the Scanned PDF

advertisement

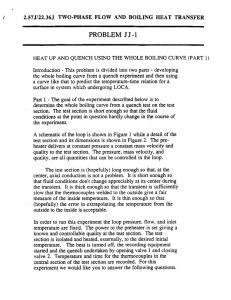

American Mineralogist, Volume 65,pages 1053-1056, 1980 A simplerapid-quenchdesignfor cold-sealpressurevessels Genv K. JAcoBsAND DERRTLLM. Kennrcr Departmentof Geosciences, ThePennsylvaniaState University University Park, PennsylvaniaI 6802 Abstract A simple rapid-quenchdesign,utilizing conventionalcold-sealpressurevessels,operates by flushing the capsulechamber with cold water injected through an axial capillary tube. Comparedto a conventionalair quench,improved quench ratesare gained without the disadvantagesassociatedwith other rapid-quenchmethods(e.g.water-bathimmersionor waterjacketed tilt mechanisms).The need for a rapid quench is illustrated by quenchreactionsin experimentswith wollastonite-bearingequilibria in H2O-CO, fluids. Upon air quenching, wollastonitereactswith CO, to form calcite and (presumably)silica in solution. Quenching experimentsinvolving wollastoniteand HrO-CO, fluids indicate that back-reactionduring cooling is minimized through use of the new rapid-quenchdesign. Introduction to minimize temperature gradients (Boettcher and Kerrick, l97l). Temperatures(12"C) were measured with an internal, inconel-sheathed,chromel-alumel thermocouplewhich, along with capillary A (Fig. l), extendsthrough the hollow filler rod to the position of the capsules.Both the thermocoupleand capillary A were silver-solderedto the nipple at the top of the T-junction. Valve A is used to isolate the pressure vesselfrom the main pressureline aftbr final pressure adjustments are completed. Using water ?s a medium, pressureswere generatedwith an air-driven hydraulic pump (Haskel # osxuw-903). Pressures (120 bars) were monitored with a bourdon-tube gauge for each vessel,catbrated against a factorycalibrated standardgauge. At the end of an experiment,pressurein the main line (Fig. l) is equalizedto that in the vessel.Valve A is then openedto connectthe vesselto the main pressure line. The vesselis then removed from the furnace,placedin a streamof compressedair, and valve B is immediately opened,allowing the hot water in the vesselto exit through the T-junction, capillary B, and bleed line. Cool water, pumped in through capillary A as the hydrautc pump cyclesto maintain constant pressure,flows over (and quenches)the. capsules (see inset in Fig. l). A large-volum€ water Rapidquenchmechanism reservoirbetweeneach vesseland the main pressure Figure I is a schematicdiagram illustrating the line should help reduce momentary pressuredrops rapid-quenchdesignusedin this study. In our exper- which occur between each cycle of the hydraulic iments, the pressurevesselwas oriented horizontally pump. When the vesselis cool, pumping is stopped 0003-004x/80/09 l 0-I 053$02.00 1053 Interpretation of hydrothermalexperimentscan be complicated by the precipitation of undesirable phasesduring quenching of conventional cold-seal pressurevessels.For example,calcite readily forms during compressedair quenchesin experimentsinvolving wollastonite equilibria in HrO-CO, fluids (Kerrick and Ghent, 1980;Johannes,personalcommunication; Shmulovich, 1977;Ziegenbein and Johannes,1974).Although rapid quenchingof the pressurevesselthrough immersioninto a water bath may alleviate this problem, repeated quenching by this method can shortenvessellife and lead to explosive failure. Use of water-jacketedrapid-quench vessels can be quite successftrlin reducingquenchproblems, provided precautions pointed out by Ludington (1978) and Rudert et al. (1976\ are observed.The present paper describesa new rapid-quench design that utilizes a conventional cold-sealvessel(Tuttle, 1949)through which cool water is injected into the capsulechambervia an axial capillary tube; this procedureresultsin a rapid temperaturedrop in the immediate vicinity of the capsules.This new design is simple and requireslittle modification of a cold-seal hydrothermal laboratory. t054 JACOBS AND KERRICK: COLD.SEAL PR,ESSUNE VESSELS lnternol Thermocouple 'Leods - MoinPressure Lrneto Pump C o p i l l o rAy V o l v eA ..Closure Assembly Cold-Seol Pressure,' Vessel_,-, T ,,r_ I I I .