, das, and dsr alarm codes

advertisement

THERMO KING TRUCK, TRAILER, CR, DAS, AND DSR ALARM CODES THIS DOCUMENT SHOWS ALL CURRENT TRUCK, TRAILER, CR, DAS, AND DSR ALARM CODES. NOT ALL CODES ARE POSSIBLE ON ALL UNITS. IF THE ALARM APPLIES TO A MULTI-TEMP ZONE, THAT ZONE WILL BE IDENTIFIED. BE SURE TO RECORD ALL ALARMS THAT OCCUR. THEY ARE VALUABLE TO THE SERVICE TECHNICIAN. ALARM CODE NUMBERS MARKED WITH PARTENTHESIS (XX) MAY EXIST WITH ALARM CODE 84 AND MAY CLEAR AUTOMATICALLY. COLOR CODE DEFINITIONS OK TO RUN CHECK AS SPECIFIED TAKE IMMEDIATE ACTION THESE ARE SUGGESTIONS ONLY. ALWAYS CONSULT YOUR COMPANY FOR FINAL DECISIONS. Num 00 02 03 04 05 06 07 08 (09) (10) 11 12 13 14 15 16 (17) (18) (19) (20) (21) (22) 23 24 25 (26) (27) 28 29 30 31 32 33 34 35 (36) 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 61 62 (63) 64 65 66 67 68 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 Color Description Operator Action No Alarms Exist Check Evaporator Coil Sensor (Zone) Check (Control) Return Air Sensor (Zone) Check (Control) Discharge Air Sensor (Zone) Check Ambient Temp Sensor Check Coolant Temp Sensor Check Engine RPM Sensor Unit Running on Coil Sensor (Zone) High Evaporator Temperature (Zone) High Discharge Pressure (or Temperature) Unit or Zone Controlling on Alternate Sensor (Zone) Sensor or Digital Input Shutdown (Zone) Sensor Check (Zone) Defrost Terminated by Time Check Glow Plugs or Intake Air Heater Manual Start Not Completed Engine Failed to Crank High Engine Coolant Temperature Low Engine Oil Pressure Engine (Vapor Motor CR) Failed to Start Cooling Cycle Check (Zone) Heating Cycle Check (Zone) Cooling Cycle Fault (Zone) Heating Cycle Fault (Zone) Alternator Check Check Refrigeration Capacity (Zone) Vapor Motor RPM High (CR) Pretrip or Self Check Abort Defrost Damper Circuit Check (Zone) Defrost Damper Stuck Closed (Zone) Check Oil Pressure Switch Refrigeration Capacity Low (Zone) Check Engine RPM Check Modulation Circuit Check Run Relay Circuit Electric Motor Failed to Run Check Engine Coolant Level Electric Phase Reversed Check Water Valve Circuit Check High Speed Circuit Check Engine Coolant Temp Unit Forced to Low Speed Unit Forced to Low Speed Modulation Check Fuel System Check Hot Gas or Hot Gas Bypass Circuit Check Air Flow (Zone) Remote Sensor Shutdown Check Belts or Clutch Check Spare Sensor 1 Reset Clock Check Shutdown Circuit Check Heat Circuit (Zone) Check Economizer Valve Circuit Test Mode Timeout Check Engine Speeds Check Evaporator Fan Low Speed (Zone) Check Evaporator Fan High Speed (Zone) Low Battery Voltage Ammeter Out of Calibration Engine or Vapor Motor Stopped Pretrip Reminder Abnormal Temperature Differential (Zone) Low Engine Oil Level Check Liquid Line Solenoid Circuit (Zone) Internal Controller Fault Code Hourmeter Failure Hourmeter 4 Exceeds Set Time Limit Hourmeter 5 Exceeds Set Time Limit Hourmeter 6 Exceeds Set Time Limit Controller Reset to Defaults Controller RAM Failure Controller EPROM Failure Controller EPROM Checksum Failure Data Log EPROM Failure Internal Data Logger Overflow Check Compressor Temp Sensor High Compressor Temp High Compressor Temp Shutdown Low Engine Coolant Temp Restart Null Forced Unit Operation Check Discharge Pressure Sensor Check Suction Pressure Sensor Reserved for CR Check Electronic Throttling Valve (ETV) Circuit Electric Overload No action required. Manually monitor temperature. Report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Manually monitor temperature. Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Unit/zone cannot operate and is shut down. Repair immediately. Manually monitor temperature. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Unit/zone cannot operate and is shut down. Repair immediately. Unit/zone cannot operate and is shut down. Repair immediately. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Unit cannot operate and is shut down. Repair immediately. Report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Unit/zone cannot operate and is shut down. Repair immediately. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Unit/zone cannot operate and is shut down. Repair immediately. Report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Unit cannot operate and is shut down. Repair immediately. Unit cannot operate and is shut down. Repair immediately. Switch to Diesel Mode Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor temperature. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Add fuel as necessary. Otherwise, report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Unit/zone cannot operate and is shut down. Repair immediately. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Clear alarm and restart unit. Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Unit cannot operate and is shut down. Repair immediately. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Unit cannot operate and is shut down. Repair immediately. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. THERMO KING TK 40933-8-CH Rev 14 (02-25-15) If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. COLOR CODE DEFINITIONS OK TO RUN CHECK AS SPECIFIED TAKE IMMEDIATE ACTION THESE ARE SUGGESTIONS ONLY. ALWAYS CONSULT YOUR COMPANY FOR FINAL DECISIONS. Num 91 92 93 94 95 96 97 98 99 (100) 101 (102) 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 163 175 176 177 178 180 188 203 204 216 233 234 235 250 251 252 253 254 Color Description Operator Action Check Electric Ready Input Sensor Grades Not Set (Zone) Low Compressor Suction Pressure Check Loader #1 Circuit Check Loader #2 Circuit Low Fuel Level Failed Remote Return Air Sensor (CR) Check Fuel Level Sensor High Compressor Pressure Ratio Heater Fan Failure (CR) Controlling on Evap Coil Outlet Temp (CR) Low Evaporator Coil Temperature (CR) Low Heater Fuel Level (CR) Check Remote Fan Speed (Zone) Check Receiver Tank Press Sol Circuit Check Purge Valve Circuit Check Condenser Inlet Sol Circuit Door Open Timeout (Zone) Check High Discharge Pressure Sensor Check Suction Line Sol Circuit (Zone) Unit Not Configured Correctly (Zone) Check Remote Fans (Zone) Check Electric Heat Circuit (Zone) Multiple Alarms - Can Not Run (Zone) Check High Pressure Cut Out Switch Check High Pressure Cut In Switch Auto Switch from Diesel to Electric Auto Switch from Electric to Diesel Reserved for CR Check Alternator Excite Circuit Check PMW Liquid Injection Circuit Check Diesel/Electric Circuit Check Evap Coil Inlet Temp Sensor (CR) Check Evap Coil Outlet Temp Sensor (CR) Check Tank Level Sensor (CR) Check Back Pressure Regulator (CR) Setpoint Not Entered (Zone) Engine Run Time Maint Reminder #1/Service Due Engine Run Time Maint Reminder #2 Electric Run Time Maint Reminder #1 Electric Run Time Maint Reminder #2 Total Unit Run Time Maint Reminder #1 Total Unit Run Time Maint Reminder #2 Controller Power On Hours Check Spare Digital Inputs Check Spare Digital Outputs Check Damper Motor Heater Output Log DAS Real Time Clock Battery Failure (DAS) Abort Evacuation Mode Not currently used Auto Switch Diesel to Electric Disabled Check Thermax Valve Check Remote Drain Hose Heater Output (Zone) Lost CAN Communications to Expansion Module Lost Controller ON Feedback Signal Software Version Mismatch Check Multi-Temp Fan Speed Control Output (Zone) Auto Switch Electric to Diesel Disabled Alarm Not Identified Sensor Out of Range Low (DAS and HMI) (Zone) Sensor Out of Range High (DAS and HMI) (Zone) DAS Failed Sensor (DAS) Expansion Module Flash Load Failure Low Suction Pressure Switch Failure Lost CAN Communications to HMI Check Suction/Liquid Heat Exchanger Bypass Valve OptiSet Plus Profile Mismatch Primary Software Failed to Load Check Battery Condition Lost CAN Communications to Radio Expansion Board Log DAS Real Time Clock Invalid (DAS) Emission Control Failure Check Electronic Expansion Valve (CR) Check Evaporator Pressure Sensor (CR) Check CO2 Tank Pressure Sensor (CR) Low CO2 Fuel Level (CR) TriPac Compressor Alarm Log DAS Microprocessor Fault (DAS) Check Display Return Air Sensor (Zone) Check Display Discharge Air Sensor (Zone) Check DAS Digital Inputs (DAS) REB Switching Off, Conservative to Full Null Check Relative Humidity Sensor Circuit High Engine Coolant Temperature Check DAS Clock Time Reset (DAS) Check Radio Expansion Board Configuration Check Auto Fresh Air Exchange Circuit REB On Back Up Battery, Alarms Disabled Check Auxiliary Coolant Temp Sensor If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Add fuel as required. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor temperature. Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Manually monitor temperature. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Close doors. Report alarm at end of day. Replaced by Alarm Code 86 If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Unit/zone cannot operate and is shut down. Repair immediately. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Normal operation – does not affect performance. Normal operation – does not affect performance. THERMO KING TK 40933-8-CH Rev 14 (02-25-15) If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Manually monitor load temperature. Report this alarm at the end of the day. Be sure setpoint is adjusted to required temperature. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Unit cannot operate and is shut down. Repair immediately. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Manually monitor load temperature. Report this alarm at the end of the day. Report alarm at end of day. If unit/zone is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Unit cannot operate and is shut down. Repair immediately. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Manually monitor temperature. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. THERMO KING PRECEDENT 500 SERIES ALARM CODES The 500 Series Thermo King Alarm Codes shown below are used on Thermo King Precedent applications. COLOR CODE DEFINITIONS OK TO RUN CHECK AS SPECIFIED TAKE IMMEDIATE ACTION THESE ARE SUGGESTIONS ONLY. ALWAYS CONSULT YOUR COMPANY FOR FINAL DECISIONS. Num Color 500 501 505 506 507 508 509 510 511 512 513 514 515 516 518 519 520 521 522 523 524 525 526 528 529 530 531 538 539 540 542 543 544 545 546 547 548 549 550 551 552 553 599 Description Operator Action Check Host Evaporator Blower Low Speed Check Host Evaporator Blower High Speed Check Roadside Condenser Fan Motor Speed Circuit Check Curbside Condenser Fan Motor Speed Circuit Check Digital Scroll Output Circuit (Scroll Only) Speed Request Communication Error ECU Failed to Enable ECU Run Signal Failed Engine Wait to Start Time Delay Expired High Compressor Suction Pressure (Scroll Only) Low Compressor Suction Ratio (Scroll Only) Low Compressor Discharge Pressure (Scroll Only) Minimum ETV Discharge Superheat Temp (Scroll) I/O Controller to Application Controller Com Failure Generator Ground Fault Check Battery Charger Input Power Check Battery Charger Output Power Battery Charger External/Environmental Fault Battery Temperature Sensor Alarm Battery Charger Indicated Conditions Generator Op Limit Vout to Frequency Ration Generator Frequency Range Fault Generator Operational Limit Output Current Failed J1939 CAN Comm Base Controller/Charger Check Fuel Pump Circuit Low Pressure Differential (Scroll only) Check Economizer Pressure Sensor (Scroll only) Engine J1939 CAN Data Link Degraded Engine J1939 CAN Data Link Failed Illegal Engine Operating State Battery Charger Fault – Unit Forced to Low Speed Battery Charger Internal Short Battery Charger External Short Battery Charger Output Voltage Exceeded Limit Battery Charger Operating Bulk Voltage Out of Range AC Bus Phase Loss Battery Charger Temperature Below Operating Range Battery Charger AC Input Overvoltage Battery Charger Internal Overvoltage Fault Battery Charger Internal Temp Sensor Fault Battery Charger Charging – Low Battery Battery Charger Operating Derated Due to High temp Engine Service Tool Connected Not implemented Not implemented If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. The unit is no longer able to operate and has been shut down. Repair immediately. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Maintenance information only. Report alarm at end of day. Maintenance information only. Report alarm at end of day. Maintenance information only. Report alarm at end of day. Maintenance information only. Report alarm at end of day. Maintenance information only. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Maintenance information only. Report alarm at end of day. Maintenance information only. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Report alarm at end of day. PRECEDENT 600 SERIES YANMAR DIAGNOSTIC TROUBLE CODES (DTC) If the Yanmar Engine Control Unit (ECU) determines an engine related problem exists, one or more Yanmar Diagnostic Trouble Codes (DTC’s) will be set by the ECU. As a result, one or more Thermo King 6xx codes will also be set and displayed on the HMI Control Panel and the ServiceWatch Data Logger as shown below. COLOR CODE DEFINITIONS OK TO RUN CHECK AS SPECIFIED TAKE IMMEDIATE ACTION THESE ARE SUGGESTIONS ONLY. ALWAYS CONSULT YOUR COMPANY FOR FINAL DECISIONS. Num 600 601 603 604 605 607 608 609 610 611 613 614 615 616 617 618 619 620 623 624 625 626 642 699 Color Description Operator Action Check Crankshaft Speed Sensor Check Camshaft Speed Sensor Check Exhaust Pressure Sensor Check Coolant Temp Sensor Check Fresh Air Temp Sensor Check Fuel Temperature Sensor Check Rail Pressure Sensor Check Intake Pressure Sensor Check Atmospheric Pressure Sensor Check Glow Plug Circuit Check Injectors Check High Pressure Fuel Pump Rail Pressure Fault Engine Overspeed Internal ECU Fault Check EGR System ECU Main Relay Fault No RPM Detected During Start Attempt TRUCAN Message Timeout Check EGR Temperature Sensor Check Intake Air Temperature Sensor Check Exhaust Temperature Sensor ECU Forced Low Speed Unknown ECU Fault Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. If unit is shut down repair immediately. If unit is shut down repair immediately. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. THERMO KING TK 40933-8-CH Rev 14 (02-25-15) Otherwise, report alarm at end of day. Otherwise, report alarm at end of day. Otherwise, report alarm at end of day. Otherwise, report alarm at end of day. Otherwise, report alarm at end of day. PRECEDENT 800 SERIES PEUGEOT DIAGNOSTIC TROUBLE CODES (DTC) If the Peugeot Engine Control Unit (ECU) determines an engine related problem exists, one or more Peugeot Diagnostic Trouble Codes (DTC’s) will be set by the ECU. As a result, one or more Thermo King 8xx codes will also be set and displayed on the HMI Control Panel and the ServiceWatch Data Logger as shown below. COLOR CODE DEFINITIONS OK TO RUN CHECK AS SPECIFIED TAKE IMMEDIATE ACTION THESE ARE SUGGESTIONS ONLY. ALWAYS CONSULT YOUR COMPANY FOR FINAL DECISIONS. Num Color 800 801 804 807 808 809 810 811 813 815 818 819 820 825 826 827 828 829 830 832 833 834 836 838 839 840 841 842 843 844 845 846 847 853 854 899 Description Operator Action Crankshaft Position Sensor Error Camshaft Position Sensor Error Engine Coolant Temperature Sensor Error Fuel Temperature Sensor Error Rail Pressure Sensor Error Intake Air Pressure Sensor Error Atmospheric Pressure Sensor Error Glow Plug Circuit Error General Injector Error Fuel Pressure Regulator Error EGR Valve Actuator Error ECU Power Relay Error Main ECU Relay Error T1 Air Intake Temperature Sensor Error T2 Air Intake Temperature Sensor Error EGR Valve Position Sensor Error Lambda System Error Engine Communication Error Air Flow Meter Error Engine Power Supply Error High Pressure Pump Fuel Metering Unit Error Water in Fuel Sensor Error Major ECU Failures Intake Air System Error Engine Speed Error Fuel Injection Energizing Error High Pressure Pump Wear Engine Running in Safe Mode – Low Speed Fuel Injection System Error Engine Failed to Crank Starter Relay Error T50 Switch Error Variant Coding Error Engine Overspeed (No DTC) Engine Protection Self Shutdown Unknown ECU Fault Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. If unit is shut down repair immediately. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Otherwise, report alarm at end of day. Otherwise, report alarm at end of day. Otherwise, report alarm at end of day. DIRECT SMART REEFER (DSR) ALARM CODES The DSR Series Thermo King Alarm Codes shown below are used on Thermo King Direct Smart Reefer applications. COLOR CODE DEFINITIONS OK TO RUN CHECK AS SPECIFIED TAKE IMMEDIATE ACTION THESE ARE SUGGESTIONS ONLY. ALWAYS CONSULT YOUR COMPANY FOR FINAL DECISIONS. Code P1E P2E OL bAt HP LP PSE tEP tP4 dr1 dr2 tCO SOF -C- Color Description Operator Action Return Air Temperature Sensor Fault Remote Return Air Temperature Sensor Fault Electric Standby Overload Low Battery Voltage High Discharge Pressure Low Suction Pressure High Pressure Sensor Fault Electric Standby Motor Thermal Protection Alarm Power Supply Thermal Protection Alarm Door 1 Open/Door Switch 1 Failure Door 2 Open/Door Switch 2 Failure Electronic Control Module Internal Temperature Exceeds Limit Microprocessor Software Failure Communications Failure, Microprocessor to In-Cab Control Box Report alarm at end of day. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. Close door. Report alarm at end of day. Close door. Report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day. THERMO KING TK 40933-8-CH Rev 14 (02-25-15) If unit is shut down repair immediately. Otherwise, report alarm at end of day. If unit is shut down repair immediately. Otherwise, report alarm at end of day.