ASHRAE 191 Comments.xlsx

advertisement

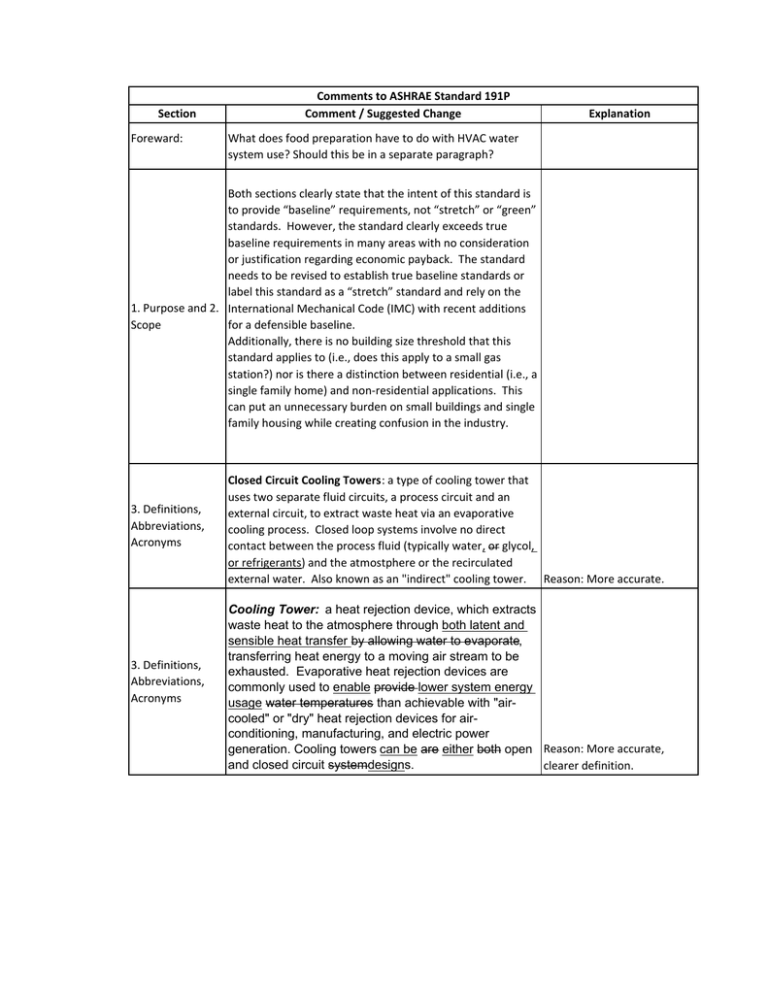

Section Foreward: Comments to ASHRAE Standard 191P Comment / Suggested Change Explanation What does food preparation have to do with HVAC water system use? Should this be in a separate paragraph? Both sections clearly state that the intent of this standard is to provide “baseline” requirements, not “stretch” or “green” standards. However, the standard clearly exceeds true baseline requirements in many areas with no consideration or justification regarding economic payback. The standard needs to be revised to establish true baseline standards or label this standard as a “stretch” standard and rely on the 1. Purpose and 2. International Mechanical Code (IMC) with recent additions Scope for a defensible baseline. Additionally, there is no building size threshold that this standard applies to (i.e., does this apply to a small gas station?) nor is there a distinction between residential (i.e., a single family home) and non‐residential applications. This can put an unnecessary burden on small buildings and single family housing while creating confusion in the industry. 3. Definitions, Abbreviations, Acronyms 3. Definitions, Abbreviations, Acronyms Closed Circuit Cooling Towers: a type of cooling tower that uses two separate fluid circuits, a process circuit and an external circuit, to extract waste heat via an evaporative cooling process. Closed loop systems involve no direct contact between the process fluid (typically water, or glycol, or refrigerants) and the atmostphere or the recirculated external water. Also known as an "indirect" cooling tower. Reason: More accurate. Cooling Tower: a heat rejection device, which extracts waste heat to the atmosphere through both latent and sensible heat transfer by allowing water to evaporate, transferring heat energy to a moving air stream to be exhausted. Evaporative heat rejection devices are commonly used to enable provide lower system energy usage water temperatures than achievable with "aircooled" or "dry" heat rejection devices for airconditioning, manufacturing, and electric power generation. Cooling towers can be are either both open Reason: More accurate, and closed circuit systemdesigns. clearer definition. 3. Definitions, Abbreviations, Acronyms Cycles of Concentration (COCs): Cycles of Concentration are defined as the ratio of the makeup rate to the sum of the blowdown and drift rate. The COCs can also be monitored by calculating the ratio of the chloride ion, which is highly soluble, in the system water to that in the makeup water. The number of COCs is dependent on the composition of the Reason: More accurate, clearer definition. Drift can makeup water, particularly the quantity of minerals and their quantity contained in the makeup water supply. be considered as part of the blowdown as this is also a It would also be good to show the calculations for COCs. loss of water from the tower, though typically very small. 3. Definitions, Abbreviations, Acronyms Evaporative Condenser: hHeat‐transfer device in which refrigerant vapor is condensed in coils that are cooled by the evaporation of water flowing over the outside of the tubes. These systems usually incorporate an air fan system for forced air movement, a recirculating water pump, a water Reason: More accurate, spray system, and a cooling coil. See also “Cooling Tower.” clearer definition. 3. Definitions, Abbreviations, Acronyms The definition for Evaporative Coolers should be further clarified for direct and indirect evaporative coolers. 3. Definitions, Abbreviations, Acronyms Facility Operations: a facility is operational during the time when the primary activity that facility is designed for is taking place. For Group A and Group M occupancies, this is the time during which the facility is open to the public. Define group A and M occupancies. 3. Definitions, Abbreviations, Acronyms 3. Definitions, Abbreviations, Acronyms 3. Definitions, Abbreviations, Acronyms 4.1 Scope Hybrid Wet/Dry Closed Circuit Coolers and Evaporative Condensers: hybrid heat rejection equipment contains both wet and dry heat transfer modes and offers the benefits of saving water with dry operation and saving energy while operating in the evaporative mode. Reason: More accurate, clearer definition. Open Circuit Cooling Towers: a specialized heat exchanger transfer device in which two fluids (air & water) are brought into direct contact to affect transfer of heat energy. Cooling is achieved through a combination of latent and sensible heat transfer and Reason: More accurate, evaporation of a small percentage of the circulating water is evaporated. clearer definition. Should a definition for add‐on evaporative precoolers used for condensers be added? There is no size criteria. Provisions can be justified on larger buildings, but questionable on small buildings. 