-l I I I I I I I I I -..lI I Qumch reactions The rapid-quenchmechanismwas used to reduce quench reactions in experimentsdealing with wollastonite in HrO-CO, fluids. As noted in the introduction, several authors have observed that wollastonite reacts with CO, during the quench to form calcite and SiOr. X-ray analysis(Guinier camera)of some experimental charges where wollastonite reacted with CO, during the quench yielded patterns of wollastonite and calcite, but not quartz. This phenomenon, which was also observed in experiments by Shmulovich(1977),implies that quartz is not precipitating along with calcite; thus, silica remains in solution, and/ot is present as an amorphousphase. SEM photographs of wollastonite from such experimental charges support this hypothesis. Abundant calcite rhombohedrons can be seenon the wollastonite grains; however, quartz is noticeably absent. One of the authors (D. M. Kerrick) has frequently encountered this phenomenon in thin sections of wolThermocouple Well lastonite-bearing metacarbonaterocks. Agro-Pdrocapsules were loaded with equal Fig. l. Schematic diagram of the rapid-quench design. Enlarged inset shows details of hollow filler rod, internal thermocouple, and capillary A, illustrating flow of cool water (arrows) around the capsules. and the pressureallowed to drop by closing valve A and letting the water flow out of the bleed line. Experimental results o Compressed Air Quench o "Roprd" Quench 400 T("C) 300 Quenchrates Quench rates from conventional compressed air quenches are compared to those utilizing the rapidquench mechanismin Figure 2. The rapid-quench apparatus yields significantly larger temperature drops over the first 40 secondsofthe quench.In fact, temperaturesrecorded with the rapid-quench mechanism averaged150'C below thoseof the compressed air quench for the time span of 20-40 seconds. A temperaturedrop of 400o (from 600o to 200'C) occurs in about two thirds of the time with the rapidquench design as it does with a compressed air quench. These results indicate that problems with quench reactionsmay be alleviated (or minimized) by utilizing the rapid-quench apparatus. 20 40 60 80 100 ',120 140 160 Time (secs) Fig. 2. Temperature-time plot comparing conventional comprcssed-air quench to that using the rapid-qucnch design. Each symbol representsan averageof3 values. Initial temperature was 600oC at a total pressureof 2.0 kbar. JACOBS AND KERRICK: COLD.SEAL PRESSURE VESSELS Initiol moles CO2 x 106 45 90 135 180 o a (o -8 a -rz f N o o -re o c) o -20 E 4 -ro a Compressed Arr Quench o " R o p i dQ" u e n c h 04 Initiol a a a 06 08 X"o" Fig. 3. Change in moles of CO2 (final moles - initial resulting from the quench reaction: wollastonite * COz + * SiO2. Runs were quenched from the wollastonite + fluid 700"C and a total pressure of 1.0 kbar. A value of zero ordinate indicates no back-reaction. moles) calcite field at on the amounts of -325 mesh wollastonite (for a chemical analysis of this specimen see Kerrick and Ghent, 1980)and silver oxalate + HrO for the generationof various initial values of Xco, (Hunt and Kerrick, 1977;Slaughteret al.,1975). For each capsul€,the ratio of wollastonite to fluid was approximately 8:2 (by weight). To eliminate any reaction betweenthe wollastoniteand CO, which may have occurredduring the run-up, the capsuleswere first subjectedto 914 day runs at 700"C and I kbar-conditions well within the wollastonite stability field (Greenwood, 1967).Somevesselswere then quenchedwith a conventional compressedair stream,while others were cooled with the rapid-quench apparatus.The final compositionof the fluid phasewasdeterminedby the weight-lossmethod of Johannes(1969).Initial and final amountsof CO, in the capsulesshould be identical if no quench reaction occurred.However,if wollastonite reactedwith CO, during the quench, a net loss of CO, should be observed.Becausepressure, X"o,, arlrdsurface area of wollastonite were kept constant in setsof experimentsutilizing the two quenching techniques,the change in moles of CO, should provide a good comparisonof the degreeof back-reaction of the two different quench methods for each set of runs. Figure 3 showsthe resultsfrom the quenchingexperiments.At all initial X.o. values,someback-reaction occurred,evidencedby the net lossof CO, for all data points. However, the rapid-quench technique yielded smaller CO, lossesthan the compressedair quench.This is especiallyevident at high initial Xco, values.For theseCOr-rich compositions,the quench path entersthe calcite + qaaftz stability field at relatively high temperatures,where enhancedreaction kinetics causegreater lossesof COr. Note, however, that for both quench methodsthe maximum loss of CO, occurs at initial Xco,: 0.6 rather than initial X.o, : 0.8. Apparently, quenching at initial Xco,: 0.6 representsthe optimal combination of the rateenhancingeffectsof HrO and elevatedtemperature. Back-reactionis very limited at initial Xco,:0.2 and 0.4 (seeFig. 3), which implies that even though the fluids are very water-rich,the temperaturesat which the quench path penetratesthe calcite * quartz field are too low for extensive back-reaction to occur. Thus, for this reaction, quench products are most likely to form in CO,-rich fluids during the initial temperature drop of the quench, where the rapidquench apparatus was shown to be most effective (seeFig. 2). Discussion Our rapid-quenchdeviceyields fasterquenchrates thair conventional compressed air methods. Although quenchrateswith this deviceare not as rapid as water-immersion methods or water-jacketedtilt vessels,this new design does offer some advantages. It avoids the large temperature gradients which can be associatedwith somewater-jacketedrapid-quench vessels(Ludington, 1978;Rudert et al.,1976).In addition" with this new designit is possibleto carefully check sampletemperaturesthrough use of an i-nternal thermocouple;the design of tilt-mechanismvesselsprecludesthe useof internal thermocouples.Our rapid-quench design should provide a safe alternative to water-immersionmethodsunder normal operatimgP-T conditions for cold-seal vessels,because compared to water immersion, the relatively small mass of injected water yields smaller overall shortterm strain on the vessel.No failures have occurred in approxinately two dozenruns with the new design at pressuresto 2 kbar and temperaturesto 700'C. Actual quench rates with other pressuremedia such as Ar or CO, have not been measured;however,improved quench rates are anticipated with the rapidquenchdesigncomparedto compressedair quenches with thesepressuremedia. As evidencedby experimentson the back-reaction of wollastonite during quenching, the new design does not eliminate all quench problems, but it does reducethem to a more acceptablelevel. 1056 JACOBS AND KERRICK: COLD-SEAL PRESSURT VESSELS Acknowledgments We thank I-Ming Chou and D. H. Eggler for their careful review of this paper. This work represents part of G. K. Jacobs' Ph.D. research and was supported in part by NSF grants EAR 7684199 and EAR 79-082,U (D. M. Kerrick) and an Owens-Corning Fiberglas Graduate Fellowship (G. K. Jacobs). References Boettcher, A. L. and D. M. Kerrick (1971) Temperature calibration in cold-seal pressure vessels. In G. C. Ulmer, Ed., Research Techniquesfor High Pressure and High Temperature, p. 179-193. Springer-Verlag, New York. Greenwood, H. J. (1967) Wollastonite: stability in H2O-CO2 mixtures and occurrence in a contact-metamorphic aureole near Salmo, British Columbia, Canada. Am. Mineral.,52, 1669-1680. Hunt, J. A. and D. M. Kerrick (1977) The stability of sphene: experimental redetermination and geologic implications. Geochim. Cosmochim. Acta, 4 l, 279-288. Johannes, W. (1969) An experimental investigation of the syst€m MgO-SiO2-H2O-CO2. Am. J. Sci., 267, 1083-1104. Kerrick, D. M. and E. D. Ghent (1980) P-f-Xco, relations of equilibria in the system: CaO-AI2O3-SiO2-CO2-H2O. (in Rus- sian) In V. A. Zharikov, V. L Fonarev, and S. P. Korikovskii' Pelrology,p. 32-52. D. S. Eds., Problemsol Physico-chemical Korzhinskii CommemorativeVolume. Ludington, S. (1978)Temperaturegradientsin rapid-quenchcoldseal pressurevessels-the effect of inclination (abstr.). Geol. Soc.Am. Abstractswith Programs,10,47. Rudert, V., I-M. Chou and H. P. Eugster(1976)Temperaturegradi€nts in rapid-quenchcold-sealpressulevessels.lm' Mineral., 61, lol2-lol5. Shmulovich,K. l. (197't-)Stability limits of grossularand wollastonite in the H2O-CO2 systemup to 6 kbar. Geokhimiya,12' ' 180G1816.ltransl. Geochem.Int., 14, 126-114(1978)1. (1975) Experimental V. Wall J. Slaughter,J., D. M. Kerrick and and thermodynamic study of equilibria in the system CaOMgO-SiOz-HzO-CO2.Am. J. Sci.,275, 143-162. Tuttle, O. F. (1949)Two pressurevesselsfor silicate-waterstudies' Geol. Soc.Am. Bull., 60, 1727-1729. Ziegenbein,D. and W. Johannes(1974) Wollastonitbildung aus Quarz und Calcit bei Pr: 2, 4, und 6 kb' Fortschr'Mineral', 52, 77-79. Manuscript received, February 15, 1980; acceptedfor publication, May 9, 1980.