4.3.1.2 There is no justification offered to exceed EPA’s recommendation of a 30% reduction in water use for this baseline standard. The use of “a minimum of” also encourages landscapers to exceed the reduction rather than just comply with the reduction. Additionally, the 4.3.1.2 Landscapes shall be designed to reduce supplemental EPA spreadsheet is marked irrigation water use by a minimum of 4030% from the “Beta” on their website; baseline for those improved landscape areas as calculated in additionally, the final version EPA’s Water Sense budget tool as provided on their website. of the spreadsheet should be made available on the ASHRAE website so that continuity can be maintained if the tool is discontinued or revised on the EPA website. In the scope there are no size criteria. This probably can be justified on larger buildings, but questionable on small buildings. 4.3.5.2 4.3.5.2 Where not expressly prohibited under the regulations established by the AHJ, alternative water source(s) shall only be utilized for aAny vegetative roof irrigation required shall only use alternative water source(s) except where expressly prohibited under the regulations established by the AHJ. What is the justification for 4.3.6.1 Water use shall comply with the following: inclusion of makeup water ornamental fountains and other ornamental water features meters and leak detection shall be supplied either by alternate, on‐site sources of systems on fountains, water or by municipally reclaimed water delivered by the especially given that no local water utility acceptable to the AHJ. Fountains and other fountain size limitation is features shall be equipped with: (1) makeup water meters, included? In addition, (2) leak detection devices that shut off water flow if a leak of alternate sources of water, more than 3.7 L (1.0 gal) per hour is detected, and (3) depending on the specific equipment to recirculate, filter, and treat all water for reuse water quality, can contain within the system. Potable water shall not be used for this biological contamination purpose. which can be amplified by use in an ornamental Exception: Where municipally reclaimed water is not fountain or water feature, available within 1000 ft of the building project site, or justifying the addition of this alternate on‐site sources of water are not available in exception (note 5.3 refers to sufficient quantity for the intended purpose, or where the this situation). use of the alternate water source(s) increases the risk of water related disease as determined by a qualified water professional, potable water is allowed to be used for start‐up and makeup water. 4.3.6.1 All alternate sources shall meet the water quality requirements of the AHJ. The use of alternate on‐site sources of water shall comply with IAPMO Green Plumbing and Mechanical Code Supplement, Chapter 5, or ICC Green Construction Code, Chapter 7, and meet the ANSI/NSF 350 or 350‐1 standard for water quality or the standards set by the AHJ. 5.2 The water quality requirements must be listed in the Standard rather than simply the reference standards. Without the specific requirements included, proper compliance cannot be attained, it is unfair to force users to acquire other standards for compliance with this standard, and raises the risk of changes in the other standards subverting the intent of this standard. Clarifies the exception for If municipally reclaimed water is available within 1,000 feet cooling towers and reclaimed of the property boundary, it shall water by making this an be used for all landscape irrigation water requirements and exception rather than a note. for cooling tower makeup, toilet, and urinal flushing except where cost prohibitive or not feasible because of health concerns, such as medical facilities where immune‐compromised patients may be present. Note: Cooling tower makeup water using non‐potable sources shall meet evaporative heat rejection equipment manufacturers’ recommended water chemistry guidelines. Exception: Potable water can be used for cooling tower make‐up if the non‐potable water sources do not meet the evaporative heat rejection equipment manufacturers’ recommended water chemistry guidelines. There should be some minimum quality requirements for use in cooling towers as the impact on fouling and corrosion could be significant and may increase energy consumption. 5.3 5.3.1 5.3.2 5.3.2 A minimum building size should apply. The water quality requirements must be listed in the Standard rather than simply the reference standards. Without the specific requirements included, proper compliance cannot be attained, it is unfair to force users to acquire other standards for compliance with this standard, and raises the risk of changes in the other standards not meeting the requirements intended in this standard. Can this be cost justified for residential buildings? Define residential. A residence where people sleep. 5.3.2 5.3.3.1 Residential: construction or materials that are expressly intended for and/or are designated by the AHJ as appropriate for use in providing living accommodations. While reclaimed water is often satisfactory for cooling At a minimum, potential uses for the alternate sources of water shall be quantified on a daily basis based on monthly tower use, many of the alternate sources of water climatic and operational factors. listed can be problematic for use in cooling towers. These potential uses that shall be quantified shall include: 1. Cooling tower makeup (excluding cooling tower bleed). 21. Landscape irrigation, including irrigation of vegetative roofs. 5.3.3.2 5.3.4 For a baseline standard, a threshold of 250 gallons per day is not cost justified. Per the AWWA, the average water cost for the U.S. is $1.50 per 1,000 gallons. Even at 10x this cost, 250 gallons per day is only $3.75/day, hardly a level to justify the expense of such systems (so at 37.5₵ per day this requirement is far from justified in a baseline standard). The limit for a baseline standard must be much higher to be economically justified. 5.3.3.2 Other potential uses of non‐potable water that may Furthermore, this limit will be included in the analysis includes, but is not limited to: vary by locality, water costs, treatment costs to make the 1. Flushing of plumbing fixtures. alternate water supply 2. Priming of floor drains. usable, etc. Thus there 3. Other beneficial uses as identified and approved by the should be no requirement to AHJ. use alternate sources of water but instead Exemption: The applicant is exempt from these provisions if requirements for use of the potential use of reclaimed or on‐site sources of non‐ alternate water sources, potable water is less than 250 gallons of water per day or the when justified needs to be sum of the sources of reclaimed or on‐site sources of non‐ included in the standard. potable water is less than 250 gallons per day. Trying to force users to incorporate alternate sources Need to tie to a minimum building size Note: makeup water using non‐potable sources shall meet evaporative heat rejection equipment manufacturers recommended water chemistry guidelines 5.4.2 Should be defined. Suggest you work with manufacturers to develop a consensus and not leave it open 5.4.3 5.6 6.3.3.1 For a baseline standard, 10 years is too long a payback period for the use of alternate water sources. Three years or less in more common and all costs for the system must be accounted 5.4.3 For sites where municipally reclaimed water is not for (keeping in mind that available, a minimum of one half of the non‐potable, on‐site money for an alternate water alternate sources of water identified in 5.3.1 shall be reused system could also be used for on site if acceptable uses for that water identified in 5.3.3.1 other purposes, such as the purchase of more efficient are present and the use of that water has less than a 10 3‐ year simple payback, which shall include all costs for the HVAC or lighting systems. reclaimed water system, including but not limited to first Furthermore, AHJs may not cost, ongoing maintenance costs, and both initial and be qualified to determine the ongoing testing costs. A certified water professional will usability of alternate water determine the usability of these sources and tThe AHJ will sources, which should be the confirm the determine the usability of these responsibility of a certified sourcesconclusions of the water professional. water professional. Who are the submittals sent to? The standard claims to not covering processes, but processes are listed (i.e. car wash). Will all processes be excluded? Subsystem Sub‐Metering Threshold Cooling Towers Primary flow > 30 L/s (500 gpm) >3,800 L/day (1,000 gal/day) Table 6‐2 6.3.3.3 Meter Data Collection. All building meters and sub‐ meters installed to comply with the threshold limits in 6.3.3.1 shall be configured to communicate water consumption data to a meter data management system. Meters shall provide data a minimum of daily and shall record a minimum of hourly consumption of water. 6.3.3.3 6.3.3.4 6.3.3.4 Data Storage and Retrieval. The meter data management system shall be capable of electronically storing water meter and sub‐meter data and creating user reports showing calculated hourly, daily, monthly, and annual water consumption for each meter and sub‐meter and provide alarming notification capabilities. justification offered for inclusion of make‐up and blowdown submeters on a cooling tower, nor for a remote reading and data storage system, for a baseline system (though a user may choose to do so as part of their water treatment plan in place of a conductivity probe, which is the typical method). Metering requirements for large, multi‐cell installations are also likely to be problematic from a piping viewpoint. Likely the metering requirements for other subsystems are not justified either (i.e., evap coolers, 6.3.3.3 Why doesn't the standard require a water management system? p Systems. For the purposes of this section, sources of hot or tempered water include water heaters, boilers, hot water circulation loops, and electrically heat‐traced pipe. The volume of water in the piping between water heaters or boilers and fixture fittings the serve shall not exceed 32 ounces (0.945 L). The volume of water contained in fixture branch piping that connects to a hot water circulation loop or electrically heat‐ traced pipe shall not exceed 16 ounces (0.47 L). The volume shall be calculated in accordance with Table 6‐3. While reduction of hot water system volume is worthwhile, this borders on micromanagement and does not belong in a baseline standard on water use. 6.3.4.1.1 Volume Calculation. The volume of water between the source of hot or tempered water and a given outlet shall be calculated by adding the internal volume of all piping, fittings, valves, meters, and manifolds between the source and the outlet. Piping volumes shall be calculated using Table 6‐3. Where water is supplied by a circulating hot or tempered water system or an electrically heat‐traced pipe, the hot water source shall be the loop or the heat‐traced pipe, and the volume shall include the portion of the fitting on the loop that supplies the fixture branch. While reduction of hot water system volume is worthwhile, this borders on micromanagement and does not belong in a baseline standard on water use. 6.3.4.1 6.3.4.1.1 Table 6.3 Delete 6.3.4.2.1 6.3.4.2.1 Pipe Insulation. Piping shall be thermally insulated in accordance with Table 6-4. Building cavities and interstitial framing spaces shall be large enough to accommodate the combined diameter of the pipe plus the insulation, plus any other objects in the cavity that the piping must cross. Table 6‐4 TABLE 6‐4 MINIMUM PIPE INSULATION THICKNESSa 6.4.2 6.4.2 The prescriptive option is met if the project achieves a 30 percent reduction in water use when compared to typical water use for a building of the same type. While reduction of hot water system volume is worthwhile, this borders on micromanagement and does not belong in a baseline standard on water use. Pipe insulation is well‐ covered by other energy codes such as Standard 90.1 and does not belong in this standard. Pipe insulation is well‐ covered by other energy codes such as Standard 90.1 and does not belong in this standard. 6.5 Performance Option A method or source is needed to establish the “typical water use for a building of the same type”. Otherwise, this requirement will be subject to gamesmanship and be rendered meaningless. What is a typical building? 6.5.1 If the performance option is followed, a document describing how the plumbing systems meet the water demands or a document that describes the method implemented to increase water efficiency shall be submitted to the AHJ. Additionally, this section applies to “Plumbing Systems”, yet the requirement is a 30% reduction in water use for a typical building. Is this 6.5.2 The performance option is met if the project achieves a requirement for the entire 30 percent reduction in water use when compared to typical building or just the plumbing water use for the same building typology using methodology system? This is unclear in the pre‐approved by the AHJ. standard. 6.5 Table 7.1 There is no economic justification offered for inclusion of makeup and blowdown submeters on a cooling tower, nor for a remote reading and data storage system, for a baseline system (though a user may choose to do so as part of their water treatment plan in place of a conductivity probe, which is the typical method). Metering requirements for large, multi‐cell installations are also likely to be problematic from a piping perspective. Likely the metering requirements for other subsystems are not justified Subsystem Threshold Values for Sub‐Metering either (i.e., evap coolers, Requirement boilers, etc.). Either drop the Cooling Towers and evaporative heat requirement or make the rejection equipment (meter on makeup water threshold(s) the same as “any and blowdown) large water using process”. Cooling tower flow through tower >500 gpm (30 l/s) Drop the requirement for Evaporative Coolers, air washers Makeup water >0.6 gpm remote data collection and (0.04 l/s) storage – the first cost and Steam and Hot Water Boilers >500,000 Btu/h (50 kW) input maintenance of these meters will be expensive, 7.3.4 7.3.5 7.3.6 If the drift is less than these numbers can eliminators be dropped? Provide cost analysis. 7.3.5 Cooling tower blowdown stream water shall be recovered for reuse in accordance with the local AHJ. This requirement is not 7.3.6 Building projects located in regions where the ambient justified in a baseline mean coincident wet‐bulb temperature at 1% design cooling standard and no economic condition is greater than or equal to 72°F (22°C) shall have a justification is offered. This is system for collecting condensate from air‐conditioning units more appropriate for a with capacities greater than 65,000 Btu/h(19 kW) , and the “stretch” standard like 189.1. condensate from all steam systems shall be recovered for reuse. While on the surface a good idea, building energy 7.3.7 General. Baseline Minimum Energy Efficiency Requirements – equipment shall comply with ASHRAE 90.1‐ requirements in a water standard will lead to 2010, Efficiencies – Standard Rating and Operating Conditions , and comply with Sections 5.4, 6.4, 7.4, 8.4, 9.4, confusion in the industry. and 10.4 of ANSI/ASHRAE/IESNA Standard 90.1‐2010. Equipment shown in Tables 6.8.1A, B, C, D, F, G, H, I, and J of Simply say compliance with efficiency standards. ASHRAE Standard 90.1‐2010 shall meet the minimum requirements at the specified rating conditions when tested in accordance with the specified test procedure. 7.3.7 7.4.1 2. Hybrid Wet/Dry Coolers and Condensers: Design shall incorporate hybrid heat rejection equipment to optimize water use and reduce the demand on potable or non‐ potable makeup water. 1. Water Treatment Plan 7.4.1 2. Hybrid Wet/Dry Coolers and Condensers 7.4.1 Provide Cost Justification 3. Cooling Equipment Designed for Non‐Potable Water Makeup: Evaporative cooled heat rejection equipment shall be designed to accommodate makeup water from the specific non‐potable source(s) used in the system, whether including rainwater, stormwater, air handler condensate, recycled treated wastewater foundation drain, or reclaimed municipal water, or some combination thereof. 7.4.1 This requirement, as written, requires all evaporative heat transfer equipment to be hybrid designs, which is not justified as a prescriptive requirement, especially in a baseline standard. Should be tied to a minimum building size. For example, is this really justified on a 1 ton evaporative cooler? 3a. Makeup water from non‐potable sources shall meet evaporative heat rejection equipment manufacturer’s recommended water chemistry guidelines. 7.4.1 What do you do if it does not comply? Provide minimum quality specification As written, evaporative equipment must be designed for all of these water sources, yet the design for one of these non‐potable sources may be very different from another. Therefore the design should be for the specific water quality of non‐ potable water available at the site. Often, non‐chemical water treatment systems must also use chemical for proper 4. Non‐Chemical Water Treatment: When used, the blowdown from evaporative heat rejection equipment with water treatment, whether it non‐chemical water treatment shall be recovered for reuse. be a corrosion inhibitor or secondary biocide. These additional chemicals may be Exception: Blowdown shall not be recovered from non‐ problematic in a non‐potable chemical water treatment systems that require the use of water reuse system. additional chemical water treatment. 7.4.1 7.4.1 Filtration is not required on most systems, is relatively expensive, and is a parasitic energy use (especially if not required on a system). There must be a legitimate, justifiable need for filtration 5. Mechanical Filtration: Mechanical filtration shall be utilized for the removal of solids 44 micron and larger (visible to be called for, especially in solids) in cooling water systems and shall recover purge and a baseline standard, even if a prescriptive option. or backwash water for reuse. 7.4.2.1 Define building performance model. Models for small buildings can be very expensive (~$5k per building per Energy+ model) Because energy savings correlates to water savings, a building performance model shall be used to minimize the total evaporative heat load by minimizing the air‐ conditioning load through building thermal efficiency features and shall include an analysis for the potential of cold thermal storage systems and heat recovery. 7.4.2.1 A prescriptive requirement for an expensive building model for buildings with evaporative cooling systems amounts to a restraint of trade. If a building model is called for, it must be called for on all buildings especially as water is also used in the production of energy and reducing load will save water at the building and/or at the power plant. While on the surface a good idea, building energy The heating, ventilating, and air‐conditioning systems shall requirements in a water comply with Section 6 of NSI/ASHRAE/IESNA Standard 90.1 standard will lead to 2010 with the following modifications and additions, and confusion in the industry. building products shall comply with one of the following: Additionally, it is my understanding that Standard 1. Energy Policy Act (EPAct) baseline. Products shall comply 90.1‐2010 with Addenda is with the minimum efficiencies addressed in the National more energy efficient than Appliance Energy Conservation Act (NAECA), EPAct, and the Standard 189.1. Energy Independence and Security Act (EISA). Violates fed preemption for 2. Higher Efficiency. Products shall comply with the greater federally covered products of the ENERGY STAR requirements in Section 7.4.7.3 and the and is not allowed if this is a values in Normative Appendix C of ASHRAE Standard 189.1‐ min efficiency standard 2011. These requirements supersede the requirements in Tables 6.8.1.A to 6.8.1J of ANSI/ASHRAE/IESNA Standard 90.1‐2010. The building project shall comply with Sections 7.4.5.1 of ASHRAE Standard 189.1. 7.4.2.2 7.4.3.1 Most of the requirements in the standard are system/installation requirements; however, this states “Hot Water boilers shall incorporate a leak detection system…” Suggest changing that to “Hot Water Hot Water boilers systems shall incorporate a leak detection boilers systems shall incorporate a leak detection system… t ” 7.4.3.2 Chilled Water Systems shall incorporate a leak Not cost effective on small detection system with an alarm or positive displacement chillers. meter on water makeup points to prevent fluctuation in the internal system pressure. 7.4.3.2 Is this required on all sizes? 7.4.7.6 2. Boiler blowdown ‐ the system shall be equipped with a water tempering device which operates only when the discharge temperature to the sanitary system exceeds 140 deg F or recover the heat off the discharge water, when recommended in the manufacturer's instructions. As written, the standard could be misinterpreted to force unnecessary controls on boilers that do not recommend blowdown as part of their regular maintenance. While the use of thermal storage is beneficial in many instances, no criteria for the level of water savings is listed, rendering this path questionable. Thermal storage systems often use more energy than 1. Evaluate thermal energy storage systems to reduce water conventional systems, but consumption at the building site and its energy source. this energy is off peak and thus lower cost. Either drop 2. Where the utility rates are favorable, the evaluation shall this section or include a consider: water use reduction goal and a. Full thermal storage systems. the path to determine the b. Partial thermal storage systems. reduction (.i.e., include c. Air cooled with ice thermal storage systems. source energy water use?). 7.4.8 7.5 High Performance Option 8.2 8.3.2 If this is a minimum standard then this will violate preemption. Unless, you only comply with water requirements (chapter 5?). 8.2 Compliance Entire section needs to be reviewed as to proper “code All appliances and equipment shall comply with Section 8.3, ready” language. There is “Mandatory Provisions” and Section 8.4, “Submittals”. and also no prescriptive or high those listed below. performance section listed in this public review draft. 1. Section 8.4, “Prescriptive Option.” 2. Section 8.5, “High Performance Option.” Many will consider these processes and the standard does not cover processes. Scope should be changed. 5. Shall use air‐cooled ice machines that comply with the requirements of the U.S. EPA Energy Star Program for Commercial Ice Machines 8.3.2 8.4 Submittals These can increase cooling demand. Why exclude water cooled that complies with the These can increase cooling demand. Why exclude water standard for water use. cooled that complies with the standard for water use. Closed‐ Closed‐loop/cooling tower loop/cooling tower water cooled machines may be best water cooled machines may design alternative. be best design alternative. Does not specify where to send submittals